Ever wonder what makes a three-plate mold tick? Dive into the mechanics of this essential tool in plastic manufacturing.

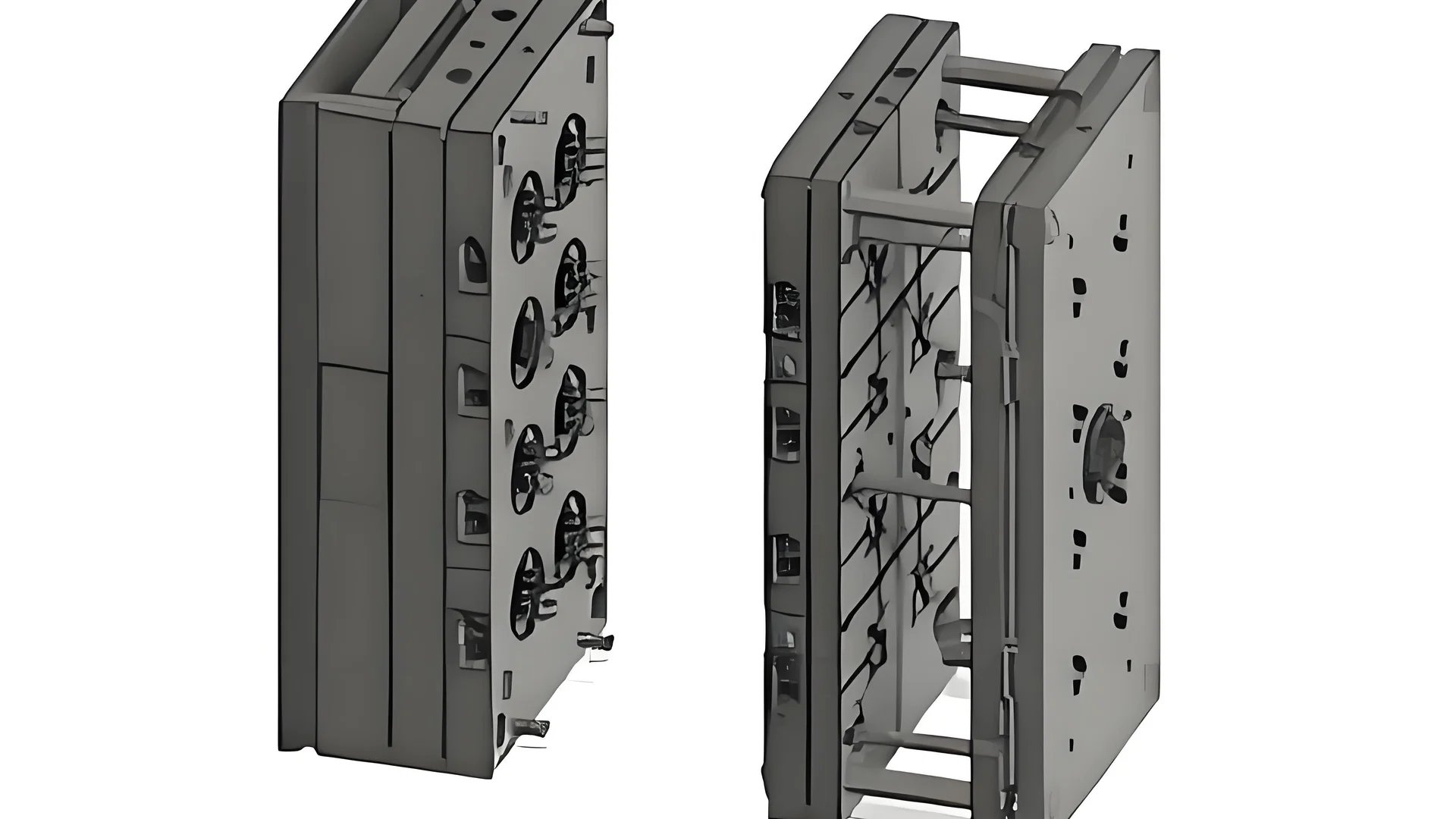

A three-plate mold consists of three key parts: a fixed plate, an intermediate runner plate, and a moving plate. This design enhances flexibility in sprue systems, enabling efficient separation of parts from runner systems, which boosts production efficiency and improves product quality.

Let me tell you, when I first got my hands on a three-plate mold, it was like unlocking a new level in a video game. You see, the real magic lies in how these molds operate—offering more than just basic functionality. Imagine the thrill of seeing complex shapes and designs come to life, all thanks to the mold’s ingenious structure. In particular, the intermediate runner plate provides an added layer of sophistication, offering greater control over the mold’s flow paths.

This enhanced control means products with intricate details and high-quality finishes are more achievable. It’s like customizing your own pizza—everything fits together perfectly because you have more choices with the toppings (or in this case, the gates and sprue systems). And let’s not forget about the automatic ejection process that keeps production humming smoothly, like a well-oiled machine, minimizing manual intervention. It’s these small details that make all the difference in producing top-notch plastic components.

Three-plate molds use two plates for part separation.False

Three-plate molds use three plates: fixed, runner, and moving.

Three-plate molds enhance production efficiency.True

Their design allows flexible sprue systems, improving efficiency.

- 1. How does the structure of a three-plate mold differ from a two-plate mold?

- 2. What Are the Key Components of a Three-Plate Mold?

- 3. How Does the Molding Process Work in a Three-Plate Mold?

- 4. Why Choose a Three-Plate Mold for High-Quality Plastic Products?

- 5. What Are the Common Applications of Three-Plate Molds in Manufacturing?

- 6. Conclusion

How does the structure of a three-plate mold differ from a two-plate mold?

Ever wondered how a simple tweak in mold design can revolutionize your product’s quality and efficiency?

A three-plate mold, unlike a two-plate mold, features an additional intermediate plate, offering enhanced flexibility in sprue and gate placement. This allows for superior quality control and more complex designs through uniform melt distribution.

Basic Components of Two-Plate and Three-Plate Molds

When I first stumbled upon the world of molds, the simplicity of the two-plate mold fascinated me. It’s essentially composed of a fixed plate and a moving plate. Think of it like a sandwich with two slices of bread. But then, I discovered the three-plate mold, and it’s like adding an extra layer to that sandwich—an intermediate plate. This runner plate changed everything for me, adding flexibility to the sprue system and accommodating more intricate designs I once thought were impossible.

Component Comparison Table

| Component | Two-Plate Mold | Three-Plate Mold |

|---|---|---|

| Plates | 2 | 3 (includes runner plate) |

| Sprue System | Basic | Flexible |

| Ejection Mechanism | Simple | Complex |

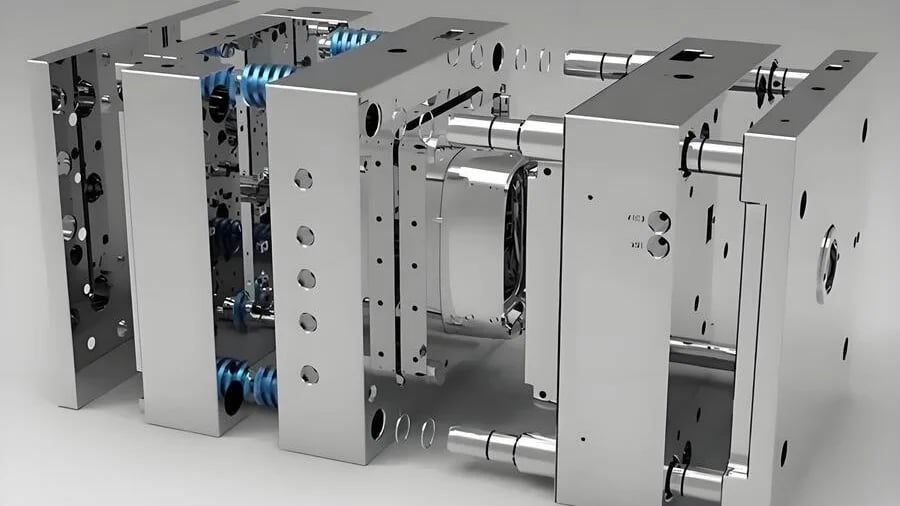

Molding Process and Action Sequences

In my early days as a designer, I quickly learned that the molding process in a two-plate setup was straightforward—open the mold, release the product. However, with a three-plate mold1, things get interesting:

- First Mold Opening: Separates the fixed and intermediate plates to remove the runner condensate.

- Second Mold Opening: Allows for further separation, which improves automation—making it feel like watching a well-orchestrated dance.

Melt Flow Path Efficiency

The efficiency of melt flow in these molds was a game-changer for me. In particular, the three-plate mold2 provides more gate placement options, such as pin-point gates. This flexibility enables more uniform filling—crucial when you’re working on products where appearance is everything.

Applications and Advantages

I’ve found that three-plate molds shine when manufacturing products with stringent gate trace requirements, such as high-end electronics. Their ability to automatically separate gates and runners has made automated production much more feasible for me.

Application Scenarios

| Product Type | Mold Preference |

|---|---|

| High-grade electronics | Three-Plate |

| Basic plastic components | Two-Plate |

Exploring how these molds impact production efficiency has been an exciting journey. It’s amazing to see how they can elevate quality standards across various industries. Dive deeper by investigating different scenarios3.

Three-plate molds have more plates than two-plate molds.True

Three-plate molds include an additional runner plate, totaling three.

Two-plate molds offer more gate placement options than three-plate molds.False

Three-plate molds provide more gate placement options due to their design.

What Are the Key Components of a Three-Plate Mold?

Ever wondered how those sleek plastic designs come to life? It all starts with a three-plate mold, a marvel in manufacturing that I’ve come to admire in my own design journey.

A three-plate mold is composed of a fixed plate, an intermediate plate, and a moving plate. Key components include the main runner, manifold, gate, and ejection mechanism, which collectively allow for precise melt flow control and efficient product ejection.

Basic Structure of a Three-Plate Mold

When I first began exploring the world of mold design, the complexity of three-plate molds fascinated me. These molds are built with three main parts: the fixed plate, intermediate plate, and moving plate, each playing a crucial role.

- Fixed Plate: This is like the mold’s anchor, where the main runner channels the plastic melt from the injection machine.

- Intermediate Plate: Often referred to as the runner plate, it creatively distributes the melt to different gates.

- Moving Plate: Think of this as the mold’s helping hand, efficiently ejecting products once molded.

Detailed Component Analysis

| Component | Function |

|---|---|

| Main Runner | Introduces plastic melt into the mold. |

| Manifold | Distributes melt from the main runner to each gate. |

| Gate | Connects manifold to the cavity, controls entry point for melt. |

| Ejector Mechanism | Ejects molded products post-molding. |

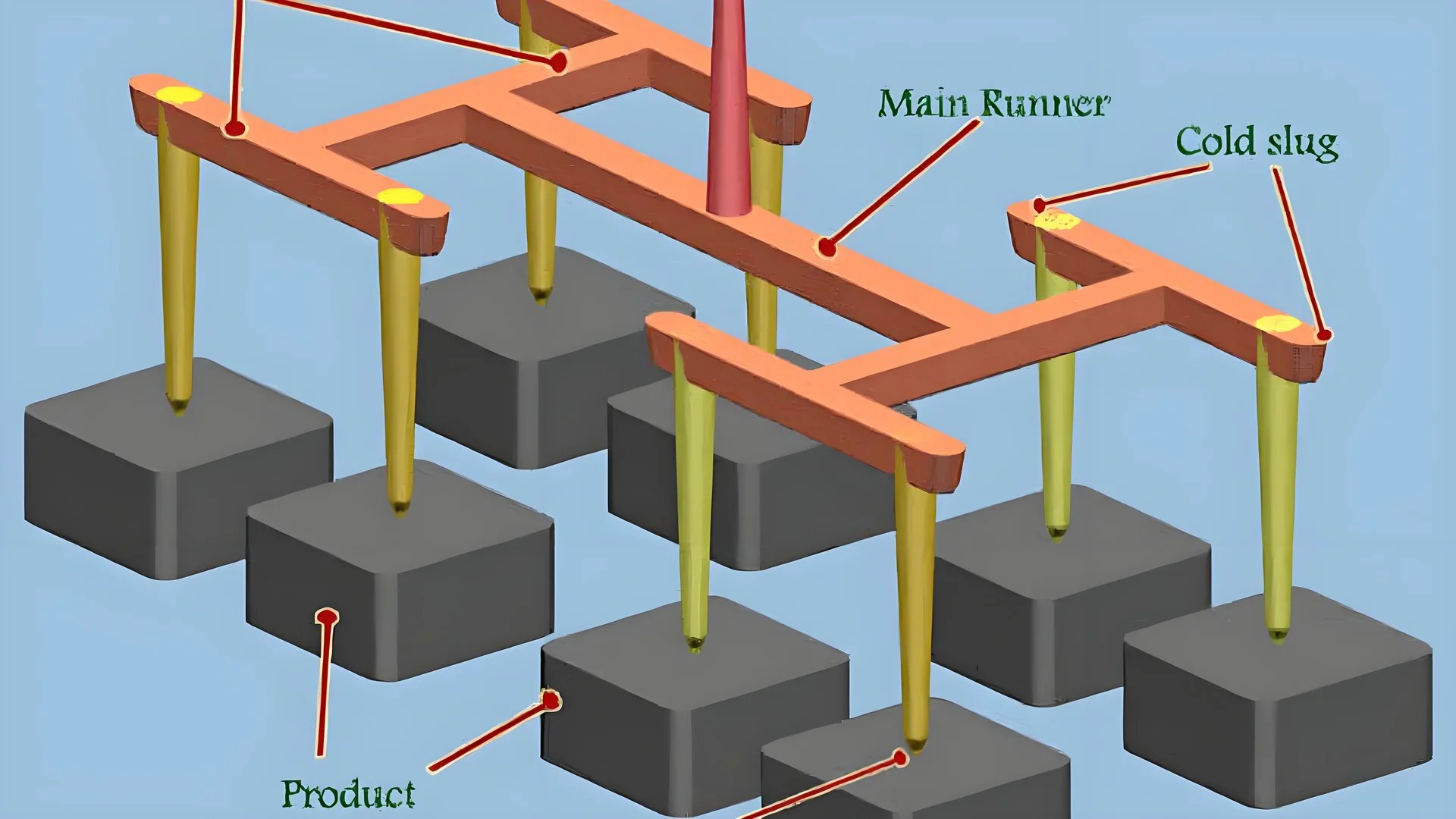

The manifold’s flexibility is particularly fascinating because it allows for diverse gate locations such as pin point gates4. This flexibility ensures a uniform melt distribution for even the most complex designs.

Molding Process and Sequence of Action

First Mold Opening:

The moment when the moving mold retracts is always a nail-biter. It separates the fixed and intermediate plates, disconnecting the runner condensate from the gate, leaving the product safely on the moving mold side.

Second Mold Opening:

This step feels like magic; further retraction separates the intermediate plate from the moving plate. The runner condensate is ejected via mechanisms like push plates, showcasing engineering brilliance.

Application Scenarios

In my experience, three-plate molds are indispensable for high-quality plastic products where precision is key. By efficiently separating gates from products, they enhance both automated production and product quality. This method is especially advantageous in consumer electronics5, where every detail matters. Optimizing gate placement and flow paths leads to stunning results both aesthetically and functionally.

The moving plate assists in ejecting products.True

The moving plate helps eject finished products from the mold cavity.

Three-plate molds have only two main components.False

They consist of three components: fixed, intermediate, and moving plates.

How Does the Molding Process Work in a Three-Plate Mold?

Uncover the secrets behind the three-plate mold process, a crucial technique that combines quality and efficiency in modern manufacturing.

The molding process in a three-plate mold starts with two separate openings: first, it splits the fixed and intermediate plates, and then the intermediate from the moving plate, allowing for precise removal of the runner.

Understanding the Components of a Three-Plate Mold

Have you ever wondered what goes on behind the scenes of plastic product creation? Let me take you on a journey through the fascinating world of three-plate molds. Imagine working with three main plates: fixed, intermediate, and moving. Each plays a unique role in shaping and refining the product. The fixed plate holds the main runner, guiding molten plastic into the mold like a seasoned conductor leading an orchestra. Meanwhile, the intermediate plate’s manifold deftly distributes this molten flow to each gate, setting the stage for precision and elegance. It’s like watching a well-rehearsed ballet, where every move is calculated to perfection.

| Component | Function |

|---|---|

| Fixed Plate | Holds main runner for plastic melt introduction |

| Intermediate Plate | Distributes melt via manifold, supports runner demolding |

| Moving Plate | Assists in mold opening, carries final product |

The Two-Step Molding Sequence

Picture this: the first mold opening is like pulling a curtain back to reveal a masterpiece in progress. As the moving mold shifts backward, the fixed and intermediate plates part ways. This is where the magic happens—sprue detachment—leaving the product safely nestled on the moving side while the runner gel remains with the intermediate plate. It’s all about balance and precision.

In the second act, as if on cue, the intermediate plate gracefully separates from the moving plate. An intricate runner demolding mechanism steps in to perform an encore, ensuring automatic removal of any remaining runner condensate. Efficiency takes center stage, minimizing downtime and maximizing production cycles.

Melt Flow Path in Injection Molding

Now, let’s talk about the journey of plastic melt6 through this intricate maze. It enters from the machine nozzle7 and makes its way through the manifold8 on the intermediate plate9 before finding its home in the cavities via strategically placed gates10. It’s like witnessing a river splitting into multiple streams, each one delivering life to its own corner of a lush valley.

- Melt Entry Point: Main runner on fixed plate

- Distribution: Manifold on intermediate plate

- Entry into Cavity: Through strategically placed gates

Application and Advantages of Three-Plate Molds

Three-plate molds aren’t just about function; they’re about finesse. They shine brightest when producing items with strict aesthetic demands—like sleek electronic shells or precision parts that could rival any sculpture. The separation of gates ensures that each product emerges without a blemish, ready to impress even the most discerning eye11.

And let’s not forget automation—the unsung hero of modern manufacturing. By minimizing manual cleanup, these molds elevate productivity to new heights, leaving more time for creativity and innovation.

For those curious about mold automation12, there’s a world of advanced techniques waiting to be explored. As designers like myself delve deeper into these processes, we unlock new realms of efficiency and quality—keys to thriving in high-demand sectors like consumer electronics.

The fixed plate holds the main runner in a three-plate mold.True

The fixed plate introduces plastic melt from the injection machine nozzle.

Intermediate plates do not support runner demolding.False

Intermediate plates distribute melt and support runner demolding.

Why Choose a Three-Plate Mold for High-Quality Plastic Products?

Ever wondered why three-plate molds are the go-to for top-notch plastic products? Let me take you on a journey through their impressive flexibility and efficiency.

Three-plate molds are perfect for high-quality plastic production because they automatically separate the runner from the product, offering unparalleled design flexibility and enhancing the appearance of complex components.

Key Components of a Three-Plate Mold

When I first delved into the world of mold design, I remember being fascinated by the three-part harmony of a three-plate mold: the fixed plate, the intermediate plate (also known as the runner plate), and the moving plate. This clever design doesn’t just add an extra plate compared to two-plate molds13—it adds a whole new level of flexibility.

| Component | Function |

|---|---|

| Fixed Plate | Holds the main runner; introduces plastic melt into the mold. |

| Intermediate Plate | Houses the manifold; distributes melt to each gate. |

| Moving Plate | Facilitates product ejection post-molding. |

This setup allows for more versatile gate placements, making it perfect for complex designs. The first time I saw this in action, it was like witnessing a dance where each part played its role to perfection.

Molding Process Sequence

The magic of a three-plate mold unfolds in two distinct opening stages:

- First Mold Opening: The fixed and intermediate plates part ways, leaving the product on the moving mold side. It’s like watching a curtain lift, revealing a work in progress.

- Second Mold Opening: Further separation allows for automatic removal of runner condensate via an ingenious runner demolding mechanism14. This process is so automated that it minimizes manual intervention—a godsend in streamlining production.

Advantages in Melt Flow Path

One of the things that sold me on three-plate molds is their ability to control melt flow paths. This is crucial when you’re crafting products that need to look as good as they function. The intermediate plate allows for pinpoint gates, which fill cavities more uniformly.

Benefits include:

- Enhanced appearance due to reduced gate marks.

- Improved filling for complex designs.

Ideal Application Scenarios

If you’ve ever held a sleek electronic device casing, chances are it was molded using a three-plate system. These molds shine brightest with products that demand both aesthetic finesse and precision, like those beloved gadgets we can’t live without. Their ability to automatically eject runner condensate also cuts down on manual cleaning—something I learned to appreciate during long production runs.

For anyone diving into mold design or manufacturing, understanding these elements can transform your approach to creating high-quality plastic products. The knowledge I’ve gained has not only informed my choices but has also elevated my appreciation for the artistry involved in mold making. Explore plastic mold applications15 for more insights into practical uses of three-plate molds.

Three-plate molds have two opening stages.True

The process involves separating plates twice for product and runner removal.

Three-plate molds require manual runner removal.False

The mold design allows automatic runner condensate ejection, minimizing manual work.

What Are the Common Applications of Three-Plate Molds in Manufacturing?

Ever wondered how your sleek smartphone casing or your car’s dashboard came to be? It might just be the magic of three-plate molds.

Three-plate molds are essential in creating high-quality plastic products, especially when aesthetics and gate trace are crucial. They’re widely used in electronics, automotive, and precision parts industries, offering efficient, automated production.

Application in Consumer Electronics

I still remember the first time I held a perfectly crafted smartphone case and marveled at its flawless finish. That’s the kind of craftsmanship you get with three-plate molds in the consumer electronics industry. These molds are perfect for producing high-quality exterior casings and those intricate internal components we often take for granted. The best part? They ensure that sleek designs come with barely noticeable gate marks16, keeping the aesthetic appeal intact.

- Advantages:

- Minimizes visible gate marks

- Allows complex design geometries

- Enhances product durability

Manufacturers, like the one I worked with, love the automated processes these molds enable. The runner system detaches effortlessly, cutting down on manual labor.

Role in Automotive Parts Manufacturing

In my previous projects in automotive design, I saw firsthand how crucial three-plate molds are. They’re used to craft everything from dashboards to panels, where precision and finish aren’t just expected—they’re demanded. I’d often chat with the production teams who praised how these molds reduced manual handling thanks to automatic ejection.

| Component | Benefits of Using Three-Plate Molds |

|---|---|

| Dashboards | Uniform surface finish, precision in dimensions |

| Panels | Reduced manual handling due to automatic ejection |

The seamless integration of automated systems17 ensures consistent quality—a must in the auto industry.

Precision Plastic Parts Production

Working on medical and scientific equipment taught me that precision is everything. Three-plate molds shine here too, offering incredible control over melt flow and fill patterns, which is essential for manufacturing those small yet complex parts.

- Key Benefits:

- Precision in small component manufacturing

- Consistency across multiple production runs

The ability to manage melt flow dynamics18 effectively means manufacturers can confidently meet strict quality standards.

Challenges and Considerations

But let’s not sugarcoat it—there are challenges with three-plate molds. The complexity can hike up initial costs and requires specialized expertise for upkeep. However, the long-term gains in quality and automation make it worth considering. Whenever I weigh the cost-benefit ratio19, it’s clear these molds offer a strategic advantage for boosting product quality and production efficiency.

Adopting three-plate molds can be a game-changer for manufacturers aiming to elevate their product offerings. Each industry application leverages the mold’s unique capabilities to meet specific demands, be it aesthetic finesse or mechanical precision.

Three-plate molds are used in consumer electronics.True

They produce high-quality casings and components, crucial for aesthetics.

Three-plate molds increase manual labor in automotive manufacturing.False

They reduce manual handling by automating the runner system detachment.

Conclusion

Three-plate molds enhance plastic manufacturing by providing flexibility in design, efficient melt flow, and automated runner removal, making them ideal for high-quality products in various industries.

-

Learn about the specific sequence in a three-plate mold that aids in automation. ↩

-

Discover how pin-point gates enhance product appearance and quality. ↩

-

Identify industries and products that benefit from using three-plate molds. ↩

-

Explore various gate types to understand their impact on mold filling efficiency and product quality. ↩

-

Discover how injection molding shapes consumer electronics, focusing on aesthetics and functionality. ↩

-

Explore detailed explanations and diagrams that illustrate how a flexible sprue system enhances mold efficiency. ↩

-

Learn strategies to streamline production cycles in injection molding, enhancing speed and product quality. ↩

-

Discover cutting-edge automation techniques to boost productivity and reduce manual intervention in molding processes. ↩

-

Discover cutting-edge automation techniques to boost productivity and reduce manual intervention in molding processes. ↩

-

Explore detailed explanations and diagrams that illustrate how a flexible sprue system enhances mold efficiency. ↩

-

Learn strategies to streamline production cycles in injection molding, enhancing speed and product quality. ↩

-

Discover cutting-edge automation techniques to boost productivity and reduce manual intervention in molding processes. ↩

-

Understand the comparative advantages of three-plate molds over traditional two-plate designs, aiding in informed decision-making. ↩

-

Learn about mechanisms that automate runner removal, crucial for enhancing production efficiency. ↩

-

Discover specific industrial applications where three-plate molds excel, providing real-world context. ↩

-

Explore how three-plate molds reduce gate marks, enhancing product aesthetics and quality. ↩

-

Learn how automation in molding reduces labor costs and improves consistency. ↩

-

Understand how controlling melt flow impacts the precision and quality of molded parts. ↩

-

Evaluate if the benefits of three-plate molds justify their initial investment. ↩