Mastering the art of injection molding threads can feel like a complex puzzle with many intricate pieces.

Optimize mold design for thread alignment, select suitable materials, maintain precise temperature control, and implement proper venting and ejection techniques for successful injection molding of threads.

Every time I embark on a new project involving threaded components, I remember the first time I faced the challenge. My heart raced as I wrestled with the alignment and material selection, but with persistence and a few seasoned tips, it all started to click. Let’s dive deeper into these essential strategies to ensure your injection molding process goes smoothly and efficiently.

Thread alignment is crucial in injection molding.True

Proper thread alignment ensures precision and prevents defects.

Temperature control is irrelevant in thread molding.False

Precise temperature control is essential for quality and durability.

- 1. What Are the Key Design Considerations for Molded Threads?

- 2. How Do Material Choices Affect Thread Injection Molding?

- 3. How Can You Ensure Precise Thread Alignment?

- 4. How Can You Overcome Common Challenges in Thread Molding?

- 5. Why Is Temperature Control Crucial in Molding Threads?

- 6. How Does Venting Impact Thread Injection Molding?

- 7. Conclusion

What Are the Key Design Considerations for Molded Threads?

Picture this: you’re designing a plastic gadget, and those tiny molded threads can make or break the whole thing. It’s all about the details!

When designing molded threads, consider the right materials, thread geometry, mold design, and shrinkage. These factors ensure your plastic components are both reliable and easy to manufacture.

Material Selection

I’ve learned through trial and error that picking the right material is like choosing the foundation of a house. You need something robust enough to withstand the pressures it will face. Imagine crafting a plastic widget meant to resist harsh chemicals or bear significant loads. Thermoplastics like ABS or polycarbonate are often my go-tos because they strike a perfect balance between durability and moldability.

Thread Geometry

Getting the thread geometry right can sometimes feel like solving a complex puzzle. A while back, I was designing a component that had to support a significant load without slipping. I opted for Buttress threads, which worked wonders in handling the axial stress. V-threads are my choice when the application is more about general fastening. The trick is finding the right pitch and depth to prevent any stress concentrations and ensure reliable engagement1.

| Thread Type | Best Use Case |

|---|---|

| V-Thread | General fastening applications |

| Buttress Thread | High axial load applications |

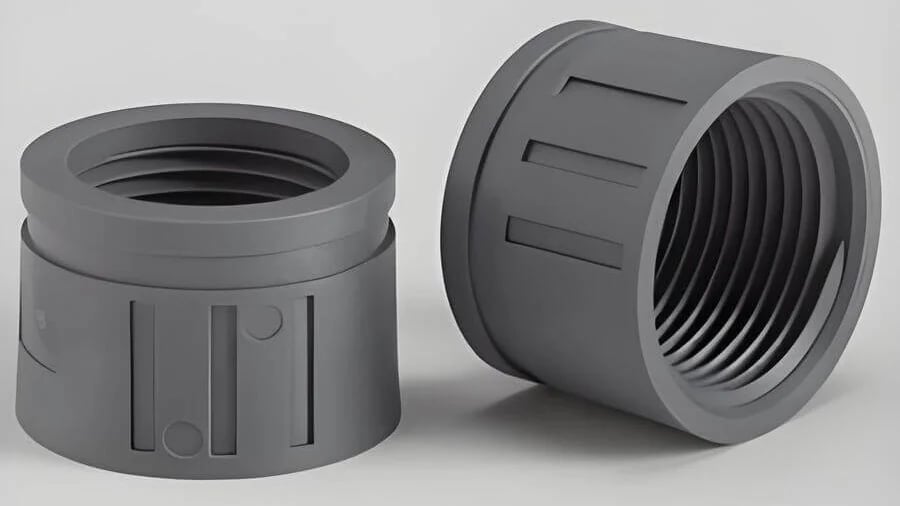

Mold Design

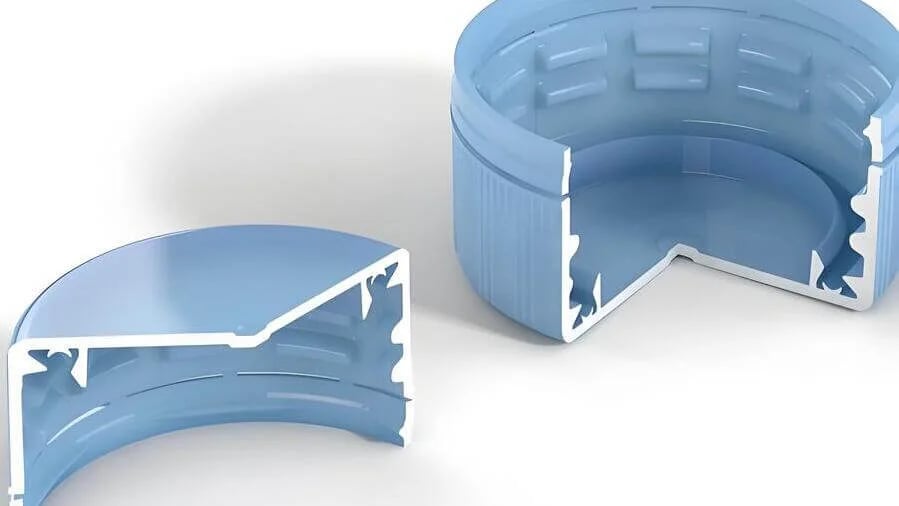

Designing a mold feels like sculpting art where precision is key. I remember a project where I had to avoid undercuts like they were pitfalls in a video game. Ensuring adequate draft angles was crucial for easy ejection of parts. Sometimes, using split molds2 is necessary for those intricate shapes without sacrificing quality. And don’t forget about the cooling channels—they’re vital for preventing warping!

Accounting for Shrinkage

Shrinkage can be as sneaky as your favorite trickster in a heist movie. Early in my career, I underestimated this factor, which led to mismatched parts. Now, I rely heavily on simulation tools to predict shrinkage accurately, and shrinkage charts3 from material suppliers are indispensable in fine-tuning designs.

By focusing on these considerations, I’ve managed to design molded threads that not only meet rigorous performance standards but also streamline the manufacturing process. It’s all about avoiding pitfalls like thread distortion or misalignment in plastic components, ensuring everything fits together seamlessly like pieces of a well-crafted puzzle.

ABS is preferred for molded threads due to its strength.True

ABS offers a balance of durability and moldability, ideal for threads.

V-threads are best for high axial load applications.False

V-threads are for general fastening; Buttress threads handle high axial loads.

How Do Material Choices Affect Thread Injection Molding?

Ever wondered how the right material can make or break your thread injection molding project?

Choosing the right material in thread injection molding affects the product’s strength, heat resistance, and finish. It’s crucial to consider the plastic’s flow properties, shrinkage rate, and compatibility with threaded designs for optimal results.

The Importance of Material Properties

Reflecting on my journey in product design, I’ve seen firsthand how choosing the right materials can transform a project’s outcome. It’s like selecting the perfect ingredient when cooking; each brings its own flavor and texture. When it comes to thread injection molding4, the mechanical properties of plastics are key. I remember a time when we used polycarbonate for a project. Its impact strength and transparency were game-changers, offering not just durability but also a sleek, polished look.

| Material Type | Key Properties |

|---|---|

| Polycarbonate | High impact resistance, clarity |

| Nylon | Toughness, wear resistance |

| Polypropylene | Chemical resistance, flexibility |

Every material offers unique benefits and compromises. For instance, nylon is exceptional in toughness and wear resistance but might need extra treatments for UV stability—a lesson learned after a few trials and errors.

Impact on Mold Design and Process

Material choice can dramatically impact mold design. Some plastics shrink more than others during cooling, affecting the precision of threaded components. I remember adjusting mold dimensions for polypropylene because of its flexibility and high shrinkage rate—an exercise in patience and precision.

Moreover, the heat resistance5 of a material dictates how fast we can cool molds and cycle them through production. Faster cooling materials mean quicker cycles, which is critical when you’re racing against time in high-volume production settings.

Compatibility with Thread Designs

Not all plastics are created equal when it comes to forming threads. The flow properties of a material during molding can determine its ability to form detailed threaded structures without defects. Acrylonitrile butadiene styrene (ABS), for instance, has excellent flow characteristics and finishes, making it ideal for complex thread designs.

I’ve learned that using the wrong material can lead to issues like incomplete threads or warping—a costly mistake if not caught early. It’s about striking the right balance between material flow properties and thread design intricacies to ensure quality.

Consideration for Environmental Factors

Environmental conditions also play a big role in material selection. I’ve had projects where using UV-stabilized materials6 was non-negotiable due to outdoor exposure needs. It’s about ensuring longevity and performance over time.

In summary, understanding how each material interacts with mold design and processing conditions is vital for successful thread injection molding. It’s like piecing together a puzzle—every detail matters in ensuring designs align perfectly with project requirements.

Polycarbonate offers high impact resistance and clarity.True

Polycarbonate is known for its high impact strength and transparency.

Nylon is unsuitable for outdoor applications due to UV issues.True

Nylon requires UV stabilization for outdoor use to prevent degradation.

How Can You Ensure Precise Thread Alignment?

You know that moment when everything just clicks into place? That’s what precise thread alignment feels like in manufacturing—absolutely essential. Let me walk you through some tried-and-true techniques to keep those threads perfectly aligned and avoid those dreaded missteps.

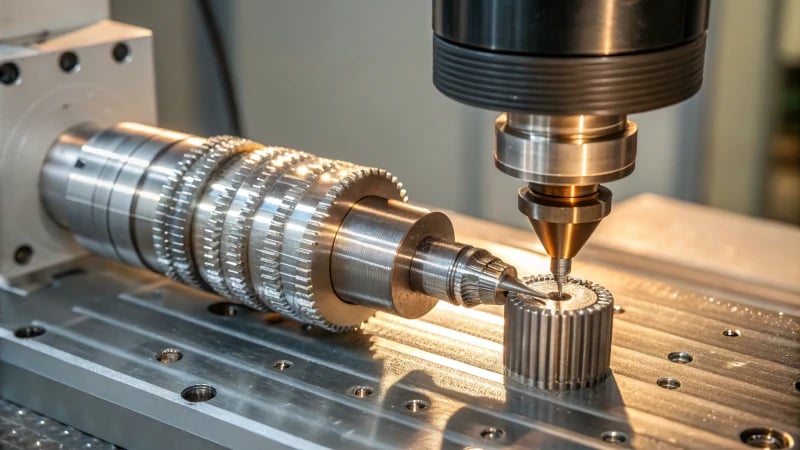

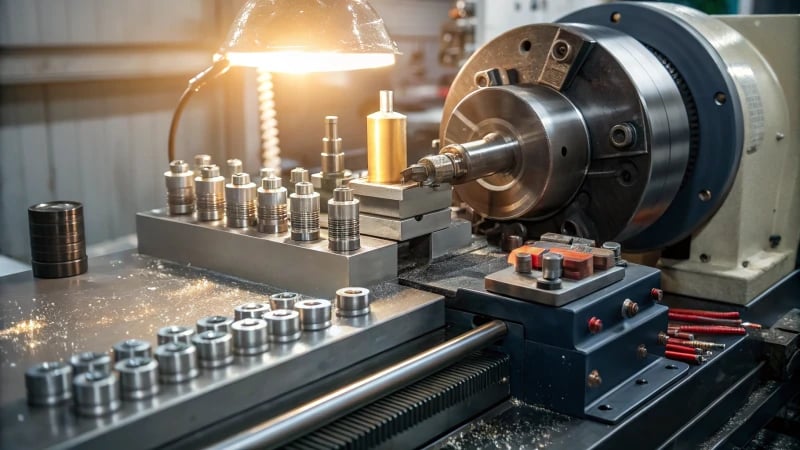

Ensure precise thread alignment by using thread gauges, applying thread lubricants, and employing CNC machines, which maintain thread integrity and prevent cross-threading.

I remember the first time I faced a serious misalignment issue. It was one of those projects where everything seemed perfect until it wasn’t. That’s when I realized the importance of the tools and techniques at my disposal to get the job done right.

Using Thread Gauges

Thread gauges have become my go-to for ensuring precise thread alignment. They’re like a trusted friend who points out any little deviation you might miss. By checking the dimensional accuracy against specified tolerances, I can catch misalignments before they become a problem. With thread gauges7, I’ve been able to avoid costly defects that could derail a project.

Application of Thread Lubricants

Applying the right lubricant is like greasing the wheels of success. I can’t stress enough how much smoother assembly becomes with the right lubricant, reducing friction and the risk of cross-threading. Plus, it’s like giving your components a longer lease on life by preventing wear and tear over time8.

CNC Machines for Consistency

Then there are CNC machines—talk about precision! These machines have transformed how I approach threading tasks. By programming them with exact specifications, I get consistent results across large production runs without the slip-ups that sometimes come with manual work.

| Technique | Benefits |

|---|---|

| Thread Gauges | Ensures dimensional accuracy and defect detection |

| Thread Lubricants | Reduces friction, prevents wear |

| CNC Machines | Provides precision and consistency |

By mastering these techniques, not only do I enhance the quality of threaded components, but I also boost production efficiency. It’s all about understanding these methods in greater detail9 to implement them effectively in any manufacturing setup.

Thread gauges detect dimensional inaccuracies.True

Thread gauges are used to verify the dimensional accuracy of threads.

CNC machines increase human error in threading.False

CNC machines minimize human error by providing precise, consistent threading.

How Can You Overcome Common Challenges in Thread Molding?

Thread molding can be a bit like solving a complex puzzle with missing pieces. But fear not, I’ve learned some tricks along the way that can turn these challenges into opportunities for success.

To overcome thread molding challenges, optimize thread design, control mold temperature, select suitable release agents, and ensure consistent maintenance and calibration for improved production outcomes.

Understanding Thread Design Challenges

I’ve spent many late nights staring at CAD models, trying to nail down the perfect thread design. It’s like the Goldilocks of engineering: too loose and it won’t hold; too tight, and it’s impossible to fit. One time, I almost sent a design to production that would’ve caused catastrophic misalignments. Luckily, I caught it just in time. The key is ensuring that the thread profiles match perfectly with screw mechanisms10. If they don’t, you risk issues like stripping or misalignment—problems I’ve unfortunately encountered more than once!

Importance of Mold Temperature Control

There was this one project where no matter what we tried, the threads kept coming out all wrong—like they had a mind of their own. Turns out, our mold temperature was fluctuating like a rollercoaster. Implementing robust temperature control felt like turning on the AC during a heatwave; it immediately stabilized the thread dimensions11, leading to a much smoother production process.

| Issue | Impact | Solution |

|---|---|---|

| Temperature Fluctuations | Inconsistent thread quality | Implement precise control |

| Poor Thread Design | Misalignment/stripping | Optimize design |

Effective Use of Release Agents

I remember the first time I dealt with threads sticking to molds—it was as if they were bonded for life. Choosing the right release agent was like finding the perfect dance partner; suddenly everything moved effortlessly. A good release agent ensures that the molded part ejects smoothly without damaging its integrity.

Regular Maintenance and Calibration

If there’s one thing I’ve learned over the years, it’s that skipping maintenance is like ignoring your car’s oil change—it might work for a while, but eventually, it’ll catch up to you. Regularly checking for wear and tear in molds is crucial. Precise calibration has saved me from countless headaches and helps ensure consistent production quality.

Addressing these areas can truly transform your thread molding challenges into streamlined processes. I’ve found that by focusing on these strategies, not only does efficiency improve, but so does the overall quality of the products we manufacture. It’s all about finding your rhythm and sticking to it. Dive deeper into proper calibration techniques12 to enhance both mold longevity and performance.

Precise mold temperature control prevents thread defects.True

Consistent temperature ensures uniformity in thread dimensions.

Poor thread design does not affect alignment.False

Misalignment can occur if threads are poorly designed.

Why Is Temperature Control Crucial in Molding Threads?

As a mold enthusiast who’s spent countless hours perfecting the art, I’ve learned that temperature control isn’t just a technical necessity—it’s the heart of crafting perfect threads.

Temperature control in molding threads ensures dimensional accuracy, prevents defects, and maintains consistent quality, optimizing production efficiency and meeting stringent standards.

The Role of Temperature in Molding Threads

I remember the first time I watched a batch of molded threads come out less than perfect. It was a rookie mistake: I hadn’t paid close enough attention to the temperature settings. You see, temperature deeply influences the viscosity13 of the polymer material we use. A stable temperature ensures the material flows just right into the mold, capturing every fine detail of the thread design.

| Temperature Effect | Consequences |

|---|---|

| Too High | Flashing, Burn Marks |

| Too Low | Short Shots, Sink Marks |

Once, I adjusted the temperature slightly to combat some deformation issues we were facing. It was a revelation—temperature truly holds the thread’s strength14 and functionality in its grip.

Temperature Control Techniques

I’ve found that properly calibrated temperature control units are lifesavers. They keep mold temperatures consistent, preventing issues like warpage15 or shrinkage.

- Chillers: These are my go-to for efficiently removing excess heat.

- Heaters: They come in handy during idle times to maintain optimal temperatures.

Getting these techniques down ensures that every molded thread aligns with industry standards. It’s like having a safety net for quality.

Impact on Production Efficiency

When I think about production efficiency, I see how precise temperature control can enhance cycle times16. By minimizing cooling periods without skimping on quality, I can boost throughput and cut down on energy use. Advanced monitoring systems with real-time feedback are my secret weapon—they help me spot deviations early and correct them instantly.

These experiences have shown me just how vital it is to integrate robust temperature control mechanisms into our thread molding processes. It’s not just about following protocol; it’s about creating products that stand the test of time.

High temperatures cause flashing in molded threads.True

Excessive heat leads to material overflow, creating flash defects.

Temperature control is irrelevant to thread strength.False

Inaccurate temperatures can deform threads, weakening them.

How Does Venting Impact Thread Injection Molding?

Ever wondered what makes thread injection molding tick? It’s all about venting—an unsung hero that ensures flawless results every time.

Venting in thread injection molding enables trapped air to escape, ensuring smooth flow and preventing defects such as voids and incomplete threads, essential for producing high-quality molded parts.

Why Venting is Essential in Thread Injection Molding

Have you ever had that moment when you’re trying to perfect something, only to find out there’s a hidden snag? That’s what happens when air gets trapped during thread injection molding. I remember the first time I saw a batch come out with tiny voids and surface burns—it was a wake-up call to the importance of venting. Without proper venting, air trapped inside the mold cavity can wreak havoc, leading to defects and incomplete fills. The magic happens when venting allows this air to escape, smoothing the way for molten plastic to flow and fill every intricate detail, especially those pesky threads.

Techniques for Effective Venting

There are several nifty techniques for effective venting, each with its own flair:

- Venting Channels: Think of these as the secret passageways for air. They’re small channels precisely placed in the mold that let air escape. The catch? They need to be just right—wide enough for air but not for plastic.

- Parting Line Vents: These are my go-to for larger areas. They’re etched along the parting line of the mold, but beware—they need careful machining to avoid flash, which is that annoying excess plastic around the edges.

- Pin Vents: Perfect for deeper molds, these thin pins act as breathers for trapped air. They’re fantastic but do add a layer of complexity.

| Venting Method | Advantages | Considerations |

|---|---|---|

| Venting Channels | Easy to implement | Requires precise dimension control |

| Parting Line | Effective for larger areas | Risk of flash if not executed properly |

| Pin Vents | Suitable for deep cavities | Increases mold complexity |

Challenges and Considerations

Venting isn’t just about poking holes here and there; it’s an art form. It needs a balance—enough airflow but not at the expense of material. I learned this when a vent was misaligned, and we ended up with a part that looked like Swiss cheese! In thread molding, getting vents right is crucial for crisp, complete threads.

Mold designers like myself must consider everything from the plastic’s viscosity to its cooling rate when planning vents. Plus, keeping those channels clean is non-negotiable—a blocked vent can lead to a cascade of problems. Embracing these nuances helps us mold designers refine our craft, ensuring every injection-molded part not only meets but exceeds expectations. Here’s to chasing perfection, one vent at a time!

Understanding these aspects helps mold designers optimize their designs for efficiency and quality, enhancing the performance of injection-molded parts17.

Venting prevents voids in injection-molded threads.True

Venting allows trapped air to escape, preventing voids in molded threads.

Pin vents reduce mold complexity in thread molding.False

Pin vents increase mold complexity due to their intricate placement needs.

Conclusion

Mastering injection molding threads requires optimizing mold design, material selection, temperature control, and venting techniques to ensure precision and high-quality threaded components in production.

-

Learn about optimizing thread engagement to enhance reliability and durability in plastic components. ↩

-

Explore situations where split molds are necessary to achieve complex geometries without quality compromise. ↩

-

Access shrinkage charts to help adjust mold designs for precise part dimensions post-molding. ↩

-

Explore how different materials impact the quality and function of threaded components in injection molding. ↩

-

Understanding heat resistance is vital for efficient mold cooling and cycle time management. ↩

-

Discover materials that are resistant to UV light, crucial for outdoor applications. ↩

-

Discover best practices for using thread gauges, ensuring accurate measurements and avoiding costly defects. ↩

-

Learn how thread lubricants can enhance durability and prevent damage during assembly. ↩

-

Explore how CNC machines can be programmed to achieve high precision in threading. ↩

-

Discover how proper thread design ensures compatibility with various screw mechanisms, preventing alignment issues. ↩

-

Learn why maintaining consistent mold temperature is crucial for producing uniform thread dimensions. ↩

-

Explore effective calibration methods to ensure high-quality thread production and equipment durability. ↩

-

Explore how temperature variations impact polymer viscosity, crucial for achieving precision in thread molding. ↩

-

Learn about the impact of temperature on the strength of molded threads to ensure durable products. ↩

-

Discover strategies for using temperature control to prevent warpage in molded threads. ↩

-

Understand how precise temperature management can improve cycle times and efficiency. ↩

-

Discover strategies for enhancing the quality and precision of injection-molded components. ↩