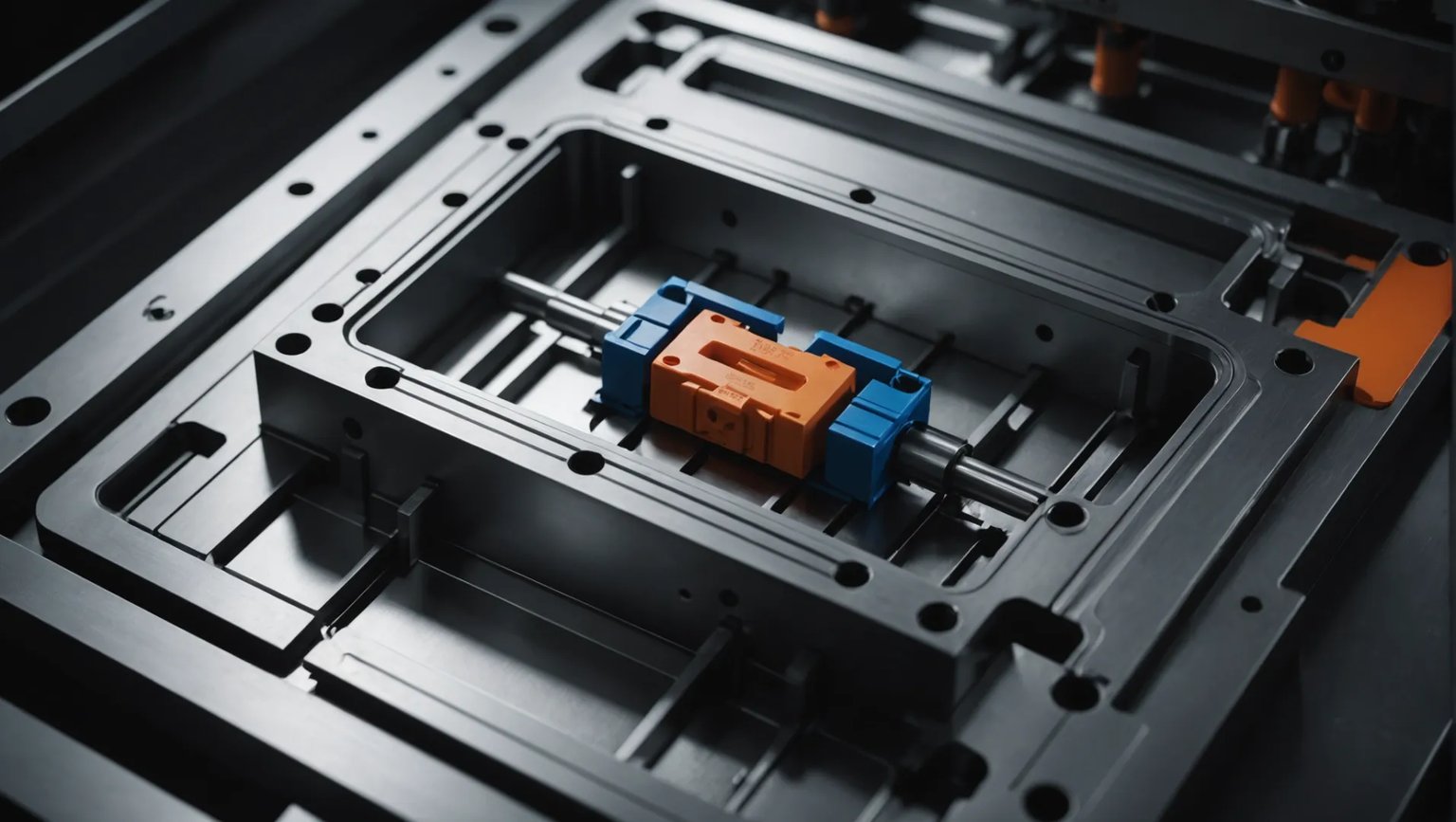

Are you tired of seeing defects in your injection molded parts? Believe me, I’ve been there. It can be frustrating when things don’t go as planned. But optimizing your runner layout could be the key to overcoming these challenges.

The best optimization techniques for runner layout in injection molds include designing appropriate runner sizes and shapes, using balanced or unbalanced layouts based on product complexity, and employing numerical simulation tools to predict and mitigate potential defects.

Let’s dive deeper into strategies and real-world applications that can truly transform your production line. I promise you’ll find insights that can elevate your processes to new heights.

Runner layout optimization reduces molding cycle time.True

Optimized layouts minimize flow distance, reducing injection time.

Why Is Runner Layout Optimization Essential for Injection Molding?

Optimizing runner layout is crucial to boosting product quality and production efficiency in injection molding.

Runner layout optimization ensures uniform melt flow, appropriate filling time, and reduced molding cycles, enhancing both quality and efficiency in injection molding processes.

Enhancing Product Quality with Optimized Runner Layout

In injection molding, achieving uniform melt flow is paramount. An optimized runner layout guarantees that the plastic melt flows evenly throughout the mold, significantly reducing defects like short shots, shrinkage marks, and warping. Such precision not only enhances the dimensional accuracy but also improves the overall appearance quality of the products.

Moreover, controlling the filling time by adjusting runner size and layout ensures simultaneous filling of each part. This harmonization is essential for maintaining consistent product quality, particularly in complex or multi-cavity molds.

Boosting Production Efficiency

An intelligently designed runner layout can dramatically shorten the molding cycle. By reducing the flow distance and pressure loss, it minimizes both injection pressure and time, directly translating to faster production rates. Additionally, an optimized runner system utilizes the energy of the injection molding machine more efficiently, cutting down on unnecessary energy consumption and lowering production costs.

For instance, by adopting a balanced runner layout where the structure is symmetrical, manufacturers can ensure that the plastic melt reaches all sections simultaneously. This approach is ideal for products with symmetrical shapes and smaller sizes. Conversely, unbalanced layouts cater to complex or larger products by using varied runner lengths and cross-sections.

| Runner Layout Type | Ideal Application |

|---|---|

| Balanced Layout | Symmetrical, small-sized products |

| Unbalanced Layout | Complex, large-sized products |

Leveraging Numerical Simulation for Superior Results

Utilizing numerical simulation tools like Moldflow software1 can further refine runner layouts. These tools allow for a detailed analysis of how different runner configurations affect melt flow, temperature distribution, and pressure within the mold. By predicting potential defects such as warpage or shrinkage marks before physical trials, manufacturers can save time and resources.

Such simulations provide a virtual testing ground to fine-tune runner layouts without the cost and time implications of physical trials. They enable precise adjustments that lead to superior product quality and operational efficiency.

Real-world Applications

The automotive industry, for instance, benefits significantly from runner layout optimization. By refining flow channel sizes and layouts, manufacturers can reduce product shrinkage and warping, achieving higher dimensional accuracy and aesthetic appeal. Similarly, in electronics manufacturing, optimizing flow channels not only enhances product appearance but also improves electrical performance by minimizing defects like bubbles or silver streaks.

In conclusion, runner layout optimization stands as a cornerstone in the pursuit of quality and efficiency within the injection molding industry. Through precise design and strategic use of simulation tools, manufacturers can unlock new levels of performance in their production processes.

Optimized runner layout reduces injection molding cycle time.True

It minimizes flow distance and pressure loss, speeding up cycles.

Balanced runner layouts are ideal for complex, large products.False

Balanced layouts suit symmetrical, small products; unbalanced ones fit complex items.

How Does Runner Size and Shape Impact Mold Efficiency?

Runner size and shape play a crucial role in optimizing mold efficiency, affecting product quality and production speed.

Runner size and shape directly influence mold efficiency by controlling melt flow, pressure distribution, and heat transfer during the injection molding process. Properly designed runners reduce cycle time, energy consumption, and improve product quality by ensuring uniform filling and reducing defects like warping and shrinkage.

The Importance of Runner Size in Injection Molding

Runner size is critical to controlling the flow rate and pressure of the molten plastic as it moves through the mold. Optimizing runner diameter can significantly impact both the quality and efficiency of the injection molding process. A well-designed runner system minimizes material usage, reduces cycle times, and enhances dimensional accuracy.

-

Main Runner Diameter: The main runner diameter should be selected based on the nozzle size of the injection machine and the product’s weight. A properly sized main runner ensures a balanced flow rate that prevents defects such as short shots or overpacking.

-

Branch Runner Diameter: Smaller branch runners are suitable for plastics with high fluidity, while larger diameters are necessary for heavier or more viscous materials. This adjustment helps maintain consistent flow and prevents pressure drops that could lead to defects.

-

Gate Size Considerations: The gate size affects how quickly the mold cavity fills. It must be tailored to the material’s properties and the product’s wall thickness to avoid issues like jetting or flow marks.

The Role of Runner Shape in Mold Performance

The shape of the runner also plays a pivotal role in optimizing mold efficiency. Different shapes offer unique advantages and challenges depending on the application:

| Runner Shape | Characteristics & Applications |

|---|---|

| Circular Runner | Offers minimal flow resistance and uniform heat distribution; ideal for most plastics. |

| Trapezoidal Runner | Slightly higher flow resistance but easier to process; suitable for small products. |

| U-shaped Runner | Higher flow resistance but reduces dead zones; beneficial for large products. |

The choice between these shapes depends on the specific requirements of the injection molding application, including material characteristics and product dimensions.

Strategies for Optimal Runner Layout

-

Balanced Layout: Ensures symmetrical flow paths to all parts of the mold, which is crucial for small, symmetrical products to ensure uniformity in filling and cooling.

-

Unbalanced Layout: Suitable for complex or asymmetrical shapes where different parts of the mold may require varying fill speeds and pressures to ensure even distribution.

Incorporating numerical simulation tools like Moldflow2 can further refine these layouts by predicting potential issues such as warpage or shrinkage before they occur, enabling proactive adjustments.

By focusing on these critical aspects of runner design, manufacturers can achieve significant improvements in mold efficiency, resulting in better product quality, reduced waste, and lower production costs.

Circular runners offer minimal flow resistance.True

Circular runners provide uniform heat distribution, reducing resistance.

Trapezoidal runners are best for large products.False

U-shaped runners are better for large products due to reduced dead zones.

What Role Does Numerical Simulation Play in Optimization?

Numerical simulation is revolutionizing how we optimize complex engineering processes, including injection mold runner layouts.

Numerical simulation plays a pivotal role in optimization by providing detailed insights into flow dynamics and pressure distribution. It helps predict potential defects, enabling engineers to refine designs before physical trials, thereby saving time and resources while enhancing product quality.

Understanding Numerical Simulation

Numerical simulation involves using computational models to predict the behavior of systems under various conditions. In the context of injection molding3, it enables engineers to visualize and analyze the flow of molten plastic within the mold. This powerful tool helps identify potential issues, such as uneven filling or excessive pressure, that could lead to defects in the final product.

Benefits of Using Numerical Simulation

-

Predictive Analysis: By simulating the entire molding process, engineers can foresee issues like short shots or warpage. This predictive capability allows for proactive design adjustments that mitigate these problems before manufacturing begins.

-

Cost Efficiency: Reducing the number of physical prototypes needed saves both material costs and labor hours. Adjustments can be made in the digital model, which is far more cost-effective than retooling a physical mold.

-

Quality Enhancement: Numerical simulations help ensure uniform melt flow and appropriate filling times, directly impacting the dimensional accuracy and surface quality of the molded parts.

Numerical Simulation Tools in Injection Molding

Several tools are widely used for numerical simulation in injection molding:

-

Moldflow: This software offers comprehensive analysis capabilities, including temperature distribution, cooling time, and pressure variations. It helps in optimizing runner layouts to improve product quality.

-

Autodesk Moldflow Insight: Known for its detailed simulations, this tool provides insights into complex flow behaviors, enabling more precise runner design adjustments.

Case Studies in Runner Layout Optimization

Automotive Industry

In automotive parts manufacturing, numerical simulation has been instrumental in optimizing runner layouts. For instance, by adjusting runner sizes and shapes digitally, manufacturers have reduced warpage and improved dimensional accuracy, leading to higher-quality components.

Electronics Manufacturing

For electronic products, where precision is crucial, numerical simulation aids in minimizing defects such as silver streaks or bubbles. By simulating different runner configurations, manufacturers can achieve better appearance quality and electrical performance of their products.

The Future of Numerical Simulation

As technology advances, numerical simulation will continue to evolve, offering even more precise tools for engineers. The integration of AI and machine learning into simulation software promises to enhance predictive accuracy, making these tools indispensable in manufacturing optimization.

By leveraging numerical simulation4, industries can not only improve their current processes but also innovate for future advancements.

Numerical simulation reduces physical prototypes needed.True

Simulations allow design adjustments digitally, cutting prototype costs.

AI integration in simulations decreases predictive accuracy.False

AI enhances predictive accuracy by improving simulation precision.

Which Industries Benefit Most from Advanced Runner Layouts?

Advanced runner layouts in injection molding are revolutionizing various industries by enhancing quality and efficiency.

Industries such as automotive, electronics, medical devices, and consumer goods benefit significantly from advanced runner layouts. Optimizing these layouts improves product quality, reduces defects, shortens cycle times, and lowers energy consumption.

Automotive Industry

The automotive sector5 heavily relies on high precision and durable components. Optimized runner layouts in injection molding reduce defects like shrinkage and warping, ensuring better dimensional accuracy. This not only enhances the safety and reliability of automotive parts but also accelerates production cycles, leading to cost efficiency.

In the context of electric vehicles, where lightweight and high-performance materials are crucial, advanced runner systems help in achieving uniform material distribution. This results in parts that meet stringent performance standards while minimizing waste.

Electronics Industry

The electronics industry6 demands components with intricate designs and high functionality. Optimized runner layouts address common issues such as bubbles and silver streaks, improving the appearance and electrical performance of electronic products.

With the rapid pace of innovation in consumer electronics, manufacturers benefit from shorter molding cycles enabled by advanced runner designs, facilitating quicker time-to-market for new products.

Medical Devices

In the medical field, precision is paramount. The use of advanced runner layouts ensures that medical device components meet exact specifications with minimal variability. This is critical for products like surgical instruments and diagnostic tools, where even minor deviations can lead to significant issues.

Moreover, the improved efficiency of molding cycles allows for higher throughput without compromising quality, which is essential in responding to urgent healthcare needs.

Consumer Goods

Consumer goods manufacturers also reap the benefits of optimized runner layouts. The ability to produce aesthetically pleasing and functional items with fewer defects results in higher customer satisfaction.

For example, household items like kitchenware and personal care products require both durability and attractiveness, which can be achieved through enhanced runner systems that ensure consistent product quality.

Conclusion: A Cross-Industry Asset

While specific benefits vary across industries, the overarching advantage of advanced runner layouts is clear: they enhance product quality and manufacturing efficiency. Whether you’re in automotive, electronics, medical devices, or consumer goods, leveraging these technologies can provide a competitive edge in today’s fast-paced market.

Advanced runner layouts reduce defects in automotive parts.True

Optimized layouts ensure better dimensional accuracy, reducing defects.

Runner layouts have no impact on medical device precision.False

Advanced layouts ensure components meet exact specifications, crucial for precision.

Conclusion

In summary, mastering runner layout optimization is essential for enhancing product quality and production efficiency. Embrace these techniques to stay ahead in the competitive manufacturing landscape.

-

Explore how Moldflow software enhances injection molding efficiency through simulation.: Autodesk Moldflow simulation software provides plastic injection molding and compression molding insights to improve manufactured part quality. ↩

-

Learn how Moldflow predicts and solves potential molding issues.: Moldflow simulation software lets you troubleshoot problems with plastic injection and compression molding. Advanced tools and a simplified user interface ↩

-

Learn about injection molding fundamentals and its industrial applications.: what injection molding is, what the injection molding machine looks like, and how the injection … ↩

-

Discover how numerical simulation enhances engineering processes and outcomes.: Because numerical simulation allows for rapid experimentation, it opens the door to greater innovation. Engineers and designers can test out-of- … ↩

-

Explore how runner optimization enhances safety and efficiency in automotive parts.: Layout optimization through One-Piece Flow implementation is an elementary key to efficiencies sand to ensure the success. Should be present in … ↩

-

Understand how optimized runner layouts improve electronics production quality.: The line and layout designs are fundamental elements for achieving efficiency, flexibility, and quality at the lowest possible cost. ↩