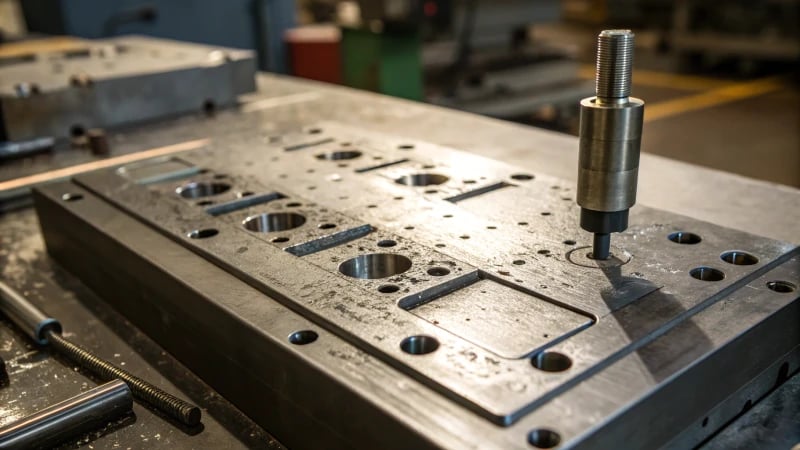

Ever thought about what might go wrong in mold production? Even experts with lots of experience encounter sudden flaws that could really mess up quality.

The most frequent problems in mold production are size mistakes, surface imperfections, shape faults and fitting troubles. These problems often arise from equipment precision mistakes. Incorrect processing details cause issues, too. Poor assembly methods also lead to defects. These issues affect how well the final product works and looks. Quality suffers because of them.

My journey in mold manufacturing taught me that understanding defects is vital. Knowing they exist isn’t enough. Dive deep into their causes and effects. Dimension deviations showed me the importance of being precise with CNC machining. Precision matters. Every measurement must perfectly align. Grasping defect details helps troubleshoot problems and stop them from happening again. This approach improves product quality. This method also streamlines the whole manufacturing process. My work becomes more efficient and rewarding.

Dimension deviation is a common defect in mold manufacturing.True

Dimension deviation occurs due to equipment precision errors.

Surface quality problems rarely occur in mold manufacturing.False

Surface quality issues are common due to improper processing parameters.

How Do Dimension Deviations Affect Mold Manufacturing?

When I first entered the world of mold production, I did not know how crucial every small detail was. One big surprise was learning how much dimension differences affected our products. Very surprising.

Dimension differences in mold manufacturing lead to serious problems like poor fit and failures in function. These differences come from precision mistakes, tool wear and wrong assembly. They really affect the quality of injection-molded products. Quality suffers.

Causes of Dimension Deviations

I remember the first time I watched a CNC machine. It was fascinating but a little scary. Precision is super important in machining. Dimension changes often occur due to errors in the equipment, like CNC machining centers1. Even a small mistake in positioning on a CNC machine can mess everything up. As time passes, tools wear out, which creates more problems. Parts might not fit together properly because of this.

In assembly, things can also get messy. I struggled with adjusting sliders and guide rails when I started working. It’s a delicate job. Too much or too little space can lead to errors throughout the project.

| Cause | Example |

|---|---|

| Precision error | CNC machining center positioning inaccuracy |

| Tool wear | Dulling of cutting tools leading to larger cut dimensions |

| Assembly inaccuracies | Incorrect slider-to-guide rail gap adjustment |

Impact on Product Quality

These errors affect not just the job but also emotions. I felt bad when a product didn’t meet the requirements. I had to explain to both the team and the client. When a mold is wrong, parts won’t fit or work together, such as an injection-molded phone case that didn’t assemble with the inner parts.

Warping and twisting also cause trouble. They look bad and weaken the structure, affecting assembly processes. It’s annoying because it means more quality checks and maybe remaking some parts, which is costly.

| Impact | Description |

|---|---|

| Assembly difficulties | Parts don’t fit as intended |

| Functional failure | Products don’t perform their intended functions |

| Additional quality control | Extra steps needed to ensure product standards are met |

Exploring these causes and effects helps us face dimension changes directly. Buying precise machines and improving assembly rules are very helpful steps. Looking at precision error management2 can also really help a lot. The goal is to keep excellent product quality. In my experience, this approach saves many problems later on.

Tool wear leads to larger cut dimensions.True

Worn tools lose precision, causing larger cuts and dimension deviations.

Precision errors have no impact on mold quality.False

Precision errors affect mold fit and function, compromising quality.

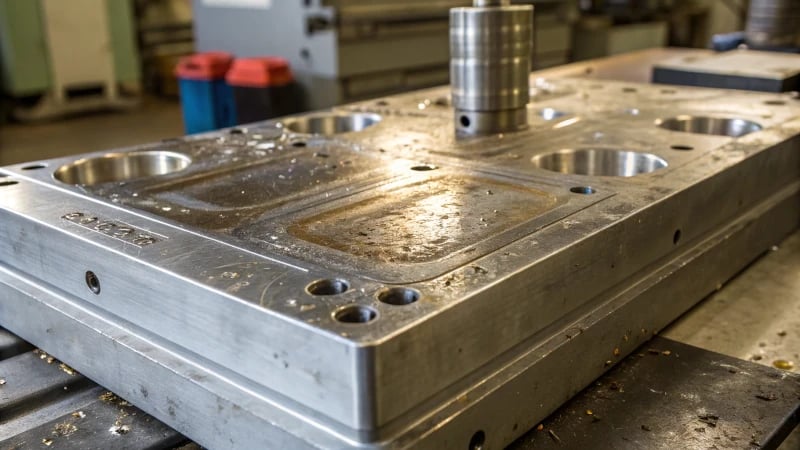

What Causes Surface Quality Problems in Molds?

Some molds never succeed. It’s more than just bad fortune.

Problems with surface quality in molds often arise from processing mistakes, material flaws or heat stress. Understanding these problems is important. Fixing them is crucial. This effort greatly improves how the final product looks and works.

Dimension Changes and Their Effects

Dimension changes are often a big problem. They happen a lot during manufacturing because of small mistakes or tools getting old. Imagine using a machine for hours only to find the mold isn’t correct. It happened to me. My measurements were wrong, and I had to do everything again. This caused big problems later during assembly. Precise work during mold assembly3 is very important.

Surface Roughness Problems

Surface roughness is tricky! Get processing settings wrong and prepare for trouble. My first experience with EDM settings was messy. The marks were huge and a big problem for automotive interiors. These rough spots can ruin projects. Picking the right settings really helps avoid these issues.

| Processing Method | Common Issues | Solutions |

|---|---|---|

| EDM | Large marks | Optimize settings |

| Milling | Surface waves | Regular maintenance |

Surface Cracks

Surface cracks are scary. I panicked when cracks appeared because of bad heat treatment. Too much heat or fast cooling? That’s bad news. Cracks ruin the product before starting. Controlling these factors is very important.

Shape Problems and Their Effects

Shape problems can destroy your work. Too much cutting force or wrong clamping methods cause trouble. Once, excessive force ruined my work – it literally crumpled. Walls deformed, thickness became uneven. Avoiding these errors is key, especially with complex designs.

Fitting and Movement Troubles

Fitting troubles were a nightmare for me until I understood clearances. Too much clearance lets plastic spill over; too little causes sticking parts—both are problems. Designing and adjusting fitting clearances4 correctly is really important for smooth work.

Keeping perfect conditions in mold making leads to high-quality surfaces and consistent performance, as experienced by professionals like Jacky from Canada, who uses CAD tools to create designs that look good and work well.

Mike Tang, creator of MoldAll, talks often about grasping these fine points for success in molding. His wisdom guides many who want excellence and freedom in this field.

CAD tools5 are essential for precise mold design, helping even the most experienced designers handle complex needs well.

CNC errors cause dimension deviation in molds.True

Inaccurate CNC positioning leads to mold cavity errors, affecting dimensions.

High quenching temperatures prevent surface cracks.False

High quenching temperatures can create internal cracks, not prevent them.

Why Do Shape Errors Occur in Mold Production?

Ever faced a project stopped by tricky mold shape mistakes? It’s annoying, but knowing the main causes really helps.

Errors in mold shape usually arise from machining mistakes, too much cutting force and wrong heat treatment. Addressing these issues directly improves mold accuracy. Product quality really benefits from these improvements.

Machining Inaccuracies

One of the main reasons for shape errors is machining inaccuracies. I remember when I first noticed a mistake in machining. Our new CNC machine missed the correct spot on the coordinate axes, leading to deviations in the mold’s shape. The mold cavity was not perfect; its size was incorrect. It seemed like a beginner’s error. Such precision problems really disrupt work, causing parts that don’t fit the design. Tool wear and programming errors can exacerbate these issues, resulting in chaos in manufacturing.

Excessive Cutting Forces

Excessive cutting forces during machining are sometimes uncontrollable and can deform the cavity or core of the mold. During a project, I increased the cutting depth too much in rough machining. The result was disastrous: cavity walls were uneven and unclear, particularly for complex designs.

| Issue | Cause | Impact |

|---|---|---|

| Deformation of cavity/core | Excessive cutting forces | Uneven wall thickness |

| Demolding mechanism issues | Long-term use or unreasonable design | Difficulty in demolding, product damage |

Like trying to shape a delicate piece with a heavy hammer, excessive force leads to significant deformation.

Improper Heat Treatment

Heat treatment is similar to baking a cake; temperature and time must be right. If not done correctly, it can lead to surface cracks or deformations. For example, if the quenching temperature is too high or cooling is too rapid, molds might crack on the surface because of improper heat treatment, compromising their integrity.

Design and Assembly Issues

Design and assembly are vital in mold production. Shape errors may also arise from design or assembly problems. Fitting clearance is crucial; if not properly considered between parts like slider mechanisms6 and guide rails, it can lead to misalignments and dimensional inaccuracies.

I once underestimated the space between slider mechanisms and guide rails. That small mistake caused big misalignments and shape errors—a lesson in paying attention to detail.

Proactive Measures

Precision is everything to fix shape errors. To mitigate these issues:

- Employ precise machining practices.

- Optimize cutting parameters.

- Conduct thorough design reviews.

- Regularly maintain machinery.

- Provide continuous training for personnel.

Learning from mistakes and using new technology leads us towards better mold production processes and enhances product quality overall. Here is a comprehensive resource7 for those curious about precision errors and their effects.

Machining inaccuracies lead to shape errors in molds.True

Precision errors in CNC machines cause deviations in mold shapes.

Improper heat treatment can cause mold surface cracks.True

Incorrect quenching temperature or rapid cooling leads to cracking.

How Do Fitting Problems Affect Injection Molding?

Faced problems with injection molding where fitting issues cause chaos in your detailed designs? I want to share my knowledge. Maybe this can help you handle these issues.

Problems in injection molding cause defects such as flash and misaligned parts. Improper clearances and flaws in design are often the reason for these defects. These issues disrupt production efficiency. Product quality suffers as well. I have personally experienced this.

Common Causes of Fitting Problems

I often face fitting problems in injection molding. These issues occur when clearances between mold parts lack careful consideration. Think of a mold where the gap is too wide between the sprue sleeve8 and the positioning ring – it brings many troubles! The plastic melt spills over during injection, causing problems with the product’s quality.

| Table: Causes and Impacts of Fitting Problems | Cause | Impact |

|---|---|---|

| Improper clearance | Flash | |

| Moving parts stuck | Damage |

Impact on Product Quality

I remember holding a product meant to be flawless, only to spot defects like flash. Flash appears as unwanted material along edges. It’s not just ugly; it increases workload and affects the look and function. This is a real issue for items like smartphone cases.

Operational Challenges

Fitting problems impact not just looks but also operations. I dealt with a mold where the slider’s guide design was flawed. Every cycle seemed risky. The slider might stick, stopping production and possibly harming the mold. The sticking problem9 causes real delays. It affects everything from mold opening to closing.

Example Scenario: Imagine using a mold for smartphone cases. If the slider’s guide rail is rough, it sticks during movement. This isn’t just a small issue; it’s a delay that impacts the entire production schedule.

For me, solving these fitting problems means focusing on exact measurements and checking every clearance during the design phase10. Using high-quality materials helps achieve reliability for mass production.

Improper clearance causes flash in injection molding.True

Improper clearances lead to excess material, causing flash defects.

Stuck moving parts do not affect production efficiency.False

Stuck parts hinder mold operations, reducing production efficiency.

What are effective strategies to prevent mold defects?

Had a very frustrating day when a tiny problem becomes a large issue? Mold defects in manufacturing are similar to that. Strategies probably stop them early.

Stop mold defects with design improvements, careful manufacturing and keeping perfect mold conditions. Important tactics are controlling temperature, using high-quality materials and regular checks and maintenance. Regular checks are critical.

Control Temperature and Humidity

I remember when I first started with mold creation. I felt overwhelmed by the possible mistakes. But, with a bit of help and some reliable strategies, I have managed to avoid those annoying mold defects.

One time, I forgot about the temperature settings. This mistake caused big problems with size changes. Lesson learned! Now, I pay attention and adjust temperature settings11 carefully. High temperatures really cause issues with material stretching. Watching it closely prevents many problems.

Use High-Quality Materials

I decided to use cheaper materials one time – big mistake! The surface cracks were a total nightmare. Now, I always pick high-quality metals that handle heat like champions, stopping any bad surface cracks12 from appearing.

Conduct Regular Maintenance

Routine maintenance might sound dull, but it is the quiet hero of mold making. Weekly cleaning and monthly checks help spot issues early.

| Maintenance Task | Frequency |

|---|---|

| Cleaning and Lubrication | Weekly |

| Inspection for Cracks | Monthly |

| Calibration | Quarterly |

Here is my regular cleaning and checking routine:

Improve Design Accuracy

Advanced CAD software helps a lot; it’s like having extra eyes. This software catches design mistakes before they cost a lot. Checking sizes before creating has saved me from errors many times by preventing dimension deviation13.

Optimize Assembly Processes

Precision during assembly is very important. Even small misalignment causes big problems. Using checklists has made a huge difference; every step gets followed exactly.

Use Technology for Quality Control

Adding sensors and automation changed everything. Real-time data lets me adjust quickly when things go wrong, significantly reducing mistakes.

These strategies have improved both efficiency and product quality for me. Preventing problems lowers repair costs and keeps everything smooth. If you’re like me and want to avoid those annoying errors, try these strategies!

High temperatures cause dimension deviations.True

High temperatures can lead to uneven material expansion, causing deviations.

Monthly inspections are not recommended for mold maintenance.False

Monthly inspections help identify wear and tear early, aiding timely repairs.

Conclusion

Mold manufacturing defects, including dimension deviations, surface issues, shape errors, and fitting problems, arise from precision errors and improper assembly, impacting product quality and efficiency.

-

Discover how CNC machining centers impact dimensional precision and identify ways to enhance accuracy. ↩

-

Learn effective strategies to manage and reduce precision errors in mold manufacturing for improved quality. ↩

-

Explore techniques for maintaining dimensional accuracy during mold assembly, crucial for product quality. ↩

-

Learn about best practices for designing fitting clearances to prevent movement issues in molds. ↩

-

Discover top CAD tools that help ensure precision in mold design for seasoned designers. ↩

-

Learn how improper clearances in slider mechanisms lead to shape errors. ↩

-

Understand how precision errors impact mold accuracy and product quality. ↩

-

This link explores common reasons for improper clearances, helping readers understand root causes and how to prevent them. ↩

-

Learn about effective methods to resolve sticking issues in mold components and enhance operational efficiency. ↩

-

Discover why careful clearance design is essential in ensuring functional and defect-free molds. ↩

-

Learn how to regulate temperature effectively in mold production environments to minimize defects. ↩

-

Explore how using high-quality materials can prevent surface defects in molds. ↩

-

Understand why precision in design is crucial to avoiding dimension deviations in molds. ↩