MANUFACTURING

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

Can One Injection Molding Machine Fit Any Mold?

This article explores why one injection molding machine cannot fit every mold. It discusses critical factors such as clamping force, injection capacity, mold size, and pressure requirements that influence compatibility. Understanding these elements is crucial for product designers to avoid ...

MANUFACTURING

What Are the Most Common Surface Finishing Techniques for Injection Molded Parts?

This article delves into the most common surface finishing techniques for injection molded parts, such as painting, electroplating, hot stamping, silk screening, pad printing, laser engraving, frosting, and polishing. Each method is designed to enhance both the appearance and performance ...

MANUFACTURING

How Does the Injection Rate Affect Injection Molding Efficiency?

Understanding the injection rate is crucial in injection molding as it directly impacts part quality, surface finish, and overall efficiency. A well-calibrated injection rate ensures complete mold filling while minimizing defects such as air entrapment or short shots. Factors influencing ...

MANUFACTURING

What Challenges Do Startups Face in Injection Molding?

Startups entering the injection molding industry encounter significant hurdles, including exorbitant equipment and mold costs, difficulties in attracting skilled talent, and intense market competition. These challenges necessitate careful strategic planning and effective resource management to ensure growth and sustainability. Funding ...

MANUFACTURING

How Can You Texture Injection Molded Surfaces Effectively?

This article delves into various methods for effectively texturing injection molded surfaces. Techniques such as Electrical Discharge Machining (EDM), chemical etching, laser texture processing, and mechanical engraving are explored. Each method offers unique benefits tailored to specific design needs and ...

MANUFACTURING

What Impact Do RoHS Directives Have on Injection Molding Materials?

The RoHS Directive significantly influences injection molding materials by enforcing strict restrictions on hazardous substances like heavy metals and brominated flame retardants. This shift compels manufacturers to seek alternative, compliant materials, often leading to increased production costs due to higher ...

MANUFACTURING

What Are the Steps to Comply with REACH Regulations in Injection Molding?

Navigating REACH compliance in injection molding is crucial for product safety and market access. This article provides a comprehensive overview of the necessary steps, including selecting compliant materials, managing suppliers effectively, maintaining rigorous process controls, and keeping detailed records. By ...

MANUFACTURING

What Are the Key Steps to Transition from Prototype to Mass Production in Injection Molding?

This article outlines the essential steps for transitioning from prototype to mass production in injection molding. Key stages include thorough evaluation of prototypes, optimization of molds based on performance tests, standardization of process parameters through experimental design methods, and establishment ...

MANUFACTURING

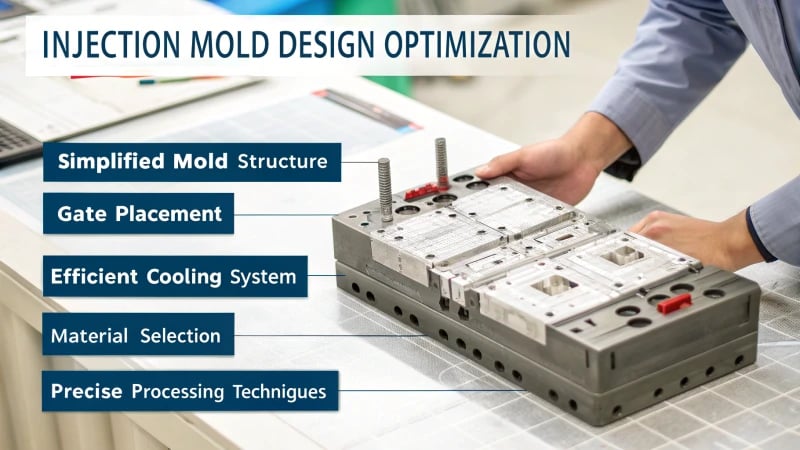

What Are the Key DFM Principles for Optimizing Injection Mold Design?

This article explores essential Design for Manufacturing (DFM) principles crucial for optimizing injection mold design. It emphasizes the importance of simplifying mold structures, strategically placing gates, designing efficient cooling systems, selecting appropriate materials, and ensuring precise processing. Each principle plays ...

MANUFACTURING

How Does Design for Manufacturability (DFM) Enhance Injection Molding?

This article explores how Design for Manufacturability (DFM) enhances injection molding by focusing on product structure design, mold design, and material selection. Key principles include maintaining uniform wall thickness to prevent defects like warping and shrinkage, strategically designing ribs for ...

MANUFACTURING

What Key Factors Should You Consider When Using Recycled Plastics for Injection Molding?

This blog post explores key factors to consider when using recycled plastics for injection molding. It emphasizes the importance of material quality, compatibility, and contamination management to maintain product integrity. The author shares personal experiences and practical solutions for designers ...

MANUFACTURING

Can Injection Molding Effectively Produce Both Plastic and Metal Parts?

Injection molding is a versatile manufacturing process ideal for producing intricate plastic parts at scale. Its adaptability to various materials allows for efficient large-scale production of complex shapes, making it cost-effective. However, when it comes to metal parts, the process ...

MANUFACTURING

What Factors Determine the Right Size of Injection Molding Machine?

Selecting the appropriate size for an injection molding machine is essential for optimizing production efficiency and product quality. Key factors include material type, shot size, clamping force, and technical specifications. Each element plays a vital role in ensuring that the ...

MANUFACTURING

What Factors Determine the Right Cooling Time in Injection Molding?

Understanding the right cooling time in injection molding is crucial for optimizing production efficiency and ensuring high-quality products. Key factors include part thickness, material properties, and mold design. Thicker parts require longer cooling times due to increased heat retention, while ...

MANUFACTURING

What Are the Steps to Apply Advanced In-Mold Decoration in Injection Molding?

Advanced in-mold decoration (IMD) is a transformative process that integrates decorative graphics into plastic components during injection molding. This technique not only elevates the aesthetic appeal of products but also ensures durability and longevity, making it a preferred choice across ...

MANUFACTURING

What is the Process of Injection Molding UHMWPE?

This blog post explores the intricate process of injection molding Ultra High Molecular Weight Polyethylene (UHMWPE). It highlights its exceptional properties such as durability, low friction, and wear resistance, making it ideal for various applications in industries like medical devices, ...

MANUFACTURING

What Are the Key Differences in Injection Molding for Large vs. Small Parts?

This article explores the key differences in injection molding processes for large versus small parts. It highlights how factors such as mold design complexity, material selection, and machinery needs vary with part size. Large parts require robust materials and larger ...

MANUFACTURING

How Can You Ensure the Accuracy of Injection Molds?

Injection molding combines precision and creativity. To ensure accuracy, it's essential to utilize precise CAD modeling, manage tolerances effectively, and implement rigorous quality control measures. Regular maintenance of machinery is crucial for sustaining high standards. Factors like material properties, design ...

MANUFACTURING

How Can You Ensure Uniform Color Mixing in the Injection Molding Process?

Ensuring uniform color mixing in the injection molding process is crucial for producing vibrant plastic products. Key strategies include utilizing high-quality masterbatch colorants, fine-tuning processing conditions like temperature and pressure, and maintaining consistent material flow. Regular equipment calibration and thorough ...

MANUFACTURING

What Are the Key Applications and Technical Requirements for Mirror Polishing in Injection Molds?

Mirror polishing is a vital process in injection mold design, enhancing both the aesthetic appeal and functional quality of products. This technique creates ultra-smooth surfaces that minimize friction, defects, and wear over time. Industries such as consumer electronics, automotive parts, ...

MANUFACTURING

How Does the Injection Mold Manufacturing Process Work?

Injection mold manufacturing is a detailed process that transforms raw materials into precision plastic components. It encompasses several key stages: mold design, manufacturing preparation, parts processing, assembly, debugging, optimization, and acceptance. Each stage is crucial for ensuring the final product ...

MANUFACTURING

How Do Single Cavity Molds Differ from Multi-Cavity Molds?

This article explores the differences between single cavity and multi-cavity molds in injection molding. Single cavity molds are ideal for high-precision, small-batch production, allowing detailed control over quality and output. In contrast, multi-cavity molds produce multiple identical items per cycle, ...

MANUFACTURING

How Can You Produce Transparent Products Using Injection Molding?

This blog post explores techniques for producing transparent products through injection molding. It covers essential material selection, precise mold design, and control of temperature and pressure to achieve optimal clarity. Key materials like polycarbonate, acrylic, and PMMA are discussed along ...

MANUFACTURING

How Can Injection Molded Products Achieve Antimicrobial Properties?

As cleanliness becomes increasingly important, industries are turning to antimicrobial plastics. By integrating additives like silver and copper ions during the injection molding process, these materials can effectively disrupt microbial cell functions. This innovation is crucial in sectors such as ...

MANUFACTURING

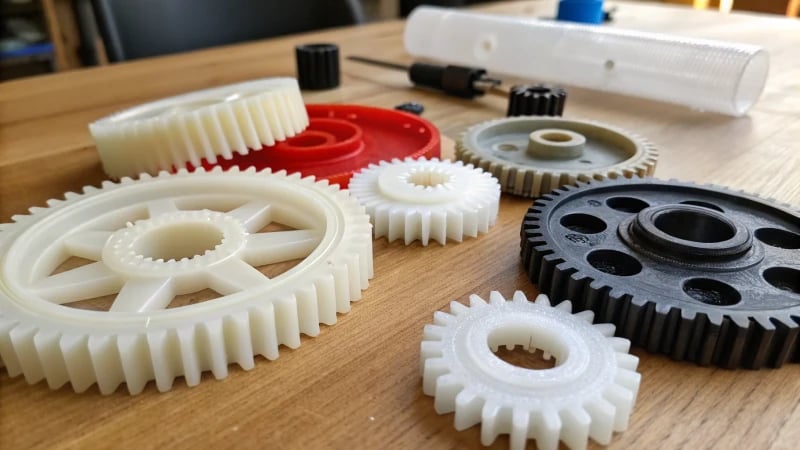

How Are Plastic Gears Manufactured Through Injection Molding?

This blog post explores the fascinating process of manufacturing plastic gears through injection molding. It details the steps involved in the injection molding cycle, highlights key material choices such as acetal, nylon, and polycarbonate, and discusses the advantages of this ...

MANUFACTURING

What Impact Do UV Stabilizers Have on Injection-Molded Products?

UV stabilizers are essential additives in injection-molded products, safeguarding them against the damaging effects of ultraviolet radiation. By absorbing or reflecting harmful UV rays, these stabilizers help maintain the physical properties of plastics, ensuring longevity and vibrant colors. Understanding the ...

MANUFACTURING

What Impact Do Colorants and Pigments Have on the Injection Molding Process?

Colorants and pigments play a crucial role in the injection molding process by altering the physical properties of plastics such as flexibility, hardness, and durability. The right selection enhances visual appeal while optimizing performance for large-scale manufacturing. Understanding how different ...

MANUFACTURING

What Impact Do Plasticizers Have on the Flexibility of Injection-Molded Parts?

Plasticizers are essential additives that improve the flexibility and durability of injection-molded plastics by inserting themselves between polymer chains. This process reduces intermolecular forces, allowing for greater mobility and adaptability in various applications. While plasticizers like phthalates have been widely ...

MANUFACTURING

What Impact Do Crystallinity Levels in Polymers Have on Injection Molding Outcomes?

This article explores how crystallinity levels in polymers impact injection molding processes. It discusses the relationship between crystallinity and mechanical properties such as strength, brittleness, and thermal stability. Understanding these factors is essential for optimizing product designs in various applications, ...

MANUFACTURING

What Are the Differences in Injection Molding for Thin-Wall vs. Thick-Wall Parts?

This article explores the key differences between thin-wall and thick-wall injection molding processes. Thin-wall molding typically requires higher pressure and faster cooling times, enhancing production speed but potentially compromising structural integrity. In contrast, thick-wall molding allows for more leeway in ...

MANUFACTURING