OPTIMIZATION

blog & article

read our latest newsletter

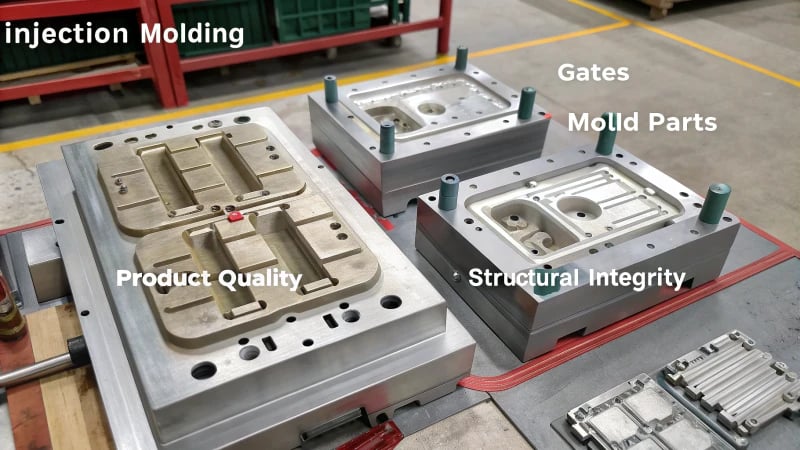

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

How Can You Balance Quality and Cost in Injection Molding?

This article explores how to balance quality and cost in injection molding by focusing on raw material selection, mold design, and process optimization. It emphasizes the importance of choosing high-strength materials like polyamide for durability while also considering cost-effective alternatives ...

OPTIMIZATION

What Are the Best Strategies to Reduce Costs in Injection Molding?

Reducing costs in injection molding requires a strategic approach that includes optimizing mold design by selecting the right number of cavities and simplifying structures. Choosing cost-effective materials like general-purpose plastics over engineering ones can significantly lower expenses while maintaining product ...

OPTIMIZATION

How Can You Effectively Prevent Knit Lines in Injection Molding?

Knit lines can compromise the appearance and durability of injection-molded products. To effectively prevent them, focus on optimizing mold design through strategic gate placement, runner system improvements, and exhaust setup. Adjusting process parameters such as temperature, speed, and pressure is ...

OPTIMIZATION

What Are Effective Solutions for Fixing Short Shots in Injection Molding?

Short shots in injection molding can disrupt production and lead to defective parts. This article provides practical solutions to tackle this issue by focusing on key factors such as melt flow rate (MFR), temperature sensitivity of materials, gate design, runner ...

OPTIMIZATION

What Are the Best Techniques for Painting Injection Molded Products?

This guide explores the best techniques for painting injection molded products. It emphasizes the importance of meticulous surface preparation, selecting compatible paints based on material properties, and applying them using appropriate methods like spraying or brushing. The article also discusses ...

OPTIMIZATION

How Can You Optimize Cycle Time in Injection Molding?

In the competitive landscape of injection molding, optimizing cycle time is crucial for enhancing production efficiency. Key strategies include refining mold design, choosing appropriate materials with high thermal conductivity, and embracing automation technologies. By understanding the components of cycle time—processing, ...

OPTIMIZATION

How Can You Optimize Acoustic Properties in Injection Molding?

This blog post explores how to optimize the acoustic properties of molded products through careful material selection, innovative mold design, and precise processing adjustments. It highlights the importance of using sound-dampening materials like polypropylene, ABS, and nylon while considering factors ...

OPTIMIZATION

How Promising Are Multi-Material and Multi-Color Injection Molding Technologies?

This blog explores the transformative potential of multi-material and multi-color injection molding technologies in manufacturing. These innovations boost design creativity, streamline production processes, and enhance product functionality while reducing costs. However, they also pose challenges regarding recycling complexities and integration ...

OPTIMIZATION

How Do Additives Impact the Properties of Injection-Molded Parts?

Additives play a crucial role in injection molding by modifying the properties of plastics to meet specific design requirements. They can enhance strength, flexibility, and durability through various types such as stabilizers, plasticizers, colorants, and reinforcements. Stabilizers protect against environmental ...

OPTIMIZATION

What Are the Best Practices for Storing Injection Molds to Extend Their Life?

Proper storage and maintenance of injection molds are crucial for extending their lifespan. Key practices include storing molds in a dry, temperature-controlled environment, regular cleaning to prevent residue buildup, lubrication to reduce wear, and frequent inspections to catch potential issues ...

OPTIMIZATION

How Can You Achieve Perfect Color Consistency in Injection Molded Parts?

Achieving perfect color consistency in injection molded parts is crucial for product quality and brand integrity. This post explores essential strategies including material selection, process control, and advanced coloring techniques like masterbatching and liquid colorant systems. It highlights the importance ...

OPTIMIZATION

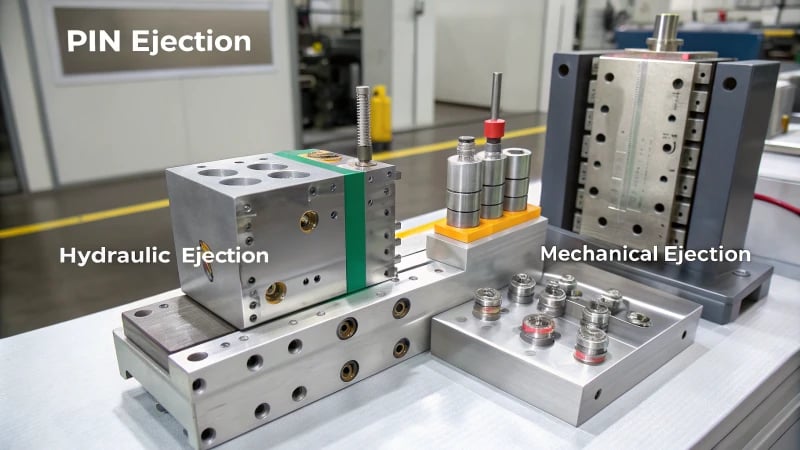

How Do You Choose the Right Ejection System for Your Mold?

Selecting the appropriate ejection system for mold manufacturing is essential to enhance production efficiency and minimize defects. Factors such as part complexity, material type, and suitable ejection methods play a significant role in this decision-making process. This guide explores various ...

OPTIMIZATION

What Are the Causes of Cold Slug in Injection Molding?

Cold slugs are a common issue in injection molding that can compromise product quality. They typically form due to material temperature inconsistencies, inadequate nozzle designs, or improper mold cooling. This blog explores the causes of cold slug formation and offers ...

OPTIMIZATION

What Are the Best Methods to Prevent Silver Grain Defects in Injection Molded Products?

Silver grain defects in injection molded products can be minimized by focusing on raw material management, precise parameter settings, effective mold design, and process optimization to enhance product quality.

OPTIMIZATION

How Can You Effectively Reduce the Manufacturing Costs of Injection Molded Plastic Products?

This article explores effective strategies to reduce manufacturing costs in injection molding, focusing on optimizing raw materials, streamlining production processes, managing equipment efficiently, and implementing robust quality control measures.

OPTIMIZATION

What Are the Best Ways to Prevent Fusion Marks on Injection Molded Products?

This article explores effective strategies to prevent fusion marks in injection molded products, emphasizing the importance of mold design, process parameter adjustments, and material selection for improved quality.

OPTIMIZATION

What Parameters Can Be Optimized by Mold Flow Analysis in Injection Molding?

Mold Flow Analysis (MFA) optimizes injection molding parameters such as gate location, runner systems, injection pressure, and cooling times to enhance production efficiency, reduce defects, and improve product quality.

OPTIMIZATION

What Are the Best Ways to Adjust Melt Temperature in Injection Molding to Minimize Fusion Marks?

This article explores the importance of adjusting melt temperature in injection molding to minimize fusion marks. It discusses material properties, mold design, cooling systems, and process parameter coordination for optimal results.

OPTIMIZATION

What Are the Best Methods to Determine the Adjustment Sequence of Injection Molding Process Parameters?

This guide explores the best methods for determining the adjustment sequence of injection molding process parameters, focusing on temperature, pressure, speed, and cooling time to enhance product quality and efficiency.

OPTIMIZATION

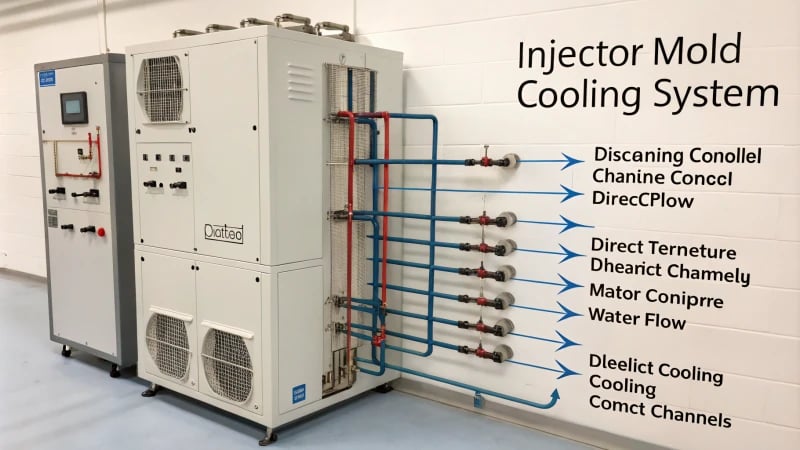

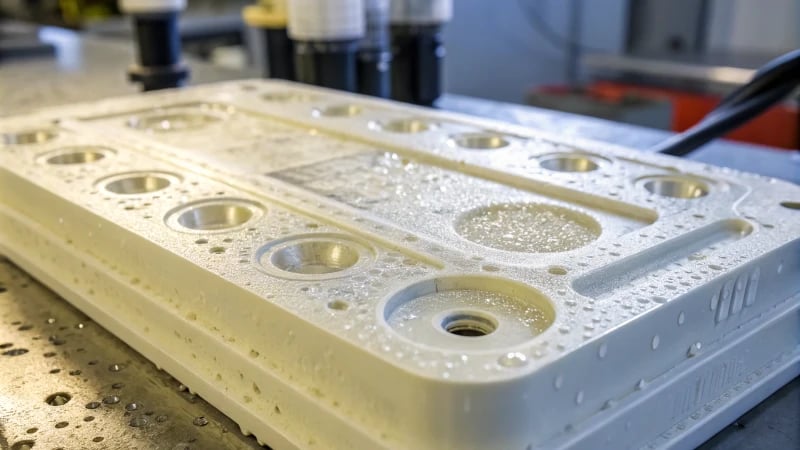

What Are the Best Strategies for Designing an Injection Mold Cooling System?

This blog post explores effective strategies for designing injection mold cooling systems, emphasizing the importance of cooling methods, layout planning, channel sizing, flow rate control, and sealing designs to enhance product quality and efficiency.

OPTIMIZATION

What Is the Best Temperature for Molding Plastic?

Discover the optimal temperatures for molding various plastics, including thermoplastics and thermosetting types. Learn how temperature control impacts product quality and essential practices for successful plastic molding.

OPTIMIZATION

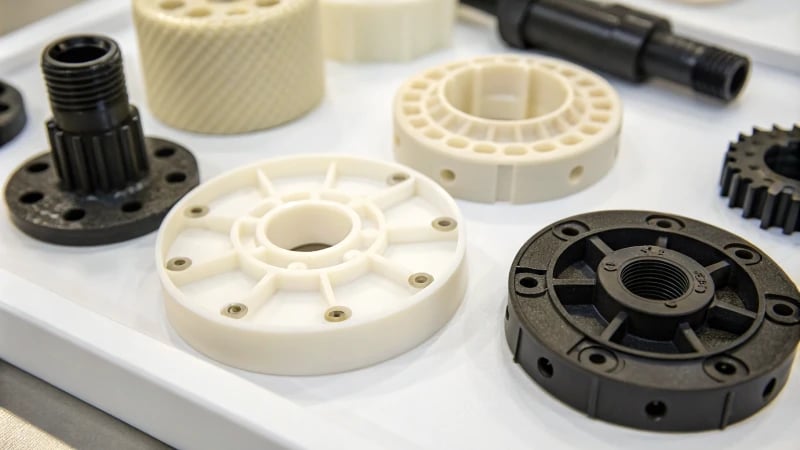

What Are the Key Factors That Influence the Injection Molding Process?

This blog post delves into the critical factors influencing the injection molding process, including raw material selection, mold quality, process parameters, and quality monitoring techniques to enhance production efficiency and product quality.

OPTIMIZATION

What Are the Best Ways to Prevent Resin from Sticking to Molds?

Preventing resin from sticking to molds is essential for smooth crafting. Utilize mold release agents like silicone oil, wax, and PTFE, optimize curing conditions, and consider internal release agents for better results.

OPTIMIZATION

What Are the Best Plastic Mold Solutions and Tips to Maximize Their Use?

This article explores essential practices for optimizing plastic mold design, cooling systems, and maintenance to enhance product quality and production efficiency in the manufacturing process.

OPTIMIZATION

How Can You Enhance the Toughness of Injection Molded Products?

This article explores effective strategies for enhancing the toughness of injection molded products. Key methods include selecting high-toughness materials like polycarbonate, modifying plastics with rubber elastomers or nanoparticles, and optimizing injection molding parameters such as melt temperature and speed. Additionally, ...

OPTIMIZATION

How Can You Effectively Deal with Bubbles in Injection Molded Products?

Bubbles can significantly affect the quality of injection molded products. This article outlines practical solutions for addressing this issue, including adjusting injection speed and pressure, optimizing holding time, controlling temperatures, improving mold design and exhaust systems, and ensuring proper drying ...

OPTIMIZATION

How Do You Choose the Right Size and Location for a Point Gate?

Selecting the appropriate size and position for a point gate in injection molding is essential for achieving high-quality products. The gate diameter should match the product's wall thickness; smaller diameters (0.5-1.5mm) are ideal for thin-walled items while larger diameters (1.5-3mm) ...

OPTIMIZATION

How Do Location and Number of Gates Impact Injection Molded Products?

The placement and quantity of gates in injection molding play a crucial role in determining the final product's appearance and mechanical properties. Proper gate positioning minimizes visible marks, enhances aesthetic appeal, and reduces internal stresses that can weaken the product. ...

OPTIMIZATION

What Are Effective Strategies to Reduce Injection Mold Processing Costs?

Reducing injection mold processing costs is crucial for manufacturers aiming to enhance profitability without compromising quality. Key strategies include refining mold design by simplifying parting surfaces, choosing affordable materials like P20 steel, and adopting advanced processing techniques such as CNC ...

OPTIMIZATION

How Does the Cooling System Enhance Injection Mold Performance?

The cooling system is crucial in injection molding, significantly enhancing performance by shortening cycle times, improving product quality, and extending the lifespan of molds. Effective cooling reduces deformation and surface flaws while maintaining optimal temperatures to prevent wear. Key components ...

OPTIMIZATION