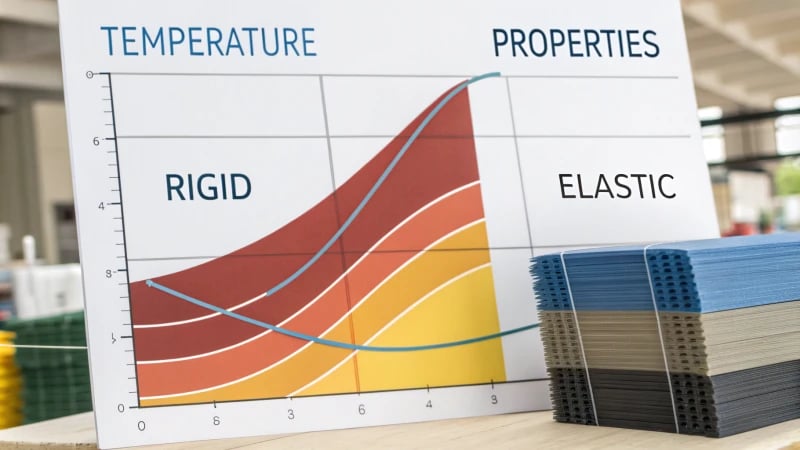

Picking the right temperature for processing is like solving a puzzle. This task becomes tricky when dealing with various materials, such as plastics.

Choosing the correct processing temperature requires knowing the material features, like how crystals form and how stable the material is with heat. Application needs are also important. Good flow happens when the temperature is right. Material damage is avoided. Product quality remains high. Quality stays really good.

I remember my first big project. I adjusted settings nervously, hoping for the perfect balance. It’s like cooking. Crystalline materials, like polyethylene or polyamide, have clear melting points. Similar to how pasta needs the right boiling time. Non-crystalline types, such as polycarbonate, soften slowly above their glass transition temperature. Getting it right avoids problems like heat damage or color changes. Maybe you are crafting sleek electronic cases or sturdy interior parts. Knowing each material’s unique traits is key. It helps reach high standards smoothly. Trust me. Seeing a perfect final product brings real satisfaction. The effort is truly worth it.

Crystallinity affects the processing temperature choice.True

Crystallinity influences how materials behave under heat, affecting temperature settings.

Higher temperatures always enhance material fluidity.False

Excessive heat can degrade materials, reducing fluidity and quality.

What Material Properties Influence Processing Temperature?

Have you ever thought about why some materials melt and others just soften? Mold designers must understand these differences. This knowledge really matters for project success.

Material characteristics such as crystallinity, thermal stability and flowability set the processing temperature. Crystalline materials require temperatures above their melting points. Non-crystalline materials rely on glass transition temperatures.

Crystallinity

When I first stepped into product design, I quickly understood the importance of knowing my materials. Crystalline materials like polyethylene (PE) and polypropylene (PP) have a specific melting point. For example, polyamide (PA6) melts around 220℃. I generally set the temperature between 240-280℃ when processing it. It truly is a balancing act. Too low, you risk incomplete melting. Too high, the material properties may change.

| Material | Melting Point / Tg | Typical Processing Temperature |

|---|---|---|

| PA6 | ~220℃ | 240-280℃ |

Crystallinity affects material fluidity1, requiring precise temperature control to ensure optimal performance.

Thermal Stability

My experiences taught me about thermal stability. PVC, for example, breaks down at high temperatures and releases harmful gases—very dangerous. The solution was to keep the temperature low, around 160-190℃ and use stabilizers to prevent thermal decomposition2. On the other hand, materials like PC and PP stand higher temperatures because of their better thermal stability.

Flowability and Viscosity

I have faced issues with low-density polyethylene (LDPE), which needs lower temperatures due to its low viscosity and great fluidity. Usually, I set the temperature between 160-260℃; it works well for ensuring smooth mold filling.

High-viscosity materials, like glass fiber reinforced polyamides, require higher temperatures for smooth mold filling.

Hygroscopicity

Materials like PA and PC absorb water and need careful handling. Drying them before processing is necessary to avoid problems such as hydrolysis or increased melt viscosity. Sometimes, I increase the temperature slightly to deal with any leftover moisture that might affect material fluidity3.

Application Requirements

Each design is unique. Thin-walled products cool quickly and demand higher temperatures to stay fluid while thick-walled items work with lower temperatures as they release heat more slowly.

| Product Type | Temperature Consideration |

|---|---|

| Thin-walled products | Higher temperature needed for quick cooling and fluidity |

| Thick-walled products | Lower temperature sufficient for slower heat dissipation |

Understanding these material properties very well helps reach the desired product performance and really improves manufacturing efficiency. Whether it’s keeping an electronic housing from warping or maintaining a perfect car interior part, mastering these details is crucial.

Crystalline materials need processing above melting point.True

Crystalline materials like PE and PP require processing above their melting point for proper fluidity.

PVC can be processed at high temperatures without stabilizers.False

PVC decomposes at high temperatures and needs stabilizers to prevent degradation during processing.

How Does Product Shape Influence Temperature Settings?

Have you thought about how the shape of a product changes its heat handling? Shapes definitely matter. This intriguing link affects how manufacturers decide on designs.

The shape of a product affects temperature settings. It changes how heat spreads and flows during production. Thin-walled designs require higher temperatures for proper flow. Thick-walled structures keep lower temperatures. The reason is slower heat loss with thick walls.

Understanding Heat Dissipation in Product Shapes

Product shape significantly influences how heat is dissipated during manufacturing. Thin-walled products, for instance, rapidly lose heat, requiring higher processing temperatures to ensure fluidity. For example, when working with thin-walled plastic containers4 made from PP materials, the barrel temperature may need to be set at 250-270℃.

Conversely, thick-walled products dissipate heat more slowly, allowing for slightly lower processing temperatures. For instance, with thick-walled HDPE products, a barrel temperature of 200-240℃ is often sufficient to ensure fluidity and proper molding.

| Product Type | Recommended Temperature Range |

|---|---|

| Thin-walled PP | 250-270℃ |

| Thick-walled HDPE | 200-240℃ |

Complex Structures and Temperature Adjustments

Products with complex shapes, like those with reinforcing ribs or undercuts, require increased temperatures for the melt to pass smoothly through intricate channels. Higher processing temperatures ensure adequate fluidity5 to fill the mold cavity entirely.

Materials such as glass fiber reinforced polyamide often need a barrel temperature of 280-320℃ to overcome high viscosity and achieve uniform distribution within the mold.

Impact on Material Properties

Material properties such as crystallinity and viscosity are closely tied to product shape and processing temperatures. For crystalline materials like PA, higher temperatures may reduce crystallinity, impacting hardness and toughness. Non-crystalline materials like PC require careful temperature management to avoid thermal degradation or discoloration.

- Crystalline Example: PA6 requires 240-280℃ to balance crystallinity and performance.

- Non-crystalline Example: PC should be processed at 280-320℃ to prevent degradation.

Special Considerations for Appearance and Performance

For products demanding high appearance standards—such as electronic housings or automotive parts—precise temperature control is crucial. Exceeding optimal temperatures can lead to defects like flow marks or bubbles. Transparent PC products, for example, should be processed within 280-300℃ to maintain clarity without yellowing.

In contrast, high-performance products might need increased temperatures to enhance material crystallinity and toughness. While higher temperatures can improve performance, they also risk degrading materials if not carefully controlled. This balance is essential in manufacturing durable consumer electronics6.

Thin-walled PP requires 250-270℃ for proper molding.True

Thin walls lose heat quickly, needing higher temperatures to maintain fluidity.

Complex shapes need lower temperatures for uniform mold filling.False

Complex shapes require higher temperatures to ensure the melt flows smoothly.

Why is controlling processing temperature essential for appearance and performance?

Ever wondered why your favorite gadgets look and function so well? Temperature control plays a crucial role. This part of manufacturing often goes unnoticed. Let’s explore its wonders together.

**Keeping the processing temperature in check is crucial. It directly influences how materials crystallize and flow. These changes affect how the final product looks and works. Precise temperature control helps materials match design specifications and reduces flaws.

Materials need careful temperature handling. This stops unwanted defects in the end product.**

Material Properties and Temperature Control

Material science explores how important temperature control really is for products. Crystalline materials like polyethylene (PE) or polyamide (PA) melt at specific points. For instance, PA6 melts at about 220℃. Heating it up means keeping it between 240-280℃ to melt correctly. It’s similar to baking a cake – getting the temperature wrong turns it into a failure instead of a success. Crystallinity affects hardness and toughness, much like the right ingredients give bread a perfect crust.

Conversely, non-crystalline materials, such as polystyrene (PS), act differently. These soften after passing their glass transition temperature (Tg). With polycarbonate (PC), the range is around 280-320℃. Overheating leads to thermal damage7 – think about a beloved toy losing its color or shape.

Application Requirements

Making thin-walled products requires keeping fluidity during quick cooling. Imagine filling a cupcake mold – if it’s too cold, the batter won’t spread; too hot and it spills over. Materials like PP need higher temperatures, perhaps 250-270℃, to fill every space before hardening.

Thick-walled products allow more leniency with temperature because they release heat more slowly. It’s like simmering versus boiling soup, gently blending everything together.

Impact on Appearance and Performance

Precision in temperature control is non-negotiable for high-aesthetic products such as car parts. Shaping a transparent PC piece needs temperatures between 280-300℃ to dodge yellowing or bubbles.

Performance demands are complex. Items needing strength rely on uniform crystallization at proper temperatures to increase toughness. Push temperatures too far and even slight degradation occurs – imagine chocolate left in the sun.

| Material Type | Example | Melting Point (℃) | Processing Temperature (℃) |

|---|---|---|---|

| Crystalline | PA6 | 220 | 240-280 |

| Non-crystalline | PC | N/A | 280-320 |

Balancing temperature is vital for materials to flow well into molds without issues. This careful attention leads to both beauty and function in manufacturing.

For those eager to learn more about processing temperatures in various industries, consider exploring this comprehensive guide8, which offers a wealth of information.

Crystalline materials have a distinct melting point.True

Crystalline materials like PE and PA have specific melting points, unlike non-crystalline.

Non-crystalline materials are unaffected by temperature changes.False

Non-crystalline materials soften above their Tg, affecting performance and appearance.

How Can You Prevent Thermal Degradation During Processing?

Have you ever felt the frustration with materials breaking down because of heat damage? It’s a common problem in material work, especially with plastics.

Avoiding heat damage requires keeping processing temperatures at the proper level. Very sensitive materials need stabilizers. Dry hygroscopic materials properly. Thorough drying is important. These actions maintain material strength and quality.

Understanding Material Properties

Learning each material’s unique traits proves vital. Crystalline materials9 such as polyethylene (PE) melt at specific temperatures. For instance, PA6 melts around 220°C, requiring a barrel temperature of 240-280°C. This range ensures complete melting and fluidity, avoiding degradation.

| Material Type | Example | Melting Point | Barrel Temperature |

|---|---|---|---|

| Crystalline | PA6 | 220°C | 240-280°C |

| Non-crystalline | PC | Tg 145-150°C | 280-320°C |

Application Requirements

-

Shape and Structure of Products

- In one project, I dealt with thin-walled PP containers. Setting the temperature between 250-270°C was crucial to fill the cavity before it cooled too quickly.

- Thick-walled products like HDPE need a slightly cooler range of 200-240°C. This slower heat dissipation gave a bit more comfort during the process.

-

Appearance and Performance Requirements

- For projects with high appearance standards, like those clear PC products10 I managed, exact temperature control avoided problems like yellowing.

Managing Thermal Stability and Hygroscopicity

Materials like PVC possess poor thermal stability and risk decomposing if mishandled. Adding stabilizers during processing often involves keeping the temperature within 160-190°C. This approach has always been reliable.

Drying hygroscopic materials such as PA and PC beforehand is something never missed. I’ve noticed moisture increasing viscosity, leading to damage if not addressed in time.

These methods successfully reduce thermal degradation, preserving material qualities and enhancing product quality. Learn more about thermal stability11 to ensure effective processing outcomes.

PA6 requires a barrel temperature of 240-280°C.True

PA6 melts at 220°C, needing 240-280°C for full melting.

PVC can be processed without stabilizers at 160-190°C.False

PVC needs stabilizers to prevent decomposition at 160-190°C.

Conclusion

Choosing the right processing temperature for materials is crucial, affecting fluidity, crystallinity, and product quality. Understanding material properties ensures optimal performance in manufacturing applications.

-

Understanding good fluidity helps in selecting the correct processing temperature for crystalline materials. ↩

-

Learn how stabilizers can prevent thermal decomposition in sensitive materials like PVC. ↩

-

Discover how hygroscopicity affects material fluidity and processing requirements. ↩

-

Learn about the specific temperature requirements for manufacturing thin-walled plastic containers. ↩

-

Understand why maintaining proper fluidity is crucial for successful mold design and product formation. ↩

-

Explore how temperature settings influence the quality of consumer electronics housing during production. ↩

-

This link explains how thermal degradation affects plastic materials’ structural integrity and appearance. ↩

-

Discover a detailed guide on optimal temperature settings for various manufacturing processes. ↩

-

Understanding crystalline materials helps in setting appropriate processing temperatures, avoiding degradation. ↩

-

Discover why precise temperature control is crucial to prevent yellowing and maintain transparency. ↩

-

Explore how stabilizers enhance PVC’s thermal stability during processing. ↩