Have you ever wondered what makes injection mold designs tick, like the heart of an intricate machine?

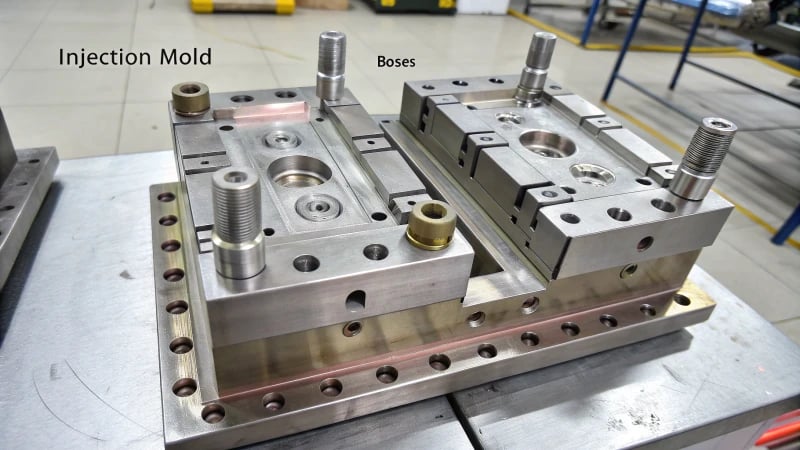

In injection mold design, a boss provides critical support for alignment, strength, and assembly, accommodating additional components or fastening, essential for complex product designs.

Reflecting on my early days in mold design, I remember the first time I realized the true value of a well-placed boss. It was like discovering the secret sauce that held everything together. The bosses were more than just functional; they were the backbone of the design. As we dive deeper, I’ll share practical insights, common challenges, and innovative strategies that have guided me in leveraging bosses effectively in mold design. Whether you’re aiming to refine your designs or avoid missteps, understanding these elements can make all the difference.

Bosses enhance alignment in molded parts.True

Bosses are designed to improve alignment, ensuring parts fit together properly.

Bosses are optional in complex product designs.False

Bosses are essential in complex designs for structural support and fastening.

- 1. How Can Bosses Make Molded Parts Stronger?

- 2. What Are the Best Practices for Designing Bosses?

- 3. How Can Bosses Affect the Assembly Process?

- 4. What Challenges Might Arise with Boss Design?

- 5. How can I optimize boss placement for better performance?

- 6. Are There Industry Standards for Boss Design in Injection Molding?

- 7. Conclusion

How Can Bosses Make Molded Parts Stronger?

Imagine the thrill of creating a design that not only looks great but stands the test of time.

Bosses strengthen molded parts by acting as anchor points, minimizing stress, and ensuring even load distribution, which prevents cracks and enhances durability through proper design.

Understanding the Role of Bosses

When I first started in product design, I was fascinated by how something as simple as a boss could make or break the durability of a molded part. It was like uncovering a secret that had been there all along. In essence, bosses act like little superheroes, holding everything together by providing stable anchor points for screws and fasteners. This function not only keeps things from falling apart but also ensures that the stress is distributed evenly across the part.

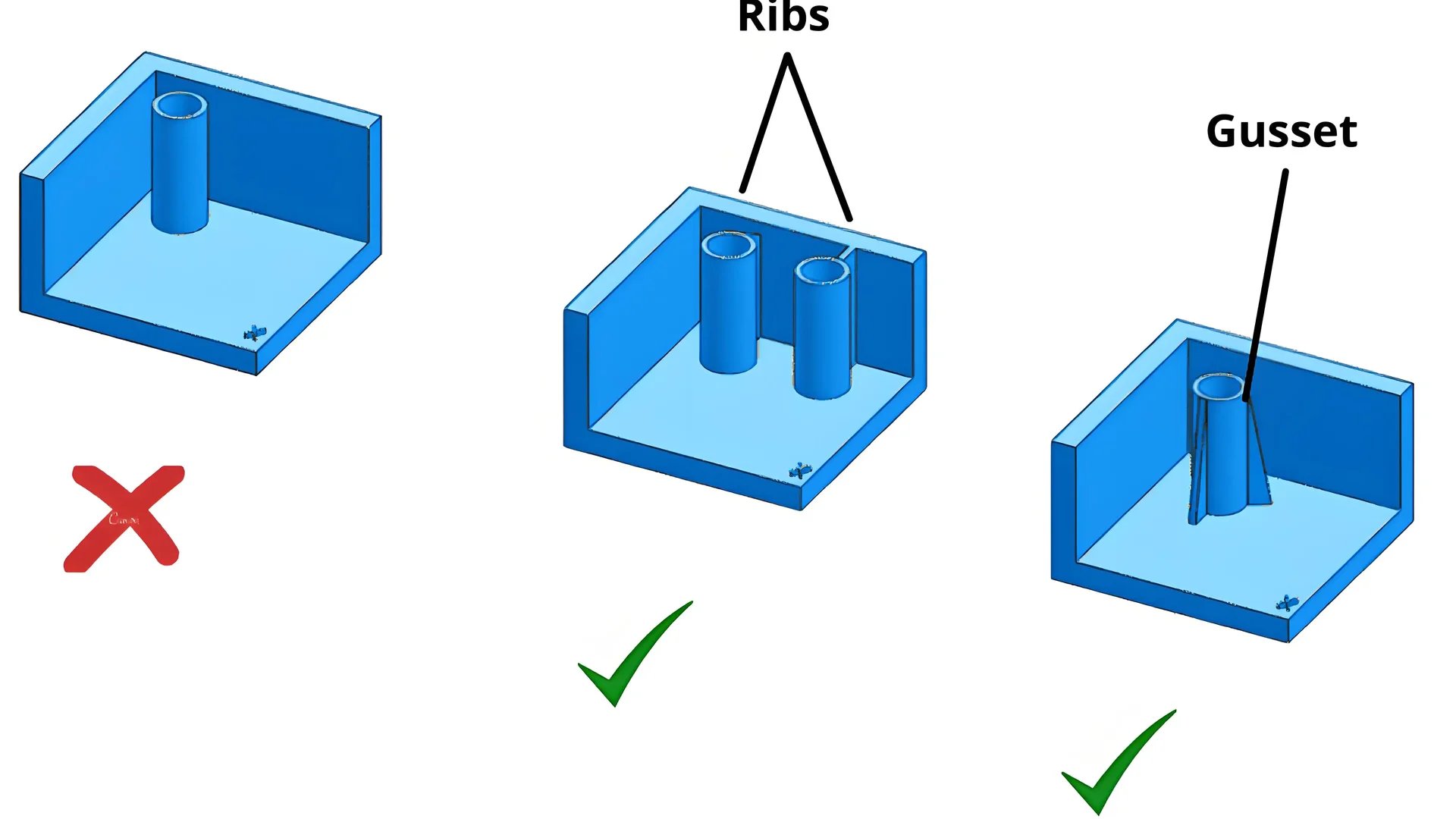

In my early days, I remember spending hours tweaking designs to make sure those bosses were supported just right by ribs or gussets. It’s amazing how these small adjustments can prevent big problems like cracking or deformation. Designing bosses with the right wall thickness relative to the surrounding material isn’t just about avoiding issues—it’s about crafting something that lasts.

Design Guidelines for Effective Boss Implementation

Whenever I’m working on a new project, there are some go-to guidelines I follow to ensure my bosses are up to the task:

| Aspect | Guideline |

|---|---|

| Diameter | Should be around 2 times the screw diameter. |

| Height | At least 2.5 times the wall thickness for stability. |

| Wall Thickness | Should not exceed 50% of the surrounding wall thickness to avoid sink marks. |

These principles have saved me countless hours of rework by ensuring that my bosses contribute positively to the part’s strength without causing issues like warping or sink marks. And trust me, running these parameters through a simulation environment1 is a game-changer for optimizing their effectiveness.

Exploring Material Considerations

I’ve learned that material choice is just as crucial as design when it comes to bosses. Working with thermoplastics, I’ve seen firsthand how carefully considered boss designs can make a world of difference due to their viscoelastic properties. Selecting materials based on tensile strength and thermal stability is key.

I once experimented with glass-filled plastics, which can significantly enhance boss strength. But it’s important to pay attention during the design process to avoid making them brittle. For more insights, diving into technical datasheets2 can offer invaluable guidance.

Grasping these concepts has not only helped me create more robust molded parts but also streamlined my manufacturing processes. It’s incredible how these small tweaks lead to cost-effective production and higher-quality products.

Bosses distribute loads evenly in molded parts.True

Bosses act as mounting points, helping distribute loads across the part.

Boss wall thickness should exceed 60% of surrounding material.False

Boss wall thickness should not exceed 60% to avoid sink marks.

What Are the Best Practices for Designing Bosses?

Ever wondered what makes a boss battle unforgettable? It’s more than just a big baddie to beat; it’s about weaving challenge, creativity, and story into a thrilling showdown.

To design memorable bosses, match player expectations, craft unique mechanics, and embed them into the narrative. Ensure balance and progression for a rewarding gameplay experience.

Understanding Player Expectations

When I first started designing, I quickly realized that boss encounters aren’t just about throwing a tough enemy at players. They’re about crafting a moment players will talk about long after the credits roll. Players crave that perfect blend of challenge and storytelling elements3—a grand finale where everything they’ve learned is put to the test. Picture it like the climax of a gripping novel, where all plotlines converge.

Crafting Unique Mechanics

I remember the first time I faced a boss that required me to adapt my strategy completely; it was exhilarating. Bosses should do more than just soak up damage—they need to introduce fresh mechanics that surprise and engage players. Here’s a quick table to explain different types:

| Mechanic Type | Description | Example |

|---|---|---|

| Environmental | Uses surroundings to challenge players | Changing platforms |

| Combat-based | Requires new fighting strategies | Unblockable attacks |

These elements are what keep players on their toes, making each encounter feel unique.

Integrating Boss into the Game’s Story

It’s not enough for a boss to be tough; they need to be meaningful. I once worked on a project where we spent weeks ensuring the final boss was the embodiment of the game’s central themes4 and character arcs. That fight felt significant because it wasn’t just about winning—it was about resolving the story.

Prioritizing Balance and Progression

Achieving the right balance in boss fights is akin to walking a tightrope. Too easy, and it’s forgettable; too hard, and it becomes frustrating. Reflecting on my experiences, it’s essential to consider factors like gradual difficulty increases and resource management. Ensuring that players feel challenged yet capable of triumph creates those "I did it!" moments we all live for.

By honing in on these aspects, I’ve learned how to craft bosses that resonate with players long after their screens go dark. For more insights into balancing gameplay, I recommend checking out guides on balancing gameplay5. These resources were invaluable on my journey.

Bosses should reflect the game's central themes.True

Boss fights should align with the narrative and themes of the game.

All bosses should have the same difficulty level.False

Boss difficulty should vary to match player progression and skill.

How Can Bosses Affect the Assembly Process?

Imagine building a puzzle, only to find a few pieces missing. That’s what assembling products without properly designed bosses feels like.

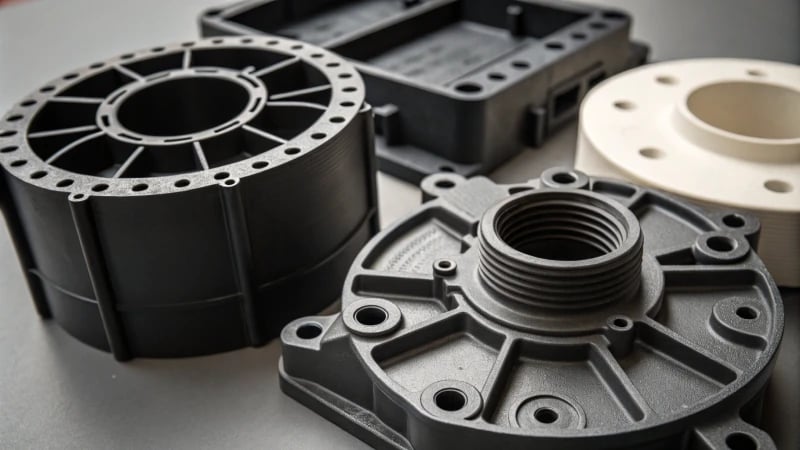

Bosses are crucial in assembly, aligning and securing parts, guiding fasteners, and serving as mounting points to ensure precise fit and structural integrity for stable product assembly.

Understanding Bosses in Manufacturing

I remember the first time I had to deal with a poorly designed boss in a project. It was like trying to assemble IKEA furniture without the instructions—frustrating and inefficient. Bosses are those small yet mighty cylindrical protrusions on plastic components that often go unnoticed but play a massive role in holding everything together. They’re the unsung heroes of the manufacturing process, ensuring that each piece fits just right, like the final piece of a jigsaw puzzle snapping into place. In injection molding6, they are critical for enhancing the structural integrity and ensuring every part fits precisely.

Key Functions of Bosses

- Alignment: Picture trying to build a LEGO set with mismatched pieces. Bosses make sure everything aligns perfectly, minimizing misalignment headaches.

- Securing Fasteners: Think of bosses as the glue in your DIY projects—they anchor screws and fasteners, providing much-needed stability.

- Distributing Loads: They distribute loads across components, preventing stress concentration and failure. It’s like spreading peanut butter on toast evenly to avoid soggy patches.

Best Practices in Boss Design

Back in my early days, I learned the hard way about the importance of getting these tiny features right. Here’s what I’ve picked up:

| Design Aspect | Recommendation |

|---|---|

| Height-to-Diameter | Maintain a 2:1 ratio |

| Wall Thickness | Balanced to avoid sink marks |

| Draft Angles | Include for easy mold release |

- Height-to-Diameter Ratio: A 2:1 ratio works like magic for stability and preventing warping.

- Wall Thickness: This needs to be just right—thick enough to handle stress but not too thick to cause sink marks.

- Draft Angles: Imagine trying to slide a cake out of its mold; draft angles help ease the removal process, ensuring fewer defects and a smooth finish.

Challenges in Boss Implementation

However, I’ve also seen what happens when bosses aren’t up to par. Warping can throw everything off balance, and sink marks can ruin the aesthetics of a part. Plus, if the design isn’t spot-on, material flow issues during molding can create defects. Utilizing simulation software has been a game-changer for me, helping to spot and fix potential issues before they turn into costly mistakes.

Leveraging Technology for Better Design

Thanks to advanced CAD tools, I’ve been able to simulate and optimize boss designs before diving into production. These tools allow me to predict stress distribution and refine boss geometries for better performance. For example, CAD simulations7 have been invaluable in assessing potential stress points and ensuring robust design outcomes.

Understanding the role of bosses and adopting best practices in their design has been crucial for enhancing assembly efficiency and product durability. Addressing challenges early on ensures top-notch quality and longevity in the products we create. If you’re looking to optimize your assembly process with innovative boss designs, you might want to check out advanced design techniques8.

Bosses are only used for aligning components.False

Bosses also secure fasteners and distribute loads, not just align parts.

A 2:1 height-to-diameter ratio is recommended for bosses.True

This ratio ensures stability and prevents warping in boss design.

What Challenges Might Arise with Boss Design?

Have you ever had a grand vision for a boss design, only to hit a wall of challenges?

Boss design challenges include balancing creativity with functionality, navigating production constraints, and ensuring engagement. Designers must creatively solve these issues to craft compelling and feasible designs.

Balancing aesthetics and functionality is crucial in boss design.True

Designers must ensure bosses are both visually appealing and functional.

User engagement is not a concern in boss design.False

Ensuring user engagement is critical to keep players invested.

How can I optimize boss placement for better performance?

Ever felt like your team could achieve so much more with the right leader in the right place? Let’s explore how to optimize boss placement for peak performance.

To optimize boss placement, focus on aligning them with team dynamics, ensuring clear communication, and enhancing delegation skills. A well-positioned boss not only boosts productivity but also inspires collaboration and effective leadership.

Understanding Team Dynamics

When I first started thinking about optimizing boss placement, it reminded me of a time when our team was struggling with communication. Each member had their own unique style and way of working, and it seemed like we were all speaking different languages. Our boss at the time didn’t quite click with everyone, which led to a lot of misunderstandings and missed deadlines. By really digging into the team dynamics9, we discovered how important it was to align a boss’s leadership style with the personalities and skills of the team members. This improved not only communication but also efficiency.

| Factors to Consider | Description |

|---|---|

| Skill Set | Align the boss’s skills with the team’s needs. |

| Communication Style | Ensure it complements the team’s preferences. |

| Cultural Fit | Match values and work ethics. |

Clarifying Roles and Responsibilities

In my experience, clarity is king. I remember a project where our roles were murky at best, which made it challenging for our boss to lead effectively. Once we established clear roles and responsibilities, everything changed. We knew exactly what was expected of us, which allowed our boss to focus on leading us towards our goals without unnecessary overlap or confusion.

Role clarification10 not only aids the boss but also enables team members to understand how their work aligns with the organization’s objectives.

Enhancing Communication Channels

Communication is the backbone of any successful team. I’ve seen firsthand how establishing open channels and regular feedback loops can transform a team’s dynamic. Whether it’s using collaborative platforms or setting up regular check-ins, these tools help maintain transparency and keep everyone aligned with the boss’s vision.

Leveraging Delegation and Autonomy

Delegation can be a game-changer. A few years ago, I was part of a team that thrived when our boss started delegating tasks based on our strengths. It empowered us and boosted our productivity significantly. When a boss effectively assesses team strengths and assigns tasks accordingly, it fosters increased autonomy11 and motivates team members to perform at their best.

Fostering Leadership Skills

One lesson I’ve learned is that leadership skills can always be honed. Whether through training programs or mentorship opportunities, developing these skills is crucial. A boss who leads by example can have a profound impact on team performance and morale.

- Training Programs: Offer structured learning paths for skill enhancement.

- Mentorship Opportunities: Pair less experienced leaders with seasoned mentors.

I’ve seen how a culture of continuous improvement inspires everyone to aim higher.

Encouraging Feedback and Adaptability

Feedback is a gift, and in my journey, I’ve realized how valuable it is for bosses to adapt to their team’s evolving needs. By encouraging open dialogue and fostering trust, teams can remain agile and responsive to changes.

- Feedback Tools: Use surveys or one-on-one sessions for feedback collection.

- Adaptability Training: Engage in workshops or real-time problem-solving exercises.

By focusing on these strategic elements, I’ve seen how organizations can boost their performance through optimized boss placement, leading to a more productive and harmonious work environment.

Boss placement impacts team productivity.True

Aligning a boss's skills and style with the team enhances efficiency.

A boss should not delegate tasks to team members.False

Delegation empowers teams, boosts productivity, and leverages strengths.

Are There Industry Standards for Boss Design in Injection Molding?

Ever wondered what it takes to make a perfectly molded plastic part? For me, it all started with bosses. They’re like the unsung heroes of injection molding, ensuring everything fits and stays put.

Industry standards for boss design in injection molding provide guidance on dimensions, placement, and structural integrity to ensure components are both functional and manufacturable.

Understanding Boss Design in Injection Molding

When I first got into designing plastic parts, figuring out how bosses worked was a game-changer. These small features are molded right into the plastic to help with assembly12. Often used for screw attachments, they need to be just right to keep everything intact and functional. Here’s what I learned about typical standards:

| Aspect | Standard Guidance |

|---|---|

| Wall Thickness | 60%-70% of part thickness |

| Height | 2.5 times the diameter |

| Draft Angle | 0.5 to 1 degree |

Importance of Adhering to Standards

Sticking to these industry standards is like a safety net that saves me from headaches like sink marks or warping. I remember the first time I didn’t follow the wall thickness guideline. It was a mess, with material piling up in all the wrong places, causing defects that had me working late into the night to fix.

Materials and Boss Design

Material choice can really shake things up. For example, when working with engineering plastics13 like ABS or PC, I’ve noticed they each have their own quirks due to their mechanical properties.

CAD Tools and Boss Design

These days, I rely heavily on CAD software—SolidWorks is my personal favorite—to design bosses. The tools make sure I’m hitting all those crucial standards and help streamline production like a charm.

Challenges in Standardizing Boss Design

Even with guidelines, it’s not always cut and dry. Every project has its own demands, which sometimes means bending the rules a bit based on specific project requirements14. It’s like cooking; you start with a recipe but have to adjust for taste.

Boss wall thickness should be 60%-70% of part thickness.True

This standard helps minimize material accumulation, reducing defects.

All boss designs must follow a universal standard.False

Variations in materials and functions require customized designs.

Conclusion

Bosses in injection mold design provide crucial support for alignment, strength, and assembly, enhancing durability and functionality of molded parts while adhering to industry standards.

-

Explore simulation tools that help optimize boss designs and ensure their functionality in real-world applications. ↩

-

Access detailed material properties that influence boss design and performance in injection molding. ↩

-

Discover how storytelling enhances player engagement in boss fights. ↩

-

Explore how integrating themes and character arcs can make boss fights more impactful. ↩

-

Learn strategies for maintaining balance in boss fight difficulty. ↩

-

Explore how bosses contribute to effective injection molding by ensuring component alignment and stability. ↩

-

Discover how CAD simulations enhance boss design by predicting potential issues and optimizing geometry. ↩

-

Learn about cutting-edge design strategies that improve manufacturing efficiency and product quality. ↩

-

Learn about how different team dynamics can influence leadership effectiveness. ↩

-

Explore why clearly defined roles boost productivity and reduce conflict. ↩

-

Understand how effective delegation increases team autonomy and productivity. ↩

-

Discover techniques to enhance assembly processes using bosses, ensuring stable and reliable component connections. ↩

-

Explore how different materials influence boss design, affecting performance and longevity of molded parts. ↩

-

Learn how to tailor boss designs to meet unique project needs while adhering to industry standards. ↩