Quality Inspection

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Causes Short Shot Defects in Plastic Products?

Short shot defects occur when the plastic melt fails to fill the mold completely during injection molding. This issue can stem from various factors including low injection pressure, slow filling speeds, material characteristics such as viscosity and contamination, as well ...

Quality Inspection

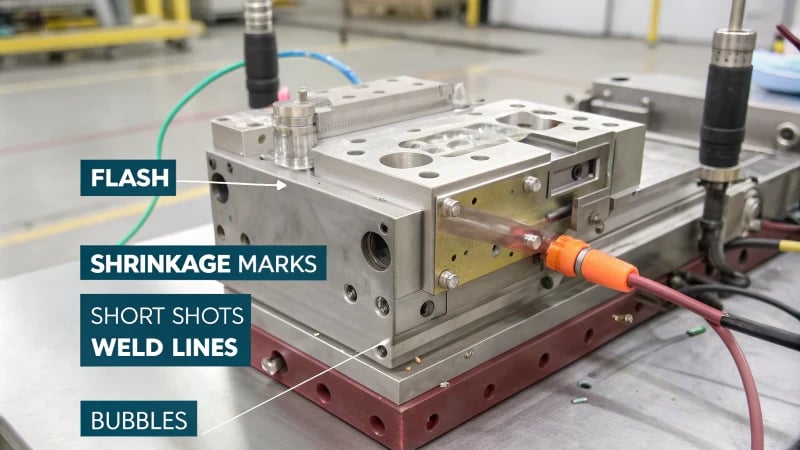

What Are the Most Common Defects in Injection Molded Products?

Injection molded products often suffer from various defects such as flash, shrinkage, weld marks, flow marks, and silver streaks. These flaws arise from issues like excessive pressure, uneven cooling, and moisture in materials. Flash occurs when excess plastic spills over ...

Quality Inspection

What Are the Common Appearance Defects in Injection Molded Products?

Injection molding can lead to various appearance defects that affect both aesthetics and functionality. Common issues include flash (overflow), shrinkage (dent), weld marks, flow marks, silver streaks, poor gloss, and bubbles. Each defect arises from specific causes such as high ...

Quality Inspection

What Are the Key Indicators to Judge the Quality of Injection Molds?

Understanding the quality of injection molds is essential for successful production. Key indicators include evaluating material quality (like P20 and H13 steel), ensuring precise manufacturing accuracy, rational structural design, assessing trial success rates, and monitoring mold service life through wear ...

Quality Inspection

How Does Injection Pressure Influence the Shrinkage of Plastic Products?

This article explores the critical role of injection pressure in plastic molding, detailing how high pressure minimizes shrinkage by compacting the melt, leading to consistent product quality. Conversely, low pressure results in increased shrinkage due to incomplete mold filling. The ...

Quality Inspection

How Does Excessive or Insufficient Shrinkage Affect Plastic Product Quality?

This article explores how excessive or insufficient shrinkage impacts the quality of plastic products. It discusses the effects on dimensional accuracy, aesthetic appeal, and internal integrity. Excessive shrinkage can lead to smaller-than-intended parts, causing gaps during assembly and compromising product ...

Quality Inspection

How Does Injection Pressure Impact the Quality of Injection Molds?

This article explores the critical role of injection pressure in molding processes, highlighting its impact on product quality, internal structure, and mold longevity. Properly adjusted pressure ensures complete filling of molds, enhances material properties, and extends the service life of ...

Quality Inspection

What Are the Most Common Defects in Injection Molding?

Injection molding can lead to various defects that affect product quality and efficiency. Common issues include flash caused by excessive pressure, shrinkage marks from uneven cooling, weld marks from flow convergence, bubbles due to moisture or poor venting, and short ...

Quality Inspection

How Do You Accurately Measure a Machine’s Heating Capacity?

Measuring a machine's heating capacity involves careful preparation and execution. Key steps include selecting appropriate tools like calorimeters and infrared thermometers, ensuring a safe environment, making precise connections, and documenting results meticulously. Proper calibration of instruments and attention to environmental ...

Quality Inspection

How Can You Ensure the Size and Precision of Injection Molded Parts?

Achieving precise dimensions in injection molded parts requires careful attention to design, material properties, processing techniques, and assembly methods. Key strategies include understanding shrinkage rates of materials like polycarbonate and polypropylene, optimizing mold designs to minimize defects, utilizing advanced equipment ...

Quality Inspection

What Are the Wear Resistance Test Standards for Plastics Using Thermal Transfer Technology?

The article discusses various wear resistance test standards for plastics processed with thermal transfer technology. It covers essential testing methods such as tape tests, friction and wear tests, water washing tests, scratch resistance tests, and falling sand tests. Each method ...

Quality Inspection

What Impact Does Low Injection Pressure Have on Product Performance?

Low injection pressure during plastic injection molding can severely impact product performance. It causes incomplete filling of molds, leading to weak structures and poor surface finishes. This results in reduced mechanical strength and toughness, as well as dimensional deviations that ...

Quality Inspection

How Does the Tonnage of an Injection Molding Machine Influence the Product Molding Cycle?

This article explores how the tonnage of injection molding machines affects various stages of the molding cycle. It discusses the influence on mold clamping force, opening and closing speeds, injection pressure during filling, holding pressure stability during cooling, and considerations ...

Quality Inspection

What Precautions Should You Take for High-Transparency Injection Molded Products?

In the manufacturing world, achieving clarity in injection molded products is not just a goal; it’s a hallmark of quality. This article delves into the essential precautions necessary to ensure high transparency, from selecting the right materials to perfecting mold ...

Quality Inspection

How Can You Prevent Cracks and Breakage in Injection Molded Products?

Ensuring the structural integrity of injection molded products is paramount for manufacturers. This article explores the importance of material selection, mold design, process optimization, and post-processing techniques to help you enhance product durability and reduce defects.

Quality Inspection

What Are the 4 Stages of Quality Control in Plastic Injection Molding?

Navigating the world of plastic injection molding can be overwhelming, but understanding the four stages of quality control is key to success. From thoughtful design to meticulous inspection, each phase is crucial for producing high-quality products. Let's dive into these ...

Quality Inspection

How Can You Ensure Color Consistency in Injection Molded Products?

Ensuring color consistency in injection molded products is not just about aesthetics; it’s crucial for maintaining brand integrity and ensuring customer satisfaction. This blog explores practical strategies to tackle common challenges, from raw material control to effective supplier relationships. Dive ...

Quality Inspection

How Does Uneven Mold Temperature Affect Injection Molded Parts?

In the intricate world of injection molding, controlling temperature is essential for producing high-quality parts. However, uneven mold temperatures can lead to a variety of issues, including dimensional inaccuracies and inconsistent surface finishes. Understanding these challenges is crucial for manufacturers ...

Quality Inspection

What Causes Debonding and Cracks in Injection Molded Products, and How Can They Be Prevented?

Injection molding is fundamental to modern manufacturing, but defects like debonding and cracks can jeopardize product quality. Understanding the causes of these issues is essential for manufacturers looking to optimize their processes. This article delves into the key factors contributing ...

Quality Inspection

What Causes Brightness in Injection Molding?

Understanding what affects brightness in injection molding can help manufacturers enhance product quality and aesthetics. Factors such as material properties, mold surface finish, process parameters, and environmental conditions play critical roles in determining the final product's gloss and appeal.

Quality Inspection

Why is Color Consistency Crucial for Quality in Injection Molded Products?

In the competitive landscape of manufacturing, every detail matters, and color consistency in injection molded products is a vital quality marker. It not only enhances visual appeal but also strengthens brand identity and ensures functional performance. This article explores why ...

Quality Inspection

How Can Real-Time Monitoring Enhance Quality in the Injection Molding Process?

In the world of manufacturing, precision and efficiency are crucial. Real-time monitoring offers a transformative approach to enhance quality in the injection molding process by continuously tracking vital parameters, allowing for immediate adjustments that ensure consistent product quality and reduce ...

Quality Inspection

What Causes Injection Molded Polypropylene Parts to Collapse?

Injection molded polypropylene parts are essential across various industries for their strength and adaptability. However, collapses can disrupt production and impact quality. Understanding the underlying causes—from material properties to mold design—is critical for manufacturers seeking to enhance their processes and ...

Quality Inspection