Materials Recommendations

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are Engineering Plastics and How Are They Used in Injection Molding?

Engineering plastics have transformed manufacturing by providing high-performance materials that excel in injection molding. These plastics offer exceptional mechanical strength, thermal stability, and chemical resistance, making them ideal for creating intricate and reliable parts. Commonly used types include polyamide (nylon) ...

Materials Recommendations

Which Mold Materials Are Ideal for High-Temperature Injection Molding?

Choosing the right mold material is crucial for high-temperature injection molding. Materials such as H13 steel and the HMAX series offer exceptional heat resistance and wear durability. Stainless steel provides corrosion resistance while hard alloys excel in toughness. Ultracur3D® RG3280 ...

Materials Recommendations

What Are the Best Materials for High-Temperature Injection Molding?

Choosing the right materials for high-temperature injection molding is crucial for project success. This article discusses top materials like PEEK, PPS, and PI while considering factors such as heat resistance, mechanical properties, chemical stability, processing performance, cost-effectiveness, and availability. Understanding ...

Materials Recommendations

How Can You Enhance Material Flame Retardancy in Injection Molding?

This article explores methods to enhance material flame retardancy in injection molding. It discusses the use of various flame retardant additives—halogenated, phosphorus-based, and metal hydroxide—and their impacts on safety and performance. The importance of understanding each additive's properties is emphasized ...

Materials Recommendations

What Challenges Arise When Molding High-Impact Resistant Materials?

Molding high-impact resistant materials involves navigating various challenges such as selecting appropriate materials, designing effective molds, and preventing defects like warping and sink marks. Each challenge requires a blend of technical skill and creativity to ensure product durability and manufacturing ...

Materials Recommendations

What Impact Do Glass Fiber and Carbon Fiber Fillers Have on the Mechanical Properties of Injection-Molded Parts?

This article explores the impact of glass fiber and carbon fiber fillers on the mechanical properties of injection-molded parts. It highlights how these materials enhance strength, stiffness, thermal stability, and weight reduction. Glass fibers improve durability and thermal resistance, while ...

Materials Recommendations

What Are the Best Practices for Choosing Materials in Medical-Grade Injection Molding?

Selecting the right materials for medical-grade injection molding is crucial for developing safe and reliable medical devices. Key factors include sterilization compatibility, mechanical properties like tensile strength and elasticity, biocompatibility to prevent adverse reactions, and adherence to regulatory standards. Understanding ...

Materials Recommendations

How Effectively Do Flame-Retardant Materials Perform in Injection Molding Applications?

This article explores the effectiveness of flame-retardant materials in injection molding applications, highlighting their crucial role in enhancing fire safety for consumer electronics. It discusses various types of flame-retardants, including halogenated compounds, phosphorous-based additives, and nitrogen-based synergists, each with unique ...

Materials Recommendations

What Are the Latest Advancements in Thermoplastic Elastomers for Injection Molding?

Thermoplastic elastomers (TPEs) are transforming manufacturing with their unique blend of flexibility and durability. Recent advancements have led to enhanced material properties, new formulations, and innovative processing techniques that improve efficiency and reduce costs. TPEs allow for intricate designs, reduced ...

Materials Recommendations

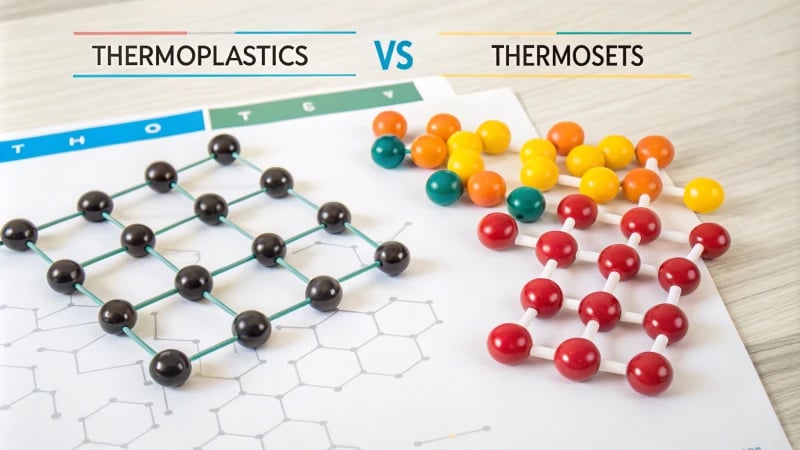

How Does the Choice of Materials Impact the Recyclability of Injection-Molded Parts?

The choice of materials in injection molding is crucial for recyclability. Thermoplastics, such as Polypropylene (PP) and Polyethylene (PE), are more recyclable than thermosets due to their ability to be re-melted and reshaped. This article explores how selecting the right ...

Materials Recommendations

What Are the Latest Trends in Injection Molding Materials for 2025?

The latest trends in injection molding materials for 2023 highlight a strong focus on sustainability. Eco-friendly polymers such as bio-based plastics and recycled content are becoming increasingly popular among manufacturers. These innovations not only reduce reliance on fossil fuels but ...

Materials Recommendations

Which Material is Best for Creating Durable Living Hinges?

This article explores the best materials for creating durable living hinges, highlighting polypropylene as the top choice due to its flexibility and fatigue resistance. It discusses various materials like polyethylene and advanced polymers, emphasizing their properties and applications in product ...

Materials Recommendations

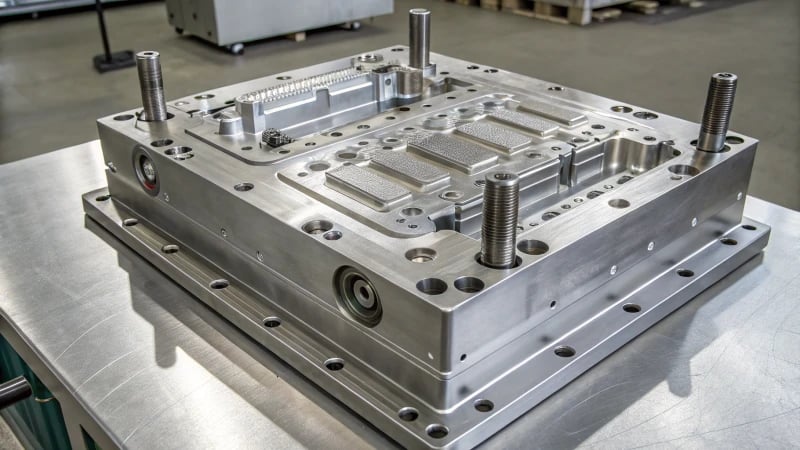

What Are the Best Materials for Making Molds?

Choosing the right materials for mold-making is crucial for project success. This guide explores various options, including steel types, non-ferrous metals, hard alloys, and composites, highlighting their unique properties and applications.

Materials Recommendations

What Makes Plastic Moldable? Discover Its Key Properties!

This article explores the key properties of plastics that make them moldable, including thermoplasticity, fluidity, processability, and repeatability. It highlights their significance in manufacturing various products across industries.

Materials Recommendations

What is the Strongest Injection Molded Plastic You Should Consider?

This article explores the strongest injection molded plastics, including Polyamide, Polycarbonate, Polyoxymethylene, and Polyphenylene Ether. Each material's unique properties make them ideal for various applications in automotive and electronics industries.

Materials Recommendations

What Is the Best Type of Plastic for Molding: A Comprehensive Guide?

Choosing the right plastic for molding is crucial for product success. This guide explores various plastics, their properties, applications, and how to select the best material for your project.

Materials Recommendations

What is the Best Material for Your Mold and How to Choose It?

Choosing the right material for mold making involves considering factors like batch size, precision requirements, complexity, performance characteristics, and cost. Advanced materials enhance durability and efficiency in production.

Materials Recommendations

What Impact Do Plastic Material Properties Have on Molding Process Selection?

Understanding the impact of plastic material properties, such as flowability, thermal stability, shrinkage rates, toughness, and brittleness, is crucial for selecting appropriate molding processes and ensuring product quality.

Materials Recommendations

What Are the Key Differences in Material Properties Between Thermoplastics and Thermosets?

This blog post delves into the key differences between thermoplastics and thermosetting plastics, focusing on their molecular structure, mechanical properties, heat resistance, chemical stability, and processing performance. Understanding these distinctions is vital for effective material selection in design and manufacturing.

Materials Recommendations

Is Polyamide More Durable Than Nylon?

This article explores the similarities and differences between polyamide and nylon, focusing on their mechanical, thermal, chemical, and weather-resistant properties to guide material selection for various applications.

Materials Recommendations

What Are the Best Materials for Blow Molding and Injection Molding Processes?

Choosing the right materials for blow molding and injection molding is essential for product design success. Key materials include PE, PP, PVC for blow molding; PC, Nylon, ABS for injection molding.

Materials Recommendations

Which Materials Are Most Commonly Used in Injection Molding?

This article explores the most commonly used materials in injection molding, including polyethylene, polypropylene, and engineering plastics like ABS and polycarbonate. It highlights their properties, applications, and selection criteria for effective product design.

Materials Recommendations

What Materials Are Commonly Used in Extrusion Molding?

This blog post explores the common materials used in extrusion molding, including thermoplastics, thermosetting plastics, rubber, and composites. Each material's unique properties enhance product design and manufacturing efficiency.

Materials Recommendations

What Factors Determine the Best Mold Material for Product Appearance Requirements?

This article explores how selecting the appropriate mold material significantly impacts product appearance. It discusses various steel types—S136 for high gloss finishes, P20 for textured designs, H13 for precision applications, and NAK80 for multi-color effects. Each material offers unique advantages ...

Materials Recommendations

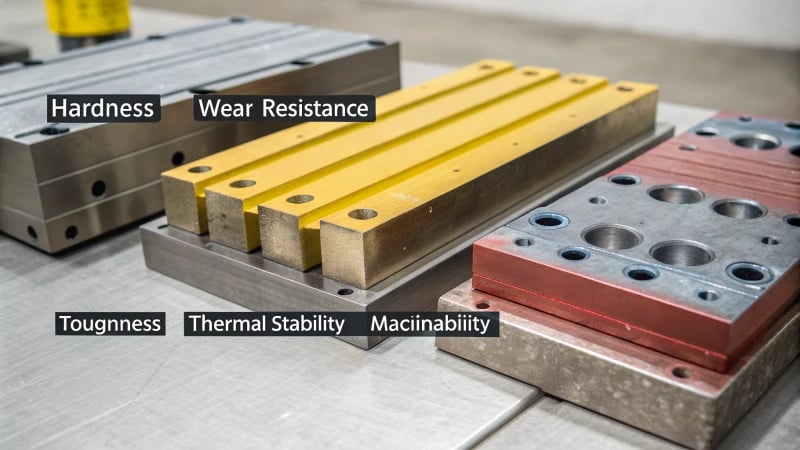

What Materials Are Needed for a Lifter and Slider?

Creating durable slant tops and sliders requires careful selection of materials with specific properties. Key factors include sufficient hardness to resist wear, good toughness to withstand impacts, thermal stability to maintain strength at high temperatures, and excellent machinability for efficient ...

Materials Recommendations

What Are the Pros and Cons of Using Mold Steels with Varying Hardness and Toughness in Injection Molding?

Choosing the right mold steel is crucial in injection molding, as it affects product quality and efficiency. High hardness steels offer excellent wear resistance and dimensional accuracy but can be brittle and challenging to process. Conversely, high toughness steels excel ...

Materials Recommendations

What Factors Should You Consider When Choosing Mold Material for Your Product?

Selecting the appropriate mold material is essential for product success. Factors such as production volume, product complexity, precision requirements, and specific material properties play a significant role in determining the best choice. For small batches under 10,000 pieces, cost-effective materials ...

Materials Recommendations

What Materials Are Suitable for Injection Molding and Which Aren’t?

Choosing the right material for injection molding is crucial for product success. Suitable materials like polypropylene and polycarbonate offer stability and resistance, while unsuitable ones like PTFE complicate processes due to high melting points. Explore how different materials impact molding ...

Materials Recommendations

What Are the Hardness Grades for Classifying Injection Mold Steel?

Choosing the right steel for injection molding is crucial for manufacturing precision and durability. In this article, I explore the different hardness grades of injection mold steel—low, medium, and high—and how they influence your project's success. I share personal insights ...

Materials Recommendations

Can Thermosetting Plastics Be Effectively Used in Injection Molding?

Injection molding is a cornerstone of modern manufacturing, praised for its efficiency and versatility. However, incorporating thermosetting plastics into this process poses challenges due to their irreversible setting nature. In this article, we’ll explore why thermosetting plastics aren’t typically used ...

Materials Recommendations