All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

How Do Injection Pressure and Holding Pressure Differ?

This article explores the critical differences between injection pressure and holding pressure in the injection molding process. Injection pressure pushes molten plastic into the mold, ensuring complete filling, especially for complex shapes. Conversely, holding pressure stabilizes the product as it ...

MANUFACTURING

What Factors Determine the Best Mold Material for Product Appearance Requirements?

This article explores how selecting the appropriate mold material significantly impacts product appearance. It discusses various steel types—S136 for high gloss finishes, P20 for textured designs, H13 for precision applications, and NAK80 for multi-color effects. Each material offers unique advantages ...

Materials Recommendations

What Are the Standard Steps in the Injection Mold Acceptance Process?

The injection mold acceptance process is crucial for ensuring that molds meet design specifications and maintain high quality standards. It consists of several key steps: first, surface quality inspection checks for defects like scratches or rust and measures roughness using ...

MANUFACTURING

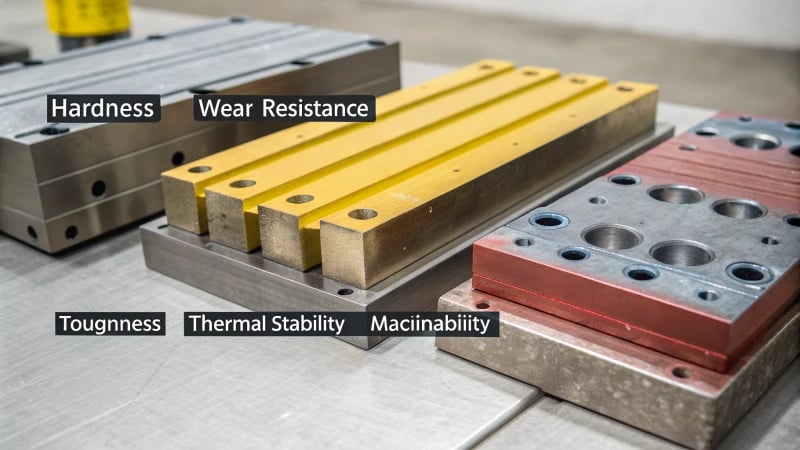

What Materials Are Needed for a Lifter and Slider?

Creating durable slant tops and sliders requires careful selection of materials with specific properties. Key factors include sufficient hardness to resist wear, good toughness to withstand impacts, thermal stability to maintain strength at high temperatures, and excellent machinability for efficient ...

Materials Recommendations

What Are Effective Strategies to Reduce Injection Mold Processing Costs?

Reducing injection mold processing costs is crucial for manufacturers aiming to enhance profitability without compromising quality. Key strategies include refining mold design by simplifying parting surfaces, choosing affordable materials like P20 steel, and adopting advanced processing techniques such as CNC ...

OPTIMIZATION

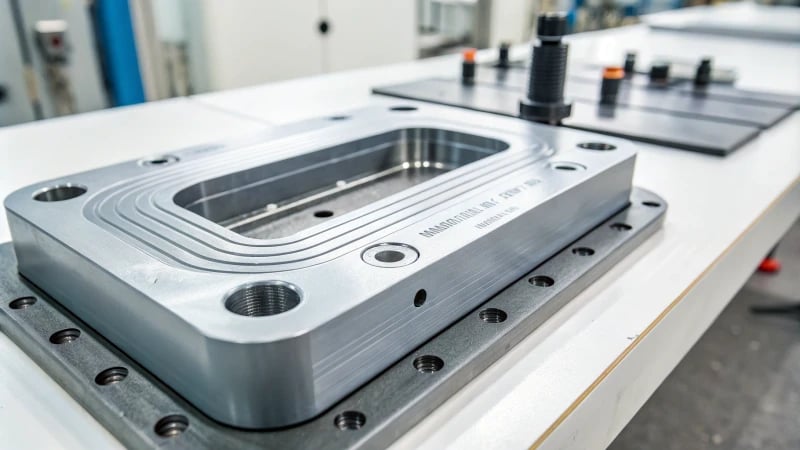

How Does the Cooling System Enhance Injection Mold Performance?

The cooling system is crucial in injection molding, significantly enhancing performance by shortening cycle times, improving product quality, and extending the lifespan of molds. Effective cooling reduces deformation and surface flaws while maintaining optimal temperatures to prevent wear. Key components ...

OPTIMIZATION

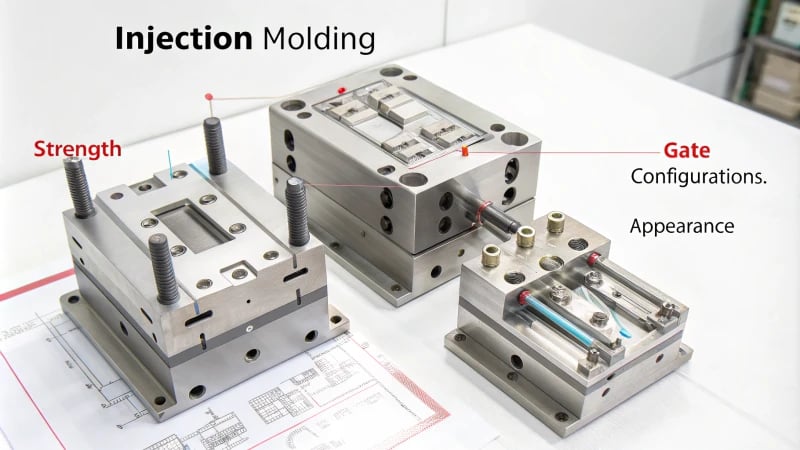

How Does Gate Location and Size Impact Product Properties?

In injection molding, the placement and size of gates are critical factors that impact both the aesthetic and functional qualities of a product. Proper gate positioning can minimize visible defects such as gate marks and flow lines, which can detract ...

Quality Inspection

How Can Mold Design Help Reduce Fusion Lines?

This article explores how careful mold design can minimize fusion lines in injection molded products. Key strategies include optimizing gate placement for uniform melt flow, designing efficient runner systems to maintain stable flow, and implementing proper venting techniques to prevent ...

DESIGN

How Do Different Gate Types Influence Product Appearance?

This article explores how various injection molding gate types impact the final appearance of products. It discusses direct sprue, side gating, spot gates, submerged gates, and scalloped gates—each with unique advantages and disadvantages. Understanding these differences is crucial for designers ...

DESIGN

How Does the Design Principle of the Latent Gate Work?

The submerged gate is an advanced mold design feature that significantly enhances the appearance and functionality of molded parts. By positioning the feeder on the mold's parting surface and allowing it to enter diagonally into the cavity, submerged gates minimize ...

DESIGN

How Do Hardness and Toughness of Mold Steel Impact Injection Mold Longevity?

The longevity of injection molds is heavily influenced by the hardness and toughness of the mold steel used. Hardness provides excellent wear resistance, crucial for maintaining mold precision against abrasive materials like glass-filled plastics. Toughness ensures that molds can absorb ...

MANUFACTURING

How Can You Achieve the Perfect Balance of Hardness and Toughness in Mold Steel?

This article explores how to achieve an ideal balance of hardness and toughness in mold steel. It emphasizes the importance of selecting suitable materials based on specific operational conditions, such as high-impact or high-friction environments. The role of alloying elements ...

DEVELOPMENT

What Causes Product Warpage Defects?

This article explores the causes of product warpage in injection molding, focusing on key factors such as mold design, cooling systems, injection pressures, and material properties. Uneven cooling is a primary contributor to warpage, often exacerbated by irrational cooling system ...

Quality Inspection

What Causes Sprue Marks on Injection Molded Products?

Sprue marks are common defects in injection molded products caused by various factors including gate design, process parameters, and material properties. Properly designed gates with appropriate sizes, shapes, and locations are crucial to minimize these marks. Additionally, adjusting injection speeds ...

Quality Inspection

What Are the Key Factors That Influence the Quality of a Parting Line?

This article explores the key factors influencing the quality of parting lines in injection molding. It emphasizes the importance of mold accuracy, design considerations, material selection, and precise control over injection parameters such as pressure and temperature. Each aspect plays ...

Quality Inspection

How Do You Determine the Location of the Parting Line in Molding?

This article explores how to determine the optimal location for parting lines in molding. It emphasizes the importance of considering product shape, functionality, and manufacturing ease. Proper placement can significantly enhance both the aesthetic appeal and functional integrity of molded ...

DESIGN

What Are the Best Techniques to Minimize Parting Line Traces in Injection Molded Products?

Parting lines can mar the appearance of injection molded products. To minimize these traces, focus on optimizing mold design by carefully positioning gates and avoiding rounded corners. Adjusting injection molding parameters like temperature and pressure is crucial for better material ...

OPTIMIZATION

How Can You Reduce the Labor Cost of Injection Molding Machine Products?

Reducing labor costs in injection molding is crucial for maintaining profitability. This article discusses effective strategies such as implementing automation, providing professional skills training, optimizing production processes, and establishing performance incentive mechanisms. Automation reduces reliance on manual labor while intelligent ...

MANUFACTURING

How Can Simulation Software Enhance Product Cooling Analysis?

This article explores how simulation software significantly enhances product cooling analysis. It details the steps involved in setting up simulations, including model creation, meshing, material property settings, cooling system design, boundary condition setup, and result analysis. By utilizing tools like ...

DESIGN

How Can You Enhance Production Efficiency in Injection Molding Machines?

This article explores strategies to enhance production efficiency in injection molding machines. Key techniques include optimizing process parameters like injection speed and cooling time, utilizing quick mold change systems, adopting hot runner technology, upgrading to high-performance all-electric machines, and implementing ...

OPTIMIZATION

What Are the Best Ways to Enhance the Toughness of High Hardness Die Steel?

This article explores effective methods to enhance the toughness of high hardness die steel. Key strategies include alloying with elements such as nickel, molybdenum, and vanadium to refine grain structure and improve strength. Heat treatment processes like tempering and deep ...

OPTIMIZATION

What Key Details Should You Focus on in Injection Molding Machine Cost Accounting?

Understanding the intricacies of injection molding machine cost accounting is crucial for financial success. Key areas include accurately calculating raw material costs while considering material loss rates and price fluctuations. Labor costs must be meticulously tracked to ensure fair allocation ...

Price Evaluation

How Does Mold Cavity Shape Complexity Impact Processing Costs?

This article explores how the complexity of mold cavity shapes impacts processing costs in manufacturing. It highlights that intricate designs necessitate advanced machining techniques like high-speed milling and electrical discharge machining (EDM), which require expensive equipment and skilled labor. The ...

Price Evaluation

What Are Effective Ways to Reduce the Cost of Injection Molding Machine Products?

This article explores effective ways to reduce the cost of injection molding machine products. Key strategies include selecting cost-effective raw materials, optimizing mold designs, enhancing production processes, and managing energy consumption efficiently. By making small adjustments in material choices and ...

OPTIMIZATION

What Are the Pros and Cons of Using Mold Steels with Varying Hardness and Toughness in Injection Molding?

Choosing the right mold steel is crucial in injection molding, as it affects product quality and efficiency. High hardness steels offer excellent wear resistance and dimensional accuracy but can be brittle and challenging to process. Conversely, high toughness steels excel ...

Materials Recommendations

How Can You Solve Warpage Defects in Injection Molded Parts?

Warpage in injection molded parts can significantly impact product quality. This article outlines key strategies for addressing this issue, including optimizing cooling systems to ensure uniform temperature distribution, adjusting gate designs for even melt flow, and carefully selecting materials with ...

OPTIMIZATION

What Are Effective Methods to Solve Sink Mark Defects in Injection Molding?

Sink marks can significantly affect the appearance and strength of injection-molded parts. This article outlines effective methods to address these defects by optimizing product design through uniform wall thickness and rib placement, adjusting injection molding parameters like holding pressure and ...

OPTIMIZATION

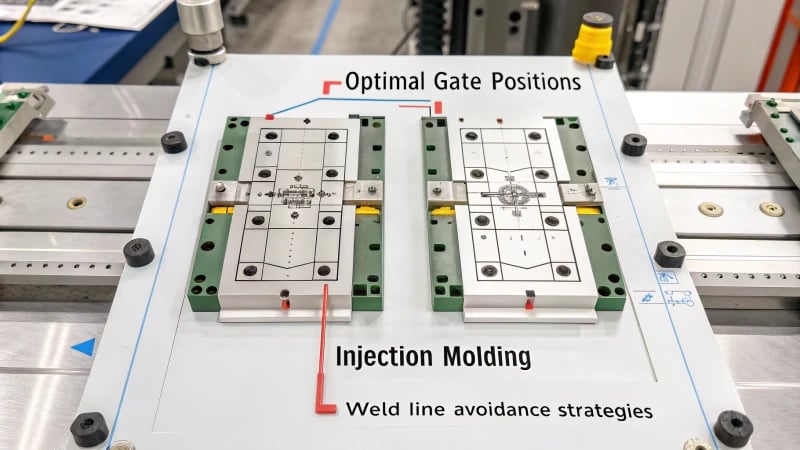

How Can You Prevent Weld Lines by Optimizing Gate Position in Product Design?

Weld lines can significantly affect the appearance and strength of molded products. This article explores how optimizing gate positions during injection molding can prevent these defects. Key strategies include placing gates symmetrically to ensure even melt flow, using sequential gating ...

OPTIMIZATION

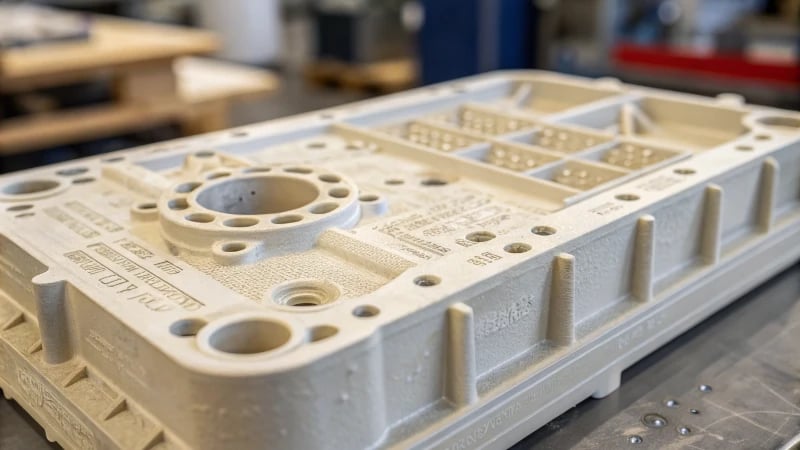

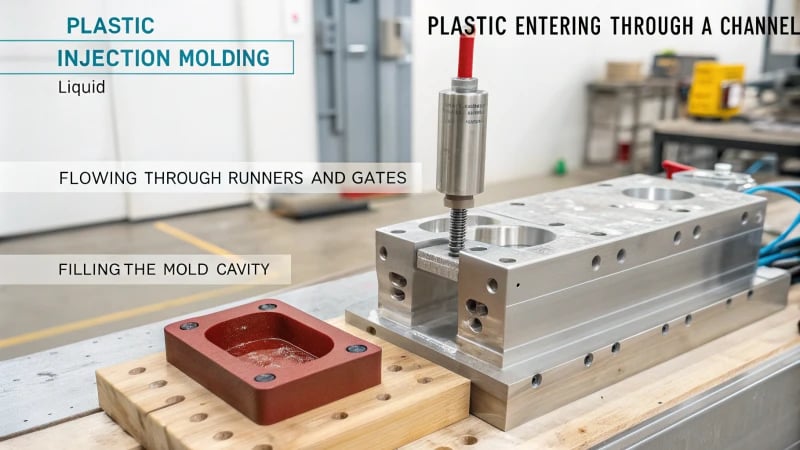

What Happens to Plastic When It’s Injected Into a Mold?

This article explores the intricate journey of plastic during the injection molding process. It details how molten plastic is injected under pressure through the main channel, runners, gates, and finally fills the mold cavity. Each stage is crucial for achieving ...

MANUFACTURING

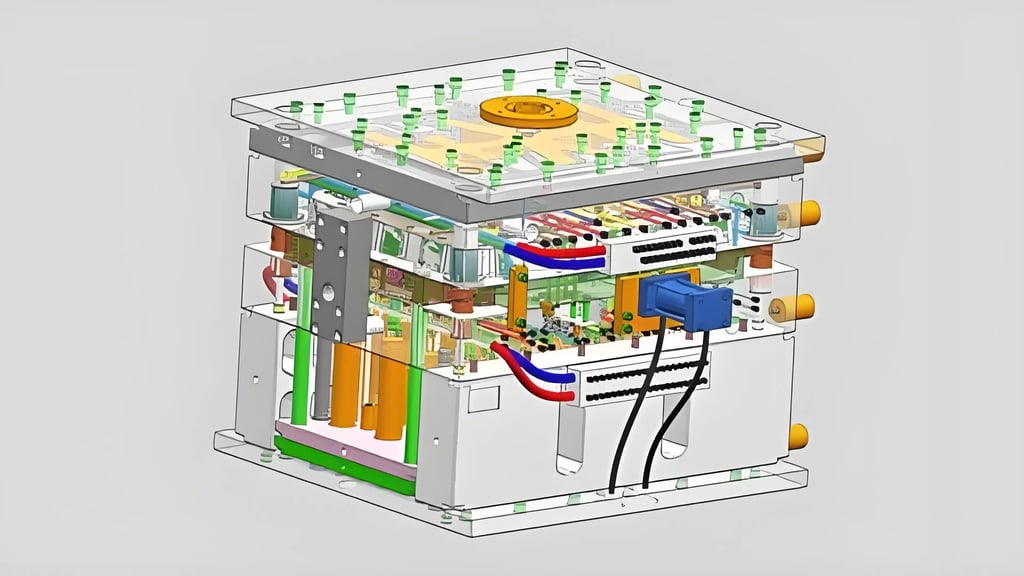

What Are the Essential Standard Parts for Injection Molds?

This article explores the essential standard parts of injection molds, including mold frames, guide parts, ejector systems, gating systems, and cooling components. Each part plays a vital role in ensuring precision and efficiency during the molding process. Mold frames provide ...

MANUFACTURING