Alright. Ready to dive deep into something I bet you never think about, but use every day.

I'm intrigued. Lay it on me.

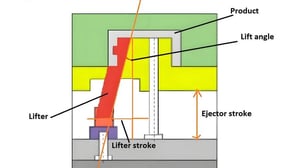

We're talking injection molding. Specifically those little lifter mechanisms that pop out everything from your phone buttons to take out containers.

Those behind the scenes heroes. I'm listening.

Our source material for this deep dive is a seriously in depth guide on a super important part of this whole process. Lifters themselves close, but even more fundamental, the mold release angle. We're talking buckle shapes, materials. It's like a secret language for perfect parts.

So it's not as simple as just yanking the part out.

Definitely not messing this up. Can mean wasted material, broken molds. It's high stakes stuff.

Okay, now I'm really curious. Start us off simple. What exactly is a mold release angle? I'm picturing a cake stuck in a pan. Am I way off?

You're closer than you think. It really is about finding that perfect tilt to get the part out.

Ah, okay. But unlike your cake, this is happening on a massive scale. In factories, right?

Exactly. And this guide keeps saying it's not one size fits all. You can't just tilt it a bit and hope for the best.

Hmm. So is it ever that simple?

Let's go back to that cake for a second. Imagine a wobbly gelatin mold versus a dense pound cake. Different approaches.

Right, Yeah, I can see that. So we're not just talking shapes, but what the part is actually made of.

Dingo. The material itself is huge. In figuring out this angle, this guy has some wild examples.

Oh, I bet. Hit me with one.

They talk about flexible materials like tpe. Think super stretchy rubber band. Those only need a teeny angle, like 3 to 5 degrees.

Okay, that makes sense. But something stiff, like, I don't know, a ceramic plate, you'd need more tilt.

You're reading my mind. Something rigid like that, your polystyrene and such needs more like 5 to 10 degrees.

Wow. So even a few degrees is critical. What's the science behind why flexibility matters so much?

It's all about how the material reacts to force. Flexible stuff bends so it pops out easier. But rigid stuff wants to stay put. Force it too much and crack. You've got a broken part.

Okay, Starting to see why material is step one. This guide also goes deep on buckle shapes. And those diagrams looked intense.

Buckles are where things get visually cool, but also tricky. It's all about how easily the lifter, the thing pulling the part out, can detach.

So a simple buckle, like a round one, that's Easy peasy.

I think three to five degrees. Yeah. But those complex shapes in the guide, that's where things get interesting.

Darva, challenge.

Imagine navigating a maze. Simple buckle is a straight shot, but add curves, details. Suddenly the lifter needs more space, bigger angle.

Gotcha. So the guide said even a basic round buckle could be three degrees. But a fancy one, six to ten. Huge difference.

And this is where material A and D shape team up. Remember that stretchy tpe? It might handle a complex buckle at a slightly smaller angle because it's got that give.

But that same trick with a rigid material, you're asking for trouble.

Exactly. But buckle shapes check. Material properties check. What else is lurking in this guy that's going to blow our minds?

Hmm. What about how far the lifter has to move to free the part? Like, longer travel, more resistance.

You're on fire. We're talking lifter travel distance. Longer travel equals more resistance, so you need a bigger release angle to compensate.

Ah. So it's not just the buckle and material, but how much work that lifter's gotta do.

Exactly. The guide even had some examples. A short 8 millimeter travel with that stretchy TPE. Maybe 4 degrees is fine, but crank it up to 20 millimeters with something stiff like polystyrene, and you're looking at nine degrees or more.

Whoa. Almost triple the angle. Makes sense. The lifter's working harder. Is that where mold lifespan comes in? Too much force and things break.

You got it. Getting that angle wrong doesn't just risk the part, but wears down the mold itself. Adds cost headaches.

Okay, so we've got materials, buckles, how far things move. It's amazing how much goes into making a simple plastic part.

And there's one more wild card. It's all about precision, but not neatness. The actual machining accuracy of the mold itself.

Hold on. How precisely we make the mold affects how easily the part comes out. That's wild.

It's one of those hidden things that makes this so fascinating. A high precision mold where everything fits perfectly can use smaller Release angles, like 4 to 6 degrees. Smooth as silk.

But a less precise mold. Now that's where we need that bigger safety net.

Think of it like tiny imperfections. The Livdor needs more wiggle room. So you bump up the angle maybe to 6 to 10 degrees, just in case.

Ah. Building in a buffer for potential errors. But I'm guessing those super precise molds aren't cheap.

Great point. Brings us to a core challenge. Balancing cost and quality. Sometimes a less precise mold is the right call. Especially if you're not making something super intricate. But that's a whole other deep dive.

My brain's already doing backflips. Who knew there was so much to these tiny angles?

Honestly, it's the sheer amount of factors that's blowing my mind. It's not just yanking something out. It's this web of material, science, design, and even the tools themselves.

And the guide doesn't shy away from that complexity at all. It's like a puzz. Each piece is critical to the whole picture.

Totally. And I'm realizing this knowledge is valuable even if I never design a mold myself. It's a new level of understanding how things are made. The challenges, the ingenuity.

Absolutely. But this is just the tip of the iceberg. The guide hints at even more advanced stuff. Simulations, specialized applications, things that'll really make your head spin.

Okay, now I'm really hooked. But let's give our listeners a moment to digest all this. We'll be back in a flash with more fascinating insights into the world of injection molding. Stay tuned.

Welcome back. Before our brains melt from all these factors influencing that mold release angle, I think we need to shift gears a bit.

Yeah, I'm still juggling materials, buckle shapes, travel distances. Hit me with what's next.

This guide isn't just about what matters. It's about why. It's like, it's not enough to just tweak one thing.

So it's like a giant Jenga game. Pull out the wrong piece, and the whole thing collapses.

Perfect analogy. It's about balance, where all these variables, the material, the shape, the mechanism, even the mold's precision, they all got to work together.

Okay, so no easy formulas then. This guide really emphasizes experience. Real world, know how. But what does that actually look like?

Well, they give some cool examples. One was automotive parts. Think about all the different stuff in a car. The flexible bumper, the rigid dashboard, all those little buttons and knobs.

And I'm guessing each part is a whole new challenge when it comes to this release angle.

Totally. The bumper needs to bend and pop out, but the dashboard can't crack under pressure. It's like engineers have to become material whisperers, you know?

Yeah. It's not just about looks. It's about really understanding what the part is made of and how that affects making it exactly.

Get it right. Smooth production. Get it wrong. Broken parts, wasted stuff. Headaches all around.

Okay, I get the importance, but is it all just trial and error, or are there tools that help engineers find that perfect angle without endless Experiments.

That's where things get really high tech. The guide talks about simulations. Using computer design software. You can basically create a virtual mold and test things out.

Hold up. Engineers can run a virtual injection molding process on a computer that's straight out of Sci Fi.

It's becoming the norm, actually. These simulations are super detailed. Materials, temperature, even how fast the part, tools. It's like a crystal ball for how things will behave in the real world.

Okay, now that's impressive. Saves a ton of time and money, especially with complex designs. What about those high precision molds we talked about earlier? Do simulations help with those too?

Definitely. You can test different designs, play with the tolerances, find that sweet spot between precision and cost.

So no more oops, we needed a more expensive mold moments.

Exactly. It's all about minimizing risk, being as efficient as possible. And the best part, These simulations are always getting better, more powerful with technology.

It makes me wonder what the future holds for injection molding. Any crazy predictions from the guide?

Oh, yeah, they hint at some wild stuff. 3D printed molds, bio based plastics, even self healing materials.

Self healing plastics. But before we get too futuristic for those just tuning in, what are the key things to remember?

Remember, no magic formula. Each project is unique with its own challenges. Don't get stuck on memorizing numbers.

It's more about the big picture, right? How materials and shapes work together, how that lifter moving affects the mold. All those factors.

Exactly. It's about having that base knowledge so you make smart choices, whether you're designing something or just appreciating how things are made.

And never stop being curious. This field is always changing, so keep asking questions and learning new stuff.

Speaking of learning, I think it's time we see this in action. Real world examples like medical devices, electronics. See how these tiny angles shape the products we use every day?

Okay, now you're speaking my language. Case studies are where it all comes together.

And trust me, you'll see how much ingenuity goes into even the simplest plastic things. Ready to dive in?

Let's do it.

All right, case study time. Buckle up. We're going into the world of medical devices.

Ooh, medical devices. High stakes, right?

Definitely. Imagine a company making those disposable syringes, the ones you see at the doctor's office. Precision is everything.

Yeah, you can't have any leaks or anything. Those things got to be perfect.

Exactly. Super tight tolerances are key. But here's the thing. They're also disposable, so production needs to be fast to keep up with demand.

So how does our little mold release angle fit into all of this?

It's a balancing act. A small angle helps make those super precise parts, but it also increases the risk of things getting stuck if the lifter isn't perfectly aligned.

So it's all about finding that sweet spot. What's the secret?

It's a mix of clever design and lots of testing. The guide talked about using simulations to predict that ideal angle based on the material and the syringe design. Plus, they have to pick the right kind of lifter that can handle those tight tolerances without, you know, breaking down.

Sounds intense. Any room for error?

Not really. In the medical world, even a tiny imperfection can be a big problem. Real world testing is crucial to make sure those syringes are meeting the highest standards every single time. We're talking about people's health here.

No pressure then. Okay, so that's medical devices. What other industries are pushing the limits of injection molding?

How about something a little closer to home? Consumer electronics? Think about your smartphone.

A smartphone? What about it?

It's packed with plastic parts, every single one. Precisely mold the casing, the buttons, even the little connectors inside.

Oh, wow. You're right. I never even thought of it that way.

And each part needs its own approach to that release angle. A phone case needs a pretty small angle, so it keeps its shape and doesn't have any rough edges.

But the connectors inside with all those tiny pins and things, that must be way harder.

Exactly. For those delicate parts, you probably need a larger angle to make sure the lifter can come off cleanly without snapp anything.

I'm starting to see injection molding everywhere now. It's incredible how much goes into even a simple phone case.

That's what we wanted to show you. This deep dive wasn't just about the technical stuff. It was about understanding the design and engineering that goes into the stuff we use every single day.

It's like I'm learning a secret code, and now I can see how it works everywhere. So as we wrap up, what's the biggest thing you want our listeners to take away from all of this?

The key takeaway, that mold release angle. It's not just a random detail. It's a fundamental part of the whole process. If you understand how it works, how it's affected by the materials, the mold's precision, you can make better decisions, whether you're designing a product or just appreciating how things are made.

Well said. I think we can all agree we've got a new appreciation for those tiny angles that shape so much of our world. And as always, this deep dive was just the beginning.

There's always more to learn. Injection molding is constantly changing. New materials, new tech. Who knows what's next?

That's the exciting part. So to our listeners, stay curious, keep asking questions, and keep exploring. See you next