Welcome to another deep dive. Today we're going to be talking about something pretty crucial in the world of injection molding.

Crucial is right. It can make or break the entire process.

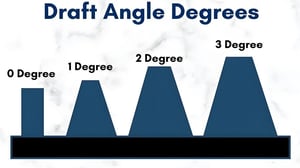

Exactly. We're diving into draft angles. You know those slight slopes that you see on molded parts?

They're not just there for looks.

Nope. They serve a very important purpose. Making sure those parts release cleanly from the mold without any damage.

Like, think about a plastic bottle.

Oh, yeah. Good example.

You know how it tapers slightly inwards?

Yep.

That's the draft angle at work. Without it, the bottle would get stuck.

In the mold and then you'd have a mess. And probably a pretty useless bottle, too.

Exactly. We actually have some sources here that dig deep into all the different methods to measure those angles, which is great.

Because it can get pretty technical. We're talking simple tools like angle rulers.

Yep. Good old fashioned angle ruler to some.

Pretty hardcore stuff like trigonometry.

A little math never hurt anyone.

True, true. And even something called a CMM coordinate measuring machine.

Now that's where things get really precise.

It's amazing how many options there are, each with its own pros and cons, depending on, like, how complex the mold is and how accurate those angles need to be.

Exactly. You wouldn't use a CMM to check the angle on a simple plastic cup, right?

Probably not. So let's start with the basics. The angle ruler. Our sources say these things can measure angles from like 0 to 320 degrees.

It's a pretty versatile tool. Actually, I use one all the time in my workshop.

Me too. For, you know, picture frames, shelves, all sorts of stuff.

And it's surprisingly accurate for something so simple. Ideal for initial checks on molds or for designs that aren't super complicated.

But what about those more demanding situations like, say, you're making medical devices or aerospace parts?

Oh, yeah. Then you need to step up your game.

No room for error there. That's where the trigonometry comes in.

Math to the rescue.

It sounds intimidating, but our sources explain it pretty clearly.

It's really just using calculations to determine the angle precisely based on measurements.

So instead of just eyeballing it with.

The ruler, you're actually taking precise measurements of, say, the height difference and the horizontal distance of the slope you want.

And then plugging those numbers into a formula.

Exactly. Let me give you an example. Say you need a slope with a height difference of 5 millimeters.

Okay. 5 millimeters.

And a horizontal distance of 100 millimeters. Using a bit of trigonometry, you can Calculate that. The angle you need is approximately 2.86 degrees.

Wow, that's pretty precise. But to get those measurements, you probably need tools that are more accurate than just a ruler.

Oh, definitely. Something like a vernier caliper or even a CMM would give you the level of accuracy you need for those calculations.

Makes sense. So angle ruler for the simple stuff, trigonometry for when you need that extra precision. Okay, but what about those truly high tech applications where those tolerances are ridiculously tight?

Like aerospace components or those tiny little microchips?

Exactly. Is that where the CMM comes in?

You got it. A CMM is like the king of measurement tools. It's basically a robotic arm with a super sensitive probe.

I've seen those in action. It's pretty impressive how it just traces along the surface of the mold.

It's collecting data points, thousands of them. Creating a digital map of the mold's surface. And then sophisticated software analyzes all those points and calculates the draft angles.

And we're talking incredible accuracy here down.

To the micron level.

It's like comparing a hand drawn sketch to a high resolution photograph.

Exactly. And that level of precision is absolutely essential in certain industries, like those car.

Parts you mentioned earlier.

You want every single part to be identical. Even the slightest variation can cause problems during assembly.

So using a CMM ensures that every part coming out of that mold will have the exact same draft angle, which.

Translates to consistent quality, less waste, and greater efficiency overall.

So it's not just about measuring angles. It's about ensuring the quality of the entire production process.

That's the key takeaway here. Accurate measurement, consistent parts, less waste, and ultimately a better product.

Okay, so we've covered the angle ruler for quick checks, trigonometry for those precise calculations, and then the cmm, which is like the ultimate weapon when it comes to precision.

I like that. The ultimate weapon.

But I'm wondering, even with all these tools, can't things still go wrong? I mean, aren't there limitations to each method? Even a CMM can't be perfect. Right?

You're right. Every tool has its limitations. Yeah, even the most advanced CMM can be affected by things like temperature variations in the environment.

Oh, interesting.

Or even, you know, the skill of the operator.

So it's not just about the technology itself, but also how it's used.

Exactly. And remember, achieving absolute perfection and measurement, it's kind of an ideal, not always a reality.

There's always going to be some level of tolerance, Right?

Exactly.

So how do manufacturers determine those tolerance levels? How much variation is acceptable?

Well, that depends entirely on the application. A tiny variation that wouldn't matter in a toy might be a huge problem in a medical implant.

Oh, yeah, of course.

So engineers have to carefully consider the function of the part, the materials being used, and the potential consequences of any imperfections.

So it's about understanding the context and applying the right level of precision.

Exactly. You don't always need to bring out the big guns, so to speak.

Sometimes a simple angle ruler is more than enough.

Exactly.

But that raises another question. So we were just talking about those tolerance levels and how even the slightest variation can make a huge difference in certain applications. But it makes you wonder, how do they actually catch those errors? Like, is there a specific moment in the process where it's like, whoops, this draft angle is off?

Well, it's not like there's a giant red button that flashes draft angle error, but there are definitely ways to catch those mistakes before they turn into a bigger problem.

So it's like multiple layers of quality control.

Exactly. And it all starts with, you know, the design failure.

Oh, really? So even before they make the actual mold, even before.

Engineers use these really sophisticated software programs these days, they can actually simulate the entire injection molding process, like, virtually.

So it's like a test run, but.

On the computer, pretty much. They can see how the molten plastic will flow into the mold.

Oh, cool.

And they can identify any potential problems. Like if there's a draft angle that's too steep.

Oh, so they catch it right there before they even make the mold.

Exactly. It saves a lot of time and money in the long run, I bet.

But what about once the mold is made? Like, they actually have this physical thing, how do they check for accuracy then?

That's where those high precision measuring tools come in. Like the CMM we talked about earlier.

Oh, yeah, the robotic arm thing.

It's like a robotic inspector going over every nook and cranny of the mold.

And making sure those angles are spot on.

Exactly. It compares the physical mold to the digital design, and any deviations, like, if the draft angle is off by even a tiny amount, it'll flag it.

So it's like a double check system.

Exactly. You want to catch those errors early on before you start mass producing parts.

Right. Because then you've got a whole batch of messed up parts, and that can.

Get expensive really fast.

So we've got the virtual simulation and then the physical inspection with the cmm. That's pretty thorough. But I'm just curious, do they do any other quality control Checks, like beyond just the draft angle?

Oh, absolutely. They actually put the parts themselves through a bunch of tests.

Oh, really? Like what kind of tests?

Well, they check for things like dimensional accuracy.

Okay. Making sure all the dimensions are exactly right.

Yep. They check the surface finish to make sure it's smooth and free of defects and even the strength and durability of the material.

So it's like a whole series of tests to make sure those parts meet all the specifications.

Exactly. You don't want to send out a batch of parts that are going to break or malfunction.

No, definitely not. Yeah, but what happens if a part fails one of those tests? Do they have to scrap the whole mold and start over?

Sometimes, but not always. Sometimes they can make adjustments to the mold itself. Itself? To fix the problem.

Oh, so they can actually tweak it?

Yeah, sometimes. But in other cases, like if the defect is really serious or if it.

Affects, you know, the strength of the part or something.

Yeah. Then they might have to redesign the.

Mold or even scrap it completely and start over.

It all depends on the severity of the problem.

Wow, that's pretty intense. It really shows you how important those draft angles are.

They're not just a small detail. They can have a huge impact on the whole process.

It's like a domino effect. One small error can lead to a whole bunch of other problems.

You got it. And that's why manufacturers are so obsessed with quality control.

Makes sense. So we've got the virtual simulations, the high tech inspections, the rigorous testing. It sounds like they've got it covered from every angle.

They do their best, but even with all that, you know, sometimes things still go wrong.

Really? Like what could go wrong?

Well, materials can behave in unpredictable ways. Machines can malfunction, and people make mistakes, too. It happens. That's why continuous improvement is so important in manufacturing.

So it's not just about catching errors. It's about learning from them and preventing them in the future.

Exactly. You're always trying to refine the process, make it more efficient, more reliable.

And as technology advances, I imagine those quality control methods are only going to get more sophisticated.

Absolutely. We're going to see more automation, more advanced measurement techniques, and maybe even AI playing a role in quality control.

AI that's interesting. Like algorithms that can predict potential problems before they happen.

Exactly. It's all about staying ahead of the curve and making sure those parts are the best they can be.

But with all this automation and high tech stuff, does the role of the skilled technician become less important? Oh, not at all, really.

In fact, I Think it becomes even more crucial.

How so?

Well, somebody has to program those robots, interpret the data, troubleshoot any problems that come up.

It's not just pushing a button and letting the machines do everything.

Definitely not. You need skilled humans to oversee the process to make sure everything's running smoothly.

So it's a partnership, really? Humans and robots working together.

Exactly. And that partnership is going to become even more important as we move towards the future of injection molding.

Speaking of the future, you mentioned AI and automation. Where do you see all this heading, what's the next big thing in injection molding?

Well, that's a great question. And it leads us right into the next part of our deep dive. We're going to be talking about some pretty mind blowing concepts like personalized manufacturing and on demand production.

On demand production, that sounds intriguing. Okay, so on demand production, that sounds pretty futuristic. Like I order something online and it's made right then and there just for me.

That's the idea. It's like having a factory that makes one of a kind products tailored to each customer's needs.

But how is that even possible?

Like logistically, it's all about combining different technologies. Things like 3D printing, advanced software and automation.

Okay, so 3D printing, we've all heard of that, but how does it fit into this on demand thing?

Well, with 3D printing, you can create almost any shape you can imagine directly from a digital design.

So no need for those traditional molds.

Exactly. And because it's all digital, you can easily customize the design for each customer.

Oh, I see. So like if I wanted a phone case with my name on it or specific design.

Exactly. You could upload your design online and the 3D printer would create it on demand.

That's pretty cool. But what about the software part? What role does that play?

Well, the software is what translates the customer's design into instructions for the 3D printer.

So it's like a language that the machine can understand.

Exactly. And then you have all the automation which connects everything together and makes the whole process seamless.

So the customer places an order, the software converts that order into Instructions for the 3D printer, and then the machines do their thing.

It's like a well oiled machine, literally.

But if everything is so automated, where do humans fit into all of this?

That's a good question. And it's something that people are discussing a lot these days. But even with all this automation, we still need humans.

In what way?

Well, humans are the ones designing the software, creating those digital designs and making sure that the whole Process runs smoothly.

So it's not like the robots are taking over and humans are out of a job.

Not at all. It's more like humans are moving into different roles. More creative roles, more problem solving roles.

So instead of like operating the machines, they're designing and managing them.

Exactly. It's a shift in skill set. But humans are still very much essential to the whole process.

That's good to hear. So you mentioned personalized medical devices earlier. What other kinds of things could be made on demand?

Oh, the possibilities are really endless. Think about customized clothing that fits your body perfectly.

Oh, like a virtual tailor.

Exactly. Or personalized furniture designed to fit your space and your style.

That's pretty cool. But are there any limitations to this on demand thing? Like, are there certain things that just can't be made this way?

Well, there are definitely challenges. One of the big ones is cost. Personalized manufacturing can still be pretty expensive compared to mass production.

Yeah, that makes sense. If you're only making one item, it's going to cost more than if you're making a thousand of them.

Exactly. But as technology gets better and more efficient, those costs should come down.

That's good to know. What about the speed? Like how long does it take to make something on demand?

That really depends on the complexity of the product. Some things can be made pretty quickly, but others might take a while.

So it's a trade off. You get a unique personalized product, but you might have to wait a bit longer for it.

Exactly. And then there are other things to consider, like sustainability and the environmental impact of all this manufacturing.

That's a good point. It's not just about making cool stuff. It's about doing it in a way that's responsible and sustainable.

Right. We need to make sure that we're not creating a whole bunch of waste in the process.

That's true. So it sounds like on demand production is still in its early stages.

It is. But it has the potential to revolutionize the way we think about manufacturing.

Yeah, it's a pretty mind blowing concept. So much has changed in the world of injection molding. From simple angle rulers to these incredible on demand factories. It makes you wonder what the future holds.

It really does. But one thing is for sure. Precision measurement is going to continue to play a vital role.

That's right. From those tiny draft angles to the complex algorithms that drive these machines, it's all about accuracy. I think that's a great note to end on.

I agree.

Thanks for joining us for this deep dive into the fascinating world of injection molding. We've covered a lot of ground, from the basics of draft angles to the future of personalized manufacturing, and who knows what incredible innovations are just around the corner. Until next time, keep on