Ever tried to get a Bundt cake out of a pan, you know, without breaking it?

Oh, yeah.

That's kind of the challenge with injection molding.

Yeah.

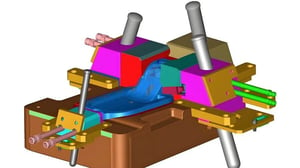

And that's what we're diving into today. The unsung heroes that help make sure products pop out of moles smoothly. We're talking about lifters and those release angles. You've given me some really cool sources here, even a technical diagram. So it should be fun to dive in.

Yeah, it's fascinating. I think people take for granted how much engineering goes into something that seems so simple.

Right. It's not just about angles. I noticed in one of the sources that the material, the shape, the size of the product itself can affect those lifter release angles. Is that right?

Absolutely. The release angle, it's. It's like a delicate dance between the product and the mold. And you really need to understand how all these factors are going to play together to ensure a clean release. I mean, think of it like the release angle prevents the product from clinging to the lifter and then getting damaged when it's ejected from the mold.

So if you don't get the angle right, what could happen?

Well, you could end up with a product that's deformed or scratched or even completely stuck in the mold.

That doesn't sound good.

Yeah, not exactly what we're going for.

Got it all.

It's kind of like peeling a sticker. Like, if you peel it at the wrong angle, it's just a mess.

Yeah, total mess. You mentioned different types of lifters.

Yeah.

How do those fit into all this?

Excellent point. So we have cam action lifters, hydraulic lifters, pneumatic lifters. They each have their own advantages and disadvantages, depending on what the product is. You know, the size, the weight, how fast it needs to be ejected from the mold. All those play a part in it.

Wow. So one of the sources mentioned polypropylene and shrinkage. Why is shrinkage such a big deal for release angles?

Well, so polypropylene or pp, it's a very popular material for injection molding, but it's known for shrinking quite a bit as it cools. I mean, sometimes up to 2.5%.

That's a lot.

Yeah. So imagine you've got your PP product, you know, nice and happy in the mold, and as it cools, it starts to shrink. And if that release angle is too small, it can actually bind to the lifter.

Ah, I see.

Because it's shrinking inwards, and that's when you start to get those sticking problems.

Oh, that makes Sense. So how do engineers actually go about calculating the right release angle? Is there like a formula they use?

Yeah, there is. It's a pretty straightforward formula. Tan A equals S over H, A being the release angle, S being the horizontal travel of the lifter, and H being the depth of the product.

Okay. I think one of the sources had an example calculation for a 100 millimeter deep product. Could you walk us through that?

Yeah, absolutely. So let's say we have a product that's 100 millimeters deep, and we're using a lifter with a horizontal travel of 10 millimeters. So you plug those values into our formula, and we get tan A equals 10 over 100, and then solving for A gives us a release angle of about 5.7 degrees.

That's interesting, but you mentioned before that depth isn't the only factor. Right. The source also talked about the width of the lifter.

You're right. You're right. The depth is just one piece of the puzzle. You also have to think about the width of the lifter relative to the width of the part it's gripping. That plays a crucial role too.

Okay. Why is that? It seems counterintuitive that the width would matter.

It's all about leverage, you know, making sure that lifter can effectively guide the product out of the mold. Let's take, for example, that buckle example from the source. The buckle was only 5 millimeters deep, but 20 millimeters wide.

Okay.

Now, if you used a lifter that was only say, 5 millimeters wide to eject that buckle, it wouldn't have enough surface area to properly grip the product.

So even though the buckle wasn't very deep, the narrow lifter wouldn't have enough grab.

Exactly. Exactly. It's like trying to lift a heavy object with just your fingertips. You need that wider grip for more leverage and stability.

Okay.

In this case, the source mentioned, they ended up using a 10 millimeter wide lifter to make sure they had enough contact with the buckle to get it out smoothly.

That's really clear. So it sounds like getting the lifter width right is just as important as that depth calculation. But what about those really intricate shapes? You know, things that aren't just simple buckles or straight sided parts? How do you deal with those, ugh, complex shapes?

That's where things get really interesting. It's like solving a 3D jigsaw puzzle.

Yeah.

You really have to think about how each part of the product will interact with the lifter and the mold during ejection.

So you can't just apply that One formula and call it a day.

Exactly. You're spot on for complex shapes. Engineers often break the design down into simpler parts and they'll calculate the release angle for each individual section, and then they'll choose the largest angle as the standard for the entire Lister system. And that's to ensure everything clears properly.

So it's like a multi step process. Break down the complex shape, calculate for each part, and then find the biggest angle to make sure nothing gets stuck.

Precisely.

So we've talked about breaking down those complex shapes and then using that largest release angle to make sure everything comes out cleanly. Right. What other tricks do engineers have up their sleeves for those intricate designs? The sources mentioned something about collapsible cores. What are those all about?

Yeah, so collapsible cores are a great tool for complex shapes that have, you know, undercuts or internal cavities. Think about molding something like a hollow plastic bottle.

Okay.

You can't just pull a straight lifter out.

Right.

Because it would get caught on the inside of the bottle.

Right, yeah, that makes sense.

So collapsible cores, they allow you to mold that internal cavity and then collapse it in inwards so that the part can be ejected.

It's like a magic trick. The core forms the shape and then it folds away.

Exactly, exactly.

That's really neat. The source also talked about side action mechanisms.

Yeah.

What are those?

So imagine you're molding a part with a hole that goes all the way through it, but the hole isn't perpendicular to the direction the lifter pulls.

Okay.

Side action mechanisms can slide in from the side of the mold to form features like that and then retract before the part is ejected.

So it's like having extra fingers that can reach in and create those features.

Yeah, exactly.

That's really cool. We can't forget about CAD software. The sources mentioned that CAD can be used to actually simulate the ejection process.

Right.

Can you explain a little more about how that works?

Yeah. Think of it as a virtual test run. So you can create a 3D model of the mold and the product and then simulate the entire molding and ejection cycle in the software. And this lets you see if there are any potential areas where the part might get stuck or deformed during ejection.

So it's like a dress rehearsal before you even build the mold.

Exactly.

That seems super valuable to avoid those costly mistakes later on.

Absolutely. I mean, it lets you catch and fix those tricky spots early in the design process. It also lets you play around with different lifter configurations and release angles virtually before you commit to that final design.

I bet that saves a lot of time and headaches.

Absolutely.

But even with all these tools and techniques, it seems like there's still a lot of expertise and judgment involved in getting it right.

Oh, for sure. Yeah. Experience plays a big role in injection molding. You learn to anticipate potential issues. You understand how different materials behave, and you really develop a feel for what will work and what won't.

So if someone's new to injection molding, what advice would you give them if they want to learn more about this stuff?

I would say start with the basics. You know, get a solid understanding of the different molding processes, material properties, the fundamentals of mold design. There are some great resources available online, in industry publications, through professional organizations, and.

Don'T be afraid to ask questions.

Oh, absolutely. Yeah.

There's so many people out there who know a lot about this stuff.

Yeah. Injection molding, it's a collaborative feel. We're always learning from each other and sharing best practices.

So we've covered material, shape, sizes, even some of those more advanced techniques for those complex designs. Is there anything else that you think our listeners should keep in mind when it comes to these lifter release angles? Any other important things?

You know, one thing that often gets overlooked is the intended use of the final product. So how will that part be handled?

Right.

Will it be subjected to any stresses or impacts? These factors, they can influence your release angle choices as well.

Can you give me an example?

Yeah, sure. Imagine you're designing a snap fit component.

Okay.

That'll be repeatedly assembled and disassembled. You might need to consider a slightly larger release angle to ensure that those snap fit features can be easily engaged and disengaged without getting damaged.

So even though it's like a small detail, that release angle can have a big impact on the final product.

Yeah, exactly. And it just highlights the importance of thinking about the entire product life cycle, you know, from design to manufacturing to end use.

It's not just about getting it out of the mold. It's making sure it works in the real world.

Exactly, exactly, exactly. And that often requires, you know, considering factors beyond just the technical aspects of the molding process. You need to understand the application, the environment that the part will be used in, even how the consumer will interact with it.

It seems like injection molding is just as much about problem solving and creativity as it is about technical knowledge.

Absolutely. Yeah. That's one of the things I love about this field. It's always evolving there's always something new to learn.

Well, you've definitely opened my eyes to the intricacies of injection molding. Yeah, I had no idea that it is so much to consider when it comes to something as seemingly simple as a lift or release angle.

Yeah, it's definitely more complex than it appears on the surface, for sure. But that's what makes it so fascinating.

Yeah, it really highlights the importance of having a skilled team of engineers who really understand all those little nuances of injection molding.

Oh, for sure.

So speaking of creativity, what are some of the most interesting products you've seen made using injection molding?

Oh, wow. I've seen everything from tiny medical implants to massive automotive components.

Wow.

All molded with this incredible precision. But one project that stands out was we were developing this specialized container for transporting live insects.

Live insects. That sounds challenging.

Yeah, it was definitely unique. You know, we had to ensure adequate ventilation to keep them alive, but also prevent any escapes. So we ended up designing these tiny vents that were molded directly into the container walls.

Wow, that's so cool.

Yeah, it was a fun one.

It seems like there's no limit to what you can create with injection molding. It's a really versatile process.

Absolutely. And it's constantly evolving. You know, we're seeing some really exciting advancements in materials like bio based and biodegradable plastics, which is really opening up new possibilities for sustainable manufacturing.

That's great to hear. So we've covered a lot of ground today. Everything from the basics of release angles to some really complex concepts. Is there anything else you think our listeners should know before we wrap up? Any parting words of wisdom?

I think the biggest takeaway is that injection molding is a fascinating and complex field with endless possibilities. So don't be afraid to dive in, explore, experiment.

That's great advice. And remember, even those tiny details, like those lifter release angles can really make or break the success of a project.

Yeah, it's all about understanding how all those pieces fit together.

So next time you pick up a plastic product, take a moment to really think about all the engineering that went into making that. Right. Those carefully calculated release angles, those intricate mold designs. There's a whole hidden world of precision and ingenuity. There's.

Yeah. And who knows, maybe this will inspire some listeners to join the world of injection molding.

That'd be great. Well, thank you so much for joining me today and sharing your expertise. I've really enjoyed our conversation.

Yeah, me too. It was my pleasure.

And to our listener, thank you so much for tuning in to this deep dive. We hope you learned something new and sparked a little curiosity about the world of injection molding. Until next time, keep exploring and keep