All right, so you want to know what happens when things go wrong with pressure during injection molding?

Sounds like it.

We've got a ton of interesting sources to dig into. Articles, technical papers, even some firsthand accounts from people out there in the field.

And it's a good thing we're focusing on pressure. It's the heart and soul of injection molding. Even the tiniest change can lead to some really obvious defects.

Right, and we're not just talking about looks here.

No, no, no.

These defects can seriously mess with how a product works, how strong it is, how it all comes together.

Exactly. It's all connected.

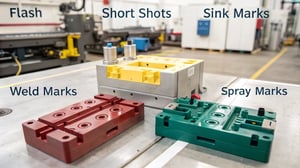

Okay, so first up, flash.

Ah, flash.

One source described it as like spilling paint on a finished artwork.

It does kind of look like that. You get this thin, raised line of.

Extra plastic along the seams of the part. Right?

Right along the seams. It's what happens when you have too much pressure during injection. The molten plastic, it's like it's trying to escape. It gets squeezed out of the mold.

So it doesn't just look bad. It can actually change the size of the product.

That's right.

I read that it can even make it hard to put different parts together later on.

Absolutely. And then someone's got to go back and trim off all that extra plastic.

More time, more money, waste of material.

Think about something simple, like a phone case. Right. If it's got flash, it might not even fit on your phone.

Makes sense.

Okay.

Okay, next up, short shots, short shots. Now, these, the source said, look like a shark took a bite out of them.

Okay, maybe a little dramatic, but I get the picture. It's when the plastic doesn't fill up the whole mold. Especially tricky with parts that have lots of detail. Thin walls, or parts of the mold that are far from where the plastic gets injected.

So basically, it's like a cake that didn't rise all the way.

Kind of, yeah. You end up with missing pieces.

And how do they make sure every little corner of the mold gets filled?

Mold design is key. It's like a puzzle. Engineers have to figure out where to inject the plastic, how thick the wall should be. Got to make sure that plastic flows smoothly.

They use computer programs to simulate the whole process, don't they?

They do very sophisticated software. It's about predicting where the problems might pop up.

So much goes on behind the scenes.

It's a delicate dance. Pressure, temperature. Everything has to be just right.

Speaking of uneven surfaces, sink marks.

Ah, those pesky sink marks.

Those little dents and depressions.

You see, sometimes I Read about someone who found a sink mark on their car's dashboard right before some big event.

Ouch.

I know, right? So sink marks happen when the outside of the part cools and hardens before the inside has a chance to shrink.

Leaving a void.

Exactly. Like a little cave under the surface. Thicker areas are more prone to it because they take longer to cool.

So with a car dashboard, it wouldn't just be about looks.

No. It could actually weaken the whole dashboard. Imagine if it cracked under pressure.

Or if a sink mark formed right where a button is supposed to go.

The whole thing could be useless. It really shows how even a tiny flaw can have a big impact.

Absolutely. Okay, let's talk about weld lines.

Weld lines.

The source compared them to a little mustache on the Mona Lisa.

I like that.

So there are these fine lines that you see.

Yeah. They show up when two flows of plastic meet in the mold, but they don't fully fuse together.

Could be because of the injection speed, the mold temperature, or even the way the part is designed.

Lots of factors.

And one article mentioned that weld lines can make a part weaker.

Right. Like a weak link in a chain. If you put too much stress on it, it's going to break right at the weld line.

So think about a kid's toy. Right.

It.

If it's got a weld line and breaks, it could be dangerous.

Sharp edges, small parts. That could be a choking hazard.

Manufacturers have to be really careful about where those weld lines end up.

It's all about safety and making sure the product is strong.

All right, last one on our list. Spray marks.

Spray marks. Those are interesting.

They're those squiggly lines, like little snakes.

Yeah.

One source talked about working on a luxury cosmetics packaging project, and it was covered in spray marks.

Not a good look for a high end product.

Definitely not.

So what happens is the plastic's injected too fast, it splatters a bit inside the mold and leaves those squiggly patterns behind.

It's like trying to fill up a water balloon too quickly.

Exactly. You get a mess.

And just like with the other defects, it affects how the product looks and how it works.

Absolutely. Think about a water bottle with spray marks. It might still hold water, but who wants to buy a water bottle that looks like that? And sometimes those spray marks can cause bigger problems.

Oh, yeah.

Like if you have a spray mark on a lens, that would make sense. Could distort the image.

Yeah.

Or think about medical devices. A spray mark could create a weak.

Point, and that could be really dangerous.

Exactly. It all comes back to precision and control in the injection molding process.

Right. Every little detail matters.

Everything. The temperature of the plastic, the design of the mold. They all play a part.

So we've talked about five big defects that can happen because of pressure problems we have. But is there anything manufacturers can actually do to prevent these defects?

Oh, absolutely. It all starts with a good mold design.

Ah, so it's like the foundation.

Exactly. You gotta have good venting, the right wall thickness, and you gotta make sure the plastic flows smoothly through the mold.

It's almost like a blueprint for success.

That's a good way to put it. But even with a perfect mold, you still need to control the injection molding machine.

So what does that involve?

You gotta monitor things like the pressure, the speed, the temperature of the plastic, the cooling time. A lot of variables.

That sounds complex.

It can be. But luckily, a lot of modern machines are automated now. They have sensors that make sure everything stays consistent.

So it's a mix of technology and human expertise.

That's right. And of course, you need to keep the machine well maintained.

Right. Regular checkups.

If you don't, you're more likely to run into problems.

Makes sense. Now, I want to shift gears a bit and talk to you, the listener, directly.

Right.

You might be thinking, this is all interesting, but I don't work in manufacturing.

I can see that.

But here's the thing. We're surrounded by injection molded products everywhere you look. Our phones, our cars, our kitchen appliances, they're all made using injection molding. So understanding these defects can actually help you be a smarter shopper.

Absolutely. It's about knowing what to look for.

So you can spot potential problems and choose better products.

Exactly. Let's say you're looking at two water bottles.

Okay.

One has some obvious weld lines or sink marks. The other one looks smooth.

I'm going for the smooth one.

Probably a good idea. It's a sign that the manufacturer has better quality control.

That's a good tip. But to be honest, some of these defects can be pretty subtle.

They can be.

Are there any other ways to spot them?

Well, we talked about the visual cues.

Right.

But you can also learn a lot by just feeling the product.

Oh, interesting.

Does it feel rough or uneven?

Ah, I see.

Are there any weak spots that feel like they might break easily?

I never thought about that.

It's about using all your senses.

So pay attention to how the product looks and how it feels.

Exactly. And don't be shy about examining it closely.

Get up close and personal.

Turn it over look at it from different angles, run your fingers over the surface.

I'm definitely going to be paying more attention now.

I think you'll be surprised by what you find.

This has been really eye opening. I feel like I have a whole new appreciation for injection molding.

It is a fascinating process. But before we move on, I wanted to go back to something we talked about earlier.

Sure.

The amazing things that can be achieved when injection molding is done right.

Right.

It's incredibly versatile. You can create really complex parts, intricate details, from tiny medical devices to huge car parts. It's amazing.

The range is incredible.

And when it's done well, smooth surfaces, precise dimensions. It's impressive.

It's like taking a simple plastic pellet and transforming it into something amazing.

It really is. And the best part is the field is always evolving.

New materials, new technologies.

It's exciting to think about what the future holds.

It does sound like there's a lot of potential. But even with all this new tech, I'm guessing defects still happen.

Oh, for sure. No manufacturing process is perfect. Injection molding, it's no different. You can have the best machines, the most experienced people, and things can still go wrong.

So you can't really eliminate defects completely.

It's more about minimizing them, catching them early, having systems in place.

Okay, so kind of like damage control.

You could say that. It's about having realistic expectations and good quality control.

Makes sense. So for the average person who just wants to be a smart shopper, what should they be looking for? We talked about visual cues, but is there anything else?

You know, it's funny you should say that, because while those visual cues are important, you can actually learn a lot just by feeling the product.

By feeling it?

Yeah. Like run your fingers over the surface. Does it feel feel rough, uneven in certain spots? Are there any parts that feel weak, like they might break easily? Those could be signs of pressure problems during molding.

So it's not just about what you see, it's about how it feels too.

Exactly. Don't be afraid to pick things up, turn them over, really examine them.

I'll definitely be doing that from now on. But before we wrap up, I want to go back to what you said about how amazing injection molding can be when it's done right.

It's true. You can create some really incredible stuff. So many different kinds of products. Tiny medical devices, huge car parts. It's mind blowing. And when it's done well, you get those smooth surfaces, the precise dimensions. The quality is just there.

It's like this whole world of plastic objects that we take for granted. But they all start from this tiny little pellet.

It's pretty amazing when you think about it. And the coolest thing is the field is constantly changing. New materials, new ways of doing things. Who knows what we'll be able to create in the future?

Well, that's a great note to end on. We've learned about common defects, quality control, and even the incredible things that are possible with injection molding.

And hopefully you, the listener, have a better understanding of those everyday plastic products.

You use, for sure. So thanks for joining us on this deep dive. And keep an eye out for those injection molding defects. You might be surprised by what you find.

Until next