Hey there. Welcome to your personalized deep dive. Looks like you're really interested in injection mold cooling times, huh? Yeah, especially how they can, you know, really make a difference in production efficiency. We've got a ton of articles and research you sent over, so let's just dive right in and see what we can find.

Sounds good. I'm excited to be here, you know, optimizing those cooling times. It can be a real game changer in injection molding.

Totally.

And there's a lot to. A lot to cover.

Yeah, for sure. You know, going through your notes, I saw that you mentioned that sometimes your production lines feel like they're like moving at a snail's pace.

Yeah.

And I gotta say, I've definitely felt that way too. Like when projects just get bogged down.

Oh, yeah.

Before we even jump into solutions, though, why is getting those cooling times right so important?

That's a great question. To start with, it's easy to think of cooling time as just this like passive waiting period, but it's actually a really dynamic part of the process. It kind of has a ripple effect on everything. If you're not optimizing cooling times, you're not just wasting time, you know? Right. You could be messing with the quality of your parts, even shortening the lifespan of the molds themselves.

It's all connected.

Yeah, exactly.

I found something interesting in one of your articles. It was about thin walled parts.

Okay.

Said that if those parts are cooling for more than 30, 40 seconds, you're probably looking at too much cooling time.

Right? Right.

Why is that the benchmark?

It comes down to efficiency. You know, how well you're using your resources. Every second that mold is just sitting there waiting for the part to cool. It's not making a new part.

Yeah.

Think about your equipment utilization rate. Ideally, right. You want those machines running at least 70%, 80% of the time.

Okay.

But if cooling times are too long, well, okay. Utilization rate just tanks and so does your output.

So like a domino effect.

Exactly.

Too much cooling time leads to lower utilization rates, which in the end affects your profits. One of the articles had an example that really stuck with me. It said that if a normal 60 second cycle gets dragged out to like 75 seconds.

Yeah.

Because of cooling issues, your production output could drop by like over 20%. That's a lot.

It's huge. And that's why it's so important to understand what affects cooling time.

Right.

And material selection is a big one.

Your notes talked about things like thermal conductivity, specific heat and density, and it's Interesting, because these aren't just like abstract science things, you know, they directly affect how fast your parts cool and ultimately how efficient your whole production process is.

That's right.

So think about it this way. You're designing a part that needs to lose heat quickly. You're not going to pick a material that acts like an insulator.

Right.

You'd want something that lets heat pass through it easily. Like some metals.

Exactly. Okay.

But we're not always using metals. A lot of injection molding involves plastics, which aren't really known for their heat conductivity. So does that mean we're stuck with longer cooling times if we're using plastics?

Not necessarily. Plastics do generally have lower thermal conductivity than metals. But there are things you can do.

Like what?

Well, you could choose plastic grades that are, you know, made for faster cooling.

Okay.

Or you could use additives that improve the thermal conductivity.

So it's all about understanding what you're working with and making good choices.

Exactly.

It's like having a toolbox full of different options.

Right.

And you need to know which tool is right for the job.

I like that. That's a great analogy.

Now, your research mentioned industry standards for cooling times too.

Yeah.

Are these standards, like, helpful suggestions or are these strict rules you absolutely have to follow?

I'd say they're a little bit of both.

Okay.

They come from years of experience, you know, and best practices in the industry. For example, one of the sources you shared mentioned that the standard cooling time for thin walled parts is around 40 seconds, while thicker parts might need up to 120 seconds.

Wow.

Following these standards helps make sure everything's consistent and the quality is good.

So these standards are there to help avoid those.

Yeah.

Common problems and make sure we're producing like, really high quality parts.

Exactly.

But are there ever times when it might make sense to, you know, deviate from the standards a little bit?

That's a good question. While the standards are really helpful, sometimes a project might have specific requirements or a material might have certain properties or anything you might need to adjust the cooling time. Say you're working with a really specialized material, something with unique cooling characteristics.

Right.

You might need to tweak those standard guidelines.

That's a good reminder that even though standards are important, we can't just blindly follow them all the time.

Yeah. You gotta use your judgment.

Now, I know you're all about efficiency.

Yeah.

What happens if we don't get these cooling times right?

Oh, that's a big one. Yeah.

What are some of the bad things that can happen that is the core of why we're talking about this. You know, when cooling times are off, it can cause all sorts of problems, starting with the quality of your parts. Too much cooling can lead to a bunch of issues like dimensional inaccuracies, warping, even internal stresses. Think of it like forcing a puzzle piece into the wrong spot. You can make it fit, but it's going to be all messed up.

Okay, Yeah, I see what you mean.

It's not just about the part looking right, you know, it's about making sure it's strong and works the way it should.

Right. And we were talking about those visible defects earlier, like those cold marks and warping.

Yeah.

Those can definitely make a product look bad.

Absolutely. People notice those things. Like if you buy a brand new car and it has a dent.

Right. It changes how you feel about it.

Exactly.

It might still run fine, but it's just not the same.

It's all about perception and meeting what the customer expects. Right. Now, about those production delays we were talking about earlier, how do long cooling times affect the whole cycle time and the efficiency of the whole injection molding process?

It's like a traffic jam. One car slows down. Hello. And everything gets backed up.

Okay.

In injection molding, the cooling stage, that's a critical part of the cycle time. If it takes too long, the whole process gets thrown off.

So it's not just about that extra minute or two of cooling. It affects the whole production line.

Exactly. It all adds up.

In one of those research papers you sent, they mentioned how this affects the financial side of things. They said that even a small increase in cycle time, like going from 60 seconds to 75, can cause a big drop in how many parts you make.

Yeah, definitely. Say you want to make 100 parts per hour, but your cycle time goes up because of cooling, you might only be able to make 80 parts per hour. That's 20% less.

Right.

And that's 20% less money you're making.

That's a real way to look at it.

Oh, yeah.

It's not just some abstract idea of efficiency. It hits your profits directly.

Absolutely.

And it's not just the immediate hit. There's the long term stuff too, like the lifespan of your molds.

Right. That's important too.

Earlier you said excessive cooling is like leaving your car engine running without moving. What does that mean for the wear and tear on injection molds?

Well, when a mold is stuck in these long cooling cycles, it goes through these repeated heating and cooling cycles. And that can lead to something called thermal fatigue.

Thermal Fatigue.

It's like bending a paperclip back and forth over and over. Eventually, it breaks.

Okay.

The molds are basically getting tiny little stress fractures, which can cause big problems later on.

I'm guessing replacing a damaged mold isn't cheap or fast.

No, it's not. Molds are expensive, and replacing them takes a lot of time. It's much better to prevent damage in the first place.

That makes sense. Be proactive, not reactive.

Exactly.

So knowing all the problems with excessive cooling times, let's talk about some ways to optimize this stage.

Okay, Sounds good.

Where should we start to find that sweet spot for cooling times?

Well, the first thing to remember is that there's no one perfect answer.

Okay.

Optimal cooling times depend on a lot of things, but a good place to start is with material selection.

Right. Earlier, you were saying that different materials have different thermal properties.

Yeah.

So how can we use that to our advantage?

Remember thermal conductivity? Choosing materials with higher thermal conductivity can really cut down those cooling times. They let heat escape faster, so your parts solidify more quickly.

So if we're using plastics, are there specific types we should be looking for?

Absolutely. Some plastics are just naturally better at conducting heat.

Okay.

For example, some grades of nylon and polycarbonate. Those are known for their good thermal conductivity. And there's also new plastics being developed with fillers or additives that make them even better at conducting heat.

So it's like getting an upgrade, but for plastics.

Exactly.

What about those process parameters? How can we adjust those to optimize cooling times?

That's another key area. It's like tuning a musical instrument. You need to adjust things, so to get the perfect sound, you can adjust things like mold temperature, injection pressure, and injection speed to control how fast that molten material cools and hardens.

So a cooler mold temperature would mean faster cooling times.

Exactly. It's basic physics. The bigger the temperature difference between the plastic and the mold, the faster the heat transfer.

Got it. Now, your research talked about the design of the cooling channels within the mold itself.

Right.

How do those affect things?

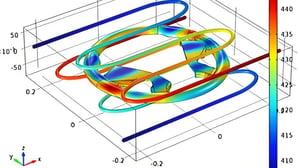

Those cooling channels are like the veins and arteries of the mold. They circulate cooling fluid, usually water, to keep the temperature even and speed up cooling. Getting the design and placement of those channels right can make a huge difference in how efficiently things cool.

So it's like designing a really good engine.

Yeah.

You want that cooling system to work perfectly.

Precisely. And just like there are different engines for different things, there are different cooling channel designs depending on the shape of the part and the material. You're using makes sense.

Now, throughout our conversation, you've talked about those industry standards. How can we make sure we're using them the right way when we're trying to optimize our cooling times?

Industry standards, they're great for benchmarks and guidelines, but you shouldn't treat them like they're set in stone. Think of them as a starting point.

Okay.

Once you get what they mean, you can use what you know about materials, process parameters and part design to decide if you need to make any adjustments.

So it's about using the standards as a base, but also being flexible.

Exactly.

It's like having a recipe, but knowing you might need to change the ingredients or cooking time based on your oven or where you live.

That's a great way to put it. It's about combining knowledge with experience.

Well, this deep dive has been really helpful. We've covered a lot, from the science of cooling times to the act actual strategies for optimizing them.

It's been a good discussion.

Before we wrap up, is there one main takeaway you want to leave with our listener?

I'd say this. Optimizing cooling times and injection molding, it's not just about making things faster. It's about finding that balance between efficiency, quality, and making sure your molds last a long time.

Right.

When you understand the factors involved and use the right strategies, you can streamline your injection molding process, make it more cost effective and higher performing.

It's about looking at the big picture and making smart choices.

Exactly.

As a final thought for our listener, what are some ways that technology can help us optimize cooling times even further?

That's a great point. Technology is changing everything about injection molding. Things like real time monitoring systems, they give you tons of data on temperatures and cooling rates so you can make precise adjustments as you go. And as AI and machine learning keep getting better, we're going to have even more advanced tools. Tools that can predict and stop cooling problems before they even happen.

So the future of injection molding is all about data and smart tech.

It seems like it.

Thanks for joining us for this deep dive.

My pleasure.

We hope you've learned some valuable things that will help you achieve manufacturing excellence. Until next time.

Yeah. And you know, those problems can really snowball excessive cooling. It can lead to dimensional inaccuracies, warping, even internal stresses in the part.

It's like you try to force a puzzle piece into the wrong spot.

Exactly.

You might be able to get it in there, but it's not going to be right.

Yeah. I'll Be all messed up.

It's not just about it looking right. It's got to be strong.

Yeah.

And it's got to work the way it's supposed to.

Right. You got to think about functionality too.

And like we were talking about before, those visible defects, the cold marks, the warping, those can really hurt how a product looks.

Oh yeah. People notice those things. It's like imagine you buy a brand new car and it has a dent in it.

Right. It totally changes your impression.

Yeah, exactly.

Might still run fine, but it's just not the same.

It's all about perception. You got to meet those customer expectations.

Right now, going back to those production delays, how do those longer cooling times actually impact the whole cycle time and efficiency of the injection molding process?

It's like a bottleneck. You know, like on a highway, one car slows down and it causes a traffic jam.

Yeah.

In injection molding, the cooling stage is a big part of that cycle time. If it takes longer than it should, it messes up the whole rhythm.

So it's not just about that extra minute or two of cooling. It's the effect it has on the whole line.

Exactly. It all adds up.

I was reading one of the research papers you sent.

Yeah.

And they talked about how this impacts the financial side.

Right.

Even a small increase in cycle time, like going from 60 seconds to 75, can really decrease how many parts you can make.

Oh yeah, for sure. Let's say your goal is to make 100 parts per hour, but your cycle time increases because of cooling issues, you might only end up making 80 parts per hour. That's a 20% drop.

Wow.

And that's 20% less profit.

That's a very concrete way to look at it.

Yeah.

It's not just some abstract idea of efficiency. It has a real impact on your bottom line.

It does. And it's not just about the immediate financial hit either. You got to think long term too, like how it affects the lifespan of your molds.

Right. You were saying that excessive cooling is like leaving your car engine running without moving.

Uh huh.

So what does that mean for the wear and tear on the molds?

Well, when a mold is going through these extended cooling cycles, it's basically going through all these heating and cooling cycles over and over again. And that can lead to something called thermal fatigue.

Thermal fatigue. Okay.

It's like if you bend a paperclip back and forth over and over, eventually it's going to break.

Right.

So the molds are kind of getting these little stress fractures and that can lead to Bigger problems later on.

And replacing a mold is not a quick or cheap process.

Nope, not at all. Molds are expensive, and replacing one takes a lot of time.

Yeah.

It's always better to prevent that damage if you can.

That makes sense. Being proactive is key. So now that we know all the problems with too much cooling, let's shift gears and talk about ways to make things better.

Okay. Yeah.

In your opinion, what's the best way to find that sweet spot for cooling times?

Well, you know, the first thing is that there's no one size fits all answer. Optimal cooling times, they depend on a bunch of factors. But a good place to start is with material selection. A good place to start is with material selection.

Okay, so earlier we were talking about how different materials have different thermal properties.

Right.

How can we use that to our advantage when we're choosing materials?

So remember when we talked about thermal conductivity? If you choose materials with higher thermal conductivity, that can really help shorten those cooling times. Those materials let heat escape more quickly so your parts harden faster.

So, say we're working with plastics, Are there certain types of plastics we should be using?

Yeah, absolutely. Some plastics are just naturally better at conducting heat than others. Like certain grades of nylon and polycarbonate are known for having pretty good thermal conductivity. And on top of that, there are new plastics being developed all the time with fillers and additives that make them even better at conducting heat.

This is like we're getting a performance upgrade, but for plastics.

Exactly.

Now, what about those process parameters? How can we tweak those to get the best cooling times?

That's another important area. It's kind of like fine tuning a musical instrument. You gotta adjust things to get the perfect sound. You can adjust things like mold temperature, injection pressure, and injection speed.

Okay.

All of those can affect how fast the material cools and hardens.

So if we have a cooler mold temperature, that would mean faster cooling times, right?

Exactly. It's simple physics. The bigger the temperature difference between the plastic and the mold, the faster the heat transfer will be.

Got it. You know, in your research, you also talked about the design of the cooling channels inside the mold itself, Right. How do those play a role?

Think of the cooling channels like the veins and arteries in the mold. They circulate that cooling fluid, usually water, throughout the mold, and that helps keep the temperature consistent and speed up cooling. The design and placement of those channels can really make a big difference in how efficient the cooling process is.

So it's like we're designing a high performance engine.

Yeah.

We need a top notch cooling system to make sure everything runs smoothly.

Exactly. And just like you have different engines for different jobs, you have different cooling channel designs depending on the shape of the part and the material you're using.

You've mentioned those industry standards throughout our conversation. How can we make sure we're incorporating those standards the right way when we're trying to optimize cooling times?

Industry standards are great for benchmarks and guidelines, but they shouldn't be treated as like unbreakable rules. Think of them more like a starting point. Once you understand the standards, you can use your knowledge about materials, process parameters, and how the part is designed to figure out if you need to adjust those standards a bit.

So it's about using the standards as a foundation, but also being flexible enough to adapt.

Exactly.

It's like having a recipe, but knowing that you might have to tweak the ingredients or cooking time, depending on your oven or even your altitude.

That's a great way to put it. It's all about combining knowledge with experience and using your best judgment.

This deep dive has been so helpful. We've gone over so much from the science behind cooling times to the practical steps for making them better.

Yeah, it's been a really good conversation.

Before we wrap up, is there one key thing you'd like our listener to take away from all of this?

I'd say this. Optimizing cooling times in injection molding. It's not just about making things faster. It's about finding that balance between being efficient, having high quality, and making sure your molds last as long as possible.

Right. It's about seeing the big picture.

Exactly. When you understand the factors involved and use the right strategies, you can make your injection molding process much more streamlined, cost effective, and high performing.

Awesome. Well, thanks so much for joining us for this deep dive.

My pleasure.

We hope you found it valuable and that it helps you in your pursuit of manufacturing excellence. Until next