All right, let's dive right in to the world of injection molding machines. I know you're already familiar with the basics. You sent us that article on how to pick the right machine.

Yeah, how to choose.

Exactly. So today, we're going to extract the most useful insights from it so you can pick the perfect machine for your product.

You know, each element, from clamping force to mold size, injection volume, it all.

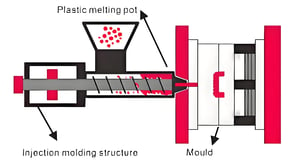

Plays a part like a puzzle, really. Okay, let's unpack that puzzle. You've probably heard of clamping force. Sometimes it's called tonnage. It's what holds the mold shut under all that pressure.

Yeah, you can think of it like when that molten plastic is injected. It's like a miniature explosion inside.

Oh, wow.

And without enough force, you could get defects, you know, like flash, where the plastic squeezes out, or even incomplete parts.

So how do we make sure we have enough force, then?

Well, the article had a really helpful formula.

Oh, okay.

Force equals pressure times the projected area of the product times a safety factor.

Safety factor. All right.

Yeah. Then just make sure you have a little extra just to be safe.

Makes sense. But how much force are we really talking here?

It really depends on the product. Let's say you're making something with a projected area of 10,000 square millimeters.

Okay. 10,000.

With an injection pressure of 50 MPa. That's MPa. You'd need around 65 tons of clamping force.

Wow. That's a lot.

It is.

I mean, that really shows how even a small change in the product size can really impact how much tonnage you need. It's like adding just a little extra ingredient in a recipe. It changes everything.

Exactly. And that brings us to another piece of the puzzle, which is mold size.

Okay.

And this is where things can get tricky, especially if you've got a larger mold.

Yeah.

You have to make sure that your mold can actually fit within the machine's template size and the space between the tie rods. That's what holds everything together.

That makes sense. Like, I'm just picturing trying to fit a giant inflatable Santa Claus into a tiny apartment. This is not going to happen.

Exactly.

But how can you be sure you have enough space?

So imagine the mold like a giant sandwich. Okay.

Yeah.

Sandwich tie rods. They're like the toothpicks holding the slices of bread together.

Okay, I see.

If your bread slices. That's the mold halves are too big. They're not going to fit between those toothpicks.

Gotcha. So if you're Making something big like a car bumper, Finding a machine with enough space. Space between the tie rods. That's crucial.

Absolutely. And that leads us to what goes inside the mold.

All right, good stuff.

Product weight and injection volume.

Okay.

This is where understanding your material becomes really essential.

I'm curious about how different kinds of plastic can impact our machine choice here.

That's a great question, because, you know, different plastics act differently when they melt. Some flow really easily, like water, while others are thicker. They need more force to push them through. So this directly impacts the injection volume. You need basically how much melted plastic you inject to make your part.

So if I've got a thicker material, I'm going to need a machine that can handle a larger volume.

Exactly. You need enough to completely fill the mold. Making sure every little corner is filled without putting too much stress on the machine.

Makes sense. But how do we figure out exactly how much melted plastic we need?

You take your product weight and you divide it by the material's density.

Okay.

So let's say you're making a 100 gram product with a plastic that has a density of 1.2 grams per cubic centimeter.

Okay.

You're going to need an injection volume of about 83 cubic centimeters.

All right, so we'd need a machine with a capacity of at least 83 cubic centimeters. But is it as easy as just getting the exact volume?

Actually, you'll want to go a little bit larger. Just a bit.

Okay.

Give yourself some wiggle room. This ensures that you'll have consistent product weight and quality, even if there are little variations during the process.

That's a good tip. But you mentioned before that the type of plastic can also affect what machine we choose.

Right. Because the properties of the plastic, like how hot it needs to be to melt and how easily it flows, that affects the machine's heating system and the screw design.

Oh.

So some plastics need to be heated to really high temperatures, which means you'll need a machine with a more powerful heating system.

It's not as simple as just matching the mold size and clamping force, then.

Nope.

We need to think about the specific plastic, too.

Exactly. And speaking of specifics, we need to talk about how much force we use to push that melted plastic into the mold.

Okay. Injection pressure.

Yes.

We talked about clamping force to keep the mold closed, but now we're talking about the pressure to inject the material itself.

Right.

So. So tell me more about why this matters.

Imagine you're kneading dough. Okay.

Okay.

Sometimes you need more force. You know, for thicker doughs to make sure it's all mixed and shaped evenly.

Yeah.

It's kind of the same with injection pressure. The force we use to inject the plastic impacts everything from how well it fills the mold to the final surface finish.

So too little pressure and we could end up with, like, incomplete parts or imperfections.

Exactly.

But what about there's too much. Wouldn't that make sure everything is filled properly?

Not always. Too much pressure can lead to problems, too. Like you can get flash where the plastic squeezes out, or you could even damage the mold.

So finding the right balance is key.

Absolutely. And that balance, it's going to be different depending on what you're making in the material. It's another reason why understanding these concepts is so important.

This is all so fascinating. We've already talked about clamping force, mold size, injection volume, and now injection pressure.

It's a lot to take in.

It is. But it's amazing how all these technical things work together. They're all just pieces of the injection molding puzzle.

They really are. And, you know, we've only just scratched the surface. There's still so much more to learn about this.

Well, I'm ready to keep exploring. But before we do, let's take a step back and remember why this is all so important.

Right. It's all about you. It's about giving you the tools to choose the right machine.

Exactly.

When you understand all these factors, how they relate to your product and what you want to achieve, you can avoid making those costly mistakes. You can ensure top notch quality and really just make your whole manufacturing process smoother.

I couldn't have said it better myself. There's still so much more to talk about, so stay with us as we keep going in this fascinating world of injection molding.

Welcome back to our deep dive. We laid some groundwork in part one, but there's still so much to discover in the world of injection molding machines.

It's easy to get lost in all those technical numbers, for sure. But it's important to remember the bigger picture. I think picking the right machine isn't just about, you know, checking off boxes on a spec sheet.

Right.

It's about how all these different factors work together.

Yeah.

To create a successful manufacturing process.

That's such a good point. It's like we're putting a puzzle together where each piece is important to get that final picture. And, you know, it's like that analogy we talked about earlier, Getting the injection volume right. It's like measuring out the right amount of ingredients for A recipe?

Yeah, that's a good one.

Too much, too little. It messes everything up. Exactly. It's all about those proportions, understanding, you know, the product's weight, the density of the plastic and how much injection volume you need.

Now, you mentioned earlier that it's better to choose a machine with slightly more injection volume than you calculate at first.

Right.

But wouldn't that just mean we're wasting material?

It might seem that way. But hear me out, okay. Having a little extra can actually save money in the long run.

Really?

Think of it as insurance.

Okay.

Because, you know, little variations in temperature or pressure, even the material itself can happen. So having that extra volume, just make sure you're producing good quality parts every time without those, you know, short shots or incomplete fillings.

So it's like a safety net.

Exactly.

You're trading a little bit of potential waste for consistency. Makes sense.

It's all about finding that balance.

So we've talked a lot about the technical stuff. Tonnage, mold size, ingestion volume, injection pressure. But what about if you choose the wrong machine? What could happen?

Okay, imagine you buy a machine that's too small. You're going to be pushing it to its limit all the time.

Yeah.

That means more wear and tear, more breakdowns, and in the end, higher maintenance costs. It's like trying to, you know, run a marathon with a car that's only meant for city driving.

You're going to have some problems.

Exactly.

So is it always better to go bigger then?

Not always.

Yeah.

Because a machine that's too big can be a problem too.

Oh, okay.

You could end up wasting energy and your operating expenses are going to be higher. It's like. Well, it's about finding that Goldilocks zone.

Yes.

Right. Yeah. A machine that's the perfect size and.

All those extra costs, they really add up over time.

Oh, for sure.

And that doesn't even include the impact. Impact on the quality of your product.

Right.

If you're always fighting defects and inconsistencies because you have the wrong machine, that can really hurt you in the long run.

Exactly. It can damage your reputation, your customers won't be happy and that affects your profits.

Choosing the right machine really is a big deal.

It's a big investment. It's not just about the price tag. It's about the long term success of your business.

So let's say someone is feeling a bit lost with all this information. What's the one piece of advice you'd give them?

Don't be afraid to ask for help.

What about advice?

There Are experts out there. Online forums, articles like the one you sent us. Just do your research, understand what your product needs, what your goals are, and then really think about your options to find that best fit.

That reminds me of that part in the article where the author talked about feeling overwhelmed at first. Once they understood how the machine's capabilities connected to their product, it made everything much clearer.

It just shows you that even the most complicated stuff can be understood. You know, with a little bit of effort and the right guidance. And once you understand it, you can make better decisions.

It's like turning a confusing puzzle into a clear path. But you know, there's another part of this puzzle we haven't talked about. The control system of the machine.

Ah, yes, the control system that's the brains of the whole operation.

It can really impact how precise, how repeatable, how efficient your whole process is.

Exactly.

I understand what you're saying about these advanced control systems, but aren't they super expensive?

Well, it depends.

Okay.

How fancy your control system needs to be really depends on the product you're making and how precise you need to be. Think of it like an oven.

Okay.

Some have those basic dials, and others have digital displays with all kinds of settings.

Right.

It's the same with injection molding machines. If you're making something simple in large quantities, a basic control system might be fine.

Okay.

But if your product is more complex or you're working with materials that need really specific conditions, then a more advanced control system is probably worth the investment.

So for those tricky parts or materials with special needs, a fancy control system can make a big difference.

Absolutely. Those advanced features, they can give you really valuable insights. You can fine tune everything, make the process more efficient, and keep the quality consistent. It's like having a whole team of experts constantly watching and adjusting things for you.

It's like using the right tool for the job. You wouldn't use a hammer to tighten a screw.

Exactly. You need the right control system for the job. One that matches how complex your product is and how precise you need to be.

So we've got material properties, tie rod spacing, and now control systems to think about.

Yeah.

Anything else we should keep in mind before we choose a machine?

One thing the article really emphasized was the importance of the actual material you're using for your product.

Oh, right. We talked about that a little before. But let's go a bit deeper.

Sure.

Different materials have different properties, right? Like melting points, how thick they are, how sensitive they are to heat.

You got it. And these things can really impact what machine you choose. For example, if you're using a material that needs a really high temperature to melt, you'll need a machine with a strong heating system.

Okay, I see.

Or if the material breaks down easily with heat, you might need a machine with a special screw design to protect it.

So it's not just how much material we need, it's also how the material behaves when it melts and gets injected.

Exactly. And this is where talking to material suppliers and machine manufacturers can be really helpful. They can guide you through those tricky details.

It's amazing how all these details are connected from the material to the tie rods to the control system. It's like a chain reaction.

It's like a perfectly orchestrated symphony where everything has to work together.

I love that. But before we get carried away with the music, let's bring it back to our listener. We've covered so much, and I want to make sure they're taking away some key insights.

Good idea. Let's recap. Okay, so first we talked about how the product's weight, the density of the plastic, and the injection volume are all related. And remember, it's better to have a little extra injection volume just in case.

Right. That safety net.

Then we discussed how injection pressure affects things like how well the mold is filled and the final look of your product. Finding that sweet spot for pressure is key.

And of course, we talked about the real world consequences of choosing the wrong machine. It can cost you money and affect the quality of what you make.

Yeah, choosing the right machine is a big decision. It can really affect your business in the long run. And let's not forget about those control systems. The complexity of your product and how precise you need to be will guide you in choosing the right one.

And like you said, the material itself plays a huge role too. The properties of the plastic, like how it melts and flows, can really impact your machine choice.

It's all about understanding those little details and getting advice from the experts. This deep dive has been really interesting so far, and I'm sure our listeners is eager to hear what other insights we can find in that article. But before we jump into the last part of our deep dive, let's take a quick pause.

And we're back for the final part of our deep dive into injection molding machines. We've covered so much ground, I'm ready to see what other insights we can squeeze out of this article.

We've definitely tackled the big stuff, but there are still a few more nuggets in there.

Oh, good. You know, it really strikes me that picking the right machine is like detective work.

How so?

Well, you gotta gather all the clues, you know, the specs, material, properties, what you're trying to achieve. And then you have to figure out which machine is the perfect fit.

I like that. And just like a good detective, you can't miss those little details. One thing the article brought up was the importance of the product's life cycle.

Life cycle?

Yeah. Like how long are you planning to make this product for? Is it just a short run or are you going to be making it for years? High volume.

Ah, okay. So how does that affect what machine we choose?

Well, if it's a short run, you might want a machine that's flexible, you know, one that can easily switch between different molds and products.

Makes sense.

But if you're in it for the long haul, making tons of this product, you're going to want something durable and reliable. Something that can run nonstop without breaking down all the time.

Right. So matching the machine to your long term plan, what other wisdom did the article have?

Something that people often forget about is energy efficiency.

Oh, right. With energy costs these days, it makes sense to think about that.

Exactly. You want a machine that's powerful, but also doesn't guzzle energy.

Good for the wallet and the planet. What should we be looking for then?

There are certain features that can help save energy. Like some machines have these servo hydraulic systems. They only use power when they need to.

Oh, okay.

Unlike those older hydraulic systems that are always running.

Interesting.

And they're also machines with regenerative braking, so they actually capture energy when they slow down.

So it's about looking beyond the sticker price and thinking about how much it costs to run the machine too. It might cost a bit more upfront, but save you money over time.

Exactly. Thinking long term, thinking about the bigger picture.

This whole deep dive has been so insightful. We've gone from being a little scared of all the jargon to discussing clamping force and injection volume like pros.

I think you've done great. You're ready to make some informed decisions.

I feel much more confident. That's for sure. But before we go, I want to leave our listener with a question to think about. Something to take away from all of this.

I like that.

How about this? If you look at your own manufacturing setup and think about all the things we've talked about, what's one area you could improve? Or what's one question you'd ask a potential machine supplier?

That's a great question. It really makes you think about your own situation and how you can use this knowledge.

It's about taking all this and putting it into action. Who knows, maybe this deep dive has inspired someone out there to start making their own products.

I hope so. That would be amazing.

On that note, it's time to wrap up this deep dive. Thanks for joining us on this journey into the world of injection molding machines. Remember, knowledge is power. And now you have the power to make smart choices for your manufacturing needs. Until next time, keep exploring, keep learning, and keep