Welcome back, everybody, to the deep dive. You know, today we are going to be diving into the world of injection molding.

Ooh, fun.

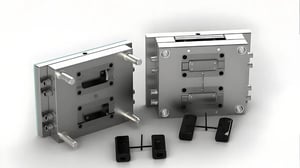

Yeah. Well, you know, we got to do it. But we're specifically looking at how the angle of the parting surface on a mold, you know, that big, giant mold that they use to make plastic parts, how that affects the life of that mold.

Right.

And, you know, you sent in some really interesting excerpts, and I think it's going to be a really fascinating dive because at first it sounds kind of technical, but it's actually really interesting when you start thinking about it. And the implications are huge. Even beyond manufacturing, we're talking about how a tiny gap, like just 0.1 millimeters can dramatically shorten the lifespan of this massive piece of steel.

Yeah. And that's one of the things that the source really drives home, is that that precision is key. Right. The fit of that parting surface is critical. It's like a giant industrial size puzzle. Each piece needs to fit together perfectly.

Yeah. They compare it to puzzle pieces. And I'm kind of curious, like, what happens when those puzzle pieces don't align perfectly? What's like, the worst case scenario?

Well, you can imagine molten plastic, so incredibly hot and under immense pressure, being injected into this mold. And if there's even the slightest gap, the plastic, which acts like a fluid under those conditions, can seep in. Right. And so the result is what we call flash, or excess plastic that forms along the seam.

Oh, so it's not just about aesthetics, then. It actually, like this flash actually damages the mold over time.

Exactly. Each time the mold opens and closes, that flash creates friction and wear. You can picture it like sandpaper slowly grinding away at the metal, especially around, like, intricate details in corners.

Right.

And it's not just the steel that's affected. You know, the mechanics of the process suffer too well.

And they also emphasize friction during demolding. I can see how a part that, you know, sticks would cause wear. But is that a common problem with injection molding?

More common than you might think, especially with these complex designs. Yeah.

So.

So if the part doesn't release smoothly, it scrapes against the mold surface as it's ejected.

Wow.

And that constant abrasion gradually wears down the mold, leading to imperfections and eventually premature failure.

Yeah. And that kind of brings to mind another point they brought up about the importance of pressure distribution during molding because it mentioned that uneven pressure can actually lead to cracks in the mold itself.

Right.

So I hope you could kind of elaborate on that.

Yeah. Think of it like bending A paperclip back and forth repeatedly. Right, right. Eventually it breaks due to what we call fatigue.

Right.

And it's similar with molds. You know, uneven pressure creates these, what we call stress concentrations, essentially weak points in the steel.

I see.

And over time, those microscopic cracks that you can't even see with the naked eye can propagate and lead to catastrophic mold failure.

Oh, wow. So, I mean, they mentioned that improper parting surface angles can actually make this whole thing worse. So how does the angle play into this pressure distribution?

Well, the angle really dictates how the force of that injected plastic is distributed across the mold surface.

Okay.

So a well designed angle ensures that pressure is evenly spread, minimizing those stress concentrations. Inversely, an improper angle can lead to pressure spikes in certain areas, and that accelerates the formation of those microscopic cracks.

So it's like designing a bridge. You need to distribute the weight evenly to prevent any one point from, you know, collapsing.

Precisely. It's all about structural integrity and understanding how those forces interact. Right. And in the case of, you know, these complex multi part molds, managing those forces becomes even more critical.

Oh, I bet.

The source actually mentioned some techniques used to address this, like strategic placement of ejector pins and the use of conformal cooling channels, things like that.

Yeah. Well, that actually brings up a point I was curious about, because they mentioned something called fretting, and I wasn't exactly sure what that meant. So you could you kind of explain how that phenomenon ties into what we've been discussing?

Yeah. So fretting is a fascinating phenomenon where microscopic wear occurs due to these tiny repetitive movements between surfaces that are in contact. So think of two pieces of sandpaper rubbing together, but on an incredibly small scale. Now, in injection molding, if the parting surface fit isn't perfect, those tiny gaps we were talking about allow for movement between the mold halves during each cycle. And so that leads to fretting, which gradually erodes the surface, compromises the seal, and ultimately impacts the mold's lifespan.

So even movements we can't even see can have a significant impact over thousands of cycles. That's pretty crazy.

Exactly. And that's why, as we've been discussing, achieving that perfect fit through a well designed parting surface angle is absolutely critical. It minimizes flash, reduces friction during demolding, ensures even pressure distribution, and helps to mitigate fretting.

Right.

It's truly the cornerstone of mold longevity.

And, you know, they go into detail about the economic impact of moldware, and I can imagine it gets pretty expensive. So can you elaborate on how those Seemingly minor issues translate into real world costs for manufacturers.

Absolutely. Premature mold failure can be incredibly expensive. You're talking about downtime for repairs or even complete mold replacement. Then there's the potential for compromised quality.

Oh, yeah.

Which leads to rejected parts and customer dissatisfaction. All of these factors contribute to increased costs and reduced efficiency.

Yeah. So it's not just about the initial investment in the mold itself. It's about the long term costs associated with keeping it running smoothly and for as long as possible.

Precisely. That's why understanding the factors that affect mold life, particularly the critical role of the parting surface angle, is so important from both a technical and a financial standpoint.

This is all fascinating, but before we move on, I'd like to ask about something else. They touched upon how material selection factors into mold during durability. It seems intuitive that the type of steel would matter. But what are manufacturers looking for when they're selecting materials for these molds?

Yeah, you're absolutely right. Material selection is crucial when it comes to mold durability. Think of it as choosing the right foundation for a building. You need something strong, reliable, and able to withstand the elements.

Yeah. So it's not as simple as just picking any steel. What makes a specific type of steel better suited for this kind of extreme environment? What are the key properties that they consider?

It's a combination of factors. Hardness is key, as the mold needs to resist wear from the constant injection and ejection of plastic.

Right.

High temperature resistance is another factor is that mold and plastic can reach incredibly high temperatures. And of course, the steel needs to have excellent tensile strength to withstand the immense pressures involved.

It sounds like it needs to be like superhuman. Are there specific types of steel that are commonly used?

There are tool steels, specifically those designed for hot work applications are the go to Choice. Grades like H13, P20, and D2 are popular due to their balance of hardness, toughness, and heat resistance.

Okay.

But the choice ultimately depends on the specific application factors like the type of plastic being molded, the complexity of the part, and the production volume all play a role.

And they also mentioned something about special coatings and treatments that can enhance a steel's properties. Is that common practice?

Absolutely. It's like giving the mold a suit of armor, adding an extra layer of protection.

Okay.

Treatments like nitriding and PVD coating are frequently used to improve surface hardness, reduce friction, and even enhance corrosion resistance.

Wow.

These coatings essentially create a barrier between the mold steel and the molten plastic, prolonging the mold's lifespan.

So we've got the right Materials. Now, what can manufacturers do to ensure that these expensive molds last as long as possible? Because they talk about maintenance quite a bit.

Yeah, Maintenance is absolutely essential. It's like taking your car in for regular checkups. You're looking for potential problems before they become major issues.

Right.

Regular cleaning is crucial to remove any residual plastic or contaminants that could accelerate where Proper lubrication is another key factor. It ensures smooth operation and reduces friction between moving parts.

And they also highlight the importance of polishing the mold surfaces.

Right.

I can see how that might improve the finish of the plastic parts, but does it also affect mold durability?

It does. Polishing serves a dual purpose. It creates a smooth mirror like finish on the mold cavity, which not only improves the aesthetics of the final plastic part, but also reduces the risk of sticking in wear. Oh, it's like buffing out a scratch in your car. You're removing imperfections that could trap plastic or cause friction during the molding.

So well polished mold is like a well oiled machine. Everything runs smoothly and efficiently.

Precisely. And speaking of running smoothly, the source also emphasizes the importance of proper training for the people operating and maintaining these molds.

Yeah.

After all, even the most durable mold can be compromised by improper handling.

Oh, for sure. It's like having a skilled surgeon operating with, you know, precision tools. You need someone who understands the intricacies of the equipment and can execute the procedures flawlessly.

That's a great analogy. Trained technicians are crucial. They understand the nuances of the injection molding process, know how to set parameters correctly, identify potential problems early on, and perform preventative maintenance tasks effectively.

So it sounds like investing in training is a pretty smart move.

Absolutely. It's about empowering the people on the front lines to make informed decisions and take proactive measures to extend mold life. And that brings us to another fascinating aspect mentioned in the source. The concept of venting.

Venting. I'm not quite picturing what that means in the context of injection molding.

So imagine molten plastic rushing into a mold cavity at high speed. It's displacing air, and if that air can't escape quickly enough, it gets trapped, creating pressure pockets that can lead to defects in the final part. Venting is all about strategically incorporating tiny channels into the mold design to allow that trapped air to escape.

So it's like a pressure release valve, ensuring that the plastic fills the mold completely and evenly without any unwanted air bubbles or voids.

Exactly. Proper venting is essential for both part quality and mold longevity. Those pressure pockets not only affect the appearance and structural integrity of the plastic part, but also put additional stress on the mold itself, Potentially leading to cracks or premature wear.

And they briefly mentioned something about hot runner systems in relation to venting. Are those related?

You're very observant. They're related. A hot runner system is essentially a network of heated channels that keeps the molten plastic at a consistent temperature before it's injected into the mold cavity.

Oh, okay.

This not only improves the flow of the plastic, but also helps to eliminate the need for sprues and runners, those extra bits of plastic that need to be trimmed off after molding.

Right.

Hot runner systems often incorporate strategically placed vents, Further enhancing the venting process and ensuring optimal part quality and mold protection.

So it sounds like hot runner systems are kind of a win win. They improve efficiency, reduce waste, and contribute to mold longevity.

They're definitely a valuable tool in the injection molder's arsenal.

And speaking of tools, the source you provided Also touches on some really interesting future trends in the world of injection molding.

Oh, yeah. It mentioned some advancements in materials and technology that could further enhance mold life and part performance.

It did. One area that's particularly exciting Is the development of new mold materials that are even tougher and more resistant to wear.

For example, we're seeing a rise in the use of powder metallurgy steels. Okay. These steels are incredibly strong and durable thanks to their unique microstructure.

So it's like taking those suit of armor coatings to the next level. The steel itself is becoming even more resilient.

Precisely.

Yeah.

And we're also seeing advancements in surface treatments like laser cladding, which can create even harder and more wear resistant surfaces on molds.

It's like those sci fi movies where they're creating these super strong materials in labs. Except this is real life, and it's impacting manufacturing.

It's a testament to the constant innovation happening in materials science. And these advancements are not only extending mold life, but also enabling the production of more complex and intricate plastic parts, Pushing the boundaries of what's possible with injection molding.

That's wild. So stronger materials are one piece of the puzzle. What else is on the horizon?

There are some incredibly exciting developments in the realm of mold design and manufacturing. For instance, the use of computer aided engineering, or cae, is becoming increasingly sophisticated. With cae, engineers can simulate the injection molding process, Virtually identifying potential issues related to pressure distribution, Cooling rates, and mold filling Before a physical mold is even built.

So it's like a virtual test run, Allowing engineers to Fine tune the mold design and optimize performance before committing to expensive tooling.

Exactly. This not only speeds up the design process, but also helps to prevent costly mistakes and rework down the line. And speaking of speed, another trend that's gaining traction is the use of 3D printing for mold making.

I've heard about 3D printing, but I'm not sure I understand how it applies to something as complex as injection molding.

Yeah, 3D printing or additive manufacturing is revolutionizing the way molds are made.

Okay.

It's particularly well suited for creating complex geometries and prototypes, allowing for faster turnaround times and greater design freedom.

I see.

Are you building a mold layer by layer from a digital design? Yeah. It opens up a world of possibilities for intricate features and custom designs.

So it's not just about making molds faster, it's about expanding the design possibilities for the parts themselves.

Precisely. And as 3D printing technology continues to evolve, we can expect to see even more innovative applications in the realm of injection molding.

This is all so fascinating. It's amazing to think about how technology is not only improving the efficiency and durability of molds, but also pushing the boundaries of what's possible in terms of design and functionality.

It's a truly exciting time to be involved in this industry. And speaking of excitement, the source also delves into some of these sustainability efforts taking place in the world of injection molding.

Yeah, we touched on the use of bio based plastics earlier, but they hinted at some larger trends towards eco friendly practices. So I'm curious to hear more about that.

Well, it seems like sustainability is becoming a major focus in a lot of industries these days, and injection molding is no exception.

Yeah, it seems like it's really becoming important, and I'm curious to hear how it's being implemented. What are some of the key initiatives?

One of the biggest areas of focus is energy consumption. Injection molding traditionally requires a lot of energy for heating and cooling, but there's a real push towards making the process more efficient.

So it's about optimizing those existing processes to use less energy. What does that look like in practice?

Well, we're seeing advancements in machine technology, like all electric molding machines that offer significant energy savings compared to their hydraulic counterparts. There's also a focus on optimizing process parameters, like using precise temperature control and minimizing cooling times to reduce energy consumption without sacrificing quality.

And they also mention alternative energy sources. Is that something that's being explored?

It is. There's a growing trend towards incorporating renewable energy sources into manufacturing facilities.

Okay.

So solar panels on factory rooftops, for instance, can help offset a portion of the energy demands and reduce reliance on fossil fuels.

That's great. So it seems like kind of a multifaceted approach is needed to really make a difference. What about the issue of plastic waste? That's something consumers are increasingly concerned about.

You're right. Plastic waste is a major concern and the industry is taking steps to address it. One approach is simply reducing the amount of material used in the first place.

Okay.

This can involve designing parts that are lighter and more efficient, or optimizing the molding process to minimize scrap.

So being more resourceful with the materials used in the first place, what about the waste that is generated? Is recycling a viable option for injection molding?

Recycling is a huge area of focus.

Okay.

Many manufacturers are implementing closed loop systems where they collect and reprocess their own plastic scrap, Turning it back into raw material for new parts. And we're also seeing advancements in the development of more easily recyclable plastics designed with end of life in mind.

So kind of creating a circular economy for plastics, Minimizing waste and reducing reliance on virgin materials. That's fantastic. And they also touched on biodegradable plastics. Is that a realistic alternative for these kinds of applications?

Biodegradable plastics are definitely gaining traction, Especially for single use applications or products designed for shorter lifespan. However, there are still challenges to overcome in terms of cost and performance of some of those more demanding applications. But research and development in this area is ongoing and we're seeing some promising innovations.

It sounds like the industry is really trying to move towards these more sustainable solutions. It's not just about making the molds last longer. It's about making the entire process more environmentally responsible.

Exactly. And it's not just about materials and manufacturing processes. Design plays a crucial role too. Designers are increasingly thinking about the entire life cycle of a product, from material selection to end of life disposal.

Right. So considering how a part can be disassembled or recycled more easily, it's like designing for sustainability right from the get go.

Precisely as a holistic approach that's becoming increasingly important. And it's not just driven by ethical considerations. There are economic benefits as well. Well, as consumers become more environmentally conscious, they're choosing products and brands that align with their values. So companies that embrace sustainability are not only doing the right thing for the planet, but also positioning themselves for success in a market that increasingly demands these kinds of eco friendly solutions.

So it makes good business sense then, to be proactive about implementing these sustainable practices.

Absolutely. And it's not just about staying ahead of the curve. It's about being responsible stewards of the resources we have and ensuring a healthier planet for future generations.

This has been such an incredible deep dive. We've gone from the microscopic level of parting surface angles to the global impact of sustainable manufacturing practices. I feel like I've gained a whole new appreciation for injection molding.

It's a field that's often overlooked, but as you've seen, it's full of innovation, complexity and a real commitment to progress.

Well, I want to thank you for sharing your expertise with us. You've made these complex topics so accessible and engaging.

The pleasure was all mine. I'm always thrilled to share my passion for engineering and to shed light on the incredible world of manufacturing.

And to our listener, we hope this deep dive has been insightful and inspiring. Keep those questions coming, keep exploring and keep marveling at the ingenuity that surrounds us.

Until next time, happy