Have you ever wondered how your eyeglasses are meticulously crafted?

Plastic injection molding machines create eyeglass frames by melting materials and injecting them into molds for lightweight, durable shapes. Lenses, however, require casting or grinding for optical precision.

I remember the first time I learned about plastic injection molding—sitting in a factory, mesmerized by the machines that seemed almost magical. Just like crafting eyeglasses, these machines need to be precise in mold design, capturing every detail from the rims to the temples. It’s incredible how materials like polycarbonate are chosen not just for their strength, but also for their ability to transform into something so sleek and durable.

And while frames come to life through this process, lenses have their own story. They often take a different path, needing methods like casting or polishing to meet their exact optical standards. It’s a journey from raw material to a piece of functional art resting on our noses.

Eyeglass lenses are made using plastic injection molding.False

Lenses are typically made through other methods for optical precision.

Injection molding ensures eyeglass frames are lightweight.True

The process uses precise molds to create lightweight, durable frames.

Why is mold design crucial in making eyeglass frames?

Imagine the world of eyeglass frames without precise mold design—chaos, right?

Mold design is essential for eyeglass frames production, enabling precise shaping and high-quality results by capturing intricate details for efficient injection molding, resulting in perfect frames.

The Precision of Mold Design

Let me share a little story from when I was knee-deep in designing my first mold. Back then, I was so focused on getting those intricate details just right—the rims, temples, and decorative touches—that I felt like an artist sculpting a masterpiece. It’s all about precision. Each mold is like a blueprint for the final product, and when done right, it can accommodate multiple frame components1 simultaneously, streamlining the entire process.

Material Selection in Mold Design

I remember my first encounter with cellulose acetate—it felt like discovering a new color in the artist’s palette. But the real game-changer was polycarbonate (PC). Lightweight yet durable, PC offers versatility and resilience, essential for creating eyeglass frames that are not only functional but stylish. Imagine wearing frames that feel as if they’re barely there yet can withstand the little accidents of everyday life. That’s the magic of choosing the right material.

| Material | Benefits |

|---|---|

| Cellulose Acetate | Traditional look, customizable colors |

| Polycarbonate | Lightweight, durable, complex shapes |

| Nylon | Flexible, resistant to stress and fatigue |

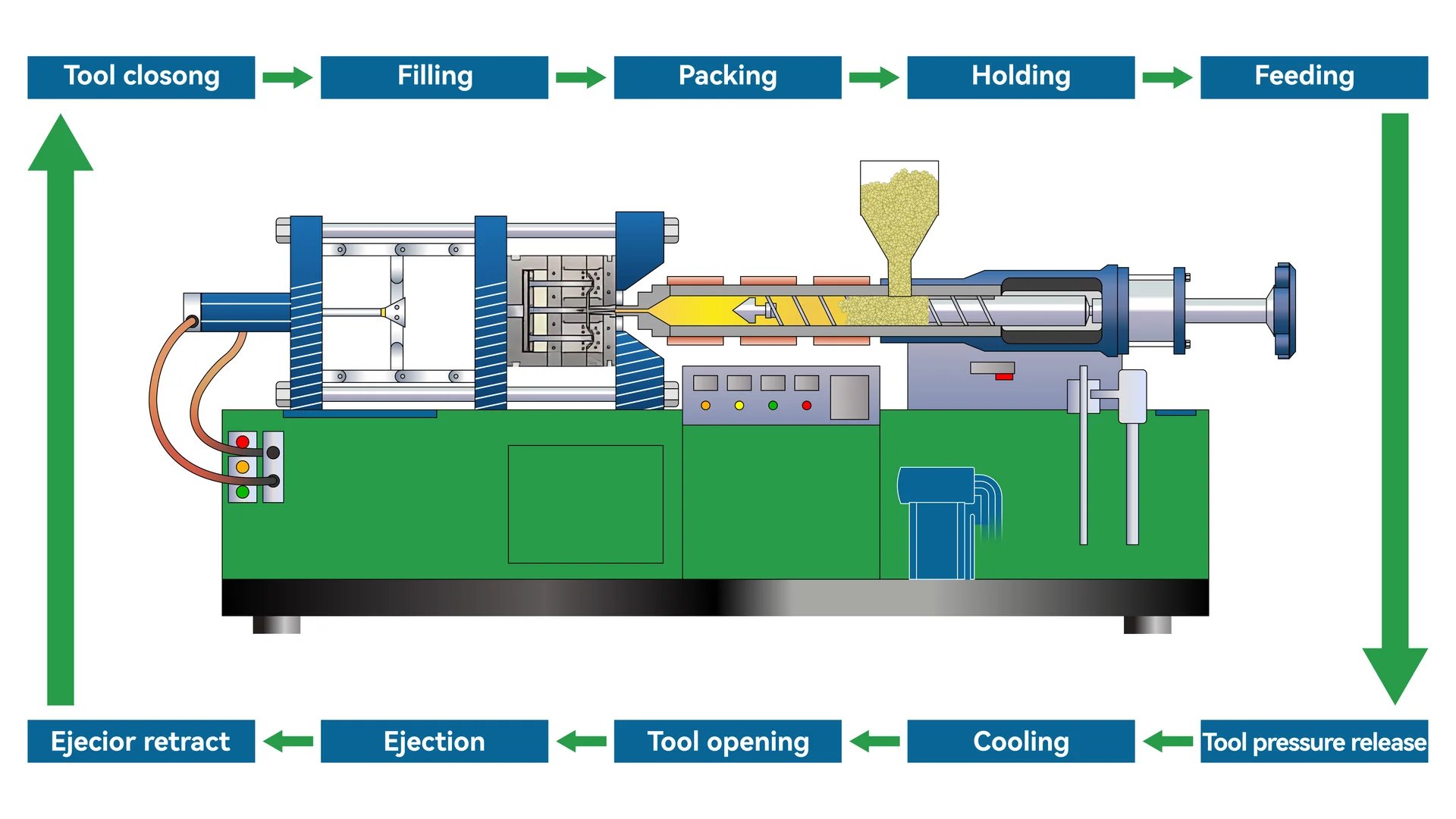

The Injection Molding Process

The thrill of watching plastic transform into a solid frame never gets old. The process starts with feeding plastic into the machine—a bit like loading ingredients into a blender. It melts down, gets injected into those perfectly crafted mold cavities, and after a bit of cooling and pressure-holding magic, out pops the frame. Every time I see it happen, it reminds me of baking a cake; you mix, you wait, and voila!—a perfect outcome.

For those curious about plastic injection molding machines2, understanding their role can significantly enhance production outcomes.

Beyond Frame Production: Additional Considerations

While molds are essential for crafting frames efficiently, lenses are a whole other story. They undergo processes like casting or grinding to meet precise optical standards. After molding, there’s still plenty to do—polishing those frames to perfection or adding textures for that unique touch. And of course, assembling everything together so each piece fits comfortably and looks just right is crucial.

If you’re as fascinated by this as I am, diving into lens production techniques3 reveals even more about the intricate world of eyewear manufacturing.

Mold design affects the durability of eyeglass frames.True

Precision in mold design ensures frames can withstand stress and usage.

Cellulose acetate is the lightest material for eyeglass frames.False

Polycarbonate is lighter than cellulose acetate, offering more comfort.

Why Is Material Selection Critical in Manufacturing Eyeglass Frames?

Picking the right materials for eyeglass frames goes beyond just looking good—it’s about creating something durable, comfortable, and functional. Let me take you through why the material choice is crucial in manufacturing eyeglass frames and how it shapes the quality of the final product.

Material selection for eyeglass frames is crucial as it impacts durability, comfort, and style. Materials like cellulose acetate and polycarbonate affect the frame’s weight, flexibility, and appearance, offering distinct benefits.

Understanding the Impact of Material Selection

Every time I pick up a pair of eyeglasses4, I’m reminded of how material selection defines their character. Imagine holding a frame that feels just right—not too heavy, not too flimsy—and complements your style with its vibrant hues. That’s what cellulose acetate can offer: a glossy finish with endless color possibilities. It’s a favorite for those who love to make a fashion statement but don’t mind a bit more heft.

Popular Materials in Eyeglass Frame Manufacturing

- Cellulose Acetate: It’s like the chameleon of eyeglass materials. You can mold it into any color or pattern imaginable, and it’s kind on sensitive skin. If you’ve ever had a frame that didn’t irritate your skin, you might owe it to this hypoallergenic wonder.

- Polycarbonate (PC): If you’ve ever dropped your glasses only to find them intact, you might have polycarbonate to thank. It’s lightweight and resistant to impacts—perfect for those of us who lead active lives or are just plain clumsy.

- Nylon: This one’s for the athletes or anyone who needs eyewear that bends without breaking. It’s not only flexible and durable but also resists the wear and tear of harsh environments.

| Material | Key Features |

|---|---|

| Cellulose Acetate | Glossy finish, colorful, hypoallergenic |

| Polycarbonate | Impact-resistant, lightweight |

| Nylon | Flexible, durable |

The Role of Mold Design in Frame Production

When I delve into mold design for frames, I think about precision—each curve and edge meticulously planned to bring out details that captivate the eye. A precise mold means every aspect, from those tiny rims to the hinges5 that pivot with ease, is crafted to perfection.

- Injection Molding Process: Here’s where the magic happens. Imagine molten plastic flowing into a mold with precision—this is where high-quality frames are born quickly and efficiently.

Limitations and Additional Considerations

Injection molding works wonders for frames but not so much for lenses. These require more delicate processes like casting or grinding for that crystal-clear view we all need. Once frames come out of the mold, they undergo assembly and finishing steps to ensure they fit snugly and look impeccable.

Choosing the right material affects everything from design6 aesthetics to how efficiently frames can be produced. Knowing these impacts helps manufacturers like me meet both customer expectations and production goals.

Cellulose acetate is heavier than polycarbonate.True

Cellulose acetate offers a glossy finish but is heavier than polycarbonate.

Nylon frames are not suitable for sports eyewear.False

Nylon is flexible and durable, making it ideal for sports eyewear.

How Does the Injection Molding Process Work for Eyeglasses?

Ever wondered how those chic eyeglass frames you wear every day are made? Let me take you behind the scenes of injection molding—a fascinating process that combines precision and creativity to craft eyewear that’s both durable and stylish.

Injection molding for eyeglasses uses precise molds and materials like polycarbonate to shape frame components by injecting melted plastic, ensuring durable and fashionable results.

Understanding the Injection Molding Process

When I first learned about the injection molding7 process for eyeglasses, I was amazed at the level of detail involved. Imagine crafting a mold that captures every little nuance of an eyeglass frame—from the rims that snugly hold your lenses to the temples that rest comfortably on your ears. Every decorative feature needs to be accounted for, and it’s quite the dance of precision. These molds often feature multiple cavities, allowing for simultaneous production of several components.

| Frame Component | Details |

|---|---|

| Rims | Hold lenses securely |

| Temples | Rest on ears |

| Nose Pads | Ensure comfort |

Material Selection

I remember my first project where I had to select materials, and it was like choosing the right fabric for a perfect outfit. While cellulose acetate is popular, I found that injection-moldable plastics such as polycarbonate or nylon offer great advantages. Polycarbonate is a favorite—its lightweight nature and impact resistance make it ideal for frames that need to withstand daily wear and tear while still looking sleek.

The Molding Process

The excitement really kicks in when the plastic is fed into the injection molding machine8. Watching it melt and then get injected into those meticulously designed mold cavities under pressure is like witnessing a transformation. Holding pressure ensures every nook and cranny of the mold is filled, compensating for any shrinkage as the material cools. Once the plastic solidifies, it’s almost magical to see the frame components pop out, ready for the next steps.

Beyond Frames: Limitations and Additional Considerations

One thing I’ve come to appreciate is that while injection molding is fantastic for frames, lenses are a whole different story. Their precise optical properties mean they’re usually crafted through casting or grinding. This makes sense once you’ve seen how even slight imperfections can alter vision.

The assembly and finishing stages bring their own set of challenges. Surface finishing, hinge assembly, and lens fitting all require a careful hand. Sometimes adjustments are necessary to ensure everything fits just right on the face.

Practical Applications in Eyewear Production

In my experience, the injection molding process is a game-changer for producing high-quality, intricate eyeglass frames efficiently. It’s no surprise designers like Jacky9 can strike that perfect balance between style and function using this method.

With advanced CAD tools10, we can optimize designs for manufacturing, ensuring that each pair of glasses isn’t just a visual masterpiece but also structurally sound. It’s a thrill to see how these tools transform creative ideas into wearable art.

Injection molding is used for eyeglass lenses.False

Eyeglass lenses require precise optical properties, often made by casting.

Polycarbonate is favored for eyeglass frames due to clarity.True

Polycarbonate offers clarity and can be molded into intricate shapes.

What Are the Limitations of Using Injection Molding for Eyewear?

Ever wondered why injection molding, despite its popularity, isn’t the go-to for every aspect of eyewear production? Let’s dive into its limitations and explore what that means for designers like you and me.

Injection molding for eyewear is limited by high initial costs, difficulty achieving precise lens optics, and material constraints. Frames are easily made, but lenses need alternative methods for clarity and precision.

High Initial Costs and Investment

I remember when I first learned about injection molding; the sheer scale of investment needed was eye-opening. It’s not just about buying a machine—it’s about the customized molds11 and specialized equipment that come with it. For smaller producers, this can feel like climbing Everest without the right gear.

| Cost Component | Description |

|---|---|

| Mold Design | Custom designs for each frame type are required. |

| Machine Setup | Specialized equipment for precision is needed. |

It’s essential to really think about whether your production scale can justify these expenses before diving in.

Lens Production Challenges

While injection molding shines in crafting intricate frames, lenses are another ball game entirely. Picture this: you’re trying to mold something as precise as a telescope lens—it’s just not feasible. Lenses often call for methods like casting or grinding and polishing12 to achieve the clarity and precision needed.

- Precision Needs: Achieving optical clarity through molding is a tough challenge.

- Alternative Methods: Lenses are typically made through casting or grinding for that perfect finish.

Material Limitations

Not all materials make the cut when it comes to injection molding. Take polycarbonate or nylon, for example—they’re great for many uses but might not deliver the premium feel some eyewear demands13.

- Material Selection: Limited options that can be molded without sacrificing durability or clarity.

- Aesthetic Concerns: Getting that high-end look can be tricky with standard plastics.

Assembly and Finishing Complexities

Once frames are molded, the real work begins. Remember my first assembly project? Each hinge and finishing touch felt like a puzzle piece needing careful placement. This manual labor increases costs and can stretch timelines.

- Assembly: Requires a lot of manual work, upping labor costs.

- Finishing Touches: Essential for a smooth finish and proper fit.

These steps can complicate and lengthen the production cycle, impacting efficiency and cost-effectiveness. Exploring alternatives or enhancements in these areas could lead to better results in the eyewear industry14.

Injection molding is cost-effective for small-scale eyewear producers.False

High initial costs make injection molding prohibitive for small-scale producers.

Injection molding is ideal for creating optical lenses.False

Precision needed for lenses is challenging to achieve with injection molding.

Conclusion

Plastic injection molding machines create eyeglass frames by melting materials like polycarbonate and injecting them into molds, ensuring lightweight, durable designs while lenses require different production methods for optical precision.

-

Explore detailed information about various frame components crucial in eyewear production. ↩

-

Understand how these machines enhance production efficiency in manufacturing industries. ↩

-

Gain insights into advanced methods used to produce high-quality lenses for eyeglasses. ↩

-

Explore different materials used in eyeglass frames to understand their benefits and limitations. ↩

-

Learn how precision in mold design enhances the quality and functionality of eyeglass frames. ↩

-

Discover how choosing the right materials impacts product design and manufacturing outcomes. ↩

-

Learn about the initial stages of designing molds for eyeglass frames. ↩

-

Understand the mechanics behind injection molding machines used in eyewear production. ↩

-

Explore professionals who excel in designing eyewear using modern techniques. ↩

-

Discover essential software that enhances design efficiency for injection-molded products. ↩

-

Learn about the financial implications of creating custom molds in injection molding. ↩

-

Discover methods to achieve high optical precision in lens production. ↩

-

Explore materials that elevate the quality and aesthetics of eyewear frames. ↩

-

Understand broader production challenges faced by the eyewear industry. ↩