Picture a world where one material fits many uses – that’s nylon in injection molding.

Nylon is prized for its excellent mechanical strength, abrasion resistance, and low frictional properties in injection molding. Different types of nylon, such as Nylon 6, 66, and others, offer varied benefits like heat resistance and low water absorption, influencing their application.

Knowing the basic traits of nylon is important. But looking at each kind more closely offers detailed knowledge useful for specific uses. We should see how various nylons differ in performance and how they need to be processed.

Nylon 6 has a higher melting point than Nylon 66.False

Nylon 6 liquefies at about 220°C. Nylon 66 softens at roughly 260°C.

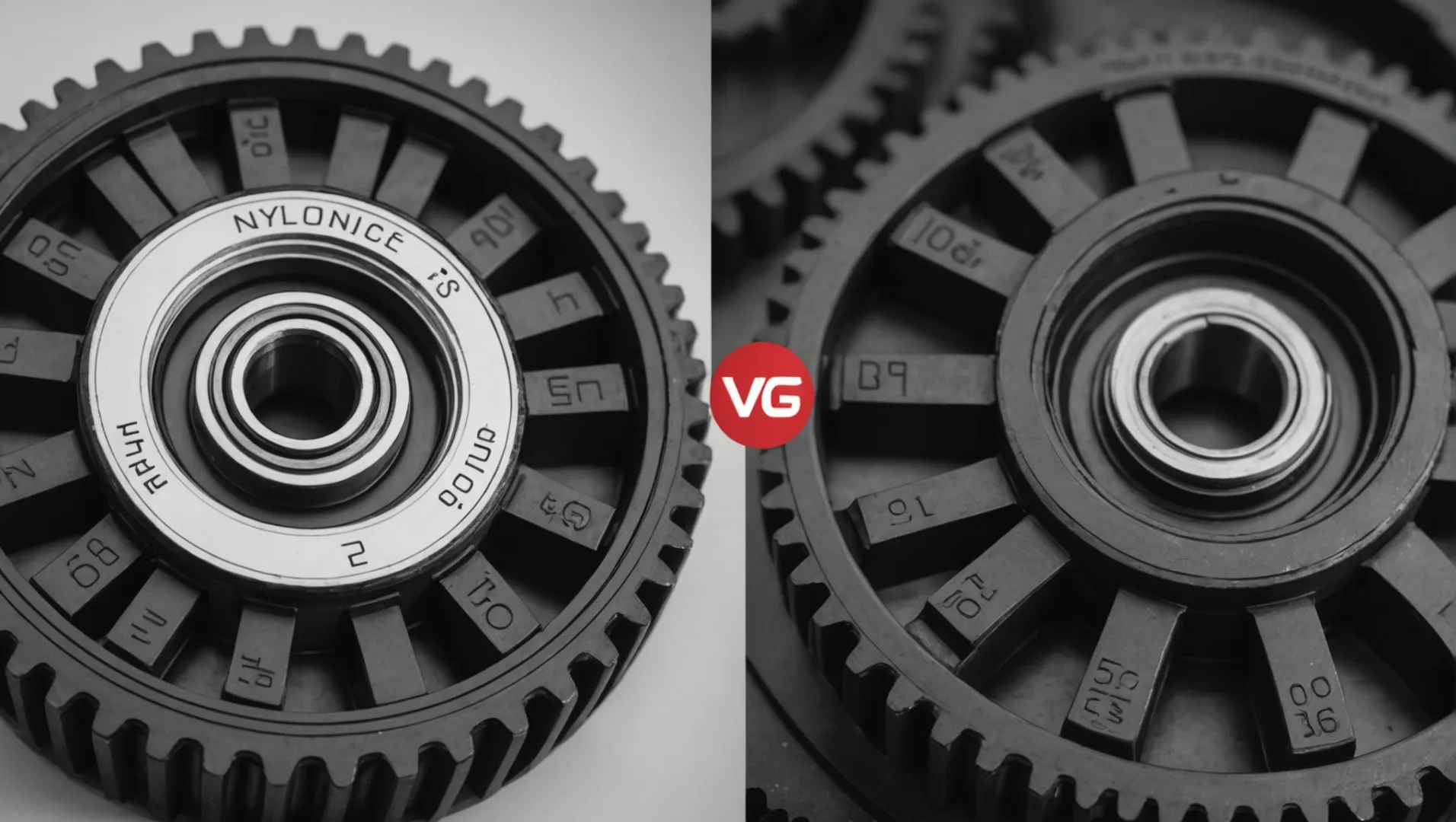

How Does Nylon 6 Compare to Nylon 66?

Nylon 6 and Nylon 66 are two popular materials used by many industries. But what differentiates them?

Nylon 6 and Nylon 66 differ primarily in their melting points, mechanical properties, and water absorption rates. Nylon 6 is easier to process due to a lower melting point, while Nylon 66 offers superior strength and temperature resistance. These distinctions determine their suitability for different applications.

Mechanical Properties

Nylon 6 boasts high strength and toughness, making it a popular choice in applications where flexibility is key. Its tensile and bending strengths are robust, but it lacks the rigidity of Nylon 661.

Nylon 66, on the other hand, provides higher strength and hardness. Its increased rigidity makes it suitable for more demanding applications that require a sturdier material.

Thermal Properties

The thermal differences between these nylons are significant:

- Nylon 6 has a lower melting point around 220°C, which eases processing but limits its high-temperature applications.

- Nylon 66 melts at a higher temperature of approximately 260°C, allowing it to withstand harsher thermal environments.

These characteristics make Nylon 66 preferable for parts exposed to higher heat.

Water Absorption

Both types of nylon absorb moisture, but Nylon 6 tends to have a higher rate. This can lead to dimensional changes in humid conditions, affecting performance.

In contrast, Nylon 66 absorbs slightly less moisture, improving its dimensional stability. This property makes it ideal for precision parts that need consistent performance across various environments.

Processability and Applications

- Nylon 6: Easier to process due to its lower melting point. Suitable for injection molding and extrusion processes.

- Nylon 66: Requires higher processing temperatures and pressures but delivers superior performance under stress.

Application Examples:

| Property | Nylon 6 Application | Nylon 66 Application |

|---|---|---|

| High Strength | Automotive components | Industrial gears |

| Thermal Resistance | Consumer goods | High-temperature fittings |

| Moisture Sensitivity | Textile industry | Precision engineering |

Understanding these differences helps manufacturers choose the right nylon for their specific needs, balancing processing efficiency with performance requirements. For more detailed guidance on specific uses, explore nylon material applications2.

Nylon 6 has a higher melting point than Nylon 66.False

Nylon 6 liquefies at about 220°C, which is lower than Nylon 66's 260°C.

Nylon 66 absorbs less moisture than Nylon 6.True

Nylon 66 possesses superior shape stability as it absorbs less moisture.

What Are the Thermal Properties of Different Nylon Types?

Nylon has different warmth traits depending on its type. These differences influence how each type works in various situations.

The thermal properties of nylon types differ mainly in melting point, glass transition temperature, and heat resistance. For instance, Nylon 6 and 66 have relatively lower melting points compared to specialized nylons like 6T and 9T, which can withstand higher temperatures, making them suitable for demanding applications.

Overview of Thermal Properties

Nylons are types of polyamides known for their great thermal stability. However, their thermal properties change a lot between different nylon types due to their distinct molecular structures. These differences change how suitable they are for various industrial purposes.

Melting Point Comparison

The melting point is important in deciding a nylon’s thermal performance3. Here is a comparison of melting points among different nylon types:

| Nylon Type | Melting Point (°C) |

|---|---|

| Nylon 6 | 215-225 |

| Nylon 66 | 260-265 |

| Nylon 11 | 190 |

| Nylon 12 | 180 |

| Nylon 46 | High (not specified) |

| Nylon 6T | 370 |

| Nylon 9T | High (not specified) |

| Nylon 10T | 316 |

This table shows the wide range of melting points, explaining why some nylons are chosen for high-temperature uses. For instance, Nylon 6T, with its high melting point, is often found in car parts that need strong heat resistance.

Glass Transition Temperature

The glass transition temperature (Tg) is another key part of a nylon’s thermal properties. It shows the temperature range where the material turns from hard and glass-like to soft and rubbery. Nylons with higher Tg are often better for places where mechanical stability in heat is very important.

| Nylon Type | Glass Transition Temperature (°C) |

|---|---|

| Nylon 6 | 48 |

| Nylon 66 | 65 |

| Nylon 6T | 180 |

| Nylon 9T | 125 |

Heat Resistance and Continuous Use Temperature

The continuous use temperature shows how well a nylon functions under constant heat without losing quality. It is crucial for uses that need long exposure to high temperatures. Aromatic nylons like PA6T and PA9T offer excellent long-term heat resistance, suitable for electronics and automotive4 purposes.

Analyzing Application Suitability

Each nylon type’s thermal characteristics determine their ideal use:

- Nylon 6 and 66: Good for general use, but they have lower heat resistance than aromatic nylons.

- Nylon 11 and 12: Best for low-temperature uses due to their lower melting points and great flexibility.

- Aromatic Nylons (e.g., PA6T, PA9T): Chosen for high-performance needs that require strong thermal stability.

Knowing these thermal properties helps engineers and designers pick the correct nylon type for specific needs, probably leading to better performance and longer use.

Nylon 6T has the highest melting point among nylons.True

Nylon 6T melts at 370°C. This is hotter than other nylons.

Nylon 11 is suitable for high-temperature applications.False

Nylon 11 melts at a low temperature of 190°C. It is not good for high temperatures.

How Does Water Absorption Affect Nylon Molding?

Nylon absorbs water, which probably changes its properties and affects how suitable it is for different uses.

Water absorption in nylon can lead to dimensional changes, mechanical property shifts, and processing challenges. Types like Nylon 6 and 66 absorb more moisture, affecting their strength and rigidity, while others like Nylon 11 and 12 maintain stability due to lower absorption rates.

Understanding Water Absorption in Nylon

Water absorption is a critical factor in nylon molding as it directly impacts the material’s properties and performance. Most nylons are hygroscopic, meaning they tend to absorb moisture from the environment, which can lead to various changes in their physical properties.

Impact on Mechanical Properties

The absorbed water acts as a plasticizer within the nylon matrix. This leads to a reduction in tensile strength and rigidity but improves flexibility and toughness. For instance, Nylon 65 and Nylon 666 are known for their high water absorption, which can result in noticeable changes in mechanical properties when exposed to humid conditions.

| Property | Dry State | Saturated State |

|---|---|---|

| Tensile Strength | High | Reduced |

| Flexibility | Moderate | Improved |

| Rigidity | High | Reduced |

Dimensional Stability

Water absorption causes nylon to swell, leading to dimensional changes. This is particularly important in applications where precision is crucial. Materials like Nylon 117 and Nylon 128 exhibit lower water absorption, offering better dimensional stability compared to their counterparts.

Processing Considerations

When it comes to molding, the moisture content of nylon must be carefully controlled. Excess moisture can lead to defects such as splay marks or bubbles in the final product. Pre-drying is often necessary, especially for high-absorption types like Nylon 6 and 66, to ensure quality and prevent hydrolysis during processing.

Comparing Different Nylon Types

Each type of nylon has unique water absorption characteristics that dictate its use in various applications:

- Nylon 6: High water absorption; requires pre-drying; used where toughness is key.

- Nylon 66: Slightly less absorption than Nylon 6; excellent strength when dry.

- Nylon 11 and Nylon 12: Low water absorption; suitable for precision parts.

Understanding these differences helps manufacturers choose the right type of nylon for specific applications, balancing between mechanical performance and environmental stability.

Nylon 6 absorbs more water than Nylon 11.True

Nylon 6 absorbs a lot of water. Nylon 11 absorbs little water.

Water absorption increases nylon's tensile strength.False

Water absorption lowers nylon's pulling strength by behaving as a softener.

What Are the Processing Considerations for Aromatic Nylon?

Aromatic nylon is unique in polymer engineering. It needs special attention during processing.

Processing aromatic nylon demands high temperatures, specialized equipment, and precise control over parameters such as injection pressure and mold temperature to maintain its superior mechanical properties.

High-Temperature Needs

Aromatic nylon requires very high temperatures for processing compared to other nylons. Injection temperatures usually range between 300°C and 350°C. This heat is important for proper flow and fill during molding. Machinery used must operate well at these high temperatures, so it’s necessary to invest in strong equipment.

| Parameter | Typical Range |

|---|---|

| Injection Temperature | 300°C – 350°C |

| Mold Temperature | 150°C – 200°C |

Special Equipment Needs

Due to the high heat, special machines for injection molding are often needed. These machines handle high temperatures and have strong parts for repeated use. Aromatic nylon absorbs little water, so drying before processing is not needed, which simplifies preparation.

Exact Process Control

Exact control of process details is very important with aromatic nylon. Injection pressure, speed, and time must be controlled closely to prevent problems like empty spaces or incomplete parts. Keeping the mold temperature high (150°C to 200°C) is important for the final product’s strength and quality.

With its high strength, aromatic nylon is chosen for uses where excellent wear resistance and durability are needed. It’s used in areas like automotive and electronics, where strong materials offer many benefits.

Challenges in Processing

Despite its good qualities, processing aromatic nylon has challenges. Its high melting point might degrade the material during molding if not managed well. Operators should prevent oxidation and breaking down during processing. Regular equipment checks and strict quality controls help reduce these risks.

Understanding these special needs helps in using aromatic nylon better in various industrial areas. For those wanting to learn more about different types of nylon9 and how they perform, many resources explain the benefits and challenges of each type.

Aromatic nylon requires high injection temperatures of 300°C-350°C.True

Aromatic nylon needs high heat for good movement and filling.

Specialized equipment is unnecessary for processing aromatic nylon.False

High heat needs special machines.

Conclusion

Selecting the suitable nylon increases project efficiency and performance. Consider application needs to improve nylon choice.

-

Explore how mechanical properties influence industrial applications.: One of the differences between Nylon 6 and Nylon 66 is that, under moist conditions, nylon 6 has better impact strength and flex fatigue life than 6/6. ↩

-

Discover detailed applications of different nylon materials.: It is mainly used in sheets ods, tubes, pipes, screws, bolts safety nets, plumbing fittings and more. Custom cast nylon is used for applications … ↩

-

Explore comprehensive data on melting points of various nylons.: A Few Examples From Hundreds… Here is a table with melting points (Tm’s) for a variety of AA-BB nylons. It’s interesting to compare the decrease in Tm as … ↩

-

Discover why aromatic nylons are ideal for high-temperature environments.: Nylon’s heat resistance arises from its temperature-enduring molecular composition. It preserves structure at high temperatures, while others … ↩

-

Explores how moisture affects Nylon 6’s mechanical properties.: The effects of moisture absorption–dimensional change, and changes in physical properties–are negligible compared to those in other nylons. Figure 1. ↩

-

Details Nylon 66’s response to water absorption.: Absorbed moisture has a very dramatic effect on these hydrogen bonding forces, and as a result, significantly modifies the physical properties of the 66 Nylon. ↩

-

Shows Nylon 11’s resistance to size changes.: Nylons absorb more moisture from the air than most other polymers. This has an effect on processability, dimensional stability and physical properties. ↩

-

Highlights stability advantages of Nylon 12.: Nylon parts increase in flexibility, elongation and impact strength when they have absorbed water. For this reason some manufacturers will ship … ↩

-

Explore detailed comparisons between various types of nylon materials.: A comparison of polypropylene and polyethylene, and the properties that make both a popular choice for customers. ↩