Picture a world where molds endure for extended periods and perform with increased efficiency, saving time and money in manufacturing. These molds really last longer. Production processes become quicker. Factories benefit immensely from reduced downtime and lower costs. This dream means molds do not wear out swiftly. It is a very big change in manufacturing.

Nitriding treatment gives molds a superhero upgrade. This process strengthens their surfaces. It increases hardness and wear resistance. Molds last longer. Molds also perform better in different industrial jobs.

I recall the first time I learned about nitriding treatment for molds. It felt like finding a hidden ingredient that could change my manufacturing methods. For die-casting aluminum molds dealing with fast alloy liquids or zinc molds needing more strength against rust, nitriding seems very special.

In injection molding, nitriding works like magic on molds filled with tough materials like glass fibers. These molds stay strong, keeping their accuracy across many production runs. Cold heading and extrusion molds also gain strength from nitriding, facing heavy pressures and friction daily.

In powder metallurgy, molds face constant friction and pressure from metal powders. Nitriding helps them stay strong and keep their precision. This single treatment really improves mold performance across many uses. Nitriding becomes an essential tool in our manufacturing toolbox.

Nitriding extends die-casting mold life.True

Nitriding increases hardness and wear resistance, prolonging mold lifespan.

Zinc alloy molds require high-temperature treatment.False

Zinc alloy molds operate at lower temperatures than aluminum alloy molds.

How Does Nitriding Treatment Work on Die-Casting Molds?

I once watched a die-casting mold during nitriding treatment. I was amazed. It changed completely. Its strength and efficiency were much better. Wonder how it works?

Nitriding treatment forms a strong nitride layer on die-casting mold surfaces. This layer really increases their resistance to heat and stress. The process greatly extends the mold’s life. Durability is improved in tough casting conditions. It is a significant improvement.

Understanding Nitriding Treatment

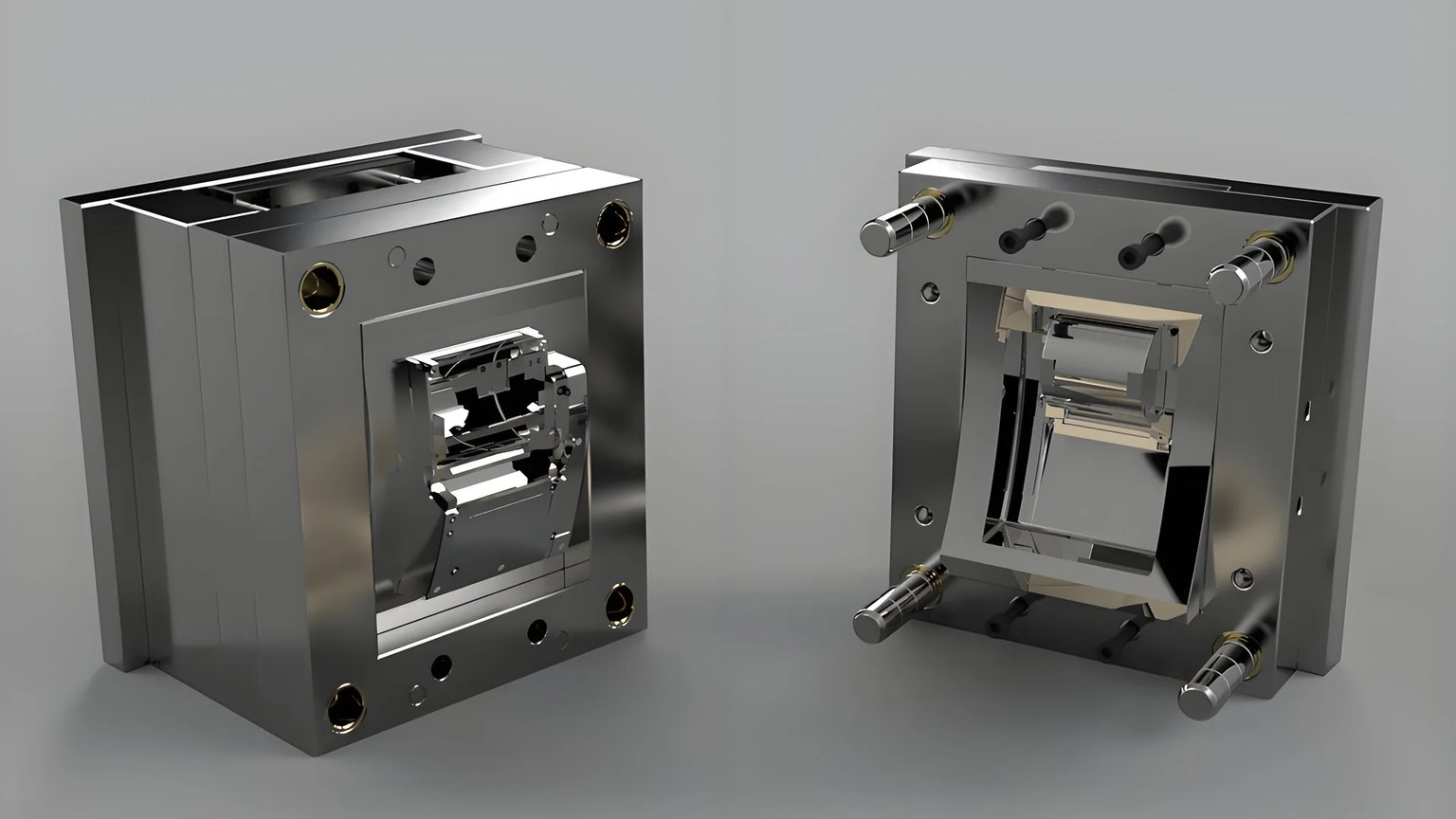

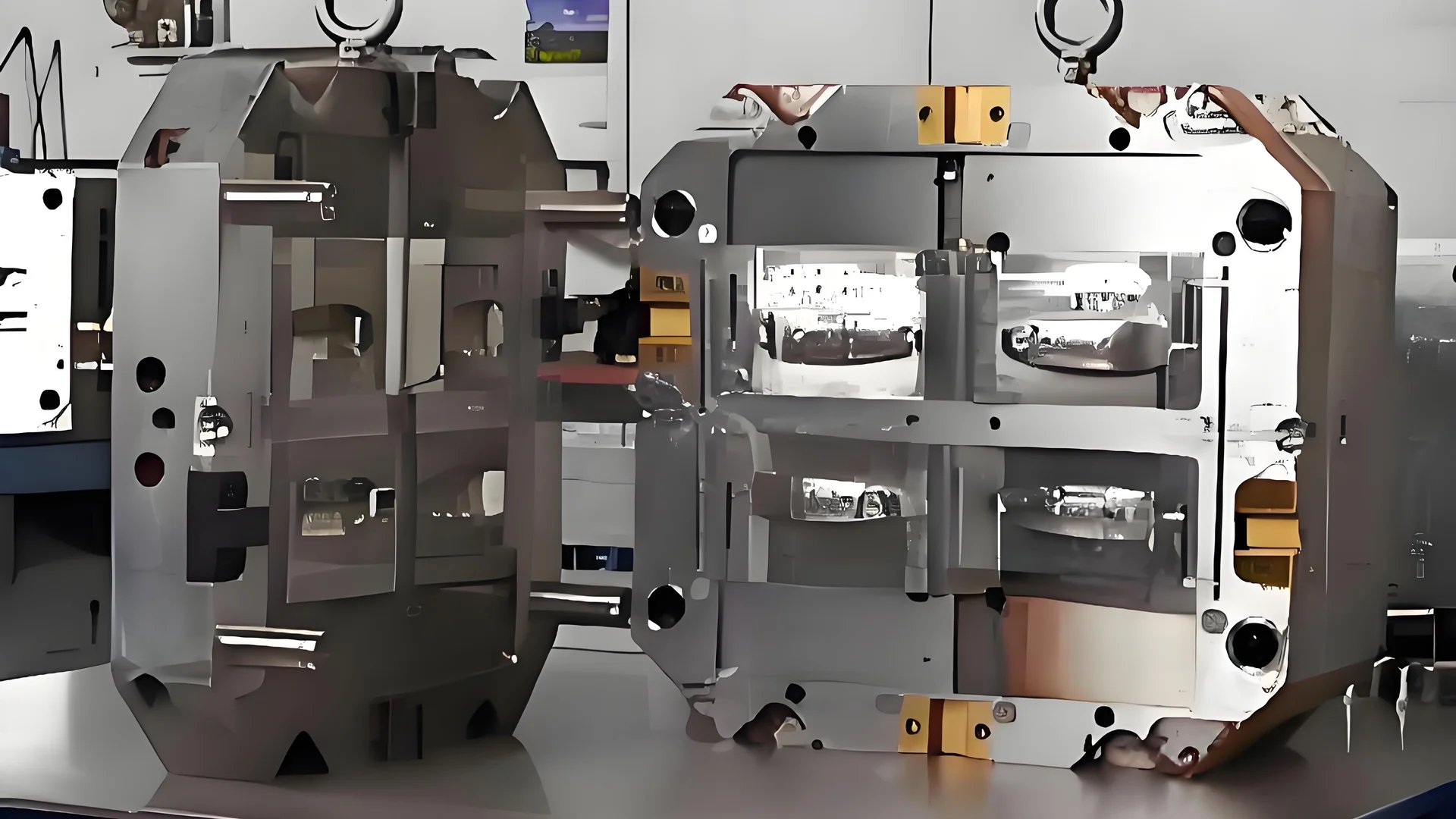

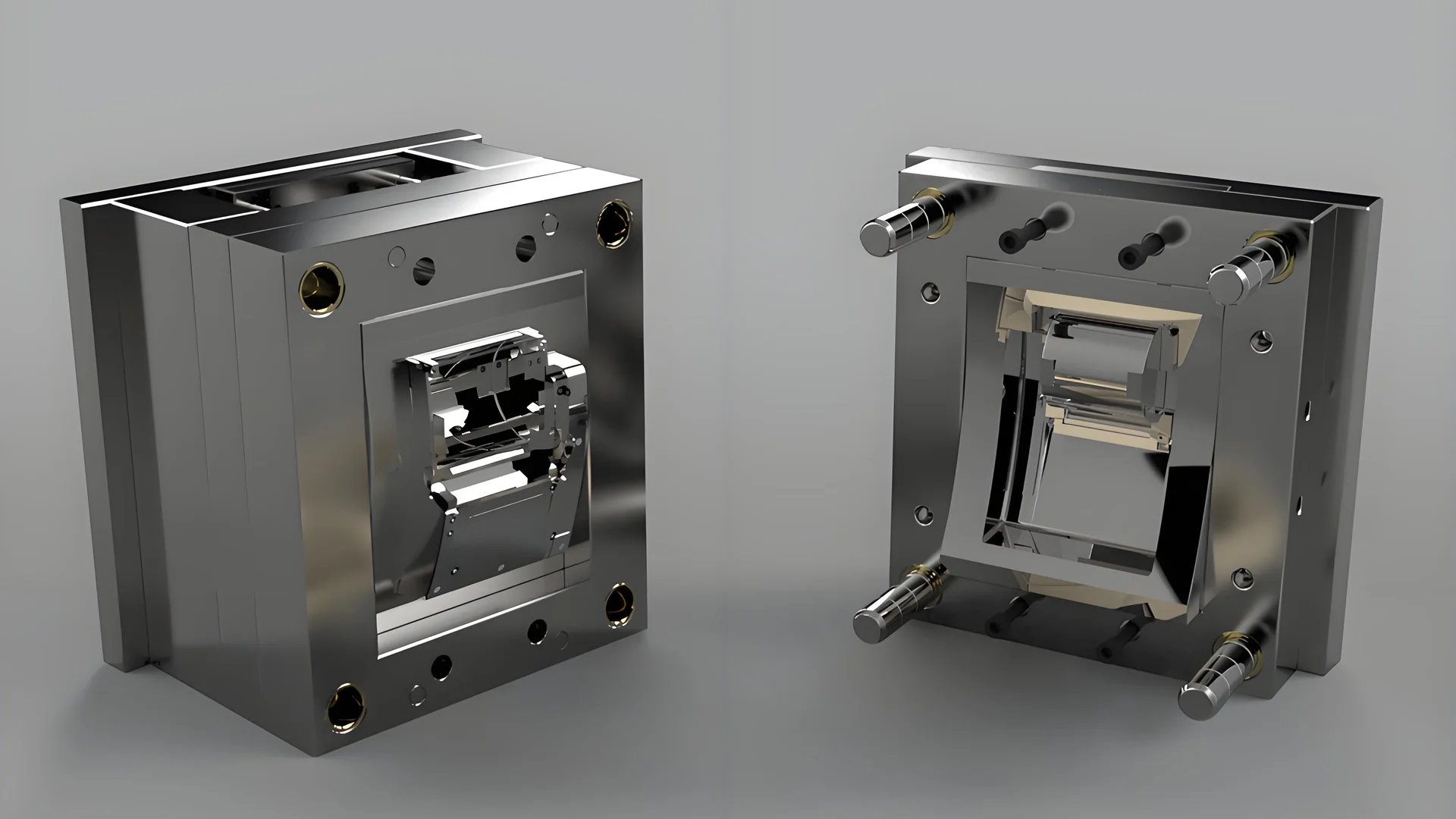

Think of a workshop where steel molds are getting ready for nitriding. This process lets nitrogen enter the steel’s surface, forming a strong nitride layer. Picture it: molds sit in an ammonia-rich space at high temperatures and nitrogen atoms join with their surfaces. This isn’t just a hard layer; it is armor for the mold. This layer offers amazing wear resistance.

Application on Die-Casting Aluminum Alloy Molds

Imagine the heat and pressure on an aluminum alloy mold, similar to those used for car engine blocks. Such molds fight against fast-flowing aluminum, thermal shocks, and mechanical stress. The nitriding layer provides a protective barrier against these stresses. For instance, molds used in casting automobile engine blocks benefit greatly from this treatment as it reduces wear and improves precision over prolonged use, reducing defects and maintenance costs.

Benefits for Die-Casting Zinc Alloy Molds

Zinc alloy molds may not handle extreme heat, but they suffer from frequent use, which wears them quickly. Nitriding serves as a defense against corrosion and wear. It enhances corrosion resistance and mold release performance, crucial for maintaining the mold’s integrity and efficiency. This is particularly beneficial for producing high-quality zinc alloy hardware products.

Comparison with Other Surface Treatments

Nitriding is like that silent hero who doesn’t brag but shows strength through good results. Compared to other surface treatments, nitriding offers unique advantages such as maintaining core toughness due to its lower processing temperatures. It keeps the mold’s core toughness due to lower processing temperatures, making it a preferred choice for molds that need to withstand high cycles without compromising dimensional accuracy.

Nitriding’s Role in Injection Molds

If you’ve ever handled plastic molds with rough materials like glass fibers, you know they suffer greatly. The nitrided surface1 acts like a protective shield due to its high hardness which allows these molds to resist wear from fillers like glass fibers ensuring long-term dimensional stability and reduced maintenance.

Cold Heading and Extrusion Molds

Think of the force in cold working processes – it is huge! Cold heading and extrusion molds bear extreme pressure and friction. Nitriding gives them extra strength by significantly enhancing their compressive strength and wear resistance preventing surface damage and prolonging life. Watching these molds produce exact pieces like bolts without failing under pressure is amazing.

These personal insights show why nitriding treatment is a big change for die-casting and other uses. Grasping its benefits really helps manufacturers use it confidently in their processes by increasing efficiency and product quality.

Nitriding increases mold wear resistance by 50%.True

Nitriding forms a hard layer on molds, significantly boosting wear resistance.

Zinc alloy die casting molds require nitriding for corrosion.True

Nitriding enhances corrosion resistance, essential for zinc alloy molds.

Why Is Nitriding Essential for Injection Molds?

Have you ever wondered how injection molds survive the constant pressure of production without failing? Let’s find out the secret behind their strength.

Nitriding is important for injection molds. It increases surface hardness and wear resistance. This process helps molds last longer. Molds that work with abrasive materials benefit a lot. Glass-filled plastics are abrasive. Nitriding helps maintain consistent quality. It also probably reduces maintenance costs.

The Role of Nitriding in Injection Molds

I remember my first steps in manufacturing felt like exploring a new world. Injection molds handle a lot of pressure, especially with hard plastics and tiny glass pieces. Here, nitriding plays a crucial role. It creates a strong shield on the mold’s surface. This shield is really important as it improves wear resistance2 and keeps everything running smoothly.

Molds that shape tough plastics have a difficult job. Glass fibers are particularly harsh. Nitriding helps these molds keep their shape and surface over many uses. Products like polycarbonate (PC) and nylon (PA) components turn out just right, every single time.

Durability for Thermoplastic Molds

Think of thermoplastic molds working non-stop. They open and close like a busy worker. Wear and fatigue become problems over time. Nitriding comes to the rescue by strengthening the mold and reducing wear, making it perfect for producing lots of items quickly.

Take the example of home appliance shells3. Using nitriding cuts down on maintenance needs, leading to fewer production breaks. This really boosts efficiency—a big advantage for any production line.

Comparing Nitriding with Other Surface Treatments

I’ve looked at many surface treatments like carburizing and hard chrome plating, but nitriding stands out. It leaves molds mostly unchanged during treatment while increasing resistance against rust—very useful for molds used with zinc alloys, which rust easily.

Manufacturers can study detailed comparisons of surface treatment methods4 to understand nitriding’s benefits better. It’s like picking the right tool; each has its use, but knowing the best fit changes everything.

Nitriding extends die-casting mold life.True

Nitriding enhances mold hardness and wear resistance, prolonging life.

Zinc alloy molds require high-temperature resistance.False

Zinc alloy die casting occurs at lower temperatures than aluminum.

What Are the Advantages of Nitriding Cold Heading and Extrusion Molds?

Have you ever thought about why nitriding changes everything for molds in manufacturing? I will explain with some real examples.

Nitriding increases the lifespan of cold heading and extrusion molds. It creates a strong, wear-resistant surface. This tough surface reduces the chance of wear. It helps molds work better for a long time. Maintenance needs are less frequent. The quality of products is also improved. Deformation during manufacturing is less likely.

Stronger Against Wear

Consider a factory where parts must fit exactly, like in bolt and nut work. The molds endure heavy friction from the pressure. Nitriding gives these molds a very tough outer layer. This helps them last longer and crack less. Mold life extends greatly, with fewer cracks appearing. Read more on bolt manufacturing5.

Greater Strength Under Pressure

Cold heading dies deal with huge pressures—imagine lifting a heavy weight all day long. Nitriding creates a strong surface that helps molds keep their shape under pressure. This is very important for making standard parts quickly. Check out more about standard parts production6.

Better Against Corrosion

Cold extrusion molds face high pressure and possible corrosion. Nitriding boosts their resistance to corrosion, which is crucial in the car industry where precision matters a lot. Learn more about cold extruded parts7.

More Efficiency and Quality

Less damage means less time fixing things, saving money and improving products. Industries using cold extrusion techniques8 for car parts see these benefits with nitrided molds.

Use in Many Alloys

Nitriding is very versatile and works well with different alloys, even those containing glass fibers. This keeps parts accurate over time and is popular in many manufacturing fields. Dive deeper into how it helps with engineering plastics9.

Nitriding extends the life of die-casting molds.True

Nitriding improves wear resistance and reduces mold wear, extending lifespan.

Cold extrusion dies do not benefit from nitriding.False

Nitriding enhances wear resistance and durability in cold extrusion dies.

How Does Nitriding Boost the Performance of Powder Metallurgy Molds?

Think back to the first moment you discovered a small adjustment could transform everything.

Nitriding changes powder metallurgy molds. It creates a tough outer layer that fights wear. This process increases mold life. The layer stands strong against friction and pressure. It helps produce high-quality products. Products are consistently good.

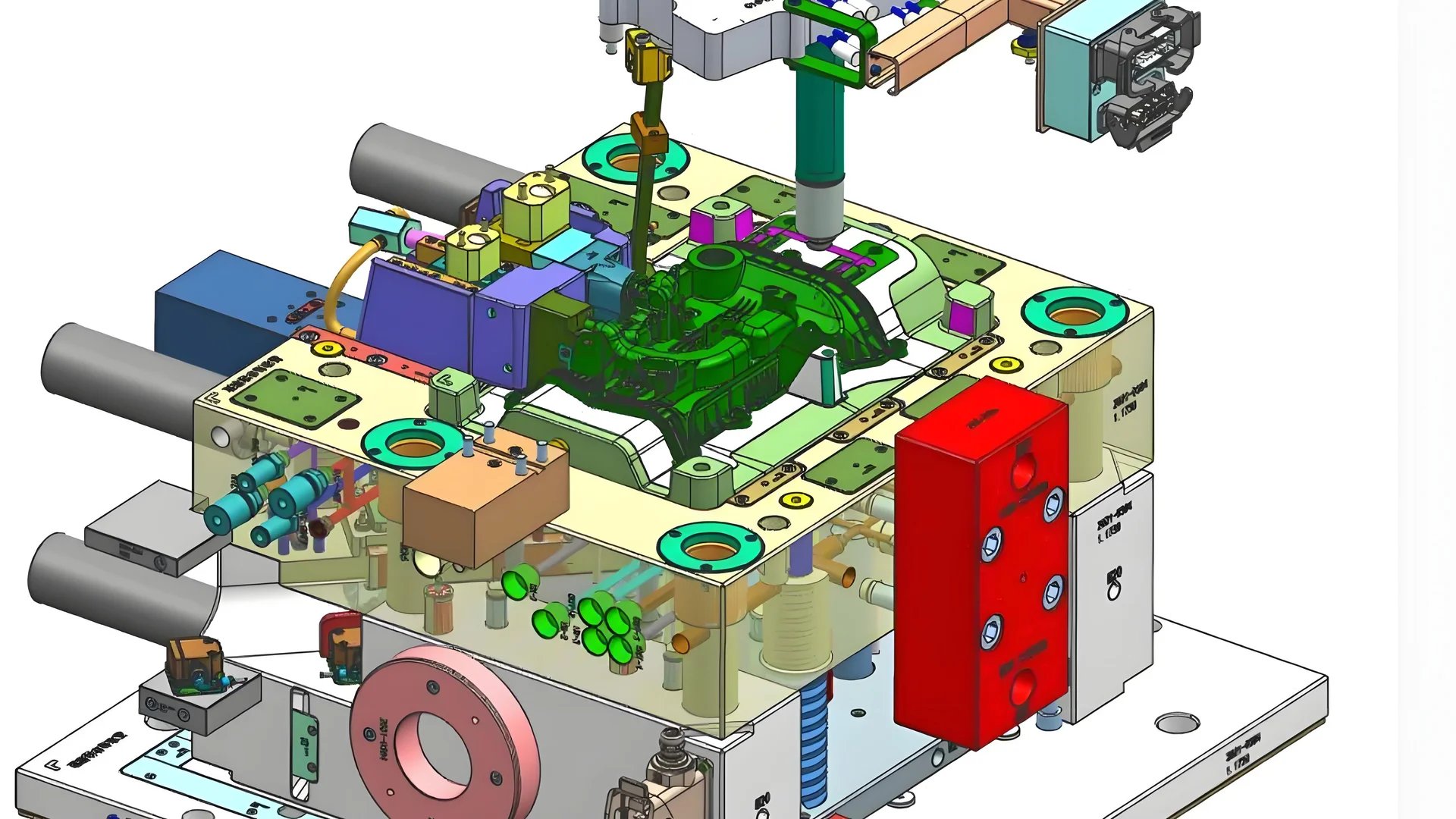

Understanding Nitriding in Powder Metallurgy

I remember when I first learned about nitriding. I was working on a project that used metal powders10. It was like finding a secret tool to make our molds stronger and last longer. Molds in powder metallurgy face constant friction and pressure. Nitriding is a heat treatment process that diffuses nitrogen into the surface of steel, forming a strong, protective layer on the mold. This greatly improves how well molds perform.

Benefits of Nitriding for Mold Performance

-

Increased Hardness and Wear Resistance: Nitriding changes the surface of molds, making them very hard, like a protective shield. This is crucial as it helps them resist wear from rough particles, which is particularly important for making parts like metal gears and bearings.

-

Enhanced Durability: Molds get stronger with nitriding as it improves their compressive strength11 and fatigue resistance. They can handle stress better, lasting longer in production runs without needing frequent replacements, thereby improving efficiency.

-

Improved Precision and Quality: The nitrided layer stays strong under pressure, maintaining high dimensional accuracy in every part made. Precision is really important in industries like automotive manufacturing where even tiny errors matter significantly.

Practical Applications of Nitriding

-

Automotive Industry: I worked with a car parts maker once who used nitriding to keep product quality high. Nitrided molds12 helped them meet strict standards easily by ensuring consistent quality and longevity.

-

Tool Manufacturing: Precision tool makers use nitriding to increase wear resistance, keeping molds in shape longer over extensive use.

Nitriding is a robust method for enhancing mold performance in powder metallurgy. It extends mold life and ensures product reliability, making every effort in the process truly valuable.

Nitriding increases mold life in aluminum die casting.True

Nitriding enhances wear resistance, reducing mold wear and extending life.

Zinc alloy molds do not benefit from nitriding.False

Nitriding improves corrosion resistance and release performance in zinc molds.

Conclusion

Nitriding treatment enhances mold performance by increasing hardness and wear resistance, extending lifespan, and improving efficiency across various applications including die-casting, injection molding, and powder metallurgy.

-

Learn about the nitriding process mechanics and its benefits. ↩

-

Learn how wear resistance impacts mold longevity and product quality. ↩

-

Discover how nitriding reduces maintenance needs in thermoplastic molds. ↩

-

Explore nitriding’s advantages over other treatments for mold durability. ↩

-

Learn how nitriding extends mold life for bolt production. ↩

-

Discover nitriding’s role in producing durable standard parts. ↩

-

Explore the benefits of nitriding in automotive parts production. ↩

-

Find out how nitriding boosts efficiency in cold extrusion. ↩

-

See nitriding’s effect on molds for plastic with glass fibers. ↩

-

Learn why powder metallurgy is crucial in modern manufacturing. ↩

-

Understand how compressive strength affects material performance. ↩

-

Explore the nitriding process and its impact on mold durability. ↩