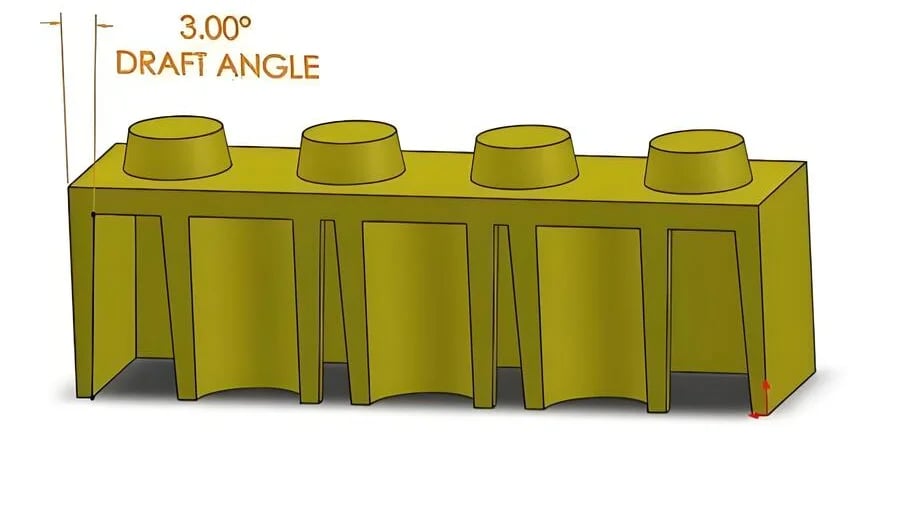

Accurate measurement of the draft angle in injection molds is vital for creating efficient and high-quality molded parts.

The draft angle of an injection mold can be measured using three main methods: an angle ruler, trigonometric calculations, or a coordinate measuring machine (CMM). Each method offers different levels of precision and is suitable for various mold complexities.

While these methods provide immediate insights into measuring mold angles, delving deeper into each technique reveals their unique advantages and specific applications. Read on to discover how each method can be applied effectively in different scenarios.

Angle ruler measures angles from 0° to 320°.True

The universal angle ruler is designed to measure angles within this range.

CMM is less accurate than trigonometric calculations.False

CMM provides high precision, often exceeding manual trigonometric methods.

What Are the Benefits of Using an Angle Ruler?

An angle ruler is a versatile tool that offers numerous benefits in precise angle measurement. Its applications extend from construction to woodworking, enhancing efficiency and accuracy.

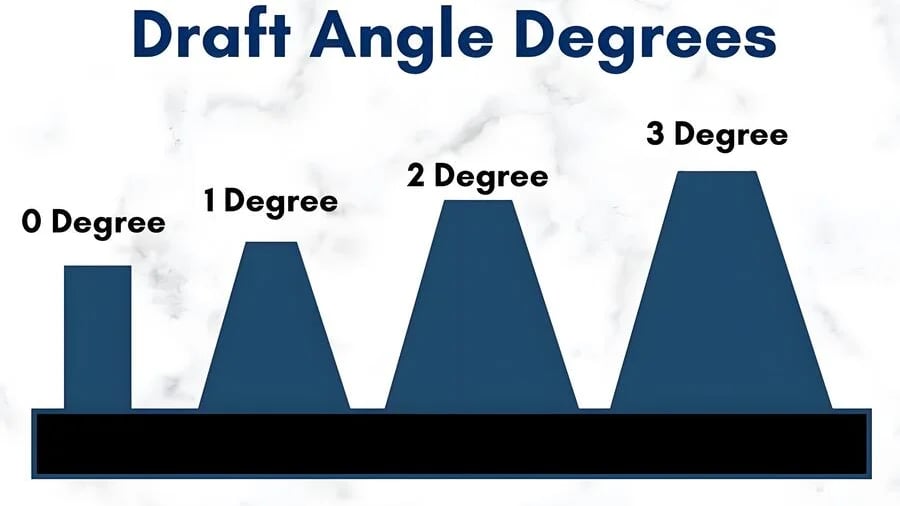

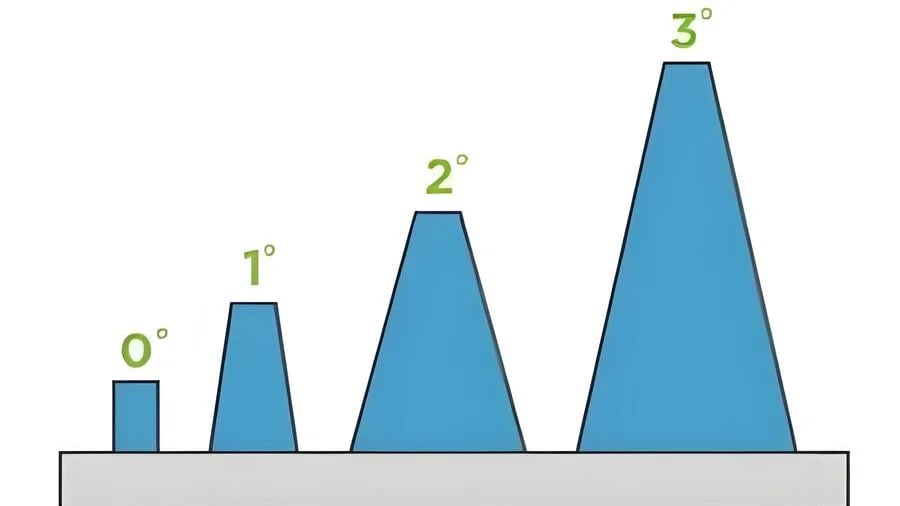

An angle ruler simplifies angle measurement with high precision, versatility, and ease of use. It efficiently measures angles between 0° to 320°, offering clear readings through a simple method, making it ideal for various industries such as injection molding and carpentry.

Precision in Measurement

One of the primary benefits of an angle ruler is its ability to provide highly accurate measurements, which is essential in fields like injection molding1. By fitting one side of the ruler to a reference plane and reading the scale, users can directly obtain angular values. This straightforward method ensures high precision, crucial for tasks requiring exact angle readings.

Versatility Across Applications

Angle rulers are not limited to a single use case; they can be employed across various domains such as construction, woodworking, and even education. Their design allows for measuring angles up to 320°, which meets the basic requirements for tasks like mold slope measurement in injection molding. This versatility makes them a preferred choice over traditional tools like protractors or simple rulers.

Enhanced Efficiency and Simplicity

Using an angle ruler significantly improves efficiency. Unlike other methods that may involve complex calculations or require multiple tools, an angle ruler simplifies the process. It allows users to quickly measure angles without additional equipment, reducing time and potential errors. This simplicity is particularly beneficial in fast-paced environments where quick, accurate measurements are necessary.

Comparison with Other Measuring Tools

When comparing an angle ruler with other tools like vernier calipers or coordinate measuring machines (CMM), the angle ruler stands out for its ease of use and practicality. While tools like CMMs offer high precision, they are often expensive and require specialized knowledge to operate. In contrast, angle rulers are affordable and user-friendly, making them accessible for both professionals and amateurs in various fields.

Overall, the use of an angle ruler in tasks requiring precision and efficiency is unmatched by other methods or tools, providing invaluable assistance in diverse applications from construction projects2 to educational settings.

Angle rulers can measure angles up to 320° accurately.True

Angle rulers are designed to measure angles with high precision, up to 320°.

CMMs are less accurate than angle rulers for measuring molds.False

Coordinate measuring machines (CMMs) offer higher accuracy than angle rulers.

How Can Trigonometric Functions Aid in Precise Measurements?

Trigonometric functions, often seen as mere abstract math concepts, play a crucial role in precise measurements across various fields. Discover their practical applications in engineering and beyond.

Trigonometric functions are essential for precise measurements in engineering and other fields, aiding in calculating angles and distances accurately.

The Role of Trigonometry in Measurement

Trigonometry is integral to fields requiring precision, such as engineering, architecture, and navigation. By applying functions like sine, cosine, and tangent, professionals can determine angles and distances that would be challenging to measure directly. This capability is critical for designing structures, mapping terrains, and even navigating through space.

Angle Ruler Measurement Method

In the context of injection molding, the Angle Ruler Measurement Method provides a practical application of trigonometry. This method involves a universal angle ruler capable of measuring angles between 0 and 320 degrees with high precision. When measuring a mold’s pulling slope, fitting one side of the ruler to a reference plane allows the direct reading of the angle. This technique ensures accuracy in molds requiring precision.

Trigonometric Function Calculation Method

Another method involves using trigonometric calculations for more complex surfaces. Here, tools like vernier calipers or a CMM (Coordinate Measuring Machine) are essential. By measuring the height difference (h) and horizontal distance (l), the angle (\theta) is determined using (\tan\theta = \frac{h}{l}). For instance, if (h = 5)mm and (l = 100)mm, then (\theta = \arctan(0.05)\approx 2.86^{\circ}). This technique is particularly useful for molds with intricate details.

Using Coordinate Measuring Machines

CMMs represent the pinnacle of precision measurement. These devices measure an object’s geometry by recording spatial coordinates. In mold measurement, selecting multiple points on an inclined surface helps calculate the angle using software analysis. This method is ideal for high-precision needs, such as automotive parts manufacturing, where exact dimensions are crucial.

Trigonometry’s applications extend beyond these examples, influencing engineering practices3, architectural designs, and even navigation systems4. Understanding these concepts allows professionals to execute tasks with unparalleled accuracy and efficiency.

By leveraging trigonometric functions, professionals in these fields can solve complex problems that require precise measurements. This mathematical tool is invaluable for those aiming to achieve exactitude in their work.

Angle ruler measures 0-320° accurately.True

The universal angle ruler can measure angles from 0 to 320° precisely.

CMM cannot measure mold pullout inclination.False

CMM is used for high-precision measurement of mold pullout angles.

Why Opt for Coordinate Measuring Machines in Mold Design?

Explore why Coordinate Measuring Machines (CMMs) are crucial in achieving precision in mold design and production.

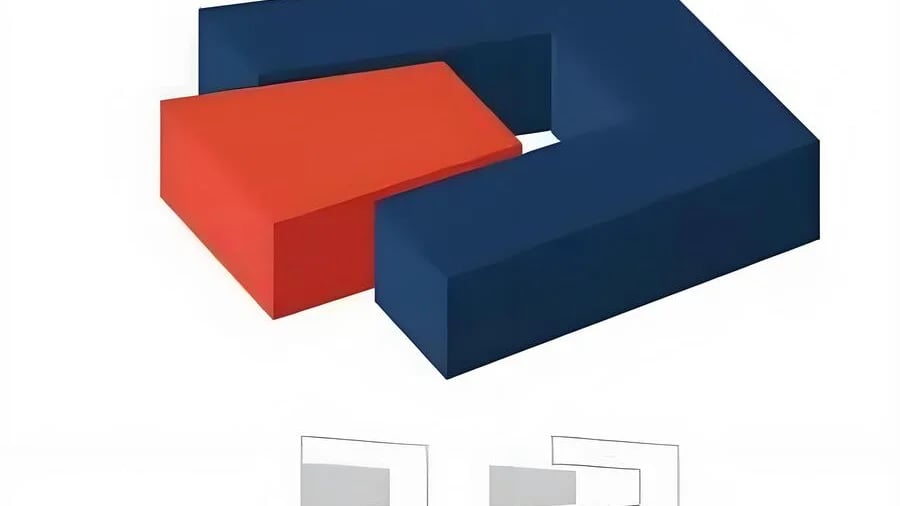

Coordinate Measuring Machines (CMMs) offer unmatched precision and reliability in mold design, essential for ensuring dimensional accuracy and quality control. By using advanced software, CMMs can measure complex geometries and surfaces that traditional methods struggle with, making them invaluable for high-precision projects.

The Importance of Precision in Mold Design

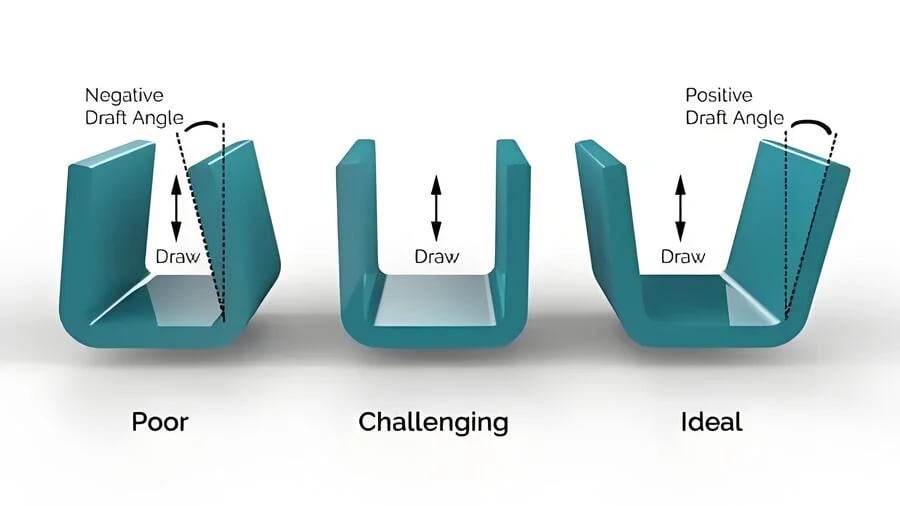

In mold design, achieving precise measurements is critical. This precision ensures that the molds produce parts that meet stringent specifications and function correctly in their intended applications. Traditional methods, like the Angle Ruler Measurement Method5, although effective for basic needs, may fall short when dealing with complex or high-tolerance projects.

Limitations of Traditional Measurement Methods

While the angle ruler and trigonometric function calculation method6 have their merits, they often lack the accuracy required for intricate designs. For instance, when using an angle ruler, the precision is sufficient for simple geometries but may not accommodate the subtleties of more complex surfaces. Similarly, calculating angles using trigonometry can introduce human error, especially when measuring height differences and horizontal distances manually.

The Role of Coordinate Measuring Machines

CMMs revolutionize the way measurements are conducted in mold design. These machines use sophisticated software7 to analyze multiple measurement points, accurately determining spatial coordinates. By fitting an inclined plane based on these coordinates, CMMs provide a high level of precision that is crucial for molds requiring intricate details.

Applications in High-Precision Projects

CMMs are particularly advantageous in industries where high precision is non-negotiable, such as automotive parts production. These projects demand exact dimensional accuracy, which CMMs readily deliver by accommodating the mold pullout inclination’s nuances through detailed measurement processes8. This capability enhances quality assurance, ensuring that all parts adhere strictly to design specifications.

Why CMMs are Preferred

The preference for CMMs in mold design stems from their unparalleled accuracy and efficiency. Unlike manual methods, CMMs minimize human error and handle complex geometries effortlessly. Their ability to deliver consistent results ensures that each mold meets the desired specifications, thus enhancing the overall quality and reliability of the finished products.

Angle rulers measure up to 320° with high precision.True

Angle rulers are designed to measure angles from 0 to 320° accurately.

CMMs are less accurate than angle rulers for mold measurements.False

CMMs offer higher precision and accuracy than angle rulers for molds.

What Impact Does Accurate Measurement Have on Production Quality?

Accurate measurements are the bedrock of high-quality production processes. They ensure that each product meets precise specifications, reducing errors and waste.

Accurate measurement significantly enhances production quality by ensuring consistency, minimizing waste, and improving efficiency. Tools like angle rulers, trigonometric calculations, and coordinate measuring machines (CMM) offer various methods to achieve high precision in manufacturing processes.

Ensuring Consistency in Production

One of the most significant impacts of accurate measurement on production quality is ensuring consistency across all products. Consistency is crucial in maintaining brand reputation and meeting customer expectations. For instance, using the Angle Ruler Measurement Method9 ensures that each mold pulling slope is identical, crucial for the uniformity of products like plastic shells. Accurate tools help maintain this consistency by allowing manufacturers to adhere to exact dimensions.

Reducing Waste

Accurate measurements play a vital role in minimizing waste during production. When measurements are precise, the likelihood of producing defective products decreases, which in turn reduces material waste. Using the Trigonometric Function Calculation Method10, manufacturers can precisely calculate angles, ensuring that every piece fits perfectly without the need for rework or scrap. This precision helps in optimizing resource use and reducing costs associated with waste.

Improving Efficiency

Efficiency in production processes is another area significantly impacted by precise measurements. Accurate measurement methods, such as those performed with a Coordinate Measuring Machine (CMM)11, enable quick and precise assessments of complex geometries. This high level of accuracy speeds up production cycles by reducing the time spent on quality control checks and adjustments. The rapid feedback loop provided by these tools allows for immediate corrections, thus enhancing overall production efficiency.

Enhancing Product Quality

Ultimately, the most direct impact of accurate measurement is on product quality. High precision in measurement ensures that products meet all specified standards and perform as intended. For example, in industries like automotive manufacturing, where safety and performance are paramount, tools like CMMs are indispensable for achieving the stringent dimensional accuracies required. This level of precision directly translates to enhanced product reliability and customer satisfaction.

Adopting Advanced Measurement Techniques

The advent of advanced measurement techniques has revolutionized production quality. Integrating technologies such as laser scanning and 3D imaging with traditional methods provides a comprehensive approach to quality assurance. These technologies offer detailed insights into product dimensions and surface features, enabling manufacturers to meet even the most demanding specifications efficiently. Embracing these innovations can lead to significant improvements in both product quality and production processes.

Angle ruler measures 0-320° accurately.True

The universal angle ruler is designed to measure angles within this range.

CMM is unsuitable for high-precision molds.False

CMMs are ideal for high-precision measurements, such as automotive molds.

Conclusion

This article discusses methods for measuring the draft angle of injection molds, including angle rulers, trigonometric calculations, and coordinate measuring machines (CMM), highlighting their precision and applications.

-

Discover how injection molding benefits from precise angle measurements. ↩

-

Learn how angle rulers enhance accuracy in construction measurements. ↩

-

Discover how trigonometry enhances engineering accuracy. ↩

-

Learn how trigonometry aids navigation systems. ↩

-

Discover how angle rulers function in basic mold measurements. ↩

-

Learn about using trigonometry for calculating mold angles. ↩

-

Explore advanced software features used in CMMs. ↩

-

Understand how CMMs handle intricate measurement tasks. ↩

-

Learn how angle rulers ensure consistent mold slopes. ↩

-

Understand how trigonometry ensures accurate angle measurements. ↩

-

Discover how CMM enhances precision in manufacturing. ↩