MANUFACTURING

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Pros and Cons of Point Gate?

Point gates, or fine water gates, are a popular choice in injection molding due to their ability to improve the aesthetic quality of molded parts. They allow for flexible gate placement, facilitating automation and reducing residual stress. However, they also ...

MANUFACTURING

What Injection Molding Defects Can Result from Improper Injection Pressure Adjustment?

This article explores how improper injection pressure adjustments during the molding process can cause various defects such as flash, silver streaks, and dimensional inaccuracies. These issues not only compromise the aesthetic appeal of molded products but also diminish their functionality ...

MANUFACTURING

Why Are Point Gates Widely Used in Injection Molding Products?

Point gates are crucial in injection molding for producing high-quality plastic items. They minimize visible gate marks, ensuring aesthetic appeal while allowing fast production of intricate designs. Ideal for electronic housings and automotive interiors, point gates provide flexibility in feeding ...

MANUFACTURING

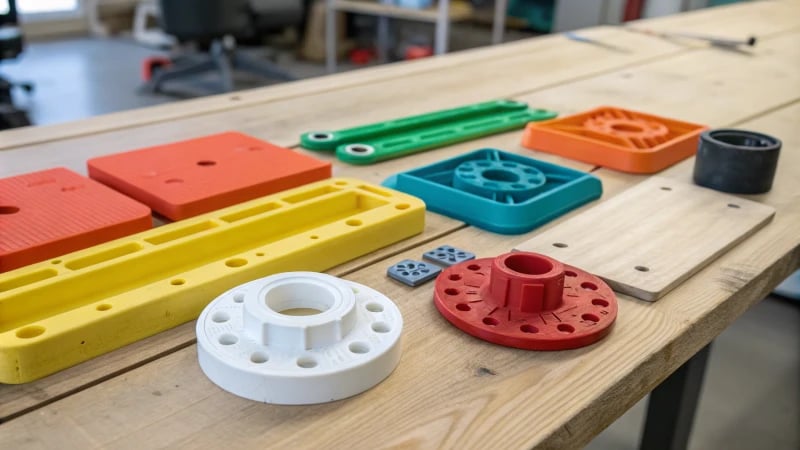

What Are the Most Common Defects in Mold Manufacturing?

This article explores common defects in mold manufacturing such as dimension deviations, surface quality issues, shape errors, and fitting problems. It discusses their causes—like equipment precision mistakes and poor assembly methods—and the significant impact these flaws have on product quality. ...

MANUFACTURING

How Do Various Factors Influence the Processing Temperature of Materials?

The processing temperature of materials significantly affects their behavior during manufacturing. Factors such as crystallinity determine melting points; non-crystalline plastics soften over a range. Molecular structure influences flow characteristics, with shorter chains requiring lower temperatures. Additives like plasticizers can reduce ...

MANUFACTURING

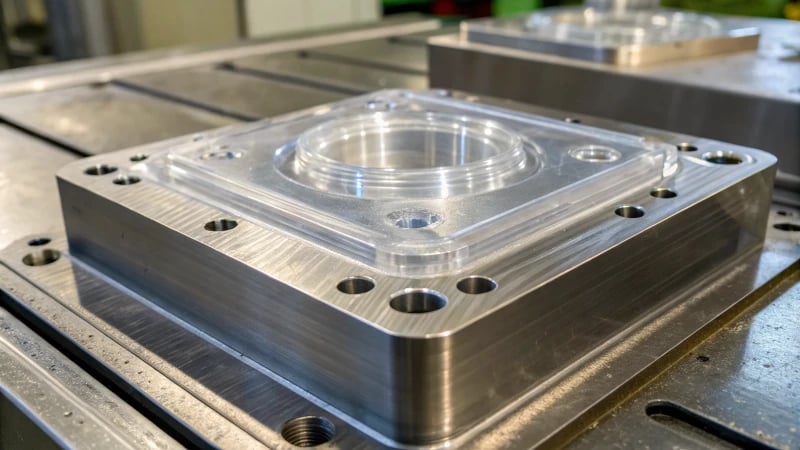

How Does Dimensional Deviation Affect Mold Quality in Manufacturing?

This article explores how dimensional deviation affects mold quality in manufacturing. It highlights the importance of precision in mold design and production, detailing the consequences of inaccuracies on mold performance, assembly difficulties, wear and tear, and overall product quality. Factors ...

MANUFACTURING

How Can You Adjust Injection Pressure According to Operating Specifications?

This article explores the critical process of adjusting injection pressure in molding operations. It emphasizes the importance of proper training for technicians, thorough equipment inspections, and a deep understanding of material properties. Key steps include starting with lower initial pressure ...

MANUFACTURING

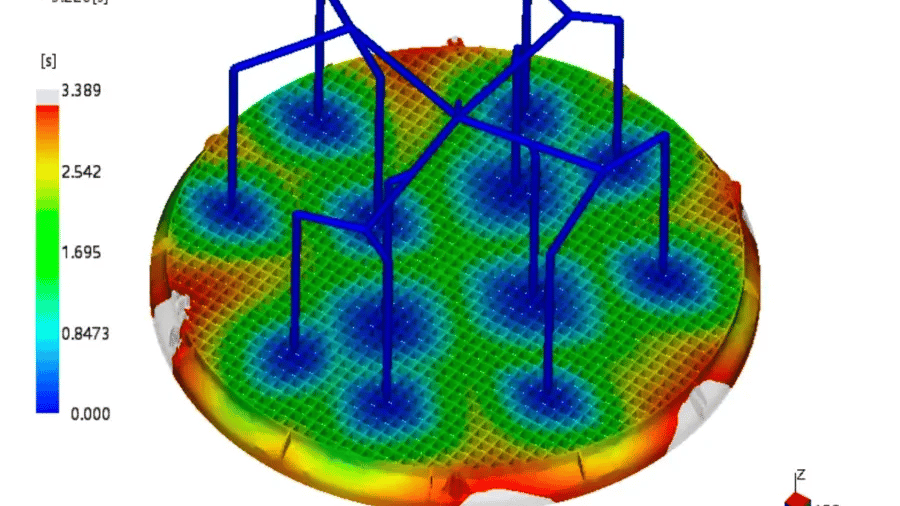

How Does Main Channel Length Design Affect the Quality of Injection Molded Products?

The main channel length in injection molding is crucial for product design, impacting appearance quality, dimensional accuracy, and internal integrity. A well-optimized channel ensures even pressure distribution and melt flow, reducing issues like flash problems and warping deformation. This article ...

MANUFACTURING

How Does Excessive Shrinkage Impact the Strength of Plastic Products?

Excessive shrinkage in plastic products can create internal structural defects, reduce density, and cause warping. These issues lead to decreased tensile strength and overall product reliability. Understanding how shrinkage affects material properties is crucial for designers to ensure the durability ...

MANUFACTURING

Should You Choose China or Vietnam for Manufacturing Injection Molds?

Choosing between China and Vietnam for injection mold manufacturing involves weighing various factors. China excels in advanced technology, production efficiency, and quality control, making it a leader in the industry. In contrast, Vietnam offers significant cost advantages due to lower ...

MANUFACTURING

How Can You Avoid Short Shots by Adjusting Injection Pressure?

Short shots in injection molding can lead to incomplete products and manufacturing frustrations. To avoid this issue, manufacturers must adjust injection pressure based on product structure and material properties. Key factors include wall thickness, melt flow complexity, and the viscosity ...

MANUFACTURING

What Are the Best Injection Molding Process Adjustments to Enhance Product Strength?

This article explores effective adjustments in the injection molding process to enhance product strength. Key factors include optimizing injection pressure and speed, managing mold temperature, and extending cooling time. By carefully balancing these parameters, manufacturers can significantly improve the density ...

MANUFACTURING

How Does Injection Pressure Affect the Quality of Injection Molded Products?

Injection pressure is a critical factor in injection molding that directly impacts the quality of molded products. High pressure can lead to defects such as flash formation, surface imperfections, oversized items, and internal stress issues. Conversely, low pressure may result ...

MANUFACTURING

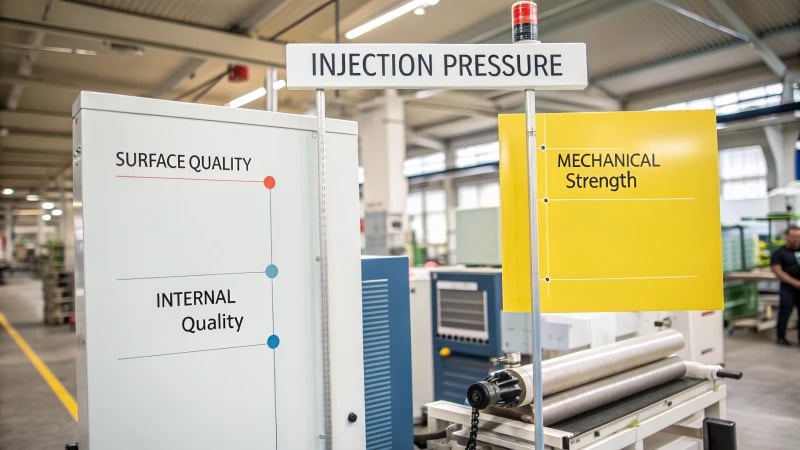

How Does Injection Pressure Influence the Properties of Plastic Products?

This article explores how injection pressure impacts the properties of plastic products, including surface quality, dimensional accuracy, mechanical strength, and internal stress. Properly managed injection pressure is crucial for achieving high-quality results in molded plastics. High pressures can lead to ...

MANUFACTURING

What Are the Best Strategies for Finding Top Injection Mold Manufacturers in China?

Finding the right injection mold manufacturer in China is essential for production success. Key regions such as Guangdong and the Yangtze River Delta are known for advanced technology and competitive pricing. This article explores these areas' strengths, including quality levels, ...

MANUFACTURING

How Can You Enhance the Strength of Plastic Products with Excessive Shrinkage?

This article explores strategies to enhance the strength of plastic products suffering from excessive shrinkage. Key methods include selecting appropriate materials like glass fiber-reinforced plastics, adjusting process parameters such as injection pressure and mold temperature, and optimizing mold designs with ...

MANUFACTURING

What Are the Most Effective Surface Treatments for Plastic Products?

This article delves into the most effective surface treatments for plastic products. It covers various methods such as In-Mold Decoration (IMD), Outside Membrane Decoration (OMD), Non-Conductive Vacuum Metallization (NCVM), and spraying techniques. Each method is analyzed for its advantages in ...

MANUFACTURING

What Are the Key Applications of Multi-Stage Injection in Injection Molding Machines?

Multi-stage injection molding is a transformative technology widely used in various sectors such as automotive, electronics, medical devices, packaging, household goods, and toy manufacturing. This advanced process allows for precise control over injection speed and pressure, resulting in improved product ...

MANUFACTURING

What Are the Key Application Scenarios for Multi-Stage Injection Molding Machines?

Multi-stage injection molding machines are revolutionizing the manufacturing of intricate plastic components. By adjusting speed and pressure throughout the process, these machines excel in creating products with varying wall thicknesses, detailed internal structures, and high precision. This method is particularly ...

MANUFACTURING

What Benefits Does the Multi-Stage Injection Function Offer in Injection Molding Machines?

Multi-stage injection molding is a transformative technique in manufacturing that significantly improves product quality. By allowing precise control over the injection process, it reduces surface defects like flow marks and silver streaks while enhancing internal integrity by minimizing residual stress. ...

MANUFACTURING

How Does Multi-Stage Injection Work in Injection Molding Machines?

This article explores multi-stage injection molding, detailing its process divided into initial injection, fast filling, slow filling, and holding pressure. Each stage requires specific settings for speed and pressure tailored to material characteristics. Understanding product structure is crucial for optimizing ...

MANUFACTURING

How Does Reducing Injection Mold Speed Enhance Product Quality?

Lowering the speed of injection molding significantly improves product quality. It reduces surface defects like flow marks and silver streaks while enhancing internal stability and density. Slower speeds allow for better replication of intricate textures and patterns, ensuring a smooth ...

MANUFACTURING

What Factors Determine the Best Injection Speed?

Choosing the right injection speed is crucial for optimizing plastic molding processes. Factors such as material characteristics (fluidity and heat sensitivity), mold design (gate size and runner system), and specific product requirements all influence the ideal injection speed. For instance, ...

MANUFACTURING

How is Injection Mold Injection Pressure Determined?

This article explores how injection mold pressure is determined by various factors including material characteristics, mold structure, and product requirements. Key aspects such as fluidity of plastics like polyethylene (PE) and polycarbonate (PC), gate size, runner system design, and the ...

MANUFACTURING

How Does the Parting Line Affect the Precision of Injection Molded Products?

This article explores the critical role of parting lines in injection molding, emphasizing their influence on dimensional accuracy, shape integrity, and assembly position. Poorly managed parting lines can lead to issues such as flash formation, uneven surfaces, and misalignment in ...

MANUFACTURING

What Is the Service Life of an Injection Molding Machine’s Heating Coil?

The lifespan of heating coils in injection molding machines ranges from 5 to 10 years, depending on factors such as environmental conditions, operating temperatures, material quality, and maintenance routines. Ceramic coils generally outlast stainless steel ones. High humidity and corrosive ...

MANUFACTURING

How Do Injection Molding Machines Achieve Temperature Control in Their Heating Systems?

Temperature control is crucial in injection molding, acting as the heartbeat of quality production. This process relies on a combination of temperature sensors, controllers, and PID algorithms to maintain steady and precise heat levels. Sensors monitor real-time temperatures in various ...

MANUFACTURING

How Does Injection Molding Melt Raw Materials?

This article explores the intricate process of injection molding, focusing on how heating systems and shear heat work together to melt raw materials like plastics. The heating rings in the machine's barrel provide controlled temperatures that soften thermoplastics, while the ...

MANUFACTURING

What Are the Key Factors Influencing Mold Processing Technology Choices?

Choosing the right mold processing technology is essential for manufacturing success. Factors such as design complexity, material characteristics, production requirements, available equipment, technician expertise, and budget constraints play a critical role in decision-making. Understanding how these elements interact helps manufacturers ...

MANUFACTURING

What Are the Key Principles for Choosing Mold Processing Technology?

Selecting the right mold processing technology is crucial for manufacturers. Key principles include prioritizing precision to meet strict standards, ensuring consistent quality across batches, balancing efficiency with cost-effectiveness, adapting processes to various materials and designs, and considering the operability of ...

MANUFACTURING