MANUFACTURING

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Key Differences Between Injection Molding and Vacuum Forming?

This article explores the key differences between injection molding and vacuum forming, two popular manufacturing techniques. Injection molding is ideal for high-volume production of intricate designs due to its efficiency and precision. In contrast, vacuum forming offers a more budget-friendly ...

MANUFACTURING

How Do Injection Molding Machines Create Plastic Balls?

Injection molding machines create plastic balls through a detailed process involving mold design, material selection, and precise control of injection parameters. Each step is crucial for producing high-quality products.

MANUFACTURING

What Exactly is the Runner in a Plastic Mold?

The runner in plastic injection molding is a crucial channel that directs molten plastic from the machine to the mold cavity. Understanding its design, including cold and hot runners, enhances product quality and efficiency.

MANUFACTURING

Is it Possible for an Injection Molding Machine to Produce 3kg Products?

This article explores the capabilities of injection molding machines to produce 3kg products, emphasizing key factors such as machine selection, product design, mold compatibility, material choice, and process parameters for optimal production.

MANUFACTURING

What Is the Process Behind How a Plastic Injection Molding Machine Works?

This article explores the intricate process of plastic injection molding, detailing each stage from raw material preparation to mold opening, emphasizing the importance of design and maintenance for quality production.

MANUFACTURING

What Are the Steps Involved in the Plastic Molding Process?

The plastic molding process involves mixing raw materials, shaping them into molds, machining for precision, joining parts, modifying surfaces, and assembling the final product. Each step is crucial for quality.

MANUFACTURING

What Are the Best Strategies for Finding High-Quality Plastic Molds?

Finding high-quality plastic molds requires clear product specifications, evaluating manufacturers' strengths, reviewing design plans, understanding manufacturing processes, and ensuring reliable after-sales support for optimal outcomes.

MANUFACTURING

How Are Plastic Products Manufactured? Discover the Process!

This article explores the intricate process of plastic product manufacturing, detailing key stages such as design, material selection, molding techniques, post-processing, and quality control to ensure high-quality outcomes.

MANUFACTURING

What Are the Key Differences Between a Mold and a Die?

Molds and dies are essential manufacturing tools that shape materials like plastics and metals. Understanding their differences in function, structure, and quality control is crucial for efficient production.

MANUFACTURING

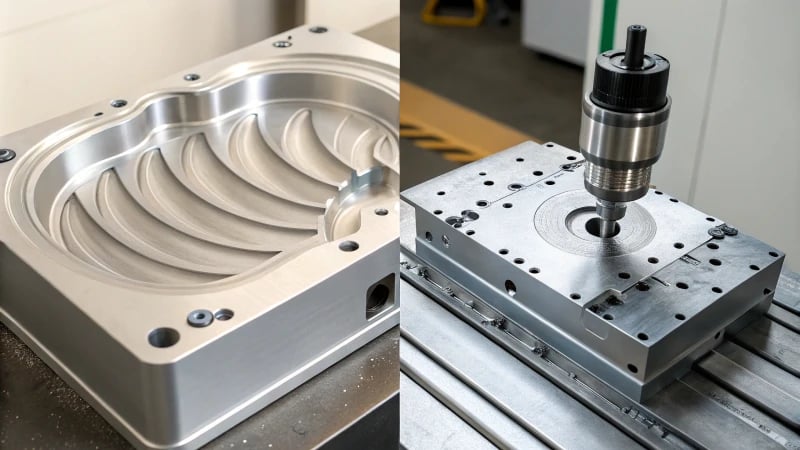

What Are the Key Steps in the Plastic Injection Mold Manufacturing Process?

This article delves into the essential steps of plastic injection mold manufacturing, covering mold design, material selection, processing technologies, cooling systems, and quality control practices to ensure high-quality production.

MANUFACTURING

How Do Injection Molding Machines Create Plastic Boxes?

This article delves into the injection molding process for creating plastic boxes, covering machine operation, mold design considerations, process parameters, and strategies for improving production efficiency.

MANUFACTURING

How Does the Injection Molding Process Work? Discover with Diagrams!

The injection molding process is a crucial manufacturing technique involving raw material preparation, mold installation, parameter setting, and cooling to produce high-quality plastic parts efficiently. Innovations like automation and biodegradable materials enhance its effectiveness.

MANUFACTURING

How Does Injection Molding Effectively Melt Raw Materials?

Injection molding is a sophisticated process that melts thermoplastic materials using an injection system with precise temperature controls, ensuring high-quality production through effective heating and cooling mechanisms.

MANUFACTURING

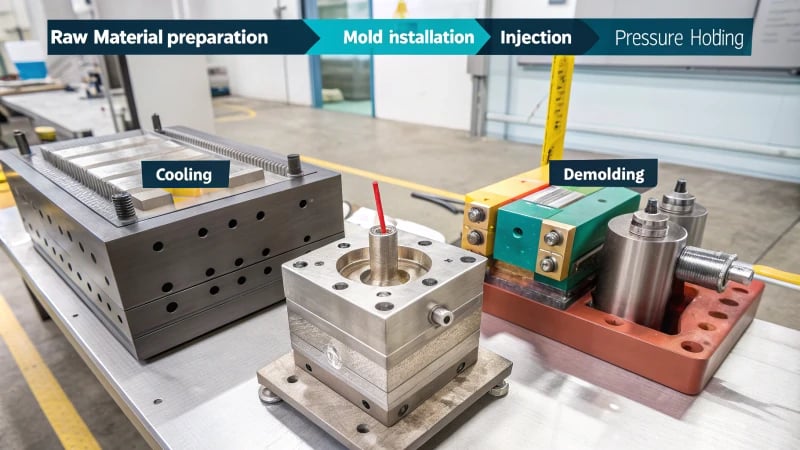

What Are the Key Steps in the Injection Molding Process?

The injection molding process involves several key steps: preparing raw materials, mold installation, injection, pressure holding, cooling, and demolding. Each step is crucial for producing high-quality plastic products.

MANUFACTURING

What Shape Does the Final Product Take in Injection Molding?

Injection molding creates diverse product shapes, including three-dimensional designs, thin-walled structures, and products with inserts. Each shape serves specific functions while balancing aesthetics and practicality in design.

MANUFACTURING

When Should You Choose Overmolding Over Two-Shot Injection Molding?

This article explores the advantages of overmolding versus two-shot injection molding, emphasizing its benefits in enhancing surface performance, accommodating complex shapes, and being cost-effective for small batch production.

MANUFACTURING

What Are the Key Differences Between Plastics for Extrusion and Injection Molding?

This article explores the key differences between extrusion and injection molding processes in plastics manufacturing, focusing on melt viscosity, thermal stability, shrinkage rates, and material toughness. Understanding these factors is crucial for optimizing product design and production efficiency.

MANUFACTURING

What Makes Blow Molding Ideal for Producing Bottles and Containers?

Blow molding is a cost-effective and efficient manufacturing process for creating hollow plastic bottles and containers. It offers flexibility in design, uniform material distribution, and high production efficiency.

MANUFACTURING

What Are the Pros and Cons of Air Ejection Demoulding Technology?

Air top demoulding technology utilizes gas pressure to gently release products from molds, significantly improving surface quality by eliminating ejector marks and enhancing production efficiency. This method simplifies mold structures, reduces wear, and is particularly beneficial for intricate designs in ...

MANUFACTURING

How Do Injection Pressure and Holding Pressure Differ?

This article explores the critical differences between injection pressure and holding pressure in the injection molding process. Injection pressure pushes molten plastic into the mold, ensuring complete filling, especially for complex shapes. Conversely, holding pressure stabilizes the product as it ...

MANUFACTURING

What Are the Standard Steps in the Injection Mold Acceptance Process?

The injection mold acceptance process is crucial for ensuring that molds meet design specifications and maintain high quality standards. It consists of several key steps: first, surface quality inspection checks for defects like scratches or rust and measures roughness using ...

MANUFACTURING

How Do Hardness and Toughness of Mold Steel Impact Injection Mold Longevity?

The longevity of injection molds is heavily influenced by the hardness and toughness of the mold steel used. Hardness provides excellent wear resistance, crucial for maintaining mold precision against abrasive materials like glass-filled plastics. Toughness ensures that molds can absorb ...

MANUFACTURING

How Can You Reduce the Labor Cost of Injection Molding Machine Products?

Reducing labor costs in injection molding is crucial for maintaining profitability. This article discusses effective strategies such as implementing automation, providing professional skills training, optimizing production processes, and establishing performance incentive mechanisms. Automation reduces reliance on manual labor while intelligent ...

MANUFACTURING

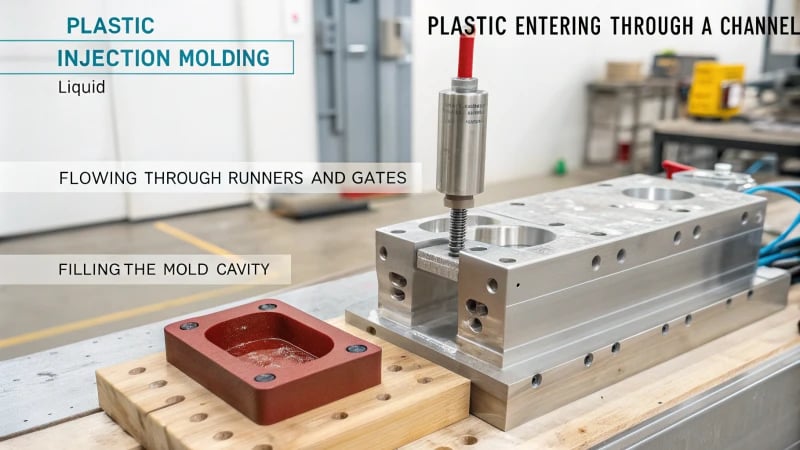

What Happens to Plastic When It’s Injected Into a Mold?

This article explores the intricate journey of plastic during the injection molding process. It details how molten plastic is injected under pressure through the main channel, runners, gates, and finally fills the mold cavity. Each stage is crucial for achieving ...

MANUFACTURING

What Are the Essential Standard Parts for Injection Molds?

This article explores the essential standard parts of injection molds, including mold frames, guide parts, ejector systems, gating systems, and cooling components. Each part plays a vital role in ensuring precision and efficiency during the molding process. Mold frames provide ...

MANUFACTURING

What Tools Can Help Adjust Injection Molding Process Parameters?

This article discusses the critical tools that enhance the injection molding process. Key technologies such as injection molding machine controllers allow precise adjustments of parameters like speed and pressure. Mold temperature controllers ensure optimal heating and cooling for various materials, ...

MANUFACTURING

How Does Mold Standardization Impact Production Efficiency?

This article explores how mold standardization significantly impacts production efficiency in manufacturing. By utilizing standardized molds and parts, designers can reduce design time and focus on innovation. Standard mold frames simplify the assembly process, enhance compatibility between different machines, and ...

MANUFACTURING

What Are the Best Injection Molding Materials for Superior Product Quality?

Choosing the right injection molding materials is crucial for achieving superior product quality. This article discusses various materials like polyamide (PA), thermoplastic elastomers (TPE), and polyetheretherketone (PEEK), highlighting their unique properties such as strength, toughness, heat resistance, and chemical stability. ...

MANUFACTURING

How Do Different Hardness and Toughness in Mold Steels Impact Injection Molding?

This article explores how different hardness and toughness levels in mold steels affect injection molding. High hardness steels offer excellent dimensional stability and surface quality but are difficult to process and prone to cracking. Conversely, high toughness steels provide good ...

MANUFACTURING

How is Multi-Stage Injection Molding Used in the Medical Field?

Multi-stage injection molding revolutionizes the medical field by providing precise control over the injection process. This technique ensures uniform wall thickness in syringes and infusion sets while enhancing the quality of medical packaging. By adjusting speed and pressure at different ...

MANUFACTURING