Have you ever wondered how injection molding materials are evolving in 2025?

The 2025 trends in injection molding materials emphasize sustainability with eco-friendly polymers, bio-based plastics, and recycled materials, enhancing performance and reducing environmental impact, fostering responsible innovation.

While these insights provide a glimpse into 2025’s material trends, delving deeper reveals how these innovations can revolutionize production processes. Imagine designing a product that not only meets your client’s needs but also contributes positively to the environment. That’s the potential these advancements hold—an opportunity to integrate sustainability into your designs seamlessly.

Bio-based plastics are a key trend in 2025.True

Bio-based plastics are increasingly used due to their sustainability benefits.

Injection molding materials in 2025 ignore recycled content.False

Recycled content is a significant focus in the latest material trends.

- 1. How Are Bio-Based Plastics Changing Injection Molding?

- 2. How Are Recycled Materials Transforming Our World in 2025?

- 3. Which Advanced Composites Are Leading the Industry?

- 4. How Do New Materials Impact Production Efficiency?

- 5. What Customization Options Do These Materials Offer?

- 6. How Are Sustainability Practices Influencing Material Choices?

- 7. Conclusion

How Are Bio-Based Plastics Changing Injection Molding?

Remember that time you realized your favorite product was eco-friendly? Well, bio-based plastics are shaking up the injection molding scene just like that!

Bio-based plastics revolutionize injection molding by offering sustainable, eco-friendly alternatives to traditional plastics, reducing fossil fuel reliance, cutting carbon emissions, and enhancing recyclability for manufacturers.

The Emergence of Bio-Based Plastics in Injection Molding

You know, when I first heard about bio-based plastics, I was intrigued. Imagine the idea of making plastics from renewable resources like plants. It felt like a step into the future, one where sustainability isn’t just a buzzword but a practice we live by. Manufacturers are increasingly weaving these eco-friendly materials into their processes, driven by a demand for sustainable materials1. Not only do bio-based plastics meet environmental standards, but they also bring unique properties that could enhance the performance of our products.

Compatibility with Existing Machinery

Here’s something that really caught my attention: bio-based plastics work with existing injection molding machines. I remember the relief of realizing that we wouldn’t have to overhaul our entire setup. These materials melt and flow much like traditional plastics, allowing us to seamlessly introduce them into production without massive machinery changes.

| Traditional Plastics | Bio-Based Plastics |

|---|---|

| Petroleum-derived | Plant-derived |

| Higher carbon footprint | Lower carbon footprint |

| Non-renewable | Renewable |

Environmental Impact and Sustainability

One of the most compelling aspects of bio-based plastics is their potential to dramatically lessen our environmental impact. By shifting away from fossil fuels, we can slash greenhouse gas emissions. Plus, many of these plastics are biodegradable or compostable, which means they won’t linger in landfills forever. This aligns perfectly with the circular economy initiatives I’ve been eager to explore.

On top of that, technological advancements2 have been continuously enhancing their durability and heat resistance, making them viable for a wider array of applications. It’s thrilling to see how far we’ve come and imagine where we’re heading.

Challenges and Future Prospects

But it’s not all sunshine and rainbows. One challenge I’ve faced is the cost—bio-based plastics are often pricier than their conventional counterparts. This can be a sticking point for some manufacturers. However, as technologies improve and demand rises, prices are expected to fall.

Research is ongoing into improving bio-based plastics’ properties. We’re experimenting with new feedstocks and processing techniques to broaden their use in injection molding. It’s heartening to witness the industry coming together through industry collaborations3 and policies that promote sustainable practices, hinting at an exciting future for bio-based materials in injection molding.

Bio-based plastics are derived from petroleum.False

Bio-based plastics are derived from renewable biological resources, not petroleum.

Bio-based plastics lower greenhouse gas emissions.True

They reduce reliance on fossil fuels, helping lower greenhouse gas emissions.

How Are Recycled Materials Transforming Our World in 2025?

Ever wondered how the everyday items we use can help save the planet? In 2025, recycled materials are doing just that, becoming heroes of sustainability and economic efficiency.

In 2025, recycled materials are crucial for sustainability, reducing waste and costs, and driving eco-friendly production, playing a significant role in meeting global sustainability targets.

The Economic Impact of Recycled Materials

I remember when my company first decided to integrate recycled materials into our production line. At first, I was skeptical about the cost savings. But, as it turns out, using recycled materials has helped us significantly cut down on raw material expenses. In industries like automotive and consumer electronics, this can mean reducing costs by up to 15% or even 20%! It’s amazing how much these savings add up over time.

| Industry | Cost Reduction (%) |

|---|---|

| Automotive | 15 |

| Consumer Electronics | 20 |

Environmental Benefits and Sustainability

Switching to recycled materials has also made me more aware of the environmental impact of our production processes. For example, using recycled aluminum instead of new aluminum saves up to 95% of the energy typically required. This not only reduces our carbon footprint but also helps us align with global climate targets4. It’s reassuring to know that we’re making a positive impact on the planet.

Innovations in Recycling Technologies

The strides being made in recycling technologies are nothing short of inspiring. Imagine being able to recycle materials we once thought were impossible to reuse! Technologies like chemical recycling are opening up new possibilities for polymer recovery5. It’s a game-changer, allowing us to make our manufacturing processes even more sustainable.

Societal Impact and Consumer Awareness

I’ve noticed a shift in consumer behavior too. People are more aware of the products they’re buying and their environmental impact. As more companies, including ours, adopt eco-friendly practices, this awareness grows. Consumers appreciate brands that care about sustainability, which boosts our brand reputation6 and fosters customer loyalty. It’s rewarding to see how our efforts contribute to a broader societal shift toward sustainability.

By understanding these multifaceted impacts, industry professionals like myself and consumers can truly appreciate the essential role of recycled materials in shaping a sustainable future. It’s exciting to be part of this transformative movement.

Recycled aluminum saves 95% energy compared to new.True

Using recycled aluminum significantly reduces energy use, saving up to 95%.

Recycled materials increase landfill waste in 2025.False

Recycled materials decrease landfill waste by promoting reuse.

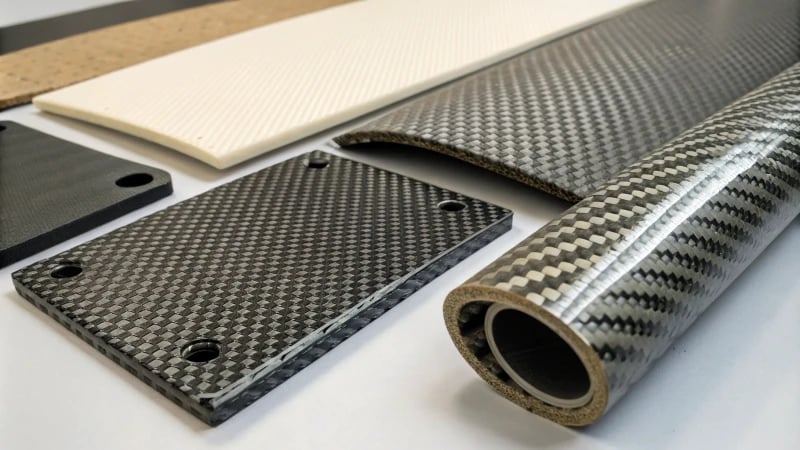

Which Advanced Composites Are Leading the Industry?

Imagine a world where materials are as light as feathers yet as strong as steel. This isn’t science fiction—it’s the world of advanced composites. Curious about which materials are at the forefront? Let’s dive into the fascinating realm where engineering dreams become reality.

Leading advanced composites, such as CFRPs, glass fiber composites, and CMCs, dominate industries like aerospace, automotive, and construction due to their lightweight durability.

When I think about the strides we’ve made in material science, it feels like we’ve crossed into a new era. Back when I was starting out in design, materials were more about compromise—strength meant weight, and lightweight often meant sacrificing durability. But today? We’re seeing the best of both worlds thanks to advanced composites.

Carbon Fiber-Reinforced Polymers (CFRPs)

I remember the first time I worked with CFRPs in a project aimed at reducing weight without compromising strength. It was almost like designing with magic. These polymers are now revolutionizing aerospace engineering7, allowing for lighter yet robust aircraft components such as wings and fuselages.

Advantages:

- Lightweight: Imagine reducing metal weight significantly while maintaining strength.

- High Tensile Strength: Perfect for those load-bearing structures we often worry about.

- Corrosion Resistance: Ideal for tough environments where longevity is key.

Glass Fiber Composites

In my years designing in the automotive industry8, glass fiber composites became a go-to for their balance between cost and performance. These materials work wonders in body panels and interior components, offering flexibility that other materials just can’t match.

| Property | Glass Fiber Composites |

|---|---|

| Weight | Moderate |

| Cost | Affordable |

| Thermal Resistance | Moderate |

Ceramic Matrix Composites (CMCs)

CMCs are nothing short of extraordinary in high-temperature settings. I once collaborated on a project involving aerospace turbines9, and CMCs were invaluable for their ability to handle extreme heat without losing integrity.

Key Features:

- High-Temperature Stability: They stand strong even at soaring temperatures.

- Thermal Shock Resistance: They don’t flinch with rapid temperature changes.

- Lightweight: A lighter alternative to traditional ceramics, making them a designer’s dream.

Emerging Trends

I’ve always kept an eye on emerging trends, and the innovations in nanocomposites10 truly excite me. Their potential to enhance electrical conductivity could revolutionize electronics manufacturing. Plus, the shift towards sustainable composites made from renewable resources11 is an encouraging step forward. It aligns with our global push towards eco-friendly production and could redefine what we consider standard in terms of environmental responsibility and performance.

By getting a grasp on these advanced composites, professionals like us can harness their unique attributes to push the boundaries of product design and manufacturing. Each material is a tool in our arsenal, ready to bring our most ambitious designs to life.

CFRPs are heavier than traditional metals.False

CFRPs are lighter than metals, offering significant weight reduction.

Glass fiber composites are used in automotive body panels.True

Glass fiber composites are commonly used in automotive body panels.

How Do New Materials Impact Production Efficiency?

Ever wonder how the latest materials are shaking up the way we make things? I’ve got some insights that might just surprise you.

New materials enhance production efficiency by increasing durability, reducing waste, and accelerating manufacturing, resulting in cost savings and improved product quality through innovations in composites and smart materials.

Understanding Material Innovation

I remember when I first stumbled upon the wonders of composite materials; it felt like discovering a new superpower for the manufacturing world. These innovations, like composite materials12 and smart polymers, are not just making products better—they’re changing how we create them. Imagine a car that’s both lighter and stronger, resulting in fuel savings that could transform industries like automotive and aerospace. That’s the magic of composites for you.

Benefits of Smart Materials

Then there are smart materials. Picture this: materials that adjust to their surroundings, almost like they have a mind of their own. These self-healing wonders can cut down on maintenance needs and extend a product’s life, slashing costs and downtime in one go. Take smart textiles13, for instance. They’re reshaping wearable technology by responding to body temperature or light, offering consumers added value without them even noticing.

| Material Type | Key Benefit | Example Application |

|---|---|---|

| Composites | Lightweight and durable | Automotive body parts |

| Smart Polymers | Self-healing capabilities | Electronics and wearables |

| Bio-materials | Eco-friendly and renewable | Packaging and utensils |

Role of Bio-materials

Let’s not forget bio-materials, those unsung heroes derived from nature. They’re stepping up as eco-friendly champions, reducing our reliance on non-renewable resources and cutting down the carbon footprint of manufacturing. I think about how bio-plastics are being used in packaging as a sustainable swap for conventional plastics—it’s exactly what we need in today’s green-conscious world.

Challenges and Opportunities

Of course, it’s not all smooth sailing. Challenges like cost and scalability linger, but I believe in the power of research to overcome these hurdles. The field of material science14 is bustling with potential, promising even more groundbreaking materials to boost efficiency.

Embracing these advancements means companies can offer superior products while slashing production times and costs. This leads to competitive pricing and better profitability—a win-win in my book. It’s an exciting time to be in manufacturing, watching these material innovations unfold.

Composites reduce fuel consumption in aerospace.True

Composites are lightweight yet strong, leading to fuel savings.

Smart polymers increase maintenance costs.False

Smart polymers reduce maintenance due to self-healing properties.

What Customization Options Do These Materials Offer?

Ever wondered how to make a product truly your own? Customization is the magic key!

Materials such as plastics, metals, and composites offer diverse customization options, including colors, textures, and functionalities, enabling tailored modifications for various design requirements.

Understanding Material Versatility

I’ve always been fascinated by how the right material can transform a simple concept into a tailored masterpiece. Each type of material—plastics, metals, composites—comes with its own unique set of customization capabilities15. Whether it’s tweaking colors, refining textures, or boosting functional qualities, these options empower designers like me to meet exact client demands.

Plastics: A Palette of Possibilities

Take plastics, for instance. They’re like a blank canvas ready to be painted in any hue or texture. I remember a project where I had to mold plastics into vibrant shades for a tech gadget. The color variations seemed limitless thanks to pigments and dyes.

- Color Variations: Think of any color under the sun, and chances are plastics can be dyed to match.

- Texture Options: From sleek gloss to subtle matte, the feel can change the entire user experience.

- Functional Enhancements: Need something more durable? Additives can enhance UV resistance or strength.

Here’s a handy table summarizing common plastic customization options:

| Option | Description |

|---|---|

| Color Variations | Wide range of hues through pigments or dyes. |

| Texture Options | Smooth, glossy, matte, or rough finishes. |

| Functional Add-ons | UV protection, flame resistance, increased durability |

Metals: The Power of Precision

When it comes to metals like aluminum and stainless steel, it’s all about precision. I once worked on a project that required intricate designs—metals were the obvious choice due to their structural reliability and versatility.

- Surface Treatments: Anodizing not only boosts appearance but also enhances durability.

- Structural Modifications: Intricate machining allows for precision in design.

- Alloying: Mix and match metals for specific properties like corrosion resistance.

Composites: Hybrid Adaptability

Composites are like the best of both worlds, combining materials to draw on their strengths. I’ve embedded sensors within composite layers for a smart tech device—it was a challenging yet rewarding experience.

- Layering Techniques: Customize layers for varying strength and flexibility.

- Embedded Elements: Integrate sensors or components within layers for added functionality.

Each material offers unique customization opportunities for designers. By understanding these options, product designers16 can craft creations that don’t just meet functional needs but also fulfill aesthetic dreams. Leveraging these possibilities allows us to stand out in competitive markets with truly personalized solutions.

Plastics can be customized with color variations using dyes.True

Plastics allow color customization through pigments or dyes.

Metals cannot undergo surface treatments for customization.False

Metals can be customized using surface treatments like anodizing.

How Are Sustainability Practices Influencing Material Choices?

Ever looked at a sleek product and wondered about the story behind its materials?

Sustainability practices influence material choices by prioritizing eco-friendly options, reducing waste, conserving energy, and enhancing product lifecycles, thereby assessing environmental impacts and achieving long-term efficiency to meet eco-conscious standards.

The Role of Eco-Friendly Materials

When I first stumbled upon the world of eco-friendly materials17, I was intrigued by how they turned everyday waste into something new and useful. Imagine working with bioplastics or recycled metals, knowing these came from renewable resources or were once discarded products given a second life. It’s like watching a caterpillar transform into a butterfly—nature reinventing itself.

| Material Type | Characteristics |

|---|---|

| Bioplastics | Derived from renewable biomass sources |

| Recycled Metals | Reused from existing metal waste |

Using such materials not only lowers our reliance on finite resources but also significantly trims down the carbon footprint of what we create. It’s like breathing fresh air into the design world.

Assessing Environmental Impacts

I remember grappling with life cycle assessments (LCAs) for the first time. It felt overwhelming, yet enlightening. It’s about weighing every choice—from production to disposal. I once compared the energy needs of aluminum versus steel for a project, discovering that sometimes the greener choice isn’t always the obvious one.

LCAs push us to make smarter, sustainable decisions, aligning our designs with a healthier planet.

Enhancing Product Lifecycle Sustainability

Thinking about a product’s entire lifecycle has been a game changer for me. Instead of seeing a design as just an object, I now view it as part of a broader ecosystem. It involves selecting materials that are easy to recycle or biodegrade.

Consider modular designs—imagine replacing just one part of a product rather than tossing it entirely. This approach not only extends its life but also cuts down on waste. It’s like giving your favorite gadget a new lease on life.

The Influence on Processing Methods

And then there’s the thrill of exploring innovative processing methods like additive manufacturing18. This technique is akin to sculpting with laser precision, using exactly what’s needed without excess.

It’s fascinating how manufacturers are leaning towards low-energy processing methods, which align beautifully with sustainability goals. These processes use less heat and pressure, making them kinder to our planet.

By weaving these sustainable practices into our designs, we’re not just keeping up with trends; we’re crafting solutions that meet today’s eco-conscious demands while paving a greener path for future generations.

Bioplastics are derived from renewable biomass sources.True

Bioplastics are indeed made from renewable biomass, reducing reliance on fossil fuels.

Additive manufacturing increases material waste.False

Additive manufacturing reduces material waste by using precise amounts needed for production.

Conclusion

In 2025, injection molding trends emphasize sustainability through bio-based plastics, recycled materials, and advanced composites, enhancing performance while reducing environmental impact in manufacturing processes.

-

Learn how sustainable materials like bio-based plastics are becoming vital in manufacturing, supporting environmental goals. ↩

-

Explore how innovations in bioplastics are enhancing their properties for broader applications. ↩

-

Discover how partnerships are driving sustainability in manufacturing through the use of bio-based materials. ↩

-

Learn how recycled aluminum significantly cuts energy use and supports climate goals. ↩

-

Explore how chemical recycling opens new avenues for reusing complex polymers. ↩

-

Find out why brands using recycled materials gain customer trust and loyalty. ↩

-

Discover how CFRPs enhance performance in aerospace engineering with their lightweight yet robust properties. ↩

-

Explore why glass fiber composites are favored in automotive design for their balance of cost and performance. ↩

-

Learn about the application of CMCs in aerospace turbines, focusing on their high-temperature resilience. ↩

-

Uncover the potential of nanocomposites in revolutionizing electronics with improved conductivity and strength. ↩

-

Investigate emerging trends in eco-friendly composites sourced from renewable materials. ↩

-

Explores how composite materials enhance durability and efficiency across various industries. ↩

-

Delve into real-world applications of smart textiles enhancing consumer experience. ↩

-

Discover cutting-edge developments in material science driving innovation. ↩

-

Explore the vast customization potential of various materials, offering insights into their unique properties and applications. ↩

-

Learn how material customization empowers designers to create innovative products that meet specific client demands. ↩

-

Explore how eco-friendly materials contribute to sustainable design by learning about different types and their benefits. ↩

-

Understand how additive manufacturing reduces material waste and energy consumption, promoting sustainable production. ↩