Have you ever thought about how a small change in temperature might ruin your well-crafted product?

Mold temperature changes warping and bending in products made by injection molding. High temperatures slow down cooling. This results in uneven crystallization. Low temperatures cause fast cooling. Fast cooling increases shrinkage. Both these things lead to warping. Warping occurs because of different cooling speeds.

I still remember when a batch of plastic covers caught me by surprise. They looked more like potato chips than smooth shells. The reason? Mold temperature. High mold temperatures cause slow and uneven cooling, especially in parts with different thicknesses. This uneven cooling leads to thermal stress. Thick areas hold heat while thin ones cool quickly. Soon, I had a bent product.

On the other side, setting the mold temperature too low is also challenging. I rushed a production with a cooler mold, thinking it would be quicker. Instead, it caused fast cooling, trapping internal stresses before the molecules could settle. Imagine a thin-walled container with a handle. The handle hardened before the main body, making it lean awkwardly.

Both experiences taught me that adjusting mold temperature is like walking a tightrope. Finding the perfect balance is everything. Everything needs to cool evenly to settle without stress.

High mold temperature causes uneven cooling.True

High mold temperatures slow cooling, leading to uneven thermal stresses.

Low mold temperature reduces product shrinkage.False

Low mold temperatures increase shrinkage, causing uneven warping.

What Happens When Mold Temperature is Too High?

When I began my journey with injection molding, I soon discovered that handling mold temperatures requires careful attention.

Mold temperatures rising too much lead to warping and deformation. The product does not cool evenly. Internal stresses cause problems. Final quality suffers because of these issues.

Effects of High Mold Temperature

Think about baking a cake with the oven set too high. The top seems ready, but inside it’s still soft. This is similar to what occurs in injection molding when mold temperature rises too much. Cooling slows, leading to uneven cooling and causing thermal stress. Thick parts hold heat longer than thin ones. After molding, they pull against each other, leading to warping.

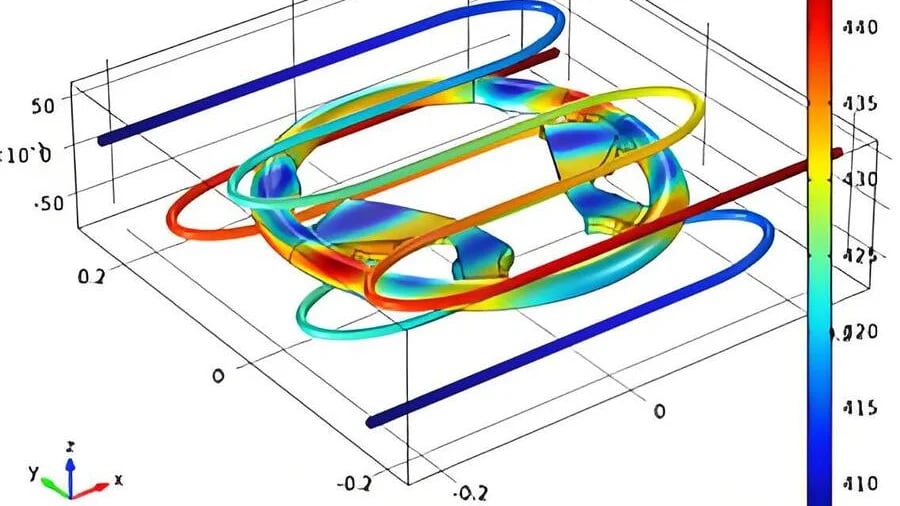

Influence on Crystallization Process

Working with crystalline plastics can be tricky at high temperatures. Crystallization might turn out uneven if not monitored closely. In one project, polyethylene products1 showed perfect crystallization at the center, yet edges lagged behind. This difference in crystallization caused warping.

Visualizing Warping

| Factor | Effect |

|---|---|

| Uneven Cooling | Warping towards thicker sections |

| Uneven Crystallization | Edge warping |

Managing Mold Temperatures

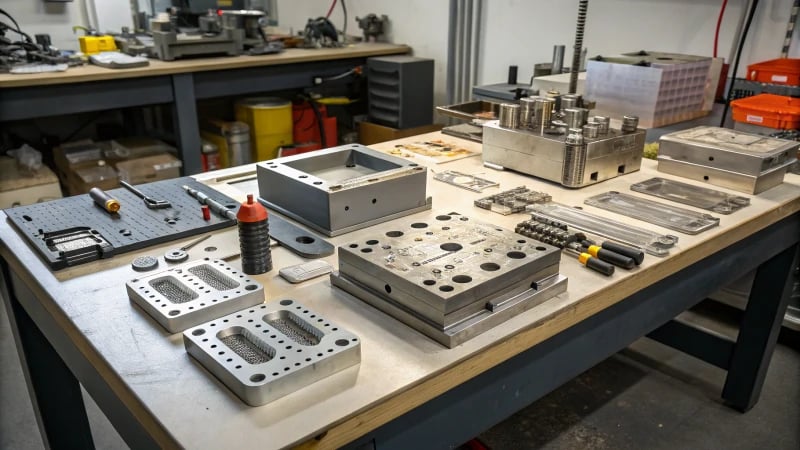

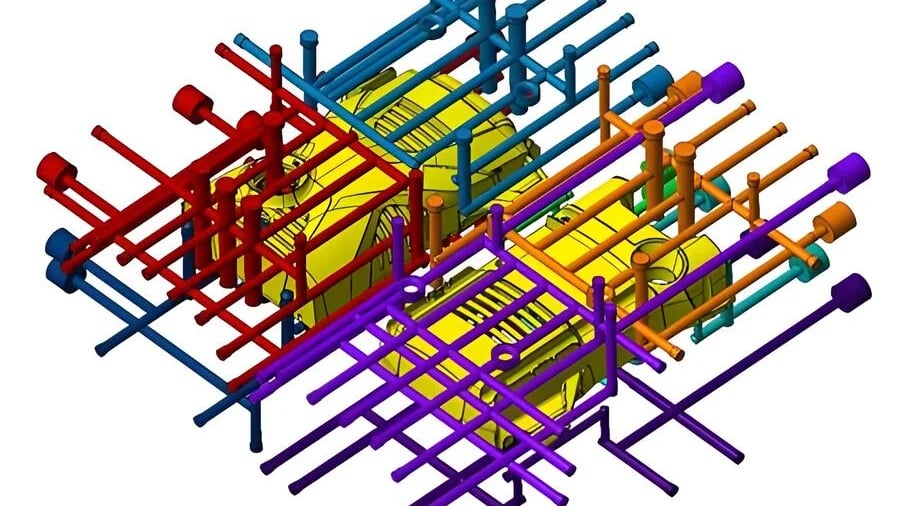

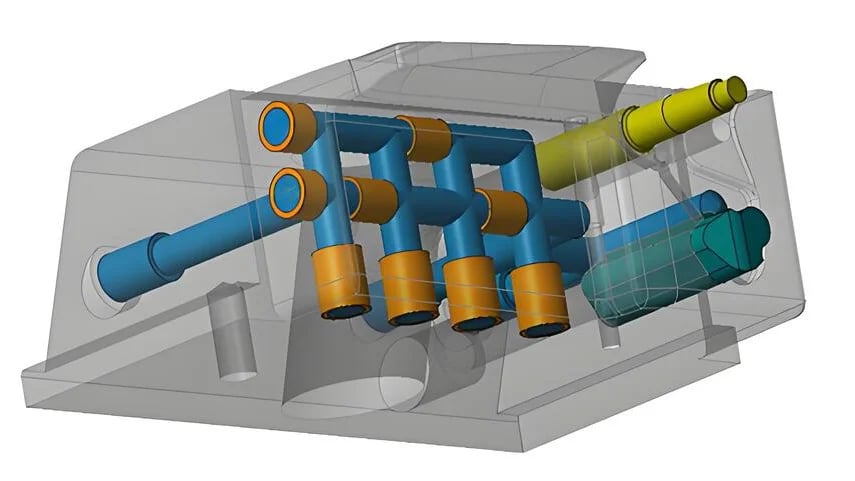

Controlling mold temperatures is key to avoiding these problems. Each project requires attention to mold temperatures to keep cooling even and crystallization correct. Advanced cooling systems and temperature sensors help maintain consistency.

Explore some temperature control techniques2 that I’ve found useful. These techniques improve product quality and make production smoother by achieving the right temperature, reducing defects, and increasing reliability.

High mold temperature causes warp deformation.True

High temperatures lead to uneven cooling, causing thermal stresses and warping.

Low mold temperature reduces product shrinkage.False

Low temperatures increase shrinkage due to rapid cooling and uneven contraction.

Why Does Low Mold Temperature Cause Rapid Cooling and Warping?

Do you ever think about why your molded parts sometimes warp? This issue isn’t just a puzzling problem; it has a lot to do with mold temperature. Mold temperature really matters. It’s important.

Cool mold temperatures result in quick cooling. It freezes molecular chains too soon, creating internal stress. Fast cooling and shrinking can cause the material to bend or twist. This happens especially in molds with complicated shapes or different thicknesses. Warping is often a problem here. It’s common in such cases.

Effects of Rapid Cooling

I recall the first time I faced the problem of things cooling down too fast. I was busy with a project for a stylish new gadget. Everything seemed fine until the prototype twisted out of shape. The trouble was due to the mold being too cold, which made the plastic3 cool down too fast. When this happened, the material’s tiny chains froze before they could move into place. This stress proves particularly challenging in designs with different sizes. Thin parts solidify while thicker parts are still settling.

Think about cooking a dish in the oven. One side cooks faster than the other. This makes the dish uneven, just like uneven cooling leads to warped molded items.

Uneven Shrinkage Dynamics

This reminds me of my early experiments with big flat plastic sheets. I aimed for a perfect surface, but the edges always curled up. The reason? Mold temperatures were too low, causing the edges to cool and shrink faster than the center. This caused annoying warps.

| Section | Cooling Rate | Shrinkage |

|---|---|---|

| Edges | Fast | High |

| Center | Slow | Low |

Handling these uneven shrinking troubles showed me how vital it is to balance mold designs and temperature settings. Every time I need to maintain flatness or evenness, these lessons guide my thinking.

Internal Stresses and Warping

A really tough time for me was when I tried making a container4 with a thin handle. As expected, the handle cooled and shrank before the main part, bending everything out of shape. Low mold temperatures were the cause, fixing shapes too soon and causing stress spots that twisted the item.

I discovered that spreading out the temperature evenly across the mold helps avoid such problems. Each mistake has been a valuable lesson; it helps me refine my design ideas, allowing me to balance how things cool and how stress is managed more effectively.

High mold temperatures cause warping in injection-molded parts.True

High temperatures lead to uneven cooling, causing thermal stresses and warping.

Low mold temperatures reduce shrinkage in plastic products.False

Low temperatures increase shrinkage, leading to uneven contraction and warping.

How Does Crystallization Affect Product Deformation?

Ever seen something break apart very slowly? Crystallization probably does that to your products.

Crystallization greatly influences how a product bends or twists by changing heat and inside forces. Uneven crystallization alters size, causing bending or warping. Proper control of mold temperatures reduces these effects. The product then keeps its planned shape and use.

The Crystallization Process and Its Impact on Product Deformation

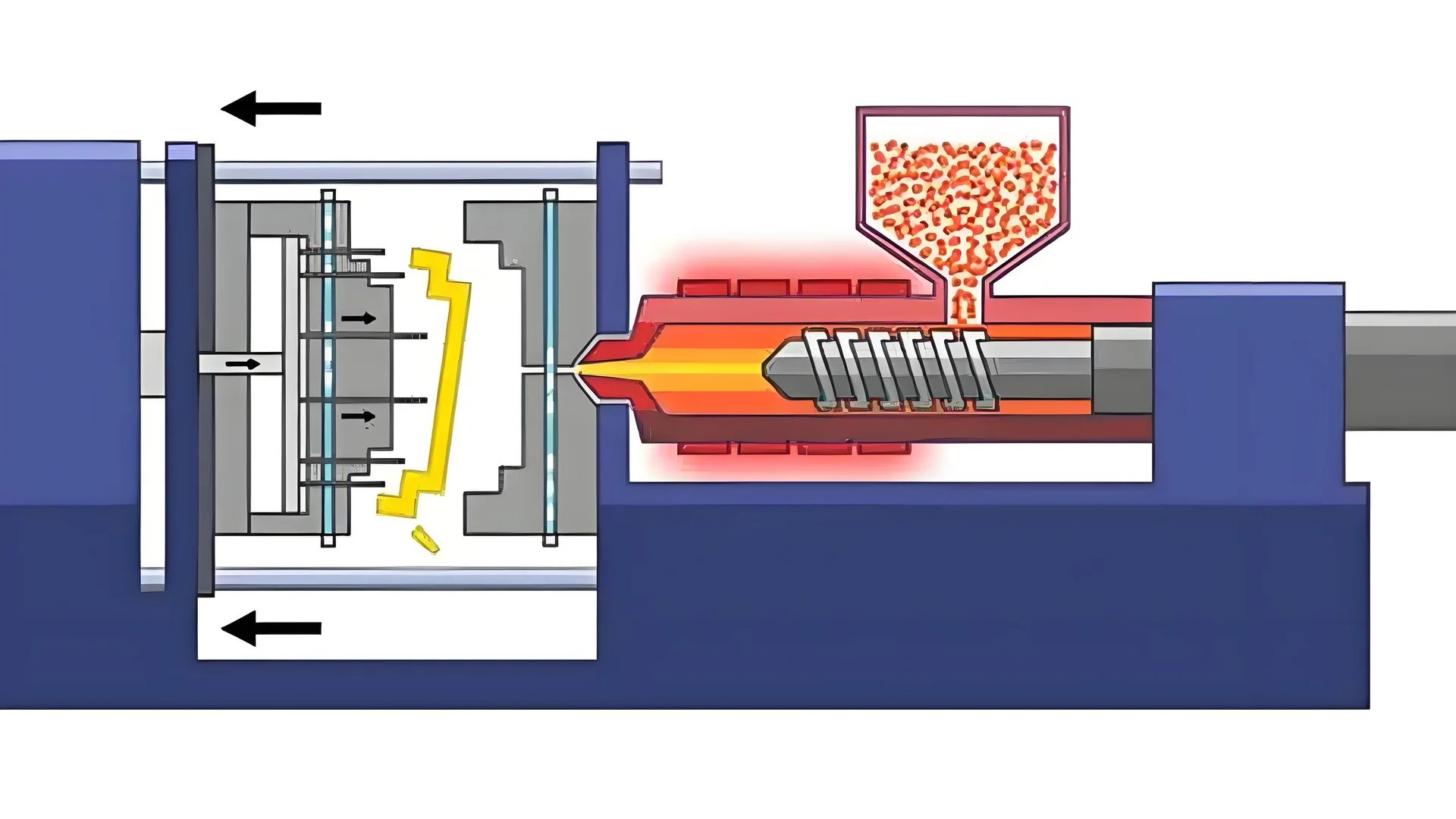

Crystallization occurs when small molecules come together to form structures known as crystal lattices. This process resembles a dance where each molecule joins in a neat line. In manufacturing, especially injection molding5, this organized lineup affects the final shape and strength of a product.

Thermal Stresses from Uneven Cooling

Sometimes, an injection-molded item emerges with an unexpected bend. Imagine a gadget case that resembles abstract art instead of a sleek piece. When mold temperatures are too high, this happens. Thicker parts cool slower, causing thermal stress and warping eventually follows.

Crystallization’s Role in Warp Deformation

Too much heat speeds up crystallization. This might seem helpful, but it can cause issues. Picture polyethylene forming crystals more in the middle than at the edges. This unequal growth causes warping. Proper design helps with this.

| Parameter | Effect on Deformation |

|---|---|

| Mold Temperature | Affects cooling rate and crystallization uniformity |

| Wall Thickness | Influences heat dissipation and internal stress |

| Crystallization Rate | Determines volume change and potential warp |

Managing Crystallization for Better Product Integrity

Keeping mold temperatures balanced is very important. Think of it like flipping pancakes—too early or late and you have a problem. Balancing mold temperatures helps control crystallization rates, ensuring uniformity across a product, reducing stress and deformation, optimizing both product use and appearance.

Internal Stresses Due to Rapid Cooling

A plastic container I examined once kept bending near its handle due to rapid cooling. The handle set in place while the rest of the container moved—it’s like trying to keep a shape while moving; really not simple.

Uneven Shrinkage Effects

Plastic plates sometimes cool unevenly; faster cooling at the edges leads to more shrinkage there, causing bending upwards. This is very important in precision engineering6, where every detail really matters.

Understanding these factors allows us to choose better materials and processes, raising product quality across various applications.

High mold temperature causes uneven crystallization.True

Excessive mold heat promotes uneven crystallization, causing stress and warping.

Low mold temperature decreases product shrinkage.False

Low temperatures increase shrinkage, leading to uneven cooling and deformation.

What Are the Best Practices for Managing Mold Temperature?

Do you remember when you first tried to bake bread? Controlling mold temperature in injection molding is similar to setting the correct oven temperature – it’s very important for a flawless product.

Controlling mold temperature focuses on improving cooling rates and keeping heat spread evenly. This lessens flaws such as warping. Product quality becomes higher. Production efficiency in injection molding becomes better.

Importance of Proper Mold Temperature

In product design, understanding the right mold temperature became critical for me. Picture it like balancing a seesaw with a child and an adult: challenging but necessary. Proper temperature affects how material cools and crystallizes. It also determines the overall quality of the product. Finding the right temperature spot reduces defects like warping7 and internal stresses.

High Mold Temperature Effects

I once worked on a project with a mold set too hot. It felt like baking a cake too quickly: the outside cooked, but the inside stayed soft. This caused thermal stress in our products. Different parts cooled at uneven rates, leading to warping.

- Warp Deformation: High mold temperatures can lead to thermal stresses from uneven cooling.

- Crystallization Issues: Excessive temperatures may promote uneven crystallization, resulting in inconsistent volume changes and internal stresses.

| Factor | Effect |

|---|---|

| High mold temperature | Uneven cooling, warping |

| Crystallization process | Inconsistent volume changes |

Low Mold Temperature Effects

On the other hand, setting the temperature too low resembles quick-freezing a lake. It gets solid quickly but might crack. Fast cooling traps molecular chains too soon, leading to high internal stresses, mostly in complex shapes.

- Rapid Cooling Stresses: Low temperatures accelerate cooling, fixing molecular chains prematurely.

- Uneven Shrinkage: Fast cooling can cause varying shrinkage rates across the product, leading to warping8.

Finding Mold Temperature Balance

Finding the right mold temperature is like choosing the best gear for cycling uphill. Calibration needs care. Sensors and control systems play a vital role here. They track and adapt temperatures, ensuring good product quality.

- Sensor Use: Sensors provide real-time data on mold conditions.

- Control Systems: Modern systems keep temperatures steady throughout the molding process.

Practical Tips for Mold Temperature Management

- Check and maintain cooling channels to prevent blockages.

- Select materials with known thermal properties for better results.

- Experiment to discover the best temperatures for new molds.

- Consider room temperature and humidity when setting temperatures.

Focusing on these methods has shown me that manufacturers improve product quality and efficiency through proper temperature settings. Adjusting temperatures for material types and product complexity transformed my injection molding work.

High mold temperature causes uneven cooling.True

Uneven cooling from high mold temperatures leads to thermal stresses and warping.

Low mold temperature reduces product shrinkage.False

Low mold temperatures increase shrinkage, causing uneven contraction and warping.

How Do I Tackle Warpage in Injection Molding?

Upon entering the injection molding world, I constantly faced the challenge of warpage. Each project taught me new ways to reduce these annoying flaws. This challenge seemed endless. It really was.

To reduce bending in injection molding, I concentrate on adjusting mold temperatures. I keep cooling rates even across the mold. Selecting the correct materials is crucial. Simulation software is essential. It helps identify possible problems early. It lets me change designs before production starts.

Understanding Why Warpage Happens

Over time, I saw how important it is to know why warpage occurs. High mold temperatures cause thermal stresses9 because parts cool unevenly. This surprised me when I learned that parts were bending because they cooled at different speeds. Meanwhile, low mold temperatures cause rapid cooling and freeze the molecular chains too soon, leading to internal stresses and warpage.

Best Mold Temperature Settings

Choosing the right mold temperature is tough. Very high temperatures cause uneven crystallization; low temperatures cool too quickly. For me, using computer simulations10 was extremely helpful. These tools show how different temperatures affect the product and help me find the right balance.

| Mold Temperature | Effect on Warpage |

|---|---|

| High | Promotes uneven crystallization |

| Low | Increases risk of rapid cooling |

Picking Materials and Design Planning

Choosing the right material matters a lot. Crystalline plastics change with temperature, so I pick materials that behave predictably to avoid warpage. Part shape influences this too; keeping thickness the same helps even cooling.

Using Modern Simulation Tools

Before I start production, I use simulation software to spot possible warpage problems early. This approach saves time and cuts waste by allowing adjustments in design and process early on—it’s like seeing the future of injection molding!

For those interested in material selection criteria11, knowing how materials act in different situations really improves the design. It’s about finding the right mix where design works perfectly.

High mold temperature causes uneven cooling.True

Uneven cooling from high mold temperature leads to thermal stresses.

Low mold temperatures reduce product shrinkage.False

Low mold temperatures increase shrinkage, causing warping issues.

Conclusion

Mold temperature significantly impacts warpage in injection molded products, with high temperatures causing uneven cooling and low temperatures leading to rapid solidification, both resulting in internal stresses and deformation.

-

This link provides detailed insights into how polyethylene reacts to high mold temperatures, offering solutions for managing crystallization issues. ↩

-

Explore innovative methods for controlling mold temperatures to prevent defects and improve manufacturing outcomes. ↩

-

Discover how low mold temperatures affect plastic melt properties, influencing cooling rates and stress formation. ↩

-

Learn how mold design can mitigate or exacerbate warping issues in molded containers. ↩

-

Explore injection molding basics to understand its role in product deformation. ↩

-

Discover how precision engineering prevents defects during manufacturing. ↩

-

This link will provide insights into how high mold temperatures can lead to defects like warping. ↩

-

Explore how uneven shrinkage affects product integrity and what steps can be taken to mitigate it. ↩

-

Understanding thermal stresses aids in designing molds that reduce warpage risk. ↩

-

Simulation tools help designers predict warpage and optimize mold settings. ↩

-

Material choice impacts part performance and susceptibility to warpage. ↩