Finding the ideal angle for lifter release in injection molding seems like solving a different puzzle every time. Each calculation is unique.

To figure out the release angle for an injection mold lifter, examine factors like material shrinkage, product depth and lifter movement. Consider the changes in size and shape when materials cool. Use tested formulas to find an angle that lets the product release easily. Include material traits and the needs of the design in your calculations.

The formula is just the start. Every project is different and needs careful attention. Materials, like polypropylene, really change things. I once had to adjust angles a lot to prevent sticking because polypropylene shrinks a lot. Deep designs are tricky. The depth makes you recalculate angles to get a smooth release. Checking the lifter’s size and movement is crucial. Small details might surprise you. Once, a lifter moved wrong, almost causing a problem. Now, I always check these sizes. Complex shapes might seem hard. Breaking them into simpler parts helps. It’s like solving a puzzle. Using CAD software or a trial mold might reduce problems later.

Larger shrinkage materials need a smaller release angle.False

Materials with larger shrinkage need a larger release angle to prevent sticking.

Complex clasp shapes require simulation for accurate angles.True

Simulation helps optimize angles for complex shapes due to potential interferences.

- 1. How Do Lifter Release Angles Affect Injection Molding?

- 2. How Do Material Properties Affect Lifter Release Angle Calculations?

- 3. Why is product shape and size crucial in determining release angles?

- 4. How Do I Correct Lifter Dimensions and Movement Stroke?

- 5. How Can I Accommodate Complex Buckle Shapes in Angle Calculations?

- 6. Conclusion

How Do Lifter Release Angles Affect Injection Molding?

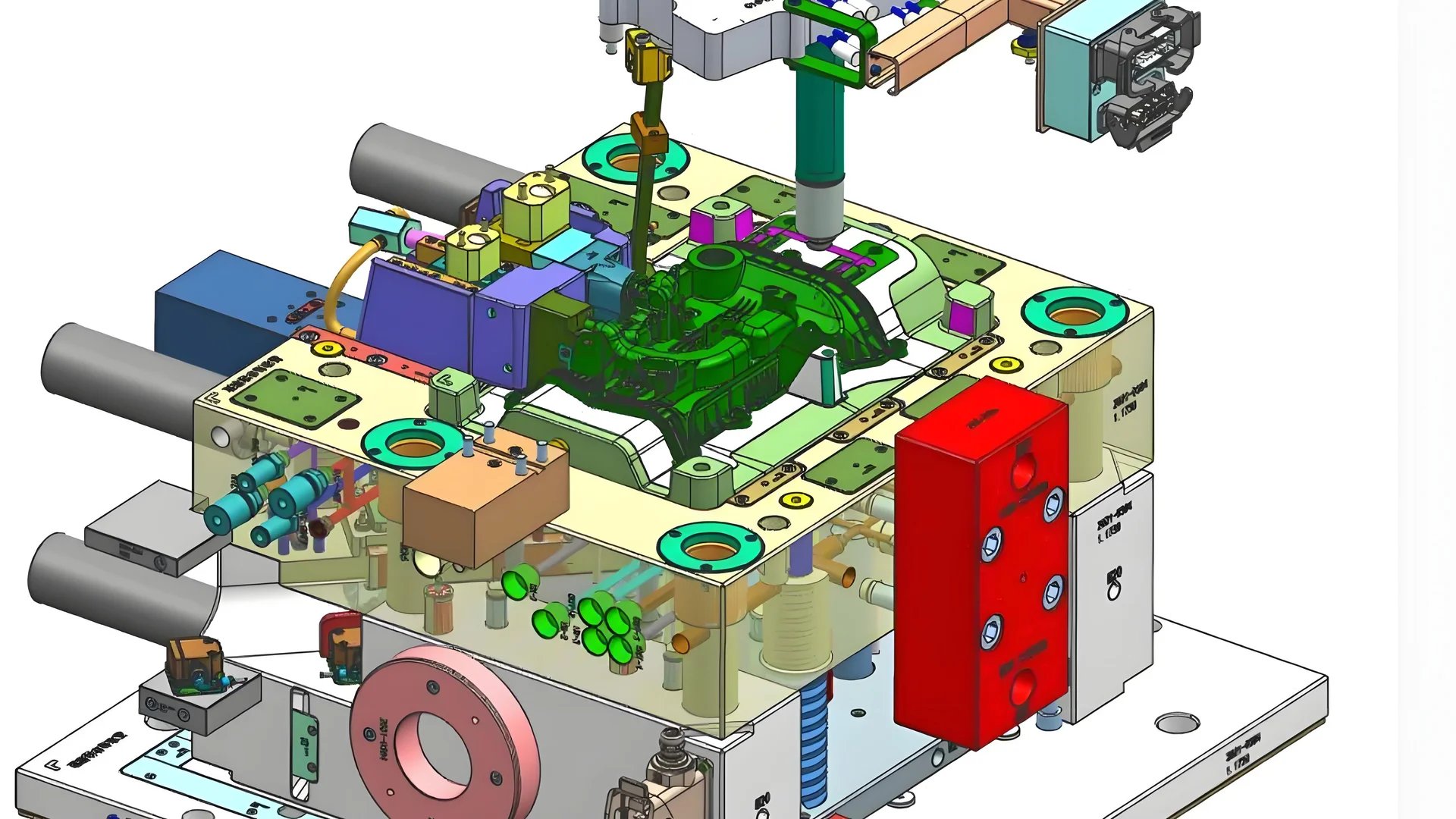

Lifter release angles often seem technical. However, they are the hidden heroes of smooth product removal. These angles help products come out without trouble. They really play an important role.

Lifter release angles help in smooth demolding during injection molding. The type of material affects these angles. Product shape and size also matter. Lifter stroke influences the angles as well.

Understanding Lifter Release Angles

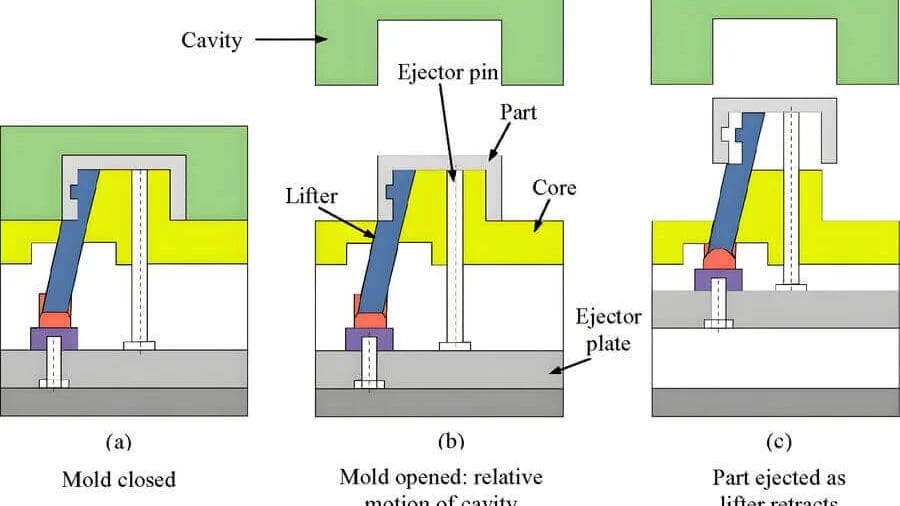

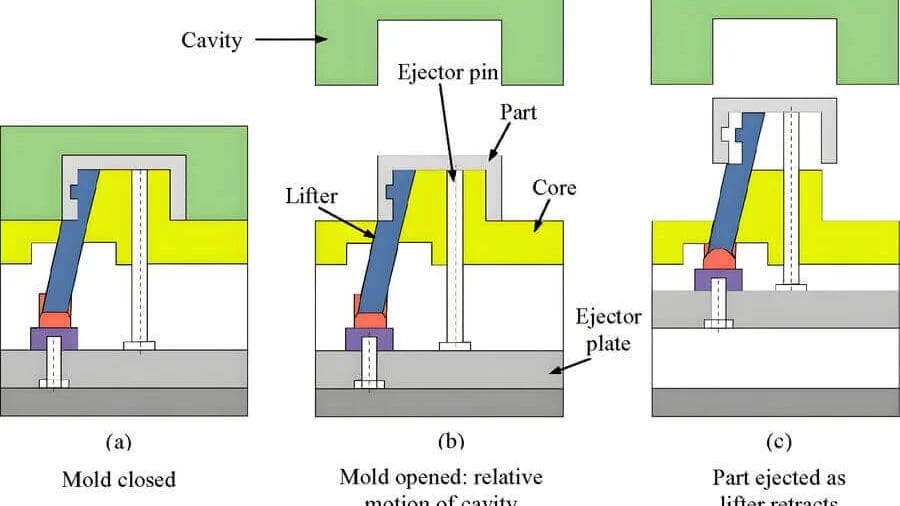

Lifter release angles play a pivotal role in injection molding by facilitating the seamless release of products from molds. The primary purpose is to prevent the product from sticking to the lifter, which can damage both the product and the mold. The size of the release angle is intricately linked to factors such as material, shape, and size of the product, as well as the stroke of the lifter.

Material Matters

Different plastics behave in unique ways. For instance, materials with high shrinkage rates like Polypropylene (PP) require a larger release angle to ensure smooth demolding. Typically, PP has a shrinkage rate between 1.0 – 2.5%. Newcomers must know these material traits well since knowing them is crucial. To learn more about how material properties affect mold design, explore material properties in molding1.

Shape and Size of the Product

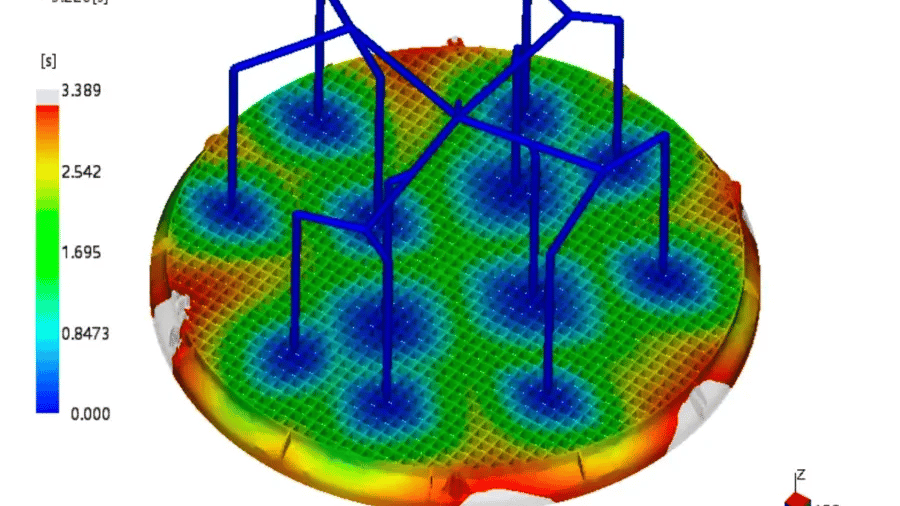

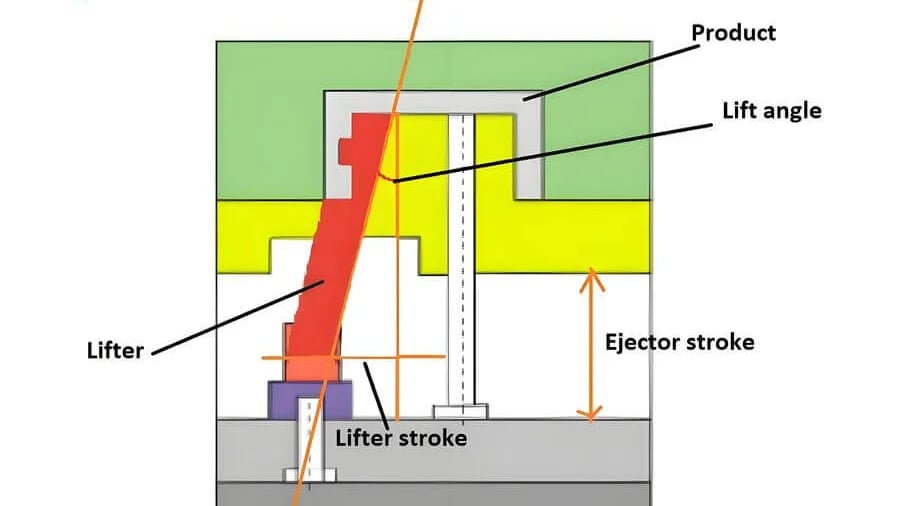

The geometry of the product significantly influences the required release angle. Deeper products, such as cylindrical shapes exceeding 50mm in depth, demand a greater lifter release angle. A common empirical formula used is tan a = S/H, where S is the horizontal travel of the lifter and H is the product depth. For example, if a product is 100mm deep and the lifter moves 5mm, then:

- H = 100mm

- S = 5mm

- Therefore, a≈2.86°.

Adjustments should be made to increase this angle to at least 3° for smoother exits.

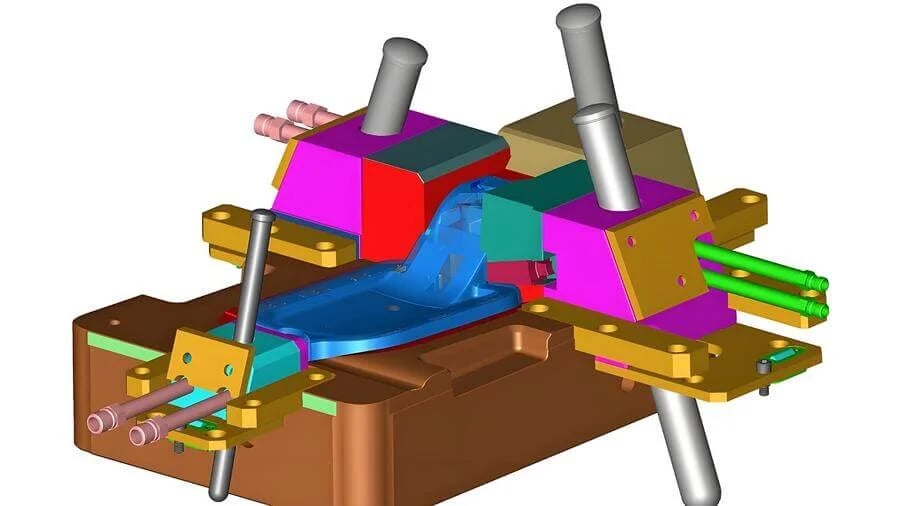

Adjustments for Complex Designs

Complex shapes pose challenges with calculations that must consider lifter dimensions and movement stroke. Designs like inverted buckles are hard to calculate accurately without precise tools or software.

For instance:

- If an inverted buckle depth is 5mm,

- Horizontal width is 20mm,

- And lifter width is 10mm,

Then: tan a≥5/(20-10)=0.5

This means: ≥arctan(0.5)=26.6°

Calculation accuracy prevents problems; therefore, using CAD software for simulation and verification can be beneficial for intricate designs. Explore how CAD software aids2 in calculating these parameters accurately.

By understanding these principles and considerations, one can ensure efficient and defect-free product demolding in injection molding processes.

Lifter release angle affects mold product detachment.True

The lifter release angle is crucial for smooth product ejection from molds.

All plastics require the same lifter release angle.False

Different plastics have varying shrinkage and friction, affecting release angles.

How Do Material Properties Affect Lifter Release Angle Calculations?

Material properties are vital for understanding lifter release angles. They affect the efficiency and quality of injection-molded products. These properties are very important.

Material properties such as shrinkage rates and friction coefficients are very important. These features affect lifter release angles. Higher shrinkage needs larger angles. High friction also demands larger angles. Larger angles prevent sticking. They help in smooth demolding.

Understanding Material Shrinkage Rates

I recall my first project using polypropylene (PP). The shrinkage rates varied from 1.0% to 2.5%. This taught me to change release angles. It felt like baking bread without knowing how much it would rise. Without a bigger release angle, removing the product from the mold smoothly would be hard. It would be like peeling a sticker off without leaving any trace.

One of the core aspects of calculating lifter release angles is understanding the material’s shrinkage rate3. Materials like polypropylene (PP), known for their significant shrinkage rates ranging from 1.0% to 2.5%, require careful adjustment of release angles.

Friction Coefficients and Their Effects

Friction coefficients can be tricky. I learned this when working with sticky materials. They cling to lifters like a toddler with a favorite toy. High friction meant I needed a larger release angle. I found ways to reduce this "clinginess." This ensured products separated from their molds easily. It was like old friends parting after a long night.

The friction coefficient of a material is another critical factor in designing molds and lifters, necessitating adjustments in the release angle for smooth ejection.

Geometrical Considerations for Release Angles

Geometry was always my strength. Designing products added complexity. Deeper products, over 50mm, needed special calculations. The formula tan a=S/H was really helpful. I used it for a cylindrical design where the release angle had to be more than 3°. It was like finding the right spot in darts.

The geometry of the product also plays a significant role in determining appropriate release angles, especially for deeper items exceeding certain depths.

Tackling Complex Buckle Shapes

Complex shapes felt like solving puzzles. I broke them into simpler parts to calculate angles. CAD software often helped me; it acted like a sidekick showing possible interference conditions that were as unpredictable as weather changes.

When dealing with intricate shapes, engineers may need to decompose them into simpler geometric forms and rely on CAD software simulations4 to refine these calculations.

PP requires a larger release angle due to high shrinkage.True

Polypropylene has a high shrinkage rate, necessitating a larger release angle.

Lifter width affects the required release angle calculation.True

The lifter width and its movement stroke influence the release angle needed.

Why is product shape and size crucial in determining release angles?

Have you ever baked a cake and had problems removing it from the pan? This is similar to how product shapes and release angles work in molding.

Product shape and size are very important for release angles. They greatly influence how easily a product leaves the mold. Bigger or more complex shapes often need greater release angles. This helps prevent sticking. Smooth ejection is important.

The Importance of Product Material

I remember trying to make candles at home for the first time. I used various waxes and quickly understood that the material is very important. In injection molding, materials like polypropylene have specific shrink rates and how they rub against surfaces. For example, materials that shrink a lot or rub roughly need a bigger release angle to stop them from getting stuck during removal.

Shape and Size Thoughts

Think of tall, thin candles I created. When products are deep – like cylinders over 50mm – the release angle needs very careful thought. A useful formula helps calculate angles based on depth H and the lifter’s stroke S. For a depth of 100mm and a stroke of 5mm, you may see tan a≈2.86°. Adjusting to 3° or more may help things run without problems.

Complex Shapes: Calculations and Tests

When I started making soaps with detailed designs, I broke the complex patterns into simpler parts. In product design, complicated clasp shapes also need breaking down for better angle calculation. Simulations or test molds check these angles using CAD tools to be sure they fit right, especially for odd shapes.

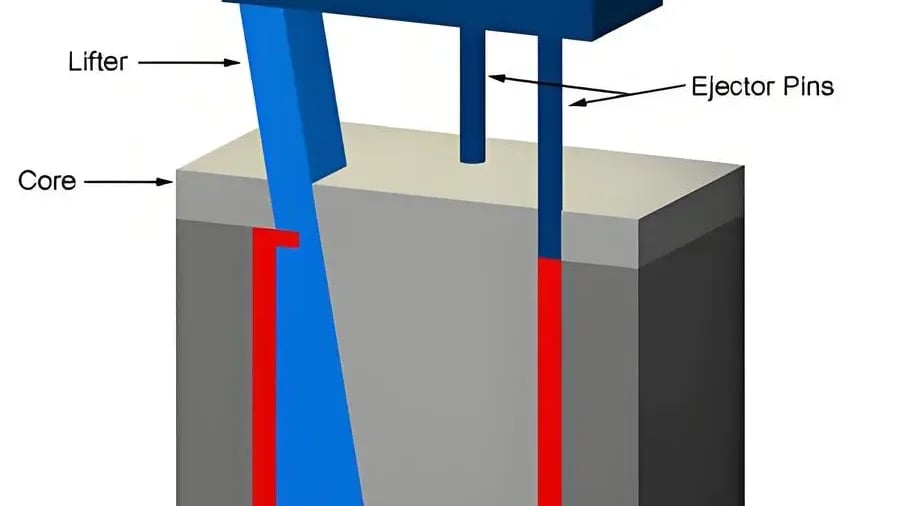

Considering Lifter Dimensions

Designing lifters is like solving a puzzle. It involves arranging pieces correctly. Their size and movement are key. The width w and horizontal movement s must be considered to avoid clashes during release. The release angle α should meet the condition tan a=h/(b-w) for smooth detachment. This is very crucial for complex designs like inverted buckles, where angle calculations5 must match the lifter’s capacity.

Larger release angles are needed for deeper products.True

Deeper products require larger angles to ensure smooth demolding.

All plastic materials have the same release angle requirements.False

Different materials have varying shrinkage and friction, affecting angles.

How Do I Correct Lifter Dimensions and Movement Stroke?

Have you ever thought about how correct lifter sizes decide the success of your mold design? Proper dimensions are crucial. They really determine whether the design succeeds or fails.

Correcting calculations for lifter dimensions means finding the best release angle. This depends on the material, shape and stroke of the lifter. The lifter needs to release the product smoothly from the mold. This is very important.

Understanding Lifter Release Angles

When I started with molds, I quickly saw how the release angle changed everything. It’s like a little trick that helps products slip out easily. Learning about this angle is very important whether you work with Polypropylene or other materials. Imagine pulling off a sticker without ripping it – the angle is crucial! For simple shapes or deep cylindrical products over 50mm, you must adjust the angle carefully.

The primary purpose of a lifter’s release angle is to facilitate smooth product release from a mold. This angle is crucial because it affects how well a product detaches post-molding. The release angle depends on several factors, including the material, shape, and size of the product as well as the stroke of the lifter.

Calculating Release Angles for Different Shapes and Materials

I once worked with materials that shrank a lot. Adjusting the release angle was the solution to avoid sticking problems. It’s like cooking – different materials need different changes. Deeper products or those with high friction need a larger angle. Finding this perfect balance is really satisfying; it’s like taking a perfect cake out of the oven!

Different plastic materials have unique shrinkage rates and friction coefficients. For products made from high-shrinkage materials, increasing the release angle can prevent sticking issues. Deeper products require larger release angles as well.

For instance, if you have a cylindrical product with a depth greater than 50mm, you might calculate the release angle using:

tan a = S/H

where S represents the lifter’s horizontal travel.

For practical purposes, this angle6 should usually not be less than 3°.

Correcting Calculations with Lifter Dimensions and Stroke

Now on to lifter dimensions and movement stroke – key parts of molding. One time, a lifter did not work well because its width was off compared to the clasp. I realized that matching these dimensions exactly avoids problems.

In addition to considering product properties, factor in your lifter’s dimensions and movement:

- Let’s say your lifter has width w and moves horizontally with stroke s.

- Ensure that if your lifter’s width w is less than clasp’s horizontal width b , then motion stroke allows complete disengagement from clasp.

- The release angle7 may need to satisfy:

tan a≥ h/(b-w)

Lifter release angle depends on product material.True

Different materials have varying shrinkage rates and friction coefficients.

Complex clasp shapes require a single release angle calculation.False

Complex shapes are decomposed into simple parts, each calculated separately.

How Can I Accommodate Complex Buckle Shapes in Angle Calculations?

Have you ever felt puzzled by complex buckle shapes in angle calculations? You are not alone! Explore these simple strategies. These tips probably make it very easy to handle.

Divide complicated buckle shapes into simple geometric pieces for angle calculations. Determine each piece’s release angle and take the highest one as your standard. CAD software simulations might adjust these angles more precisely.

Understanding Basic Principles

I recall the first time I tried to free a product from a mold without problems. It felt like sorting out a messy ball of yarn—confusing and annoying. But discovering the lifter’s release angle as the solution enlightened me. This angle matters because it relies on the product’s material, shape, size, and even the lifter’s movement.

The primary goal of calculating angles in the context of complex buckle shapes is to ensure smooth product release from molds. This involves examining factors such as material properties and the lifter’s release angle. The release angle’s size is affected by the product’s material, shape, size, and the lifter’s stroke, making it crucial to tailor the approach based on specific product requirements.

Material and Shape Considerations

Picture how various materials act. For example, Polypropylene (PP) has a high shrinkage rate, so it needs a bigger release angle. It’s similar to removing a sticky cake from a pan; you need the right tilt for a clean release. Products with deep cavities need specific calculations. Like cylindrical items over 50mm deep.

Material characteristics like shrinkage rates significantly influence angle calculations. For instance, materials with higher shrinkage may require larger release angles. In these scenarios, using empirical formulas is instrumental:

tan a = S/H

where S is horizontal travel and H is depth.

If a product has a depth of 100mm and travel of 5mm:

tan a = 5/100 = 0.05,

leading to an angle of approximately 2.86°. Increasing this to at least 3° ensures smoother demolding.

Corrected Calculation Methods

When considering dimensions and movement, things get tricky. The lifter must not interfere with the clasp during detachment—a lesson I learned when I miscalculated and had to redo a section.

When dealing with complex shapes, it’s essential to consider both lifter dimensions and its movement stroke:

tan a≥h/(b – w) is pivotal here.

For example:

inverted buckle depth = 5mm,

buckle width = 20mm,

lifter width = 10mm,

the angle must satisfy:

a≥26.6°,

or verified against stroke length.

Applying this saved me from another error.

Handling Complex Buckle Shapes

Complex buckles with curves or odd shapes resemble puzzles—one should break them into simple shapes and compute each release angle separately using methods mentioned earlier.

Simulation tools like CAD software are invaluable for testing these calculated angles—they act as an extra pair of eyes spotting things I might miss.

These tools can predict interference conditions not obvious in preliminary designs, allowing adjustments that ensure functionality and compliance with engineering standards.

For more insights into how simulation tools8 can enhance design accuracy or learn about empirical formulas9 for angle calculations, further exploration is recommended.

Release angle must be at least 3° for smooth demolding.True

To ensure smooth demolding, the release angle is usually not less than 3°.

PP materials require a smaller release angle due to low shrinkage.False

PP has high shrinkage; hence, it requires a larger release angle.

Conclusion

Calculating lifter release angles in injection molding involves considering material shrinkage, product depth, and lifter movement to ensure smooth demolding without sticking.

-

Understand how different materials impact mold design and release angles. ↩

-

Discover how CAD tools help optimize mold designs efficiently. ↩

-

Discover how shrinkage rates affect molding processes and calculations. ↩

-

Explore CAD tools for simulating complex shapes in molding. ↩

-

Learn through examples how to calculate optimal release angles. ↩

-

Learn about specific calculation methods for different materials. ↩

-

Discover practical examples for calculating lifter dimensions. ↩

-

Explore how CAD software refines design accuracy in engineering. ↩

-

Discover useful empirical formulas for engineering calculations. ↩