All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

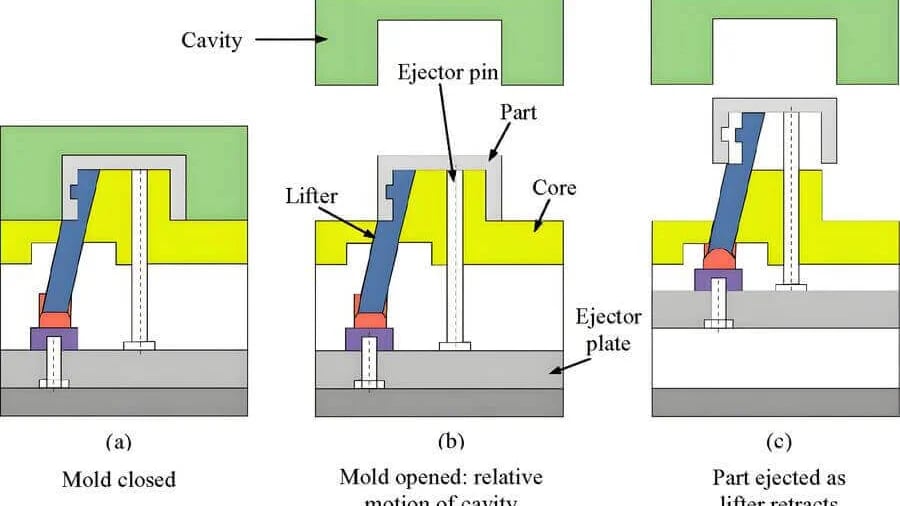

What Are Effective Strategies to Address Undercuts in Injection Molding?

Undercuts in injection molding can present significant challenges for designers, complicating ejection and increasing production costs. However, fear not! There are effective strategies to tackle these issues. From slider and lifter mechanisms to optimizing product designs, understanding how to manage ...

DESIGN

What Are the Most Effective Methods to Solve Shrinkage in Injection Molded Products?

Shrinking in injection molded products is a common challenge, but it doesn't have to be a persistent problem. By understanding the impact of material selection, mold design, and process adjustments, you can significantly enhance product quality. This guide explores effective ...

OPTIMIZATION

What Is the Lead-Time for a Plastic Injection Mold?

Navigating the intricacies of plastic injection mold timelines can make or break a manufacturing project. Understanding the lead-time is crucial as it varies significantly based on mold complexity, design requirements, and the manufacturer’s capabilities. This article delves into how these ...

MANUFACTURING

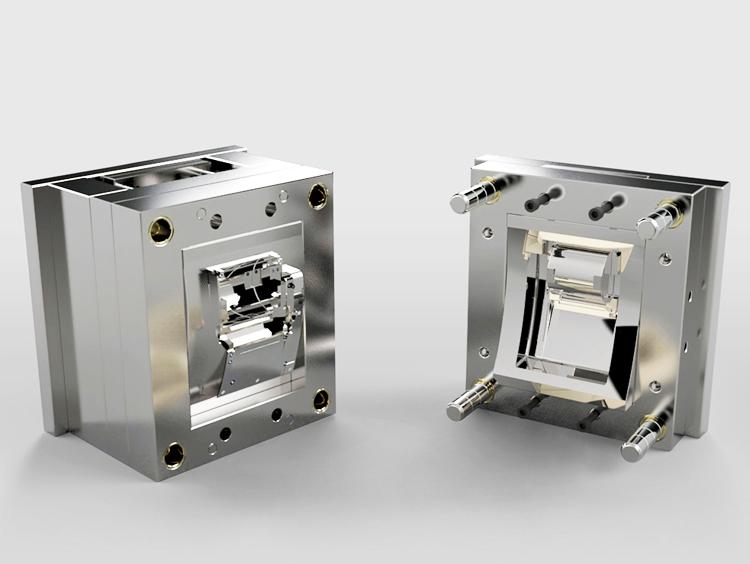

Why Are Injection Moulds So Expensive to Produce?

Injection molds are costly due to high design and material costs, complex manufacturing processes, and precision requirements that ensure quality and durability. Understanding these factors can help businesses strategize cost management effectively. Explore the details behind these expenses and uncover ...

Price Evaluation

What Materials Are Suitable for Injection Molding and Which Aren’t?

Choosing the right material for injection molding is crucial for product success. Suitable materials like polypropylene and polycarbonate offer stability and resistance, while unsuitable ones like PTFE complicate processes due to high melting points. Explore how different materials impact molding ...

Materials Recommendations

What Makes Precision Injection Molding the Best Choice?

Precision injection molding stands out in manufacturing due to its high dimensional accuracy and consistent quality. It's ideal for industries like electronics, medical, automotive, and aerospace. Explore why this technology is increasingly indispensable across these sectors, offering high efficiency and ...

MANUFACTURING

How Can You Control Wall Thickness Uniformity in Injection Molding?

Uniform wall thickness in injection molding is crucial for ensuring product quality and preventing common defects like warping or sink marks. By optimizing mold design, adjusting process parameters, selecting appropriate materials, and maintaining equipment, manufacturers can achieve consistent quality and ...

DEVELOPMENT

What Are the Best Strategies to Optimize Nozzle Design in Injection Molding?

In the realm of injection molding, nozzle design plays a pivotal role in determining the success and efficiency of the production process. From selecting the right nozzle type to ensuring proper alignment with the mold, every detail counts towards achieving ...

DESIGN

What Factors Should You Consider When Choosing an Injection Mold Cooling System?

Choosing the right injection mold cooling system is essential for maintaining product quality and operational efficiency. This article explores critical factors such as cooling mediums, pipe design, control systems, and the impact of mold materials on production outcomes. Read on ...

DESIGN

What Are the Key Design Considerations for Reinforcing Ribs in Injection Molded Products?

Designing effective reinforcing ribs in injection molded products is crucial for ensuring optimal strength and functionality. This involves a strategic approach to rib shape, layout, and material choice. Understanding these elements helps in creating robust components that perform well under ...

DESIGN

What Are the Different Gate Types for Injection Molds and How to Select the Right One?

Choosing the right gate type for injection molds is crucial in manufacturing, influencing both product quality and production efficiency. This article explores various gate types, their advantages and disadvantages, and provides insights on selecting the best one for your needs.

DESIGN

What Are the Hardness Grades for Classifying Injection Mold Steel?

Choosing the right steel for injection molding is crucial for manufacturing precision and durability. In this article, I explore the different hardness grades of injection mold steel—low, medium, and high—and how they influence your project's success. I share personal insights ...

Materials Recommendations

What Are the Most Effective Surface Treatments for Injection Molds?

In the competitive world of manufacturing, ensuring the longevity and efficiency of injection molds is paramount. Discover the most effective surface treatments available, including polishing, sandblasting, electroplating, and PVD titanium plating, to enhance mold durability and product quality.

MANUFACTURING

What Are the Latest Innovations in Injection Mold Applications for the Packaging Industry?

The packaging industry is undergoing a revolution driven by innovative injection mold technologies that prioritize sustainability and efficiency. From environmentally friendly materials to intelligent designs, these advancements are reshaping how products are packaged and delivered. In this article, I’ll explore ...

DEVELOPMENT

Why Is Temperature Control Crucial in Plastic Injection Molding?

Temperature control is a pivotal aspect of plastic injection molding, influencing every phase of the process from fluidity to final product quality. Understanding the significance of temperature can lead to improved production efficiency, better product integrity, and ultimately, customer satisfaction.

MANUFACTURING

What Are the Key Process Points in Thin-Wall Injection Molding?

Thin-wall injection molding is pivotal for producing lightweight, high-strength components efficiently. Mastering its key process points can elevate your production quality. This article explores critical areas including material selection, mold design, process parameters, and equipment choice, offering insights into achieving ...

MANUFACTURING

What Precautions Should You Take for High-Transparency Injection Molded Products?

In the manufacturing world, achieving clarity in injection molded products is not just a goal; it’s a hallmark of quality. This article delves into the essential precautions necessary to ensure high transparency, from selecting the right materials to perfecting mold ...

Quality Inspection

What Are the Best Strategies to Optimize Feed Position in Injection Molding?

In the fast-paced world of manufacturing, mastering injection molding can significantly elevate product quality and production efficiency. Understanding how feed position influences these factors is key. This article explores various strategies—from product and mold design to process parameters—to ensure optimal ...

DEVELOPMENT

What Are the Applications and Benefits of Low-Pressure Injection Molding?

Low-pressure injection molding is a transformative manufacturing process that offers exceptional product protection, cost efficiency, and rapid production cycles. It’s particularly beneficial in industries like automotive, electronics, and medical devices where delicate components require careful handling. This article explores how ...

MANUFACTURING

What Are the Challenges and Solutions in Multi-Cavity Mold Design?

In the world of manufacturing, particularly in injection molding, the design of multi-cavity molds poses a unique set of challenges. From achieving balanced gating systems to ensuring effective cooling and maintaining product quality, these intricacies can significantly impact production efficiency. ...

DESIGN

What Are the Essential Tips and Precautions for Mold Polishing in Injection Molding Production?

Mold polishing is a crucial process in injection molding that enhances product finish and performance. This article explores essential tips and precautions to ensure safety and efficiency during mold polishing, helping you achieve high-quality results in your production process.

DEVELOPMENT

What Are the Manifestations and Adjustment Methods for Insufficient Clamping Force in Injection Molding Machines?

In the world of injection molding, precision is key. Yet, one common issue that can disrupt the process is insufficient clamping force. This article explores the manifestations of this problem and offers practical adjustment methods to enhance product quality and ...

MANUFACTURING

What Are the Best Strategies to Handle Foreign Matter Inclusions in Injection Molded Products?

Foreign matter inclusions in injection molded products can be a significant challenge, affecting quality and efficiency. This article explores comprehensive strategies that involve raw material inspections, rigorous machine maintenance, diligent mold care, and maintaining a clean production environment to effectively ...

DEVELOPMENT

What Are the Best Strategies to Optimize Filling Speed in Injection Molding Production?

In the competitive world of injection molding, enhancing filling speed is essential for productivity and quality. Efficient filling reduces cycle times and defects, leading to better overall performance in manufacturing. Explore key strategies including equipment adjustments, mold design, material selection, ...

DEVELOPMENT

What Are the Essential Steps for Effective Injection Mold Maintenance?

Effective injection mold maintenance is vital for manufacturing success, ensuring both product quality and equipment longevity. This article explores the essential steps and practices that enhance mold performance, from routine inspections to proper documentation. Read on to discover how to ...

MANUFACTURING

What Are the Applications and Advantages of Hot Runner Systems in Injection Molding?

In the ever-evolving landscape of manufacturing, hot runner systems stand out as a pivotal technology in injection molding. By keeping plastic materials molten throughout the process, they significantly enhance production efficiency, reduce waste, and improve the quality of the final ...

DEVELOPMENT

What Are the Best Techniques to Improve Dimensional Stability in Injection Molding?

Struggling with inconsistent part sizes in your injection molding process? You're not alone. This guide outlines essential techniques to enhance dimensional stability, including raw material selection, mold design, and process parameter optimization. Let's explore effective strategies that can lead to ...

OPTIMIZATION

What Causes Incomplete Filling in Injection Molding and How Can You Adjust Parameters?

Injection molding is a precise manufacturing process, yet even the most controlled operations can encounter defects like incomplete filling. Known as 'short shots', this issue can compromise product integrity. This article explores the causes of incomplete filling and offers practical ...

OPTIMIZATION

What Causes Uneven Wall Thickness in Injection Molded Products and How Can It Be Optimized?

Injection molding is a complex process, and achieving uniform wall thickness is crucial for product quality and performance. This article explores the various factors contributing to uneven wall thickness, including mold design, injection pressure, and material selection. By understanding these ...

OPTIMIZATION

What Causes Color Variations in Injection Molded Parts?

Color consistency is crucial for the aesthetics and functionality of injection molded parts, yet achieving it can be challenging. In this post, I explore the various factors contributing to color variations in injection molding, including raw material quality, process parameters, ...

OPTIMIZATION