Ever found yourself curious about how those everyday plastic products are made? Trust me, diving into the world of manufacturing processes can be absolutely fascinating!

Injection molding machines do not produce plastic bags. They are designed to create various plastic items by heating, melting, and injecting plastic into molds. Plastic bags, however, are typically made through blow molding, which involves forming molten plastic into a film and shaping it into bags.

Now that we know injection molding isn’t the method for producing plastic bags, let’s explore the intriguing processes and differences between these two manufacturing techniques.

Injection molding machines produce plastic bags.False

Injection molding creates solid parts, while blow molding forms bags.

What Is Injection Molding Used For?

Explore the versatile applications of injection molding in everyday products.

Injection molding is a manufacturing process used to produce a wide variety of plastic products. It involves melting plastic and injecting it into molds to create items such as toys, automotive parts, and household goods. This method is favored for its efficiency in mass production and the precision it offers.

Understanding Injection Molding Applications

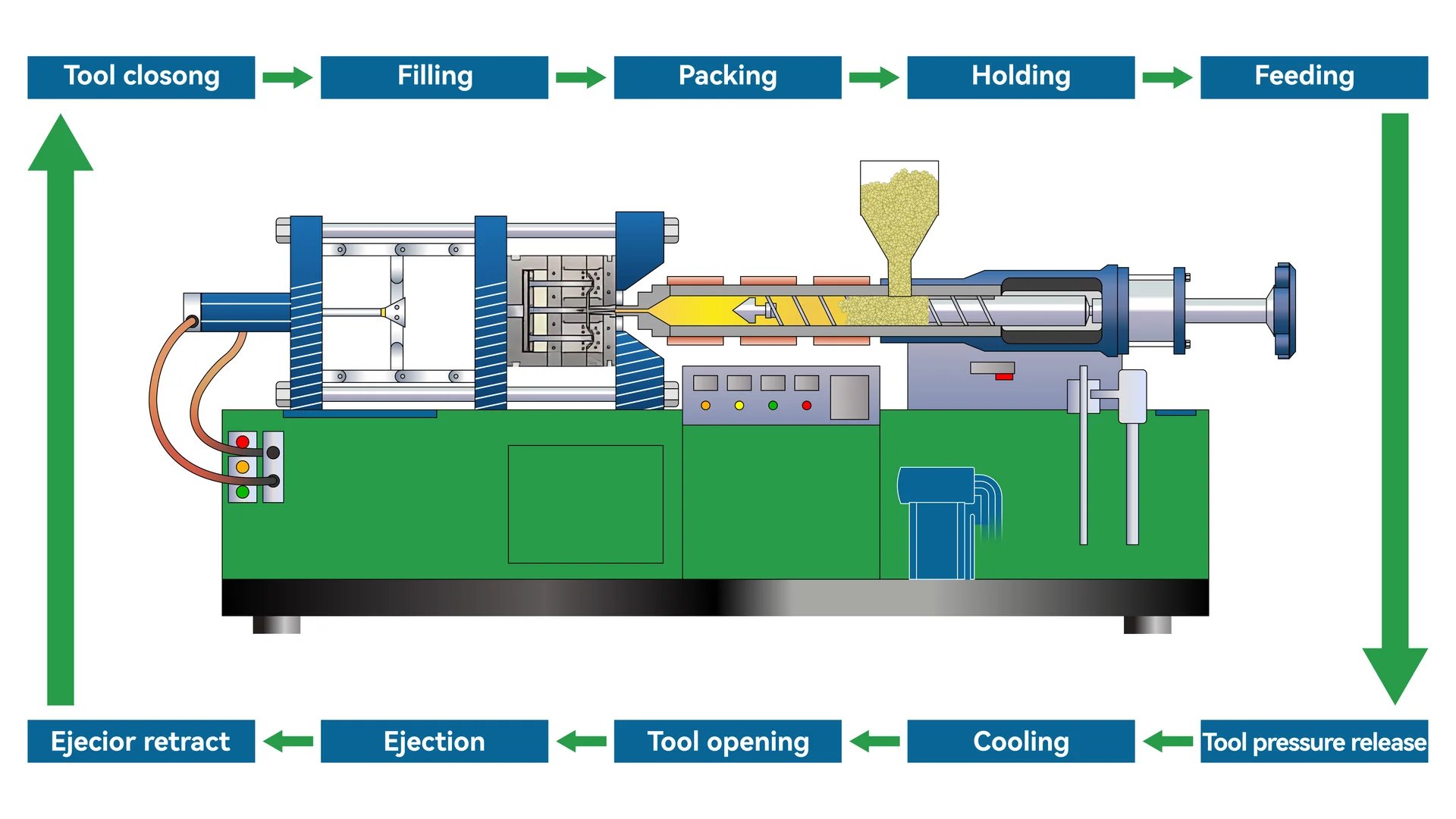

Injection molding is a cornerstone of modern manufacturing, pivotal in creating a plethora of plastic products we use daily. The process begins with melting plastic pellets, which are then injected into a mold under high pressure. Once cooled, the mold opens to reveal the finished product. This method is prized for its ability to produce complex shapes with high precision and consistency.

Common Applications

-

Automotive Industry

Injection molding is widely used in producing automotive components like dashboards, bumpers, and even smaller parts like knobs and clips. The precision and repeatability of injection molding make it ideal for such applications where exact specifications are crucial.

-

Consumer Goods

Many household items, from storage containers to kitchen utensils, are manufactured using injection molding. This process allows for the economical production of durable and diverse products that can withstand everyday use.

-

Toys and Recreational Products

The toy industry heavily relies on injection molding for creating detailed and colorful items. The ability to produce intricate designs swiftly makes it the preferred choice for toy manufacturers.

-

Medical Devices

In the medical field, injection molding is utilized to manufacture items such as syringes, surgical instruments, and components of diagnostic equipment. The process ensures sterile, precise, and repeatable production which is vital in healthcare.

Why Injection Molding?

The efficiency of injection molding1 in mass production cannot be overstated. It offers numerous advantages such as:

- Cost-effectiveness: Once the initial mold is created, the cost per unit decreases significantly.

- Scalability: Capable of producing thousands of identical items quickly.

- Material Versatility: Supports a wide range of thermoplastics, each with unique properties suitable for various applications.

- Precision: Produces intricate designs with tight tolerances consistently.

The versatility and efficiency of injection molding make it indispensable across numerous industries, revolutionizing how we create and consume plastic products today.

Injection molding is only used for plastic toys.False

It is also used in automotive, medical, and consumer goods.

Injection molding ensures high precision in production.True

It produces complex shapes with tight tolerances consistently.

How Does Blow Molding Create Plastic Bags?

Blow molding is an innovative method used to create lightweight and durable plastic bags.

Blow molding creates plastic bags by extruding melted plastic into a tubular film, which is then inflated and cooled to form bags.

Understanding Blow Molding Process

Blow molding is a manufacturing process that involves forming hollow plastic parts. This process is particularly efficient for creating items like plastic bottles and bags. It starts with melting down plastic resin, typically polyethylene, which is then extruded into a tube called a "parison."

Extrusion of the Parison

In blow molding, the plastic resin is fed into an extruder, where it is heated and melted. The molten plastic is then forced through a die to form a parison. This parison is a critical step as it forms the basis of the final product.

Inflation to Form

Once the parison is in place, it is clamped into a mold. Air is then blown into the parison, inflating it against the walls of the mold to shape it into a bag. This is similar to how a balloon takes its shape when air is blown into it.

Cooling and Ejection

After the plastic has been blown into its desired shape, it needs to cool down to solidify. The mold helps in cooling by providing a surface against which the plastic can set. Once cooled, the mold opens, and the newly formed plastic bag is ejected.

Benefits of Blow Molding for Plastic Bags

One of the key advantages of blow molding for producing plastic bags is its efficiency and ability to produce consistent thickness across the entire surface of the bag. Moreover, blow molding can produce bags with intricate shapes that might be challenging with other methods.

Applications Beyond Plastic Bags

While blow molding is ideal for making plastic bags, it is also extensively used in manufacturing other hollow plastic items such as bottles, containers, and even some types of toys. Its versatility makes it a preferred method in various industries, ranging from packaging to consumer goods.

For those interested in learning more about the intricacies and variations of blow molding, there are extensive resources available that delve into advanced techniques and applications. Explore further details2 on how this method has revolutionized modern manufacturing.

Blow molding uses parison inflation to shape plastic bags.True

Air inflates the parison against mold walls to form the bag.

Blow molding cannot create intricate bag shapes.False

Blow molding efficiently produces bags with intricate shapes.

Why Can’t Injection Molding Produce Plastic Bags?

Discover why injection molding isn’t used for producing plastic bags and what makes blow molding the go-to method.

Injection molding cannot produce plastic bags because it involves injecting molten plastic into molds to form solid parts, whereas plastic bags require blow molding, a process that forms films by extruding and inflating molten plastic.

Understanding Injection Molding

Injection molding is a widely used manufacturing process for creating plastic parts. The process involves heating and melting plastic pellets, which are then injected into a mold cavity where they cool and harden into the desired shape. This method is perfect for producing detailed and complex shapes like toys, automotive parts, and electronic housings.

Applications of Injection Molding

Injection molding is typically used for solid objects that require precise detailing. Examples include:

- Automotive Components: Dashboards, bumpers, and door panels.

- Consumer Goods: Toys, containers, and kitchen utensils.

- Medical Equipment: Syringes, vials, and surgical tools.

The Blow Molding Process for Plastic Bags

Unlike injection molding, blow molding is designed to produce hollow objects, like bottles and plastic bags. The process starts by melting plastic and extruding it into a tube. This tubular film is then inflated with air to form a bubble, which is cooled against the mold to create the final product.

Why Blow Molding?

Blow molding is ideal for making products that need to be flexible and lightweight. For instance:

- Plastic Bags: Shopping bags, garbage bags, and vacuum bags.

- Bottles: Beverage bottles, detergent bottles, and oil containers.

Key Differences Between Injection and Blow Molding

To better understand why injection molding isn’t suitable for plastic bags, consider the fundamental differences in the table below:

| Feature | Injection Molding | Blow Molding |

|---|---|---|

| End Products | Solid parts | Hollow products |

| Material Form | Solid mold fill | Inflated film |

| Flexibility | Rigid | Flexible |

| Typical Products | Automotive parts, toys | Plastic bags, bottles |

These distinctions highlight why injection molding cannot produce items like plastic bags. While both methods serve the plastic industry, their unique processes cater to vastly different needs.

The Structural Differences in Equipment

The equipment for each process is also inherently different. Injection molding machines consist of a hopper, injection barrel, and mold clamping unit. In contrast, blow molding machines have extruders, die heads, and inflation systems that cater specifically to creating hollow forms.

Understanding these differences sheds light on why each manufacturing process excels in its respective applications. For those interested in learning more about the specifics of these methods, further exploration can provide valuable insights into the nuances of plastic production.

Injection molding produces hollow objects.False

Injection molding creates solid parts, not hollow objects.

Blow molding is used for flexible products.True

Blow molding creates flexible, lightweight items like plastic bags.

What Are the Key Differences Between Injection and Blow Molding?

Understanding the differences between injection and blow molding can significantly impact product design and manufacturing decisions.

Injection molding forms products by injecting molten plastic into molds, ideal for detailed parts. Blow molding, on the other hand, creates hollow objects like bottles by inflating melted plastic against a mold’s interior surface.

Process Overview

Injection Molding: This process involves injecting molten plastic into a mold to form various products. It’s a precise technique ideal for creating detailed, solid parts like automotive components, electronic housings, and toys.

Blow Molding: This technique is used primarily for creating hollow plastic products such as bottles and containers. The process involves extruding melted plastic into a tube, inflating it into a mold cavity to take its shape.

Equipment Differences

The machinery for each process is quite distinct:

| Feature | Injection Molding | Blow Molding |

|---|---|---|

| Mold Design | Closed, multi-part mold | Open or closed mold with a cavity |

| Product Shape | Solid and complex shapes | Hollow shapes |

| Machine Function | Injects plastic into molds | Extrudes and inflates plastic |

Material Usage

Injection molding typically uses thermoplastics that can be reheated and reshaped. Common materials include polyethylene (PE), polypropylene (PP), and polycarbonate (PC). Blow molding also uses thermoplastics but is especially suited for low-density materials to maintain flexibility and formability during inflation.

Applications

Injection Molding Applications:

- Automotive parts: dashboards, bumpers

- Consumer goods: toys, kitchen utensils

- Electronics: casings, connectors

Blow Molding Applications:

- Packaging: bottles, jugs, containers

- Industrial: fuel tanks, barrels

- Consumer goods: squeeze bottles, watering cans

Cost Implications

Generally, injection molding can be more costly due to the complexity of the molds and machinery involved. However, it offers precision and efficiency in mass production. Blow molding might have lower initial costs but is limited to specific product types.

Understanding these differences helps manufacturers choose the right process for their needs, ensuring optimal efficiency and quality. For more insights into choosing between injection and blow molding3, explore industry expert opinions and case studies.

Injection molding creates solid, detailed parts.True

Injection molding is ideal for producing detailed, solid components.

Blow molding is used for solid shapes like car bumpers.False

Blow molding is used for hollow objects, not solid shapes.

Conclusion

Understanding these two methods can help us appreciate the complexity behind everyday plastic items. Next time you use a plastic bag or toy, think about the journey it took to get there!

-

Learn why injection molding is essential in efficient mass production.: What are the advantages of injection molding? · 1. Efficient high production · 2. Low cost per part · 3. Repeatability · 4. Large material … ↩

-

Discover how blow molding innovations enhance manufacturing capabilities.: The three main types of blow molding — extrusion blow molding (EBM), injection blow molding (IBM), and injection stretch blow molding (ISBM) — each involve the … ↩

-

Discover expert insights on selecting the right molding process.: Blow molding creates hollow products from thermoplastic materials. Technicians create performs, or parisons, by heating and expanding plastic tubes. The preform … ↩