Have you ever wondered how those everyday plastic boxes are made?

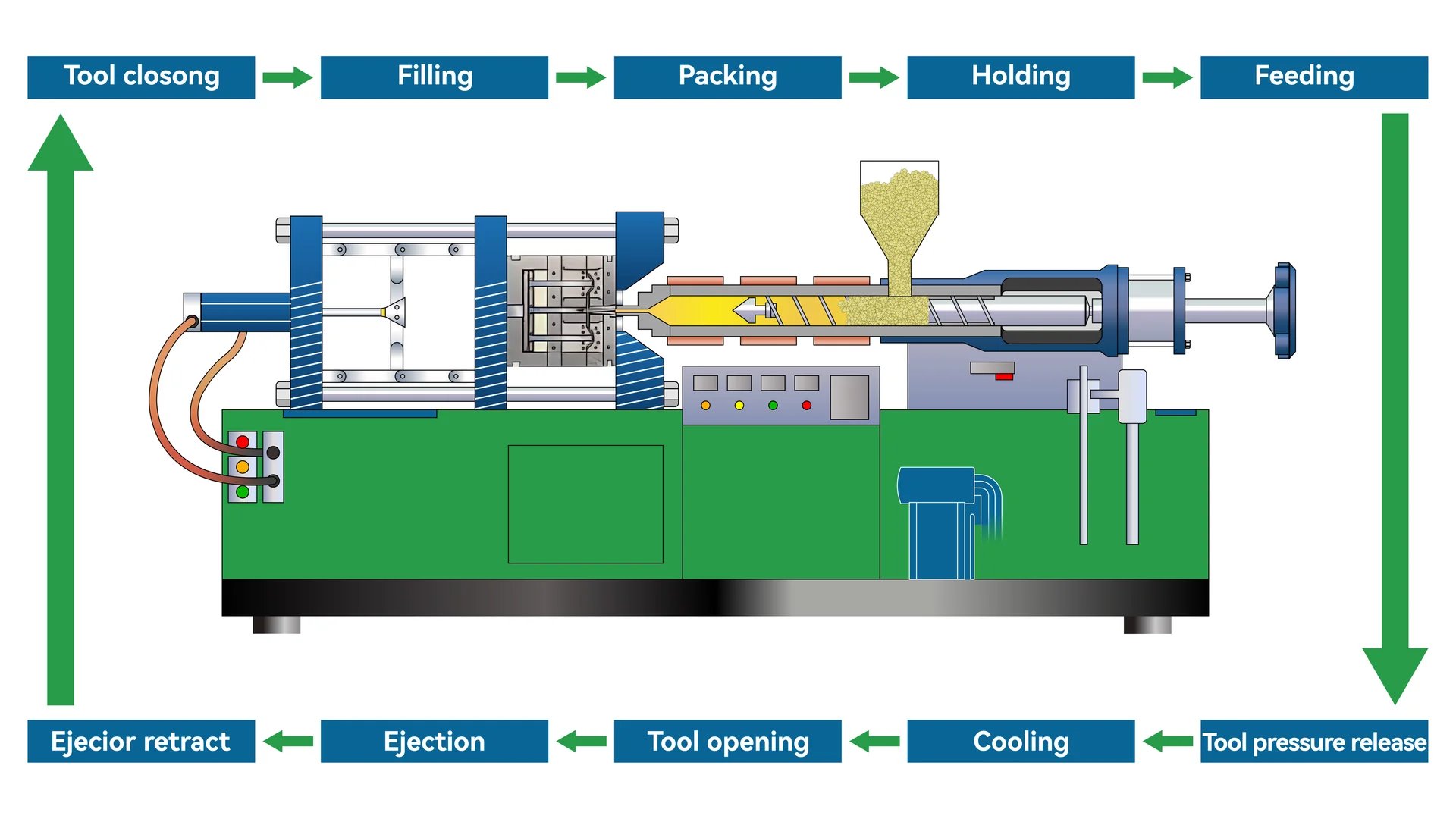

Injection molding machines produce plastic boxes by melting plastic pellets, injecting them into a mold cavity, and cooling them to form solid shapes. The process offers high efficiency, precision, and the ability to create complex designs.

While the basic steps might seem straightforward, the intricacies of injection molding reveal much more about its efficiency and adaptability. Explore how these machines bring precision and versatility to mass production, making them indispensable in modern manufacturing.

Injection molding machines can produce complex-shaped plastic boxes.True

They can create intricate designs with high precision and efficiency.

What Materials Are Used in Injection Molding for Plastic Boxes?

Understanding the materials used in injection molding is crucial for optimizing plastic box production.

Common materials used in injection molding for plastic boxes include polypropylene (PP), polyethylene (PE), polycarbonate (PC), and acrylonitrile butadiene styrene (ABS). Each material offers unique properties that affect the box’s strength, flexibility, and transparency.

Understanding Common Plastics in Injection Molding

Injection molding employs various thermoplastics, each with specific characteristics. Here’s a closer look at some commonly used materials:

Polypropylene (PP)

Polypropylene is a popular choice for plastic boxes due to its excellent fatigue resistance and chemical stability. It’s ideal for applications requiring durability and is often used for containers that need to withstand repeated use.

Polyethylene (PE)

Polyethylene, available in high-density (HDPE) and low-density (LDPE) forms, provides flexibility and impact resistance. HDPE is especially valued for its strength, making it suitable for heavy-duty storage boxes, while LDPE offers more flexibility for lightweight packaging solutions.

Polycarbonate (PC)

Known for its transparency and toughness, polycarbonate is chosen when clarity and strength are essential. This material is often utilized in applications where visibility of contents is crucial, such as display boxes.

Acrylonitrile Butadiene Styrene (ABS)

ABS combines strength with excellent surface finish qualities, making it perfect for custom designs requiring a glossy appearance. It also provides good impact resistance and rigidity, enhancing the structural integrity of the box.

Material Selection Factors

When selecting materials for injection molding, several factors must be considered:

-

Cost Efficiency: The cost of raw materials directly impacts the final product’s pricing. Polypropylene and polyethylene are generally more cost-effective compared to polycarbonate and ABS.

-

Environmental Impact: With growing emphasis on sustainability, materials like biodegradable plastics or recycled plastics are gaining popularity in injection molding processes.

-

Specific Application Needs: Consideration of the box’s end-use, whether for food storage, industrial parts, or consumer goods, determines the material choice.

By understanding these materials, manufacturers can optimize the injection molding process1 to produce high-quality plastic boxes tailored to various needs and applications.

Polypropylene is used for transparent plastic boxes.False

Polycarbonate, not polypropylene, is known for transparency.

ABS offers good impact resistance in plastic boxes.True

ABS is known for its excellent impact resistance and rigidity.

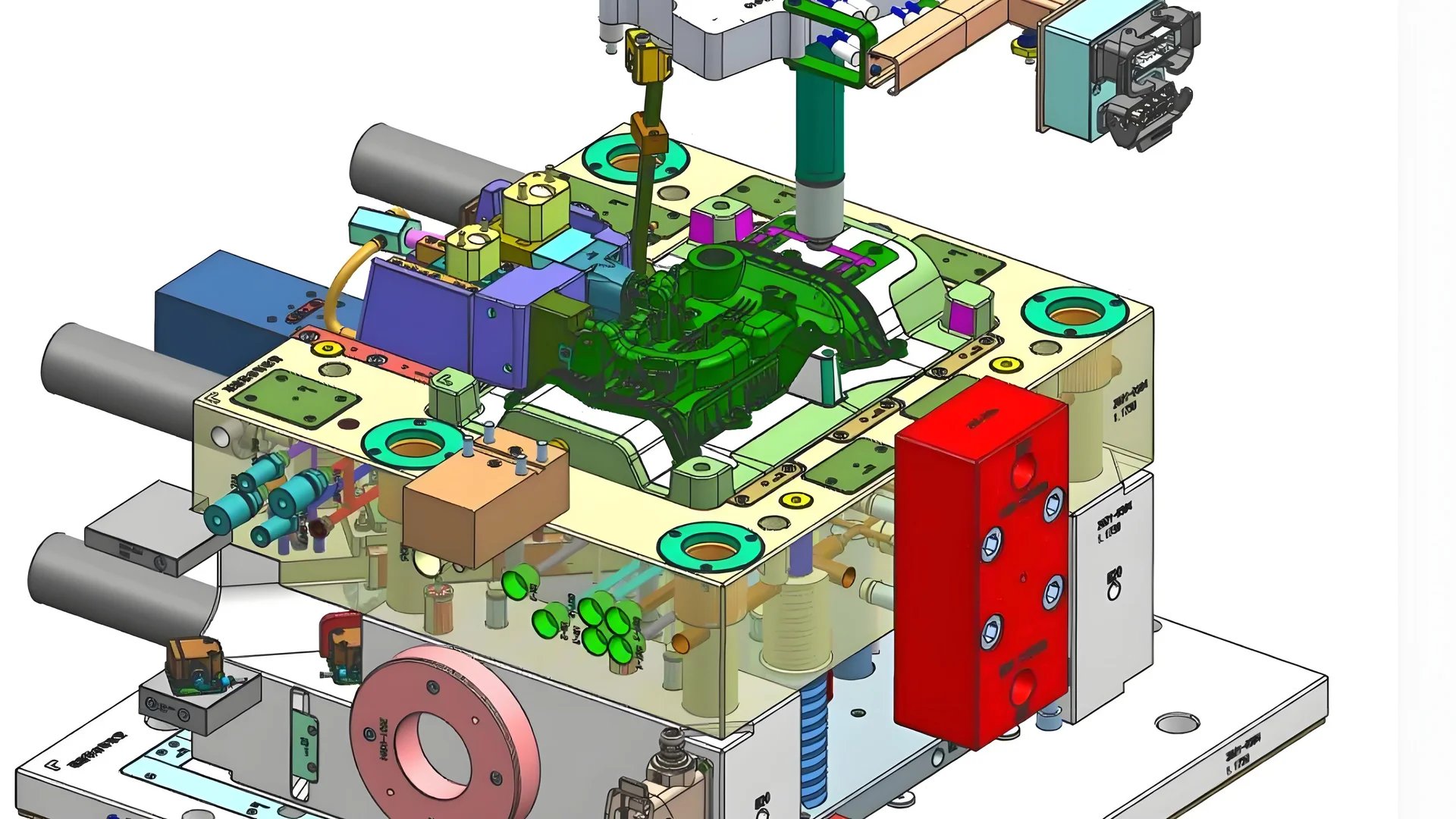

How Does the Mold Design Impact the Final Product?

The design of a mold is crucial in shaping not just the product but its overall quality and functionality.

Mold design directly influences the final product’s shape, dimensions, surface finish, and structural integrity. A well-designed mold ensures consistency, minimizes defects, and enhances production efficiency.

Understanding Mold Design Basics

Mold design is the blueprint for the final product, dictating every physical characteristic from shape to texture. The mold consists of two main parts: the cavity (female part) and the core (male part), which together form the desired geometry. Proper alignment and precise machining of these components are essential to achieve high-quality outcomes.

Influence on Product Shape and Dimensions

The mold design must account for shrinkage and other material behaviors during cooling. This requires precise calculations to ensure that the final product matches specified dimensions accurately. An example is when producing complex geometries2 where intricate designs necessitate multi-part molds or sliders to avoid defects like warping or sink marks.

Surface Finish and Texture Considerations

Surface finish quality is another critical aspect impacted by mold design. Factors such as mold material and polish determine the surface texture of the final product. For instance, a highly polished mold produces a glossy finish on plastic boxes, whereas textured molds can impart matte or patterned surfaces.

Structural Integrity and Material Flow

Mold design also influences how material flows during injection. Optimal flow paths prevent issues like air entrapment and ensure uniform distribution of material, crucial for maintaining structural integrity. When designing molds for high-strength applications3, engineers must carefully balance gate locations, runners, and cooling channels to enhance performance.

Enhancing Production Efficiency

Efficient mold designs enable faster cycle times and reduce waste. By incorporating features like automated ejector systems or quick-change inserts, manufacturers can streamline operations, leading to lower costs and increased production rates. Such innovations are vital in competitive industries where speed and quality are paramount.

Mold design affects product surface finish quality.True

The mold's material and polish determine the final product's texture.

All molds are designed without considering material shrinkage.False

Mold design must account for shrinkage to ensure accurate dimensions.

What Are the Key Advantages of Using Injection Molding Machines?

Discover the myriad benefits of injection molding machines in modern manufacturing.

Injection molding machines excel in producing plastic boxes due to their high efficiency, precision, and capability to create complex shapes. These machines ensure quick production, consistent quality, and durable products, making them a cornerstone of efficient manufacturing.

High Production Efficiency

One of the standout advantages of using injection molding machines4 is their exceptional production efficiency. These machines can churn out large quantities of plastic boxes in a relatively short time frame, reducing the overall cost per unit. This efficiency stems from the automated nature of the process, which minimizes manual intervention and accelerates production cycles.

Precision and Consistency

Injection molding machines are engineered to deliver high dimensional accuracy, ensuring that each plastic box produced meets exact specifications. This precision is crucial for applications where dimensional consistency is paramount, such as in packaging industries that require a snug fit for their products. The molds used in this process are crafted with meticulous attention to detail, ensuring that every box is identical to the next.

Complexity in Design

The versatility of injection molding machines allows manufacturers to produce plastic boxes with intricate designs and complex geometries. Whether it’s a simple rectangular box or a more elaborate design with multiple compartments and interlocking features, these machines can handle it all. This capability expands the design possibilities for manufacturers, enabling them to cater to diverse customer needs and preferences.

Enhanced Strength and Durability

Plastic boxes produced through injection molding are known for their strength and durability. The process allows for uniform material distribution, which contributes to the structural integrity of the final product. As a result, injection molded boxes can withstand significant wear and tear, making them suitable for heavy-duty applications.

By understanding these key advantages, manufacturers can leverage injection molding machines to optimize their production processes, reduce costs, and enhance product quality. The adaptability and precision offered by these machines make them indispensable in various industries, from consumer goods to automotive components.

Injection molding machines reduce production costs.True

High efficiency and automation lower the cost per unit produced.

Injection molding produces weak plastic boxes.False

The process ensures uniform material distribution, enhancing strength.

Can Injection Molding Be Used for Custom Plastic Box Designs?

Injection molding offers a versatile approach to crafting custom plastic boxes with precision and creativity.

Yes, injection molding can be used for custom plastic box designs. This process allows manufacturers to create unique shapes, sizes, and features tailored to specific needs, thanks to its ability to use custom molds and diverse plastic materials.

Understanding the Flexibility of Injection Molding

Injection molding is highly adaptable, enabling the production of custom plastic box designs that meet specific requirements. The process begins with designing a mold that reflects the desired shape and features of the box. This mold can be as simple or as complex as necessary, allowing for unique patterns, textures, and dimensions.

Designing the Perfect Mold

The mold is a critical component in determining the final outcome of the custom box. Designers work meticulously to ensure that every detail is captured, from the size and shape to any additional elements such as hinges or locking mechanisms. This level of customization means that businesses can tailor their products5 to align perfectly with their branding or functional needs.

Material Selection for Customization

Another advantage of injection molding is the broad range of materials available. Manufacturers can choose from various thermoplastics or thermosetting plastics, each offering different properties like flexibility, durability, or resistance to environmental factors. This diversity enables the creation of plastic boxes that are not only custom-designed but also suitable for specific applications.

Benefits of Using Injection Molding for Custom Designs

- Precision and Consistency: Once the mold is set, each plastic box produced is identical, ensuring consistency across large quantities.

- Cost-Effectiveness: For large production runs, the cost per unit decreases significantly, making it an economical choice for custom designs.

- Rapid Production: Injection molding machines can produce a large volume of custom boxes quickly, maintaining high production efficiency.

- Versatile Design Options: From simple shapes to intricate designs, injection molding supports a wide array of customization options, including multiple colors and textures.

Examples of Custom Applications

Custom plastic boxes are prevalent in various industries, including electronics, food storage, and retail packaging. For instance:

- Electronics: Customized enclosures for electronics often require precise dimensions to fit circuit boards and connectors securely.

- Food Storage: Custom-designed boxes can include features like snap-on lids or built-in compartments for portion control.

- Retail Packaging: Unique shapes or transparent sections in packaging can enhance product visibility and appeal.

In conclusion, injection molding stands out as an excellent choice for producing custom plastic boxes, offering unmatched flexibility and efficiency in meeting diverse design requirements. As technology advances, the possibilities for customization continue to expand, opening new avenues for innovation in product design.

Injection molding allows for custom plastic box designs.True

Injection molding uses custom molds to create unique box designs.

Injection molding is unsuitable for large production runs.False

It is cost-effective for large runs, reducing per-unit costs.

Conclusion

Injection molding machines revolutionize plastic box production with their efficiency and precision. Understanding this process can enhance your grasp of modern manufacturing techniques.

-

Explore how material choice impacts injection molding efficiency and product quality.: Plastic materials for injection molding range from commonly used polymers to specialty plastics and polymer blends. ↩

-

Explore methods for creating intricate designs with precision molds.: “The part’s complex honeycomb pattern requires the mold to have many angles and corners, causing a tortuous path for the molten plastic,” says … ↩

-

Discover strategies for enhancing durability in molded products.: High strength plastic materials are preferred—and often mandatory—for a wide range of injection molded product for military and defense, aerospace, and medical … ↩

-

Discover how efficiency boosts production and reduces costs significantly.: 1. It allows for complex geometries with tight tolerances. · 2. It’s compatible with a wide range of materials and colors. · 3. It’s very … ↩

-

Explore tailored designs that align with specific branding needs.: Deep Mould is a custom plastic box container storage mold injection molding manufacture.We are good at making custom crates and boxes moulded in plastic. ↩