Have you ever thought about how those regular HDPE bottles in your kitchen or bathroom are created?

Injection molding machines produce HDPE bottles by injecting molten HDPE into a mold, allowing precise control over the bottle’s dimensions and thread integrity. This method ensures high-quality production suited for industries requiring stringent packaging standards.

This process looks simple. Knowing details of injection molding is crucial. Temperature control, mold design and material traits matter a lot. These factors help in better production and good quality. Study these important areas more deeply.

Injection molding machines can produce HDPE bottles.True

Injection molding provides careful control over sizes, probably improving quality.

What Are the Steps in the Injection Molding Process for HDPE?

Injection molding remains a flexible method crucial for producing HDPE items with exact details and high productivity.

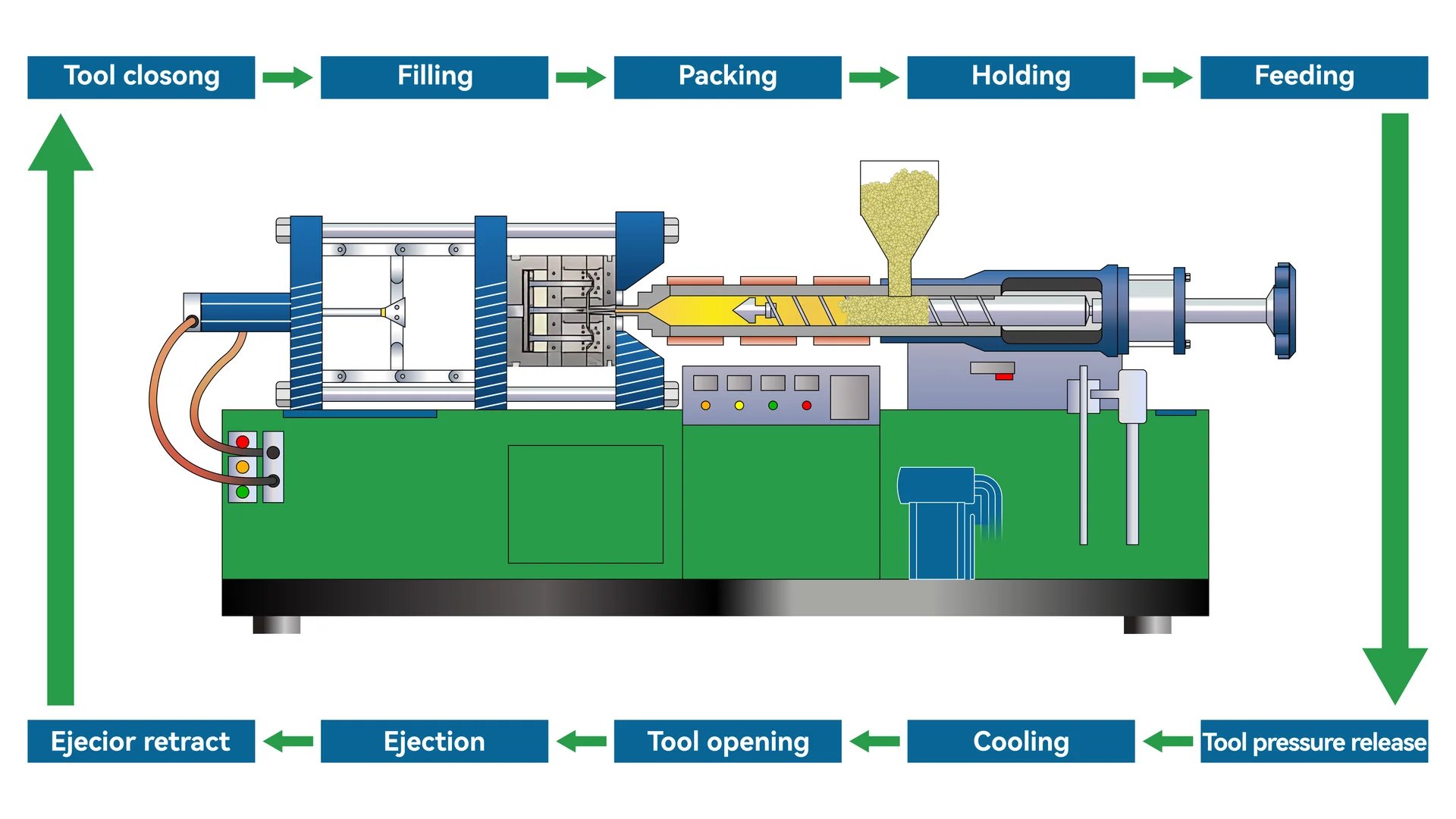

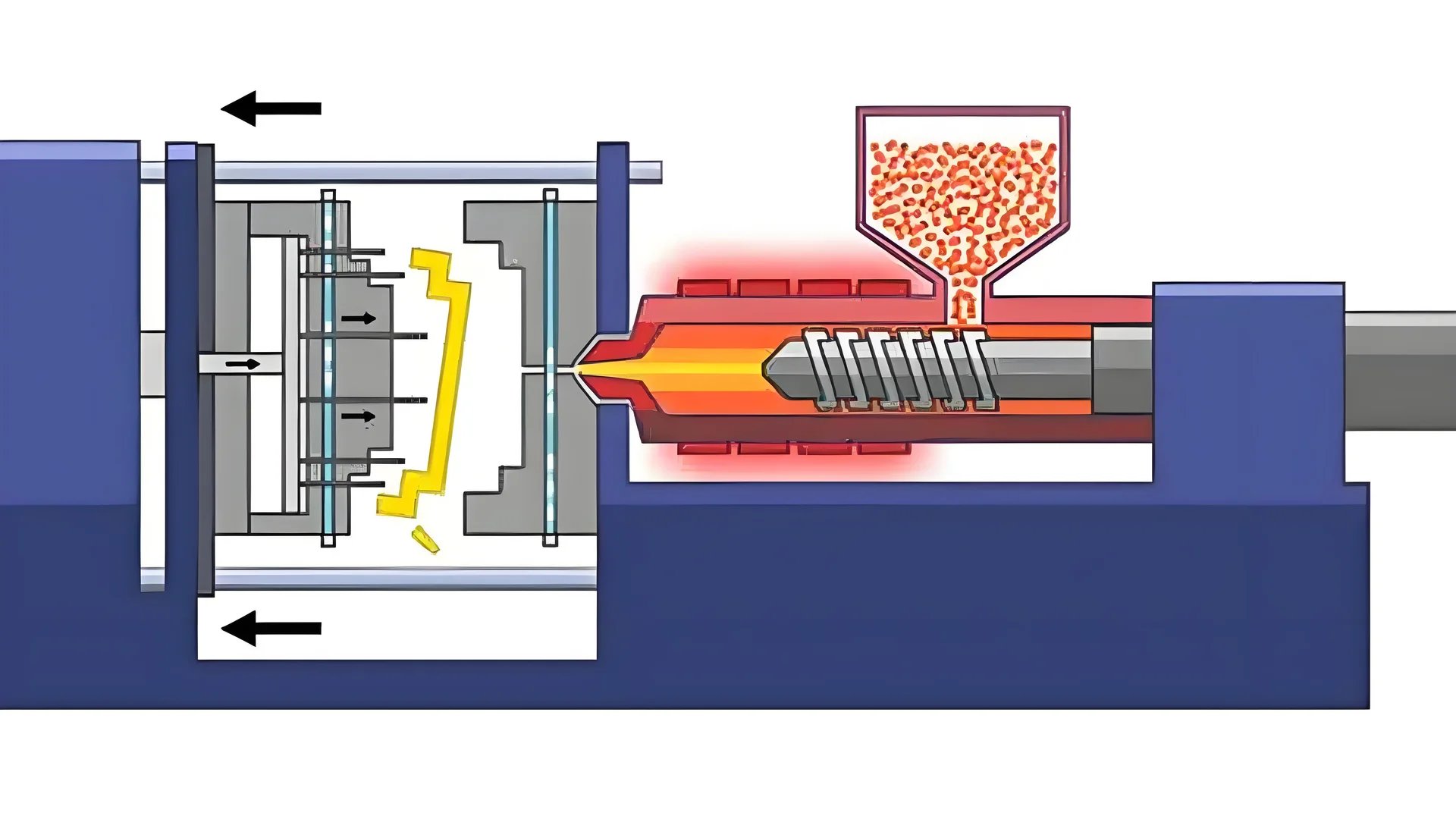

The injection molding process for HDPE involves several key steps: material preparation, mold setup, injection of molten HDPE, cooling, and part ejection. Each step requires precision to ensure the final product meets quality standards, particularly in industries like pharmaceuticals and food packaging.

Material Preparation: First Steps

First, prepare the HDPE (High-Density Polyethylene), a strong plastic. Dry the material and blend it with additives for things like UV protection or color. This helps keep the product the same and reduces mistakes.

Mold Setup: Building the Shape

Set up the mold in the machine. The mold shapes the final product. Consider shrinkage and cooling time to keep the product’s size and quality right.

- Mold Design Points: Include paths for melted plastic and cooling parts in the mold for even flow and heat spread.

- Accuracy in Mold Creation: Small errors in molds may cause problems or flaws in the final item.

Injection Phase: Forming Creations

Feed dried HDPE pieces into a heated barrel, melting them. Push the liquid plastic into the mold under high pressure with care.

- Pressure Watch: Makes sure liquid plastic fills the mold evenly.

- Speed Control: Impacts fill speed, which affects the surface and strength of the product.

Cooling: Hardening the Form

Cool the mold using water or other coolants. Cooling time is key for permanent shape and strong product.

- Cooling Time Control: Good cooling minimizes bending and keeps thickness even.

- Temperature Control: Fast heat removal cuts cycle time, improving work speed.

Ejection: Finalizing Products

After cooling, the mold opens and pins push out the solid shape. Handle carefully to avoid damaging important parts like threads.

- Ejector Setup: Should match the product’s form to prevent cracks or problems.

- Check After Ejection: Confirm each item is good before packing or further work.

These steps show how injection molding creates accurate HDPE items. Every stage is important to meet high standards for quality and use.

Mold setup is the first step in injection molding for HDPE.False

Preparing the material comes first, not setting up the mold.

Cooling time affects dimensional stability in HDPE molding.True

Correct cooling reduces bending and keeps part thickness regular.

How Does Blow Molding Compare to Injection Molding for HDPE Bottles?

Picking between blow molding and injection molding for HDPE bottles hinges on design difficulty and accuracy requirements.

Blow molding excels in producing complex, hollow shapes economically, while injection molding offers superior precision for intricate details like threads. Each method has its strengths, making the choice dependent on the bottle’s design and functional requirements.

Using Basics of Blow Molding and Injection Molding

Blow molding and injection molding help make HDPE bottles. Each one suits different uses and has unique features.

-

Blow Molding: Useful for creating hollow, complex shapes. Melt plastic and form a parison (a tube with a hole). Push air through the hole to shape it.

-

Injection Molding: Gives precise forms. Push molten plastic into a mold to shape it. Perfect for items with detailed designs, like bottle cap threads.

Blow Molding Benefits

- Lower Costs: Costs less because of cheaper molds and faster production.

- Flexibility: Excellent for making big or oddly shaped bottles while maintaining strong structure.

- Efficient Use: Uses materials well with little waste, making it environmentally friendly.

Injection Molding Advantages

- Precision: Perfect for accurate and detailed shapes like neck threads on bottles.

- Consistency: Provides the same quality every time, important for industries needing high standards.

- Tightness and Strength: Ensures strong seals and sturdy builds, crucial for medicine and food packaging.

Comparing Uses

| Aspect | Blow Molding | Injection Molding |

|---|---|---|

| Best For | Large, hollow shapes | Detailed and exact parts |

| Cost | Lower initial outlay | Higher because molds are more complex |

| Production Speed | Quicker due to easier molds | Slower but allows for more detailed designs |

| Strengths | Cheap for huge amounts | Best for detailed, small pieces |

Choosing the Right Method

Choose blow or injection molding by looking at bottle design complexity, required exactness, production amount, and cost limits. Sometimes, using both together improves work efficiency and quality.

For example, use blow molding1 for the bottle body and injection molding2 for lids. Both methods have their own strengths, showing why it’s important to know when to use each one for the best outcomes.

Blow molding is costlier than injection molding for HDPE bottles.False

Blow molding often costs less because mold expenses are lower.

Injection molding provides better precision for HDPE bottle threads.True

Injection molding is excellent at forming detailed parts like bottle threads.

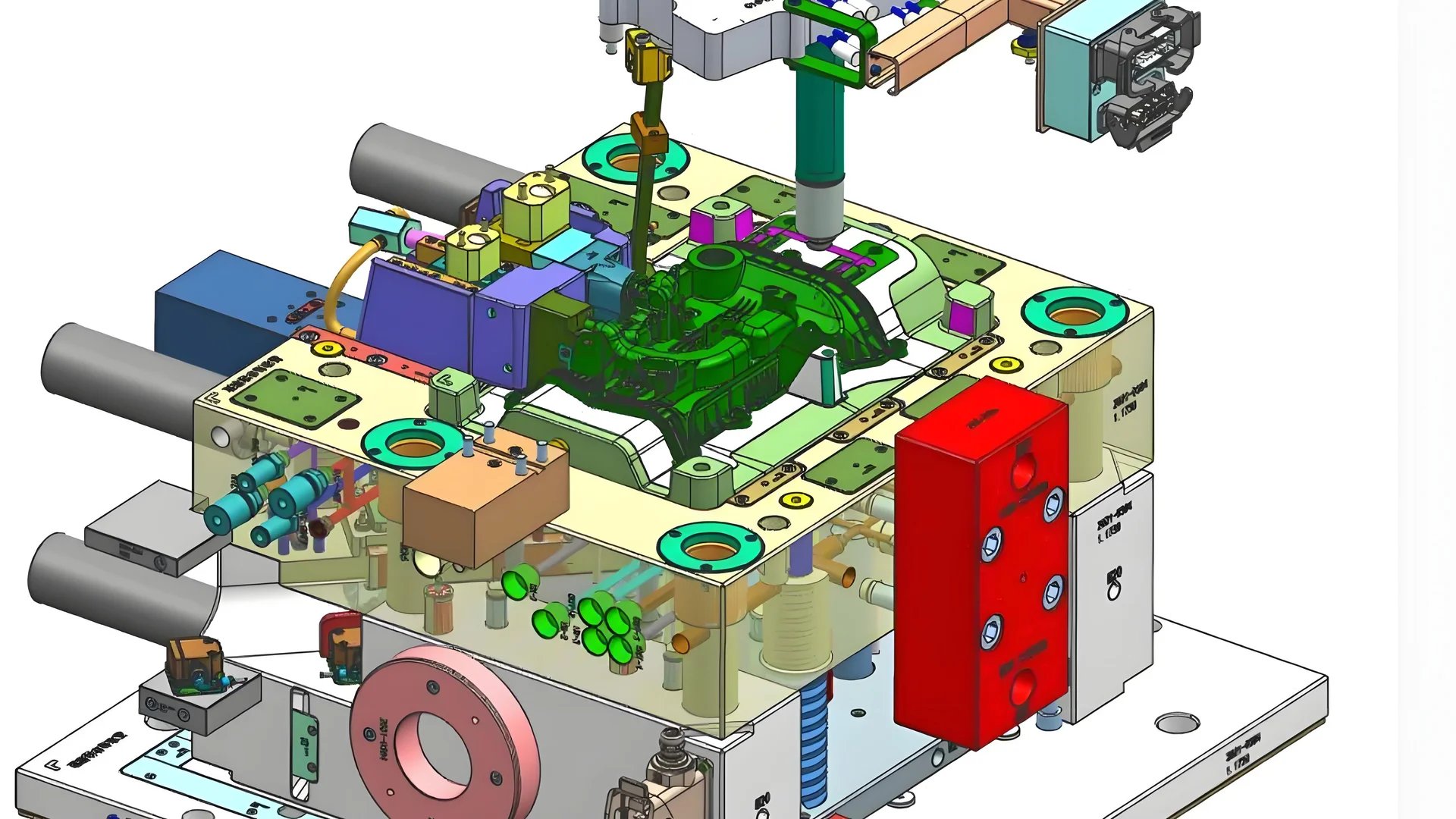

What Role Does Mold Design Play in HDPE Bottle Production?

Mold design plays an important role in HDPE bottle production. It affects accuracy, speed and quality.

Mold design in HDPE bottle production ensures precise dimensions, optimal material flow, and high-quality finishes, vital for meeting industry standards.

Understanding Mold Design in HDPE Bottle Production

Mold design holds great importance in HDPE bottle creation. It strongly affects how precise and good the final bottle is, which is very important for fields like medicine where exact sizes and tight seals are necessary. Molds, often crafted from strong materials like steel or aluminum, are specially created to form certain shapes and sizes, so each bottle fits tough industry rules.

Key Elements of Mold Design

-

Cavity and Core: The cavity and core design shape the outside and inside of the HDPE bottle. A good cavity and core provide a bottle with an even wall thickness and steady size.

-

Cooling System: Good cooling systems help keep pace and quality during production. Well-placed cooling paths stop bending and guarantee even material quality in the bottle.

-

Ejection Mechanism: The ejection system must let the bottle out without harming it. This considers the shape of the bottle and how the material cools.

Importance of Precision in Mold Design

Exactness in mold design directly influences how HDPE bottles work and look. For instance, medicine bottles need very precise necks to match caps safely, achieved through careful mold design.

Table: Comparison of Mold Materials

| Material | Durability | Cost | Suitable for |

|---|---|---|---|

| Steel | High | Expensive | Large volumes |

| Aluminum | Moderate | Affordable | Small runs |

Challenges and Solutions

Creating molds for HDPE bottles brings special difficulties. One main problem is avoiding defects like sink marks or flow lines, solved by adjusting material flow3 within the mold.

Moreover, keeping the right balance between cost efficiency4 and product quality demands careful thought and work in the mold design stage. Modern simulation tools identify possible problems and allow designers to change designs before starting production.

Mold design affects HDPE bottle dimensions.True

Mold design provides accurate measurements, essential for industry norms.

Aluminum molds are best for large volume production.False

Steel molds are chosen for big quantities because they last longer.

Why Is Precise Temperature Control Crucial in Injection Molding?

Accurate control of temperature in injection molding is important for obtaining precise and consistent products, affecting both quality and efficiency.

Temperature control in injection molding ensures uniform material flow and prevents defects, impacting the dimensional precision and structural integrity of HDPE bottles. Proper temperature management is critical for producing high-quality, defect-free products in industries with rigorous standards.

Understanding Temperature Control

In injection molding, precise temperature control directly influences the melt viscosity5 of the HDPE material. Melt viscosity affects how the molten plastic flows into the mold, determining the final product’s accuracy and quality. By maintaining the optimal temperature, manufacturers can ensure consistent flow and prevent common defects such as warping, sink marks, or incomplete filling.

Material Characteristics:

- HDPE Properties: High-density polyethylene (HDPE) is sensitive to temperature fluctuations. The material’s ability to withstand high pressure without deforming makes it ideal for injection molding, provided that temperature conditions are tightly regulated.

- Thermal Conductivity: HDPE‘s low thermal conductivity means it retains heat longer, necessitating precise temperature settings to avoid prolonged cooling times that can lead to production inefficiencies.

Effects on Product Quality

Temperature inconsistencies can compromise the structural integrity of the final product. For example, incorrect temperatures can lead to varying wall thicknesses in HDPE bottles, affecting their durability and performance. Uniform temperature distribution helps maintain the dimensional stability of intricate features like bottle threads and necks.

| Defect | Cause | Solution |

|---|---|---|

| Warping | Uneven cooling | Controlled cooling systems |

| Sink Marks | Insufficient cooling time | Extended cooling period |

| Incomplete Filling | High melt viscosity due to low temp | Optimized temperature settings |

Process Optimization Techniques

Advanced Monitoring Systems: Incorporating real-time temperature monitoring systems allows for immediate adjustments, ensuring that the material is at the ideal temperature throughout the process.

Mold Temperature Control: The use of advanced mold temperature control units can improve heat distribution and enhance cycle times, contributing to improved efficiency and product quality.

Material-Specific Settings: Different grades of HDPE require specific temperature settings to achieve optimal results. It’s vital to calibrate equipment based on the material being used to prevent issues such as thermal degradation or inadequate melting.

Challenges and Solutions

One of the main challenges in maintaining precise temperature control is balancing speed with quality. Fast production cycles often lead to higher temperatures, which might not be suitable for all materials. Thus, manufacturers should adopt a balanced approach, tailoring production settings according to specific product requirements and industry standards.

Implementing adaptive control systems6 that adjust parameters in real time can help address these challenges, ensuring optimal conditions are maintained throughout the production cycle.

Precise temperature control prevents warping in HDPE products.True

Consistent temperature allows for equal cooling, lowering chances of bending.

HDPE's high thermal conductivity aids in fast cooling.False

HDPE contains low thermal conductivity. This extends cooling duration.

Conclusion

Injection molding devices provide a good way to produce high-quality HDPE bottles. These bottles have accurate sizes and excellent sealing features, which are important for different sectors.

-

Explore how blow molding benefits HDPE bottle production.: 3. Cost-Effective. Extrusion blow molding uses a relatively lower level of pressure. This reduces the expenses incurred in the production … ↩

-

Learn about injection molding’s impact on HDPE bottle precision.: The decrease in viscosity is helpful because it reduces the amount of pressure required to inject the material into the mold, which helps to extend the lifespan … ↩

-

Explore methods to improve mold efficiency and reduce defects.: Designing molds with fillet edges and round corners will improve material flow (especially to thicker areas) and reduce flow marks. Also … ↩

-

Learn about balancing cost with quality in mold design.: Explore key strategies for cost reduction in injection moulding, including design optimization, material selection, and efficient practices. ↩

-

Learn how melt viscosity impacts flow and final product quality.: The melt viscosity is temperature-dependent, and decreases as the temperature rises. (Fig. 6.12) In injection molding, mold filling may be improved by … ↩

-

Discover how adaptive systems enhance precision and efficiency.: The adaptive process control method is introduced with the help of exemplary processing parameters from a standard thermoplastic injection moulding machine. In … ↩