MANUFACTURING

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

How Does the Choice of Mold Base Impact Your Overall Mold Design?

The choice of mold base significantly influences overall mold design by affecting structural integrity, thermal performance, and production costs. Different types of bases—standard, custom, hot runner, and stripper plate—serve specific needs in manufacturing. Material selection also plays a vital role; ...

MANUFACTURING

What Challenges Arise When Molding Multi-Material Components?

Navigating multi-material molding involves overcoming challenges such as ensuring material compatibility, designing complex molds, and maintaining efficient production processes. This post explores common hurdles faced in the industry and offers practical strategies to enhance product quality and reduce defects. Key ...

MANUFACTURING

What Are the Best Practices for Core and Cavity Placement in Injection Molding?

In injection molding, effective core and cavity placement is crucial for minimizing defects and maximizing efficiency. Key practices include ensuring precise alignment, considering parting line locations, maintaining balanced wall thickness, and selecting appropriate materials. These strategies not only enhance product ...

MANUFACTURING

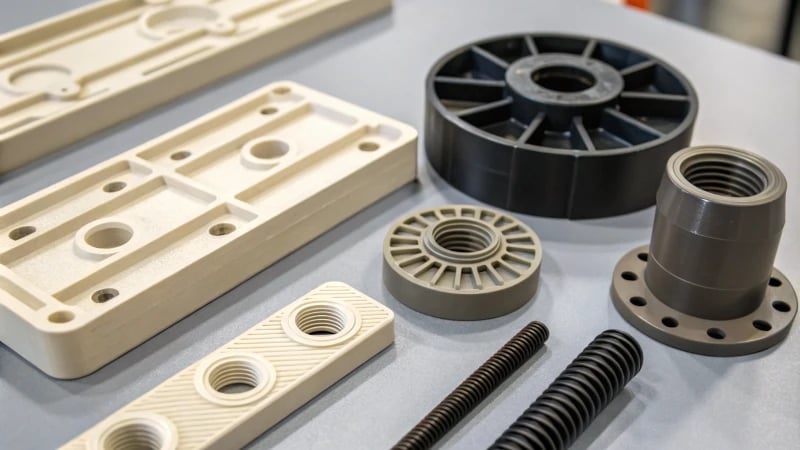

What Are the Most Effective Rapid Prototyping Techniques for Mold Making?

This blog post delves into the most effective rapid prototyping techniques for mold making. It covers 3D printing, CNC machining, and injection molding—each offering unique advantages in speed, precision, and cost-effectiveness. The article emphasizes how these methods can significantly enhance ...

MANUFACTURING

What Are the Key Differences Between Insert Molding and Overmolding?

This article explores the key differences between insert molding and overmolding in plastic manufacturing. Insert molding integrates pre-formed components into a mold, enhancing product strength and reducing assembly time. In contrast, overmolding adds layers of material to existing parts, improving ...

MANUFACTURING

How Do Injection Molding and Die Casting Processes Compare and Combine?

This article explores the differences between injection molding and die casting, two essential manufacturing techniques for creating intricate components. While both involve injecting molten material into molds, they differ significantly in terms of materials used, suitability for specific applications, and ...

MANUFACTURING

How Is Wire Cutting Technology Revolutionizing Injection Mold Manufacturing?

Wire cutting technology, particularly Wire Electrical Discharge Machining (EDM), is transforming injection mold manufacturing. This advanced technique offers unparalleled precision for crafting intricate geometric shapes essential for modern molds. It streamlines post-quenching processes and ensures high-precision insert production, significantly enhancing ...

MANUFACTURING

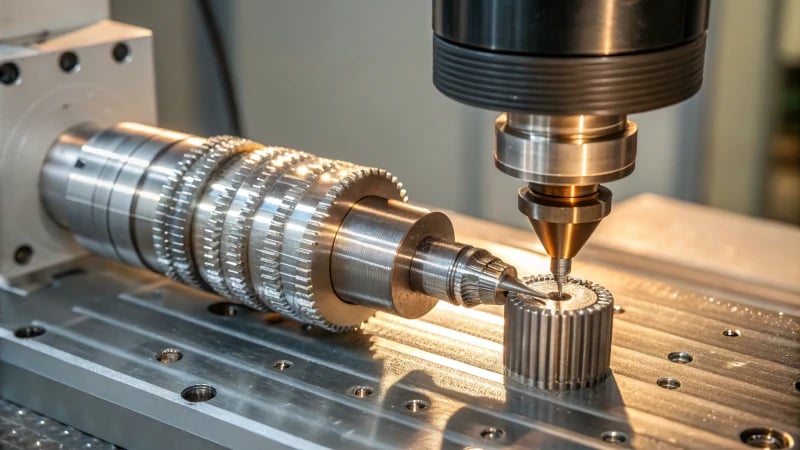

How Is CNC Machining Revolutionizing Injection Mold Manufacturing?

CNC machining is transforming injection mold manufacturing through enhanced precision, reduced lead times, and increased efficiency. This technology allows for intricate designs that were previously challenging to achieve. By automating processes, CNC minimizes human error and waste while facilitating sustainable ...

MANUFACTURING

How Does an Injection Molding Machine Work and What is Its Structure?

This article explores the intricate workings of injection molding machines, detailing their structure and processes. It highlights key components like the injection unit, mold, and clamping unit while emphasizing the importance of material selection and design strategies for optimizing production ...

MANUFACTURING

How Can You Achieve a High-Gloss Finish in Injection Molding?

This article explores how to achieve a high-gloss finish in injection molding by focusing on material selection, mold design, and process optimization. Key materials like ABS and PS are highlighted for their inherent glossiness. The importance of using gloss-enhancing additives ...

MANUFACTURING

What Are the Essential Tools for Injection Mold Making?

This blog post explores the essential tools for injection mold making, including CAD software for design, CNC machines for precision shaping, and various components like mold bases and ejector pins. Each tool plays a crucial role in ensuring molds meet ...

MANUFACTURING

How Does Insert Molding Enhance Injection Processes?

Insert molding is a transformative manufacturing technique that combines different materials into one cohesive product. By embedding components within a single mold, it enhances product durability and design flexibility while significantly reducing assembly time and costs. This method is particularly ...

MANUFACTURING

What Are the Best Practices for Managing Post-Processing in Injection Molding?

Effective management of post-processing in injection molding is crucial for achieving high-quality products. Key practices include optimizing cooling processes to prevent warping, employing various trimming techniques for smooth finishes, enhancing aesthetic appeal through surface finishing, and implementing rigorous inspection protocols ...

MANUFACTURING

What Impact Do Biodegradable Plastics Have on Injection Molding Processes?

Biodegradable plastics are transforming the injection molding landscape, offering eco-friendly alternatives that reduce waste and carbon emissions. However, they introduce challenges such as temperature sensitivity, higher production costs, and variable product quality. Understanding their unique properties is crucial for designers ...

MANUFACTURING

How Can 3D Printing Revolutionize Your Mold Making Process?

3D printing is transforming the mold-making industry by offering significant advantages such as enhanced design flexibility, reduced costs, and faster production times. This technology allows designers to create intricate molds with precision while minimizing material waste. By integrating 3D printing ...

MANUFACTURING

Is Injection Molding Possible with Glass-Filled Nylon?

Glass-filled nylon is a transformative material for injection molding, offering enhanced strength, stiffness, and heat resistance compared to standard nylon. Its unique properties make it suitable for high-performance applications across various industries including automotive and aerospace. While it presents challenges ...

MANUFACTURING

What Are the Types and Causes of Waste in Injection Molding?

This guide explores the various types of waste in injection molding, including material, time, energy, and defects. It discusses their causes—such as poor design, inefficient handling, machine malfunctions, and operator errors—and offers strategies for reduction. By understanding the intricacies of ...

MANUFACTURING

How Does the Ejector System Work in Injection Molding?

This article explores the critical role of ejector systems in injection molding, detailing their components such as motive nozzles and suction chambers. It highlights how these systems enhance efficiency, reduce production costs, and ensure high-quality outputs. Innovations like 3D printing ...

MANUFACTURING

How Are Legos Made: Are They Injection Molded?

This blog post explores how LEGO bricks are manufactured, focusing on the injection molding process that ensures precision and consistency. It highlights the use of Acrylonitrile Butadiene Styrene (ABS) plastic for durability and vibrant colors. Additionally, it discusses LEGO's commitment ...

MANUFACTURING

What Are the Key Differences Between Injection Molding and Compression Molding?

Injection molding and compression molding are two key manufacturing techniques with distinct processes and benefits. Injection molding is ideal for high-volume production of intricate designs, while compression molding excels in cost-effectiveness for larger parts. Understanding these methods helps designers optimize ...

MANUFACTURING

What Distinguishes the Core Side from the Cavity Side in Injection Molding?

In injection molding, the core side forms internal features while the cavity side shapes external surfaces. Understanding their unique roles is essential for optimizing design and production efficiency. Proper maintenance of these components prevents defects like flash and warping, ensuring ...

MANUFACTURING

What Are the Key Differences Between Injection Molding and Thermoforming?

This article explores the key differences between injection molding and thermoforming, two popular manufacturing processes. Injection molding is ideal for high-volume production with intricate designs, while thermoforming excels at creating simpler shapes in smaller batches. The discussion includes factors such ...

MANUFACTURING

What Is the Cooling Time for Injection Molding?

Cooling time is a critical factor in injection molding that affects cycle duration, energy consumption, and product quality. It involves the solidification of molten plastic within molds and is influenced by various factors including material type, mold temperature, and part ...

MANUFACTURING

How Can You Successfully Injection Mold Threads?

Successfully injection molding threads involves a comprehensive approach that includes optimizing mold design for thread alignment, selecting appropriate materials, maintaining precise temperature control, and implementing effective venting techniques. Each factor plays a crucial role in achieving high-quality threaded components. Proper ...

MANUFACTURING

How Is EDM Revolutionizing Injection Mold Manufacturing?

Electrical Discharge Machining (EDM) is transforming injection mold manufacturing by allowing for the precise creation of complex shapes and handling hard materials post-quenching. This technology enhances efficiency and product quality through its ability to maintain dimensional accuracy and surface integrity. ...

MANUFACTURING

How Does Uneven Product Wall Thickness Impact the Injection Molding Process?

Uneven wall thickness in injection molding leads to issues like imbalanced melt flow, fusion marks, and warping, affecting product quality. Understanding these effects is crucial for improving design and manufacturing processes.

MANUFACTURING

What Are the Key Differences Between Injection Molding and Vacuum Forming?

This article explores the key differences between injection molding and vacuum forming, two popular manufacturing techniques. Injection molding is ideal for high-volume production of intricate designs due to its efficiency and precision. In contrast, vacuum forming offers a more budget-friendly ...

MANUFACTURING

How Do Injection Molding Machines Create Plastic Balls?

Injection molding machines create plastic balls through a detailed process involving mold design, material selection, and precise control of injection parameters. Each step is crucial for producing high-quality products.

MANUFACTURING

What Exactly is the Runner in a Plastic Mold?

The runner in plastic injection molding is a crucial channel that directs molten plastic from the machine to the mold cavity. Understanding its design, including cold and hot runners, enhances product quality and efficiency.

MANUFACTURING

Is it Possible for an Injection Molding Machine to Produce 3kg Products?

This article explores the capabilities of injection molding machines to produce 3kg products, emphasizing key factors such as machine selection, product design, mold compatibility, material choice, and process parameters for optimal production.

MANUFACTURING