Some plastic products break easily when under pressure. Let’s explore the world of injection molding to understand why.

Injection molded products often have weak strength because of bad material quality, wrong settings in the molding process and flaws in the mold design. Fixing these problems really improves how long products last and how they perform. Products become more durable.

I remember the first time I saw a product that couldn’t handle daily use. It was annoying, especially after spending so much time designing it. I looked into the reasons and discovered three main causes꞉ the materials, the injection molding process and sometimes the mold design itself.

Materials are important. Think about using recycled plastic that’s been reused too many times – its structure weakens. It’s like trying to bake a perfect cake with old ingredients. Not good! High-quality materials are key. Choosing the right type is crucial for meeting specific strength needs. This is important. Very important.

Next is the molding process. It’s similar to cooking; if temperatures and timings aren’t right, the result isn’t great. Low injection pressure or wrong mold temperature settings cause weak spots in the final product. Details matter. Really.

Mold design is essential too. A poorly placed gate or a bad runner system affects how plastic fills the mold, leaving weak areas. An experienced person needs to notice and fix these small details.

These lessons have been very valuable in my journey as a designer. Thinking carefully about each factor not only strengthens the product but also gives comfort, knowing designs can handle what life throws at them.

Poor material quality weakens injection molded products.True

Using low-grade materials reduces the overall strength of the product.

Mold design defects do not affect product strength.False

Defective mold designs can lead to structural weaknesses in the product.

How Does Material Quality Affect Product Strength?

Have you ever thought about why some products stay in good condition longer than other ones?

Material quality is important for product strength. Impurities, bad material choice and not enough drying often make the structure weak. Using high-quality materials is very crucial. Careful processes usually create strong products. Strong products last longer.

Material Factors

When I began working with different materials, even the smallest impurity surprised me. This situation is much like baking a cake. Low-quality ingredients result in a cake that falls apart. Poor materials lead to weak products. Once, I tried using recycled plastics. Their repeated use damaged the molecular chains, and the final product lacked strength.

Choosing the right material feels like solving a puzzle. Imagine needing a strong material but ending up with something weak, like polyethylene (PE). You really need something stronger like polyamide (PA). It’s like using paper when you actually need cardboard.

I found out the hard way that nylon requires drying. Moisture caused tiny bubbles to form while molding. These bubbles seemed small yet weakened the product, much like bubble wrap pressed too hard.

Injection Molding Process Parameters

Learning injection molding was enlightening. Low injection pressure felt like filling a balloon with a tiny hole – frustrating. If plastic fails to fill the mold, the product remains incomplete.

I found the importance of getting the holding pressure and time correct. Low pressure or time results in shrinkage, weakening the structure. Too much pressure causes stress that weakens the product gradually.

Temperature control in molds is crucial. High temperatures risk overcooking, while low ones don’t let things set properly. A friend’s mishap involved low temperatures resulting in poor melt flow and cold joints, leading to brittleness.

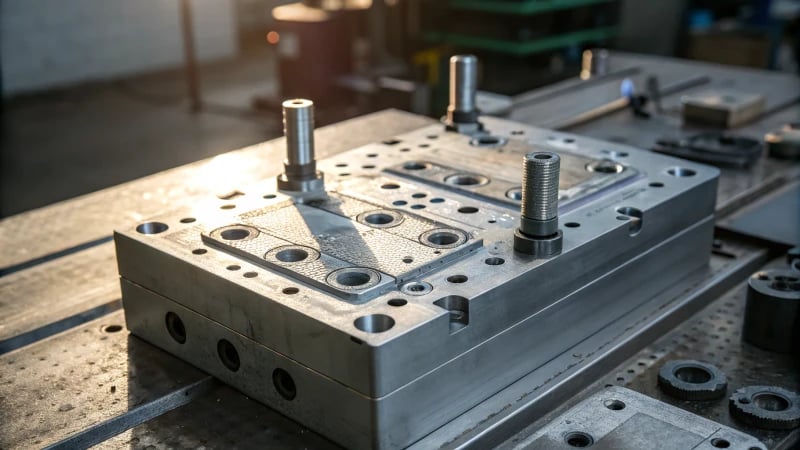

Mold Design and Manufacturing Defects

Effective mold design is vital for maintaining product strength. A poorly placed gate affects melt flow, similar to pouring water through a thin funnel.

Exhaust systems in molds are essential; I once faced trapped gases that caused short shots and weld marks—it felt like a balloon deflating suddenly.

Explore more about material properties1 and their impact on product performance. Understanding these details helps in making wise choices.

A regular conversation between design and manufacturing teams guarantees material quality, significantly improving product strength.

Poor material quality weakens product strength.True

Impurities and excessive recycling disrupt molecular structure, reducing strength.

Polyethylene is suitable for high-pressure applications.False

Polyethylene has low strength and is unsuitable for high-stress use.

Why Are Injection Molding Parameters So Important?

Have you ever thought about how a small change in injection molding settings affects your product’s strength?

Injection molding parameters include pressure, temperature and time. These are crucial for top-notch product quality. They govern how the material flows. Cooling of material also falls under their control. This directly changes the product’s structural strength. Very crucial.

Material Factors in Injection Molding

Once, I ignored the quality of plastic in a batch. Tiny cracks appeared because of impurities. This taught me a big lesson: always use the best materials. Choosing the wrong type of plastic is like wearing sneakers to climb a mountain; it just doesn’t work well. Drying materials that soak up moisture, like nylon, is really important. Without doing this, you get hidden bubbles that weaken the plastic2.

The Impact of Irrational Process Parameters

Through mistakes, I learned the right injection pressure is very crucial. If pressure is too low, it doesn’t fill up completely. If too high, unnoticed stress appears—it’s like a quiet enemy. The right holding pressure and time also matter; short times cause holes while long times add unwanted stress. Mold temperature is very important too; hot molds are unstable and cold molds don’t fill well.

| Parameter | Optimal Setting | Potential Issues if Mismanaged |

|---|---|---|

| Injection Pressure | Balanced | Incomplete filling or internal stress |

| Holding Pressure | Adequate | Shrinkage holes or stress |

| Mold Temperature | Controlled | Dimensional instability or poor filling |

Mold Design and Manufacturing Considerations

Mold design is like art. I once used a new design without proper tests, leading to uneven filling which weakened the product. This taught me that careful planning is vital. Gate size, runner systems, and air vents need proper tuning to protect product3 quality.

Putting these ideas into practice in injection molding goes beyond stopping mistakes; it’s about always reaching the level of quality and performance that matches industry needs.

High mold temperature causes dimensional instability.True

Excessive mold temperature can lead to poor dimensional stability in products.

Low injection pressure ensures complete mold filling.False

Low injection pressure often results in incomplete mold filling.

Can Mold Design Flaws Lead to Weak Products?

Picture spending much time and money on a product and then watching it fail because of unseen design problems. This situation is a real nightmare, isn’t it?

Mold design problems often produce weak products by causing defects such as incorrect filling and weak structure. These problems happen because of poor gate design, inadequate runner systems and insufficient vents. Weak products result from these issues.

Understanding Mold Design Flaws

Mold design holds a crucial place in the manufacturing process4, especially with plastic parts. An incorrect mold design once caused major issues for me. The final product’s strength and quality suffered.

Material Factors

Selecting the right material resembles choosing the ideal ingredient for cooking. Once, I selected a material with many impurities. It ended badly! The product was weak, like a cookie falling apart in your hands. Recycled materials, while eco-friendly, might have broken molecular chains. This affects strength.

| Material | Issue | Impact |

|---|---|---|

| Polyethylene | Incorrect selection | Lower strength |

| Nylon (PA) | Insufficient drying | Bubbles reduce strength |

Process Parameters

Setting injection molding parameters5 requires precision. It is like tuning a guitar. With low injection pressure, products remain incomplete. I remember dealing with surfaces looking like Swiss cheese instead of a solid piece. Improper holding pressure also causes shrinkage holes or stress.

- Injection Pressure: Completeness of mold filling

- Holding Time: Avoids shrinkage and stress

Gate Design and Runner Systems

A poorly designed gate causes inefficiency, much like filling a pool with a garden hose. I once faced issues with uneven mold filling due to bad gate placement—frustrating! Similarly, poor runner systems cause pressure loss.

Troubleshooting and Improvement

Fixing these issues feels like finding a missing puzzle piece. Adjusting mold temperature affects stability and molecular alignment. The joy of success after many trials stays with me.

- Exhaust Systems: Gases vent out correctly to prevent defects.

- Runner Design: Shorter runners and smooth surfaces reduce resistance.

For more tips, see our detailed design guide6. This guide offers insights for better product performance.

Enhancing Product Strength

Focusing on both design and process refines product durability. I have witnessed these methods transform products into strong market-ready items.

In summary, understanding and planning in mold design prevent weak products. Focusing on material quality and refining parameters reduces risks effectively. For more resources, view our mold troubleshooting PDF7.

Poor gate design weakens product integrity.True

Improper gate design can cause uneven melt distribution, weakening products.

High injection pressure causes shrinkage holes.False

Low, not high, injection pressure can lead to incomplete mold filling and defects.

What Strategies Improve Injection Molded Product Strength?

Have you ever thought about why some injection molded products last a long time while others break easily?

To increase the strength of products from injection molding, select top-quality materials. Adjust process settings carefully. Design the mold perfectly. Dry materials properly. Accurate pressure settings are very important. Perfect mold design really matters.

Material Choice is Important

Choosing the right material is like finding the best ingredients for a meal. Impurities are the "bad apples" that spoil everything. Once, I used recycled materials8 without knowing their limits, and the final result was not strong enough. Now, I focus on using high-quality materials with few impurities. For strong needs, I choose engineering plastics like polyamide (PA).

| Application Type | Recommended Material |

|---|---|

| High Pressure | Polyamide (PA) |

| General Use | Polyethylene (PE) |

Fine-Tune Injection Molding Settings

Injection pressure plays a crucial role. Before, I used low pressure and ended up with products that were not filled properly and became weak. I learned to use enough holding pressure and time to stop shrinkage holes which weaken the product.

Temperature matters equally. One time, bad mold temperature created poor structure in the product. Keeping the right temperature is a must for me now. Learn more about mold temperature effects9.

Focus on Mold Design and Creation

Mold design combines skill and science. I experienced how a badly placed gate creates weak areas due to uneven material flow. Efficient runner systems and correct mold exhaust are very important to stop gas getting trapped, which leads to weak spots.

| Design Element | Importance |

|---|---|

| Gate Placement | Uniform Fill |

| Runner Efficiency | Reduced Flow Resistance |

| Exhaust System | Prevent Defects |

These are not just small changes but key actions I use to create stronger products. By understanding and using these ideas, stronger and more reliable products are made for things like cars and electronics.

Check out best practices10 for using these methods in your work.

Using recycled materials can weaken injection molded products.True

Recycled materials may have damaged molecular structures, reducing strength.

Low injection pressure enhances product strength.False

Low pressure may lead to incomplete filling, affecting structural integrity.

Conclusion

Injection molded products often lack strength due to poor material quality, incorrect molding settings, and flawed mold design. Addressing these issues enhances durability and performance.

-

Discover how different material properties influence the durability and performance of products. ↩

-

Engineering plastics offer superior strength compared to general-purpose ones. This link provides insight into why selecting the right material is crucial. ↩

-

Mold design directly affects product integrity. Explore how design choices can make or break the final product quality. ↩

-

Understanding this importance helps in recognizing how design impacts product quality. ↩

-

Learning optimal parameters enhances mold design precision, reducing defects. ↩

-

These tips offer practical insights into refining mold design for stronger products. ↩

-

Accessing this PDF provides detailed solutions for common mold issues. ↩

-

Discover why virgin materials often provide better strength than recycled ones in injection molding applications. ↩

-

Learn about ideal mold temperatures that ensure better product strength and integrity. ↩

-

Explore proven techniques to improve the strength of your injection molded products effectively. ↩