Have you ever wondered how factories churn out so many identical items so quickly? Welcome to the world of injection molding!

An injection molding machine can produce multiple products at once by using multi-cavity molds, which allow for the simultaneous molding of several identical or different parts in a single cycle. This method enhances production efficiency and is cost-effective for large-scale manufacturing.

But don’t stop there! Let’s dive deeper into the fascinating world of multi-cavity molds and explore their intricacies and practical applications.

Multi-cavity molds enhance production efficiency in injection molding.True

They allow simultaneous production of multiple parts, reducing cycle time.

What Are Multi-Cavity Molds and How Do They Work?

In the realm of efficient manufacturing, multi-cavity molds stand out as a remarkable innovation.

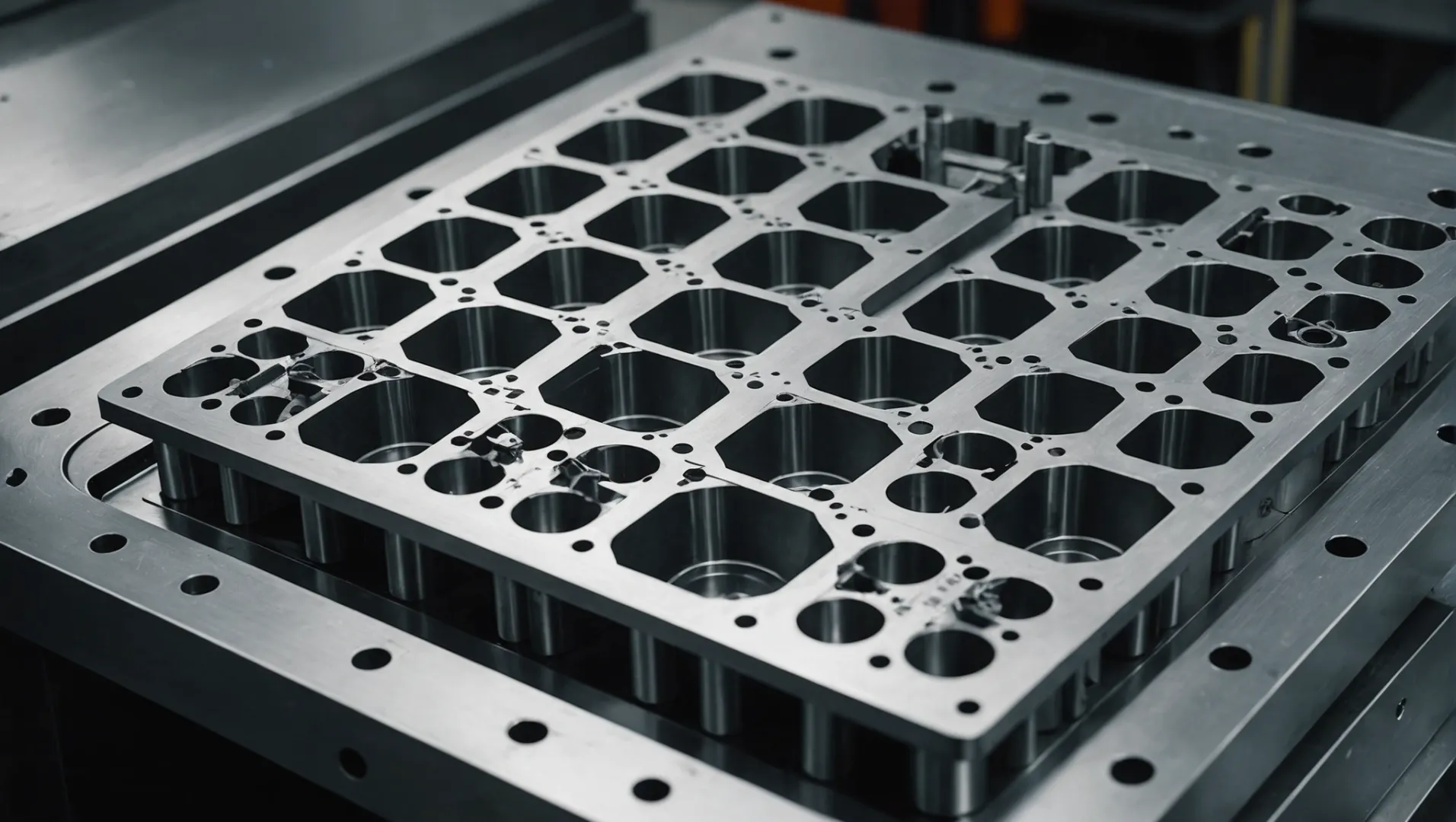

Multi-cavity molds are specialized tools in injection molding that contain multiple cavities within a single mold. Each cavity can produce a separate part during the same injection cycle, allowing for the simultaneous production of multiple identical or different products, thereby improving efficiency and reducing costs.

Understanding Multi-Cavity Molds

At the heart of injection molding efficiency1 lies the concept of multi-cavity molds. These molds are crafted with precision to accommodate several cavities, each designed to form a specific part. By utilizing these molds, manufacturers can produce a multitude of parts in one go, significantly optimizing production timelines.

Each cavity in the mold is connected to the central feed system, which distributes the molten material evenly. This setup ensures that each part is formed with consistent quality and precision. The ability to produce multiple components simultaneously is particularly beneficial in high-volume manufacturing scenarios, where time and efficiency are paramount.

Advantages of Multi-Cavity Molds

-

Enhanced Efficiency: By producing multiple parts in a single cycle, multi-cavity molds drastically cut down on production time.

-

Cost-Effective Production: The initial investment in a multi-cavity mold can be high, but the cost per part decreases significantly due to the increased production volume.

-

Consistency in Quality: With precise engineering, these molds ensure each part is identical in quality and dimensions, essential for maintaining product standards.

Practical Applications

Consider a scenario where a single injection molding machine is tasked with producing three distinct products, such as buttons, clips, and small gears. By employing a multi-cavity mold that accommodates these items, the machine can efficiently produce all three products concurrently, provided the materials and process parameters align with the machine’s capabilities.

| Product Type | Material Compatibility | Required Parameters |

|---|---|---|

| Button | High | Low temperature |

| Clip | Medium | Medium temperature |

| Small Gear | High | High temperature |

Implementation Challenges

Despite their advantages, multi-cavity molds2 require precise calibration and setup. Frequent mold changes or adjustments might lead to downtime if not managed effectively. Moreover, operators must possess a high level of skill to ensure that all process parameters are fine-tuned to maintain consistency and quality across different product types.

To mitigate these challenges, manufacturers often employ advanced monitoring systems and training programs for operators. These measures ensure that the transition between different molds or products is seamless and does not compromise production efficiency or product quality.

Multi-cavity molds can produce different products simultaneously.True

Each cavity can be designed for distinct parts, allowing diverse production.

Multi-cavity molds increase production costs per part.False

While initial costs are high, cost per part decreases with volume.

Why Choose Multi-Cavity Molds Over Single-Cavity?

In the world of injection molding, efficiency is key. But why are multi-cavity molds often favored over single-cavity ones?

Multi-cavity molds are preferred over single-cavity molds because they increase production efficiency and reduce manufacturing costs by producing multiple parts in a single cycle. This approach is ideal for high-volume production, offering consistent quality and faster turnaround times.

The Basics of Multi-Cavity Molds

In injection molding, a multi-cavity mold3 refers to a mold that contains more than one cavity, allowing it to produce multiple identical or different parts in one injection cycle. Compared to a single-cavity mold, which produces only one part per cycle, multi-cavity molds can significantly enhance production efficiency.

| Feature | Multi-Cavity Mold | Single-Cavity Mold |

|---|---|---|

| Number of Parts | Multiple parts per cycle | One part per cycle |

| Production Efficiency | Higher | Lower |

| Cost per Part | Lower (in high volumes) | Higher |

Cost Efficiency and Productivity

One of the primary reasons manufacturers opt for multi-cavity molds is their cost-effectiveness. When producing a large volume of products, the cost per part decreases significantly because multiple items are produced simultaneously. This leads to lower labor costs and reduced energy consumption, making it an economical choice for mass production.

For instance, if a factory requires 10,000 units of a particular part, using a mold with ten cavities means only 1,000 cycles are needed instead of 10,000. This reduction in cycles directly translates to lower energy use and less wear and tear on the machinery.

Consistency and Quality Control

Another advantage is consistency. Multi-cavity molds ensure that each part produced in the same cycle experiences identical conditions such as pressure, temperature, and time. This uniformity results in parts that are more consistent in quality and dimensions compared to those produced individually.

Versatility and Adaptability

The versatility of injection molding machines4 is enhanced with multi-cavity molds. By adjusting process parameters like injection speed and temperature, manufacturers can cater to different product specifications without needing separate machines for each product type. This adaptability reduces downtime associated with changing molds and recalibrating machines.

Addressing the Challenges

While the benefits are clear, utilizing multi-cavity molds does come with challenges such as increased initial costs and the need for precise calibration to maintain quality across all cavities. However, the long-term savings and increased productivity typically outweigh these initial hurdles.

By understanding these dynamics, manufacturers can make informed decisions about when and why to choose multi-cavity molds over their single-cavity counterparts. Exploring further into the specific needs of your production line can reveal more tailored advantages of this approach.

Multi-cavity molds reduce manufacturing costs.True

They produce multiple parts per cycle, lowering cost per part.

Single-cavity molds are more efficient than multi-cavity.False

Multi-cavity molds enhance production efficiency by making more parts.

What Challenges Arise When Using Multi-Cavity Molds?

Multi-cavity molds revolutionize production, yet they come with their own set of challenges.

Challenges with multi-cavity molds include ensuring consistent quality across all cavities, managing increased cycle times, and dealing with complex mold design and maintenance. These issues can impact efficiency and product quality if not properly addressed.

Ensuring Consistent Quality Across Cavities

One of the primary challenges in using multi-cavity molds is maintaining uniformity across all parts produced. Each cavity must be perfectly balanced in terms of pressure, temperature, and material flow to ensure each product meets quality standards. Variations can lead to defects, increased waste, and the necessity for stringent quality checks5.

For instance, discrepancies in cavity filling can result in uneven cooling rates, causing warping or internal stresses in the final product. Mold designers must employ advanced techniques like computer-aided engineering to predict and mitigate these issues.

Managing Increased Cycle Times

While multi-cavity molds are designed to increase output, they can also lead to longer cycle times if not managed correctly. The increased number of cavities demands more precise control over the molding parameters.

Operators often need to fine-tune settings like injection speed and pressure to optimize cycle times without compromising quality. This requires highly skilled personnel who understand the intricacies of the process.

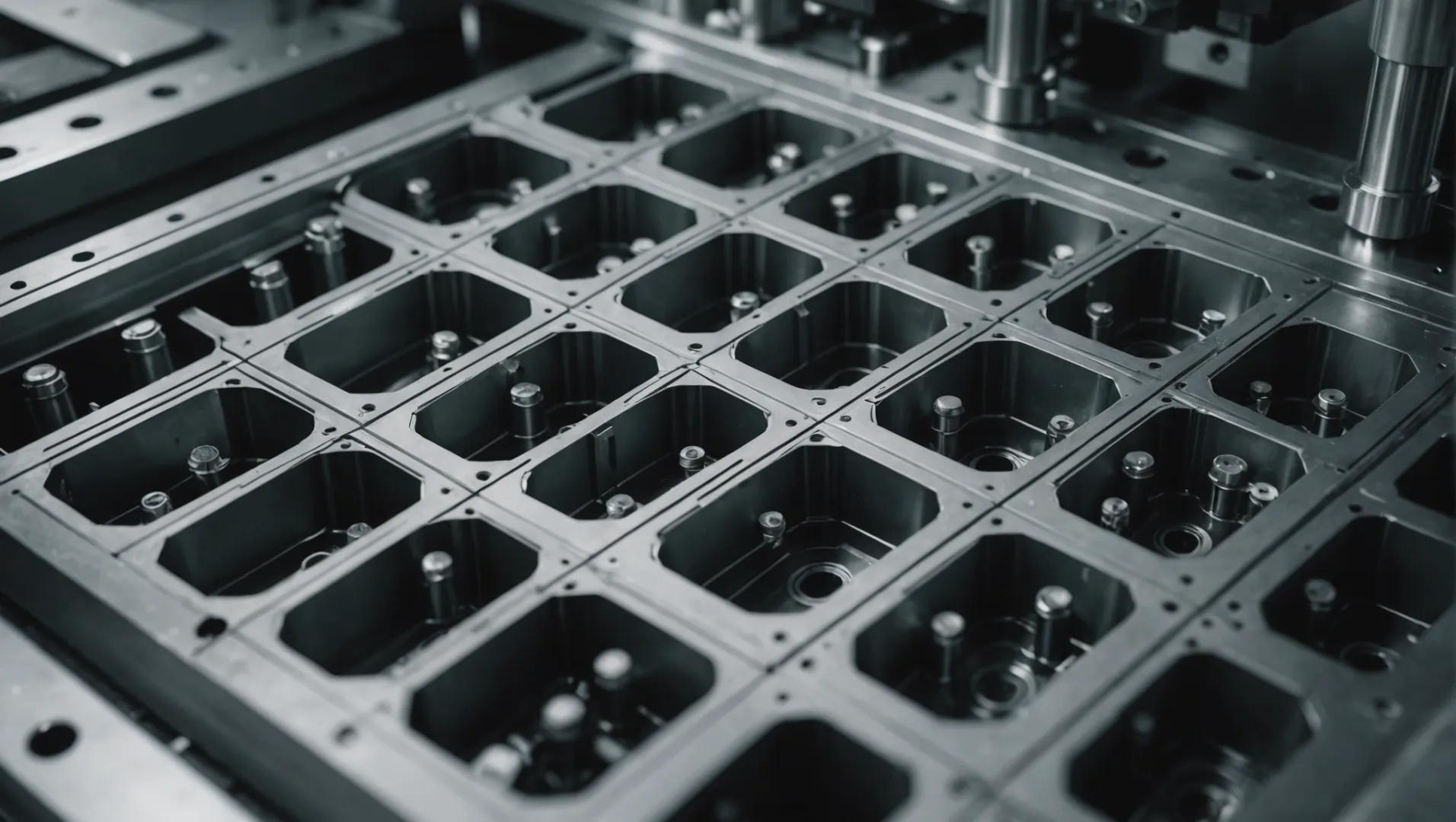

Complex Mold Design and Maintenance

Designing a multi-cavity mold is inherently more complex than a single-cavity one. Engineers must consider factors like mold flow analysis, cooling systems, and ejection mechanisms for each cavity. This complexity translates to higher initial costs and more elaborate maintenance requirements.

Over time, wear and tear on the mold can lead to inconsistencies across cavities, necessitating regular maintenance checks6 to uphold production standards.

Adapting to Material and Product Variability

Multi-cavity molds must accommodate variations in materials and product designs. Different materials have unique shrinkage rates, thermal properties, and flow characteristics, which can affect how they behave in a multi-cavity setup.

Furthermore, if the mold produces different products simultaneously, operators need to manage diverse process requirements without causing delays or defects in any of the products. This calls for flexible machines capable of quick adjustments.

Navigating these challenges requires a blend of technological acumen and strategic planning. By understanding these intricacies, manufacturers can better harness the potential of multi-cavity molds for efficient production.

Multi-cavity molds can lead to longer cycle times.True

The complexity of managing multiple cavities can increase cycle times.

Single-cavity molds require more maintenance than multi-cavity molds.False

Multi-cavity molds are more complex, requiring more frequent maintenance.

How to Optimize Injection Molding for Multiple Products?

Optimizing injection molding for diverse products requires strategic planning and precision.

To optimize injection molding for multiple products, it’s crucial to select compatible materials, design versatile molds, and fine-tune process parameters. This ensures efficient production and high-quality outcomes across different product lines.

Understanding Material Compatibility

When optimizing injection molding for multiple products, the first step is to evaluate material compatibility. Different products may require varying materials, but using similar or compatible ones can significantly reduce setup time and complexity. This ensures smoother transitions when switching between products.

Consider a scenario where you are producing both plastic buttons and small accessories. Using compatible polymers for these items can streamline the production process, as the same machine settings can often apply to both.

Designing Versatile Molds

The design of the molds is pivotal in managing multiple product outputs from a single machine. Investing in versatile mold design7 allows manufacturers to quickly swap molds without major adjustments to the machine. This includes using multi-cavity molds that can handle different shapes or sizes within the same cycle.

For example, a mold with interchangeable inserts allows for rapid transition from one product design to another, enhancing flexibility and reducing downtime.

Fine-Tuning Process Parameters

Achieving optimal results also involves meticulously adjusting process parameters such as temperature, pressure, and injection speed. Operators must possess the technical expertise to adjust these settings accurately based on the product being manufactured.

A common practice is to document optimal settings for each product type, creating a reference that can be quickly applied during production shifts.

| Parameter | Product A | Product B | Product C |

|---|---|---|---|

| Temperature (°C) | 230 | 220 | 225 |

| Pressure (bar) | 100 | 95 | 105 |

| Injection Speed | Fast | Medium | Slow |

Training and Skill Development

Frequent changes in production require operators to be highly skilled in adjusting and optimizing process parameters. Investing in comprehensive training programs ensures that the team can handle diverse product requirements efficiently.

Operators need to be well-versed in troubleshooting and maintenance to avoid production hiccups. This not only minimizes errors but also boosts overall productivity.

Quality Assurance and Consistency

Maintaining quality consistency across different products is essential. Implementing a robust quality assurance system helps in identifying defects early in the production process, reducing waste and ensuring customer satisfaction.

Regular inspections and tests should be part of the routine to verify that each batch meets the predefined standards. Using advanced monitoring systems can provide real-time data, aiding in prompt decision-making.

By integrating these strategies, manufacturers can effectively optimize injection molding processes for multiple products, achieving efficiency and high-quality outcomes.

Using compatible materials reduces setup time in molding.True

Compatible materials streamline transitions, saving time and complexity.

Versatile molds increase production downtime in injection molding.False

Versatile molds reduce downtime by allowing quick swaps and adjustments.

Conclusion

In summary, leveraging multi-cavity molds transforms production efficiency and cost-effectiveness. By understanding mold design and process optimization, we can unlock new potential in our manufacturing capabilities.

-

Learn about the efficiency gains from using multi-cavity molds.: There are several reasons to use multi-cavity molding over single-cavity molding. The most important reasons are production speed and efficiency, potential … ↩

-

Understand potential difficulties when implementing multi-cavity molds.: Designing these types of molds presents unique challenges, however. The same general guidelines used for developing a single-cavity co-injection … ↩

-

Learn how multi-cavity molds enhance production efficiency.: A multi-cavity mold has more than one cavity of the same part, and it produces more than one part per production cycle. ↩

-

Discover how machines adapt for versatile production needs.: This article highlights five pretty cool types of injection molding. Each offers a different set of materials and results, as well as cost reductions in … ↩

-

Discover effective methods to maintain uniformity across multiple cavities.: Multi-cavity molds can boost production and reduce part costs, but only after certain design ‘tweaks’ are made · adjusting the mold gate · using side-actions … ↩

-

Learn essential maintenance tips for long-lasting mold performance.: Multi-cavity molds can boost production and reduce part costs, but only after certain design ‘tweaks’ are made · Consider Material Flow for Multi-Cavity Tooling. ↩

-

Explore how versatile molds enhance flexibility and reduce production downtime.: 6 Major Advantages of Plastic Injection Molding · 1. High Efficiency- Fast Production · 2. Complex Part Design · 3. Enhanced Strength · 4. Flexibility- Material and … ↩