Welcome back, everyone. Today we're diving into something a lot of you have been asking about. Mold design. Specifically, we're looking at those channels inside the mold and how much they can actually affect how long a mold lasts. We've got some great insights from an expert in the field from an article they wrote.

Yeah, it's really interesting how much focus goes into, like, the overall mold design. But those channels, they're kind of like the unsung heroes, you know, quietly affecting everything.

It's true. And this expert, they shared a story about a project where just a small little design flaw in those channels, it caused a total breakdown of the whole mold. Really shows you those little details can make a huge difference.

Absolutely. And one of the biggest things that comes into play is wear. So every time that molten plastic flows through those channels, you get friction. It's not like a dramatic sudden crack or anything, but over time, all that rubbing, it takes its toll.

Okay, so it's like a slow and steady kind of erosion. But what makes that wear worse? Like, what should we be watching out for?

Well, the expert pointed out something really interesting about taper angles. Specifically, in high speed injection molding, if that angle is even a little bit off, it can really increase friction. In fact, they said even just a few degrees can mean, like, 20% more friction, which, of course, leads to faster wear.

20%? Wow. That's a big jump. I bet that translates to real money down the line too.

Absolutely. Think about it. More wear means more maintenance, you know, potentially for delays in production, and then the mold needing to be replaced sooner than you'd like.

Yeah, no one wants that. So getting that taper angle right is super important. What else contributes all this wear and tear?

Another big factor is the surface roughness. So if the surface of the channel isn't smooth, you get more friction as the plastic moves through. And those little imperfections can trap particles, which makes the wear even worse.

That makes sense. So it's not just the shape of the channel, but the texture matters too. Now, what about this thing called thermal fatigue? That sounds kind of sci fi, to be honest.

It's a bit less dramatic than it sounds, but just as important. Think about it. That mold's constantly heating up, then cooling down, heating up, cooling down during the injection process. And over time, all that can cause these little microscopic cracks to form and weaken the structure.

So it's not just one big impact, but the accumulation of all those little stresses that does the damage. Huh. Did the expert give any specific examples of this?

Yeah, they mention mismatched Cooling systems can actually make this whole thing worse. Because if parts of the mold are cooling faster than others, you get this uneven thermal expansion. Right. Imagine one part's expanding while another's contracting at the same time. That's how those micro cracks start.

Oh, okay. Yeah, I can picture that. It's like the mold is constantly being pulled in different directions. And I'm guessing this ties back to the channel design, too.

Exactly. The length and layout of those channels play a big part in how heat is spread out within the mold. Like, if a channel's too long, the plastic loses more heat as it's traveling through, and then that throws off the temperature balance.

Ah.

So it's like this delicate dance between the heat from the molten plastic and the cooling system. Right. Gotta be in sync right. Now, what about this stress concentration idea? That one sounds a little intimidating.

Well, think of it this way. There can be certain spots in the mold where the stress is, like, amplified because of the design, kind of like a fault line. And over time, that's where cracks are more likely to show up.

So it's like those pressure points you get on your feet if your shoes don't fit, Right?

Yeah, that's good analogy. And the expert actually mentioned one specific example, misalignment between the channel and the nozzle of the injection molding machine. Even that tiny mismatch can concentrate stress in one spot and lead to cracks after enough uses.

Wow. So something that small can have a huge impact over time. It really shows how important precision is in every single part of the design. It really does. Every little detail matters. And, you know, when you think about it, all those things we've talked about, the wear, the thermal fatigue, that stress, concentration, it's not like they happen in isolation. Right. They all work together to kind of slowly but surely wear down that mold over time.

So it's this gradual decline, unless you're actively trying to, you know, address those things. What's the real world impact of this, like, for someone who's actually working with molds every day?

Well, the first thing that comes to mind is cost. I mean, more wear means more maintenance and repairs, which adds up fast. And then eventually, you're looking at replacing the whole mold, which can be, you know, a pretty big expense.

Yeah, that's a hit to the budget nobody wants. But it's not just about the money, right?

Definitely not. You also have to think about product quality, because as a mold wears down, it can't produce those consistent, high quality parts like it used to. So you start seeing defects, inconsistencies maybe even like dimensional variations.

Well, it's kind of like a precision tool that gets dull over time. And I bet in some industries, even those tiny imperfections could be a huge deal.

Exactly. Think about things like medical devices or aerospace components. They need super tight tolerances. So if a mold's worn down, you might end up with parts that are just out of spec. And that can have some pretty serious consequences.

Right. That puts it into perspective for sure. It's not just about efficiency. It's about safety and making sure things work reliably. So let's say you're the one in charge of, you know, a molding operation. How do you make sure these channel design issues are actually being taken seriously?

That's where collaboration becomes super important, because it's not just on the mold designer. You know, you need input from materials engineers, production managers, even the operators who are working with those molds day in and day out.

So a real team effort. Everyone needs to understand the big picture. What are some specific things these teams should be looking at?

Well, if you're talking about a brand new mold design, you got to consider things like the material you're using, its flow characteristics, how the cooling system is going to interact with the hole runner design. And don't forget about the specific application rate. What are the tolerances you need, expected production volume, even the environment where the mold's going to be operating.

Wow, that is a lot to keep in mind. And I bet regular inspections are crucial too, right?

Oh, absolutely. Got to monitor that mold's condition over time, looking for any little signs of wear, anything that could become a problem down the line. Think of it like regular maintenance for a car. It's way easier and cheaper to take care of little issues before they turn into big breakdowns.

That's a great analogy. So being proactive, not reactive, what about staying up to date with technology? I feel like that could play a role too.

Definitely. Mold design is a field that's always changing. Right. There are always new materials, new techniques, new software, tools coming out.

So continuous improvement always got to be looking for ways to make things better.

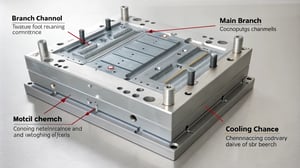

Exactly. Now let's talk a little bit about runner design. You know those channels within the mold that actually guide that molten plastic to the cavities where the parts are formed.

Right. Like the highways of the mold. And I remember the expert mentioned that runner design is kind of like planning a roller coaster for liquid plastic.

Yeah, that's a good way to put it. Because if that runner design isn't smooth and efficient, it creates a Lot of resistance. Like a roller coaster hitting the brakes suddenly. And all that resistance, it puts sheer stress on the mold, which can wear it down a lot faster.

Okay, sheer stress. That's getting a little technical. Can you break that down for us a bit?

Sure. Think of it like the force that's trying to make one layer of something slide over another one. So in this case, that molten plastic flowing through a runner, it's pushing on the walls of the channel. The smoother the flow, the less sheer stress you get. But any sharp turns, any bottlenecks, any rough surfaces, those are all going to increase it.

So it's all about minimizing those points of friction, giving the molten plastic the smoothest ride possible.

Exactly. And the expert actually shared a really cool story about this. They were working on a design where the runners were all different sizes, so the plastic was flowing through some areas way faster than others.

Ooh, I bet that caused some issues. More wear in those high flow areas.

You got it. It was like finding potholes on a brand new highway. You don't expect em to be there, but they can do a lot of damage.

That makes total sense. So consistent flow rates throughout the whole runner system, that's key. How do you actually achieve that?

Well, having those balanced runner sizes is a good start, but it's not just about that. The layout, how many bends and turns there are, even the taper angle inside the runners themselves, it all matters. And of course, the cooling system plays a role too. If those runners aren't cooled right, you can get hot spots, and then you've got uneven flow and pressure.

Again, sounds like a lot of moving parts, literally and figuratively.

It definitely is. And that's why it's so important to have people who really understand fluid dynamics and thermal management involved in the design process. But even with all that, there are some basic things that can make a big difference, like aiming for equal filling times for all the cavities. That's a good starting point.

Okay, so all the cavities should be filling up with that molten plastic at roughly the same rate. Why is that so important?

Well, it helps to keep the pressure balanced throughout the whole mold, because if some cavities are filling up way faster than others, you get those pressure imbalances, and that can lead to defects in the parts, uneven cooling, even stress on the mold itself.

It's like making sure everyone gets an equal slice of the pie. Right? No one gets overstuffed. No one's left hungry.

Exactly. And speaking. Speaking of materials, we should talk about how choosing the Right. Materials for your mold can really impact its lifespan.

So it's not just about the design of the channels, but what those channels are actually made of.

Right. Because different materials, they have different strengths, different thermal properties, different resistance to wear and tear. Choosing the right material for each part of the mold is crucial.

It's kind of like choosing the right building materials for a house. Right. You wouldn't use straw to build a skyscraper.

Exactly. For the high stress areas of the mold, like those channels and runners, you need a material that can handle the heat and friction without breaking down.

So it's not just about finding the strongest material, but the one that's best suited to what's happening inside that mold. Did the expert have any specific recommendations?

They didn't mention any specific materials by name, but they really emphasize things like thermal stability and wear resistance. Like, for thermal stability, you need materials that can handle those temperature swings without cracking or warping. Right?

Right. Like a pot on the stove that can be heated up and cooled down over and over without breaking.

Exactly. And when it comes to wear resistance, you need a material that can stand up to that constant friction from the molten plastic flowing through.

Sounds like you really need a materials expert to help make those decisions.

Oh, definitely. Material selection is a complex process, and it's not a one time thing either. You might need different materials for different parts of the mold, depending on what they're going to go through.

So another area where that team approach is so important. The mold designer, the materials engineer, even the people actually working with the mold on the factory floor.

Absolutely. Now, before we jump into practical applications, I want to touch on something we talked about earlier. Maintenance.

Right. They said even the best designed mold won't last if it's not properly maintained.

It's like a car. You can have the best engine in the world, but if you don't change the oil and check the tire pressure, it's not going to run. Right.

So regular maintenance is key for extending the life of the mold. What are some of the things people should be doing?

Well, cleaning is a big one. Got to regularly clean those channels and runners to prevent any buildup of plastic residue and debris.

Kind of like brushing your teeth. Right. A small habit that prevents bigger problems later on.

Exactly. And then there's lubrication. Keeping those moving parts moving smoothly helps reduce friction and wear.

And don't forget those regular inspections looking for any signs of wear or damage before they get out of control. It's like going to the dentist for checkups. Better to catch those cavities early.

Exactly. Early detection is key, and then documentation. Keeping good records of all your maintenance can help you see patterns and trends, so you can be even more proactive.

So it's not just about doing the maintenance. It's about learning from it too precisely.

And, you know, sometimes even with all the right procedures in place, you're going to run into a really tricky problem. That's when you got to get creative. Use your experience to think outside the box.

Do you have any stories about times you had to do that? Get really creative to solve a mold design problem?

Oh, tons. But there's one that comes to mind. It was a really complex mold with this intricate runner system, and we were having trouble with those uneven filling times and pressure imbalances we talked about. We tried adjusting the runner sizes. We messed with the cooling parameters, but nothing seemed to work.

So you were hitting a wall. What did you do?

Well, after a lot of head scratching, we decided to take a closer look at the plastic itself, specifically its rheology. Rheology is basically the study of how fluids flow under pressure. And it turned out this particular plastic had some unique characteristics that we hadn't fully considered in the design.

Interesting. So you had to get into the nitty gritty of the material itself.

Yeah. We worked with a specialist to really understand how this plastic behaved at different temperatures and pressures. And based on their analysis, we ended up making very specific tweaks to the runner design. Things like changing the angles of some of the bends and adding some little features to redirect the flow.

And that fixed it?

It did. Once we understood how that plastic really flowed, we could fine tune the runner system and get those balanced filling times and consistent pressure we were after.

That's a great example of how important it is to collaborate and be willing to learn new things. And it shows that mold design isn't just about following a set of rules. There's an art to it, too, definitely.

It's a constantly evolving field. Always something new to learn.

All right, so we've talked about a lot of theory. How about we get practical? If you're out there working with molds every day, what are the big takeaways you should be thinking about?

I think the most important thing is don't wait until something breaks. You know, we talked about wear, thermal fatigue, all that stress, concentration. Take a good look at your molds, really think about those things.

So almost like you're a detective looking for clues. Where are the wear patterns worse? Are there any, you know, discolorations or micro cracks that could be signs of Thermal stress.

Exactly. And don't just look at the mold itself. Check those runners, too. Are they balanced? Is the layout designed for smooth flow and good cooling?

So it's like a health checkup for your molds, catching those potential problems early on.

Exactly. Being proactive like that can save a lot of headaches and money in the long run. Now, let's say you're designing a new mold. What are some questions you should be asking to make sure that channel design is a top priority from the very beginning?

That's where that whole team approach comes in. Right. You can't just have the mold designer off doing their own thing.

Exactly. Talk to everyone involved. The mold designer, the materials engineer, even the people who will be using the mold day in and day out. Everyone brings something to the table.

So you've got this diverse team of experts. What ponds of things should you be asking them?

Well, think about things like how the material is going to flow, what kind of pressures and temperatures you're expecting, how the cooling system will work with those runners. And don't forget the big picture. What are the tolerances for the finished product? How many are you planning to make? What kind of environment will that mold be working in?

Man, so many things to consider. But it sounds like the main point is, don't treat channel design like an afterthought. Make it part of the whole design process.

Absolutely. And like we've been saying, even those little details like the taper angles, the surface roughness, they can have a huge effect on how long that mold's going to last and how good the parts will be.

Okay. So be proactive with your existing molds. Ask the right questions when you're designing new ones. And what about maintenance? Seems like that's an ongoing thing, right?

Oh, for sure. Even the best designed mold in the world needs proper care. Cleaning's essential. Gotta get rid of all that plastic residue and debris that builds up in those channels and runners.

It's like brushing your teeth. Gotta do it regularly to avoid bigger problems down the road.

Exactly. And lubrication's important, too. Keep those moving parts working smoothly, reduce that friction, and wear regular inspections, too.

Right. Gotta catch those problems early on. Like going to the dentist for checkups.

Exactly. Early detection is key. And documentation. Keep track of all your maintenance that can help you spot patterns and figure out how to prevent things from going wrong in the first place.

So it's not just about doing the maintenance. It's about learning from it, too.

You got it. But even with all the best practices, sometimes you're going to hit a snag, something really tricky. That's when you got to get creative.

Have you had any times where you had to, you know, really think outside the box to solve a mold design problem?

Oh, plenty. But there's one that really sticks out. It was the super complicated mold crazy, intricate runner system. And we were having all sorts of trouble with uneven filling and pressure imbalances. We tried everything. Adjusting the runners, tweaking the cooling. Nothing worked.

Sounds frustrating. So what did you do?

Well, we finally took a step back and looked at the plastic itself, something called its rheology. It's basically how fluids flow under pressure. Turns out this plastic had some quirks we hadn't accounted for in the design.

So you had to dig into the science of the material itself.

Yeah. We talked to a specialist to figure out exactly how that plastic behaved at different temperatures and pressure. And with their help, we made some really specific changes to the runner design, like changing some angles, adding little things to redirect the flow.

And that did the trick.

Yep. Once we understood how that plastic really flowed, we could fine tune that runner system and get everything working just right.

That's a great story. It shows how teamwork and being open to new ideas can really pay off. And it reminds us that mold design isn't just about following the rules. Sometimes you gotta use your intuition and experience too.

You got it. It's a fascinating field, and there's always something new to learn.

Well, I think that about wraps up our deep dive into the world of mold design. We covered a lot. Hope you found it useful.

Yeah. Hopefully you can take some of these ideas and apply them to your own work.

Remember, even small improvements to your mold design or your maintenance practices can have a big impact on your product quality and efficiency.

So keep learning, keep experimenting, keep pushing.

The boundaries, and until next time, happy molding,