Embarking on the journey of multi-cavity mold design can feel like navigating a labyrinth. Every twist and turn presents new challenges that can either make or break your production goals.

Multi-cavity mold design challenges include achieving balanced gating systems, designing effective cooling systems, ensuring mold structural strength, and maintaining product quality consistency. Solutions involve optimized design techniques, advanced materials, and precise process controls to mitigate these issues.

But don’t worry! I’m here to guide you through the maze of solutions that can transform these challenges into stepping stones for success.

Multi-cavity molds produce identical parts per cycle.True

Multi-cavity molds are designed to produce multiple identical parts, enhancing efficiency.

- 1. How Do Multi-Cavity Molds Differ from Single-Cavity and Family Molds?

- 2. What Are the Best Practices for Designing a Balanced Gating System?

- 3. How Can Cooling System Efficiency Be Improved in Multi-Cavity Molds?

- 4. What Role Does Material Selection Play in Mold Structural Integrity?

- 5. Conclusion

How Do Multi-Cavity Molds Differ from Single-Cavity and Family Molds?

In the realm of injection molding, choosing the right mold type is crucial for optimizing production efficiency and quality.

Multi-cavity molds produce multiple identical parts per cycle, increasing efficiency, whereas single-cavity molds produce one part per cycle. Family molds make different parts simultaneously, suitable for assembly products. Each type has unique design challenges and benefits, impacting manufacturing processes and costs.

Understanding Mold Types

Injection molding is a versatile manufacturing process used for producing plastic parts by injecting molten material into a mold. The choice between multi-cavity1, single-cavity, and family molds significantly impacts production efficiency, cost, and product quality.

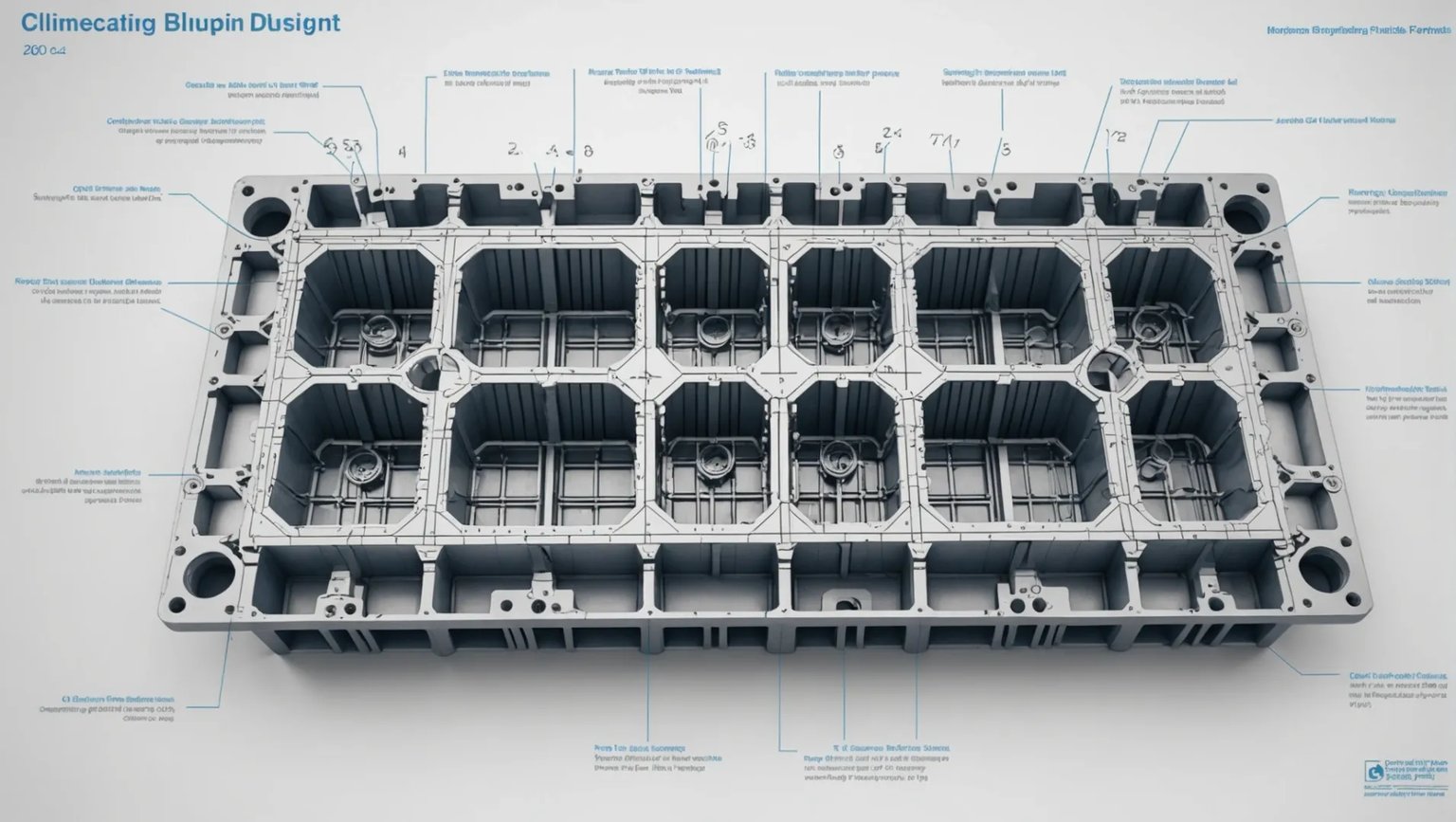

Multi-Cavity Molds

- Efficiency and Output: Designed to produce multiple identical parts in a single cycle, multi-cavity molds boost productivity and lower unit costs. This is ideal for high-volume production.

- Design Complexity: These molds require intricate designs to ensure uniform filling and cooling across all cavities. As mentioned, balancing the gating and cooling systems is paramount.

- Cost Considerations: While initial tooling costs are higher due to complexity, the cost per part decreases significantly with increased output.

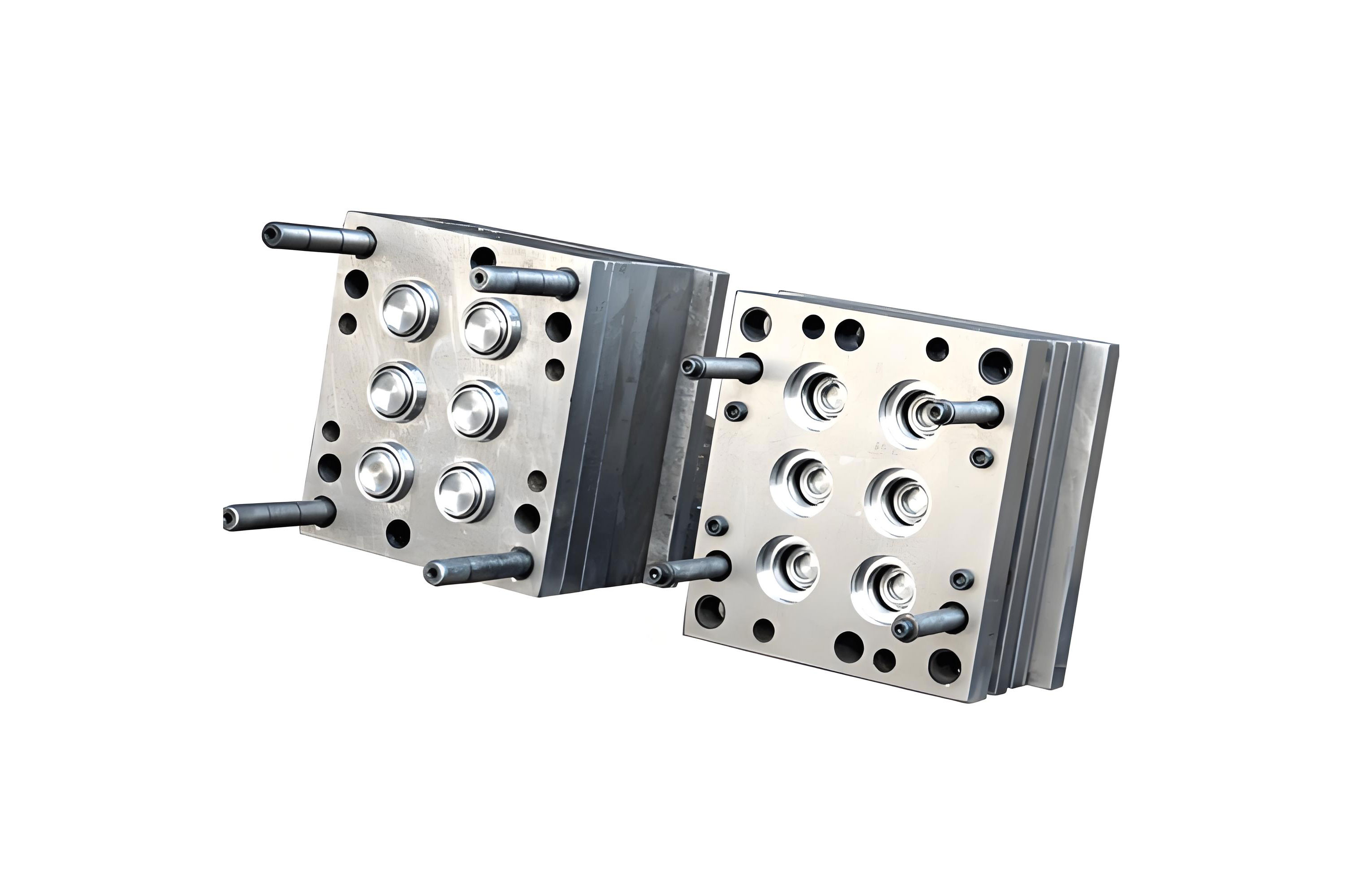

Single-Cavity Molds

- Simplicity and Control: Producing one part per cycle, these molds offer enhanced control over the molding process. They are simpler in design, reducing potential defects caused by uneven filling or cooling.

- Flexibility: Ideal for low-volume production or prototyping, where precision and detail are prioritized over quantity.

- Cost Implications: Lower upfront costs but potentially higher cost per part if scaled up.

Family Molds

- Variety in Production: Unique in their ability to produce different parts in one cycle, family molds are suited for items that will be assembled together post-production.

- Design Challenges: Requires meticulous design to ensure different parts receive appropriate material flow and cooling. This complexity can lead to variations in part quality.

- Economic Factors: Beneficial for moderate-volume runs of varied parts, reducing overall tooling costs by consolidating production.

Comparing Key Features

| Feature | Multi-Cavity Molds | Single-Cavity Molds | Family Molds |

|---|---|---|---|

| Output Efficiency | High | Low | Moderate |

| Design Complexity | High | Low | High |

| Production Volume | High | Low | Moderate |

| Part Consistency | Challenging | Easier | Variable |

| Cost Efficiency | High (in long run) | Low (unless low volume needed) | Moderate (depends on part variety) |

In sum, selecting the appropriate mold type involves weighing factors such as production volume, part consistency, design complexity, and cost efficiency. Understanding the distinct characteristics and potential challenges of each mold type enables manufacturers to tailor their approach to specific project needs.

Multi-cavity molds are ideal for high-volume production.True

They produce multiple identical parts per cycle, boosting efficiency.

Family molds offer the lowest design complexity among mold types.False

Family molds require meticulous design to ensure varied part quality.

What Are the Best Practices for Designing a Balanced Gating System?

Designing a balanced gating system is pivotal to achieving uniformity and quality in multi-cavity mold processes.

Best practices for designing a balanced gating system include optimizing runner dimensions, using flow simulation software, and adjusting injection parameters. Employing balancing devices and regular system assessments can further enhance flow uniformity across cavities, ensuring high-quality output.

Understanding Gating System Balance

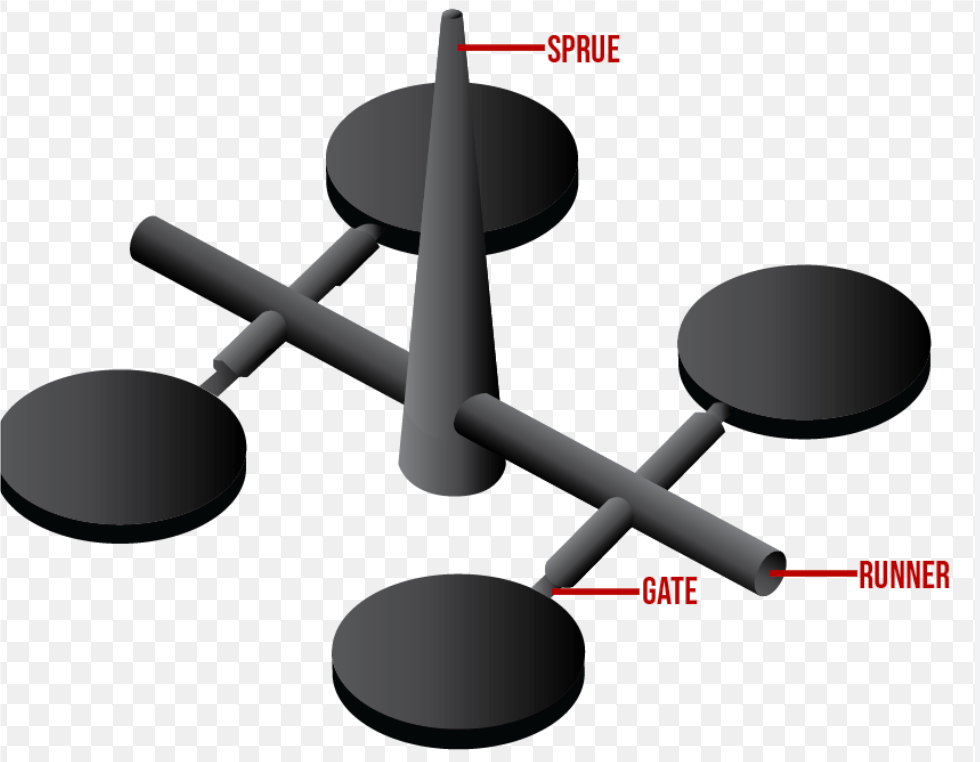

A balanced gating system ensures that each cavity in a multi-cavity mold fills evenly. This is crucial for maintaining product consistency and quality. An imbalance can lead to some cavities being underfilled or overfilled, resulting in defects. By employing a systematic approach, you can mitigate these challenges effectively.

Optimizing Runner Design

The runner system2 plays a significant role in achieving balance. By carefully adjusting the size, shape, and length of the runners, you can equalize the flow resistance across all cavities. Consider using runners with similar lengths and diameters to minimize variations in flow. Additionally, implementing flow simulation software can help optimize the design, identifying potential imbalances before production begins.

Using Balancing Devices

Balancing devices such as manifolds and balancing blocks are essential components in the gating system. These devices help distribute the flow evenly by compensating for differences in cavity geometry and position. Regularly assess and adjust these components to maintain system balance.

Fine-Tuning Injection Parameters

Injection speed, pressure, and temperature are critical parameters that impact the gating system’s performance. By fine-tuning these parameters, you can enhance the flow balance across cavities. Consider using advanced injection molding machines that allow precise control over these variables to ensure optimal performance.

Continuous Assessment and Adaptation

Regular assessment of the gating system’s performance is vital. Utilize flow analysis tools3 to monitor and adjust the system as needed, ensuring that it adapts to any changes in production requirements or materials. Adopting a proactive approach to system maintenance will help sustain balance and prevent quality issues.

Flow simulation software optimizes runner design.True

Flow simulation helps identify imbalances, optimizing runner dimensions.

Balancing devices are unnecessary in gating systems.False

Balancing devices ensure even flow distribution, crucial for system balance.

How Can Cooling System Efficiency Be Improved in Multi-Cavity Molds?

Improving the cooling system efficiency in multi-cavity molds is pivotal to achieving consistent product quality and reducing cycle times.

Enhancing cooling system efficiency in multi-cavity molds involves optimizing the cooling channel design, using simulation software, selecting appropriate cooling mediums, and maintaining precise control over temperature and flow rates.

The Importance of Cooling System Design

In multi-cavity molds, cooling efficiency is not just about speed but uniformity across all cavities. An efficient cooling system ensures that the molded products maintain their dimensional stability and surface quality, which is crucial for high-volume production.

Designing Optimal Cooling Channels

The design of the cooling channels directly impacts how efficiently heat is removed from the mold. Employing a uniformly distributed cooling pipe layout4 can significantly enhance cooling efficiency. The channels must be strategically placed to ensure that each cavity is cooled evenly. This involves considering the geometry of the cavities and the material’s thermal properties.

Cooling Channel Layout Options

| Channel Type | Benefits | Considerations |

|---|---|---|

| Spiral Channels | Enhanced cooling in deep or complex shapes | Requires precise machining |

| Conformal Cooling | Follows the shape of the cavity, improving uniformity | Costlier and complex to produce |

| Straight Channels | Simple and cost-effective | May result in uneven cooling |

Utilizing Simulation Software

To address the complexities in cooling system design, leveraging advanced cooling simulation software can be invaluable. Such tools enable engineers to visualize and optimize the cooling paths, ensuring maximum efficiency before actual production begins. This proactive approach reduces trial-and-error in physical mold iterations.

Selection and Control of Cooling Medium

Choosing the right cooling medium is another critical factor. Water is commonly used, but other mediums might be more effective depending on the polymer being molded. Moreover, controlling the temperature and flow rate of this medium is crucial. Implementing temperature controllers and flow meters5 ensures that the system remains stable, preventing any inconsistency in product quality.

Monitoring and Adjustments

Regular monitoring and adjustment of the cooling system are necessary to maintain its efficiency over time. Using IoT-enabled sensors can provide real-time data on temperature variations within the mold, allowing for immediate adjustments when necessary.

By understanding these elements and incorporating them into your mold design process, you can greatly enhance the cooling efficiency in multi-cavity molds.

Spiral channels enhance cooling in complex shapes.True

Spiral channels improve cooling efficiency in intricate mold designs.

Straight channels ensure uniform cooling across cavities.False

Straight channels may lead to uneven cooling due to their simplicity.

What Role Does Material Selection Play in Mold Structural Integrity?

Material selection is pivotal in ensuring mold structural integrity, impacting durability and performance under stress.

Material selection is crucial for maintaining mold structural integrity. High-quality materials, such as alloy steel, enhance strength and rigidity, preventing deformation or damage during injection molding. Using materials with appropriate thermal conductivity also aids in effective cooling, ensuring dimensional stability and surface quality of products.

Importance of Material Selection in Mold Design

When it comes to multi-cavity molds, the choice of material plays a vital role in determining the mold’s overall structural integrity6. High-strength materials like alloy steel and pre-hardened steel are often preferred. These materials provide the necessary rigidity to withstand the high pressures and stresses encountered during the injection molding process.

A carefully chosen material not only enhances the durability but also reduces the risk of deformation or cracking over time. This is especially critical for multi-cavity molds, which are inherently more complex and larger than single-cavity molds.

Impact on Mold Performance

The material’s thermal conductivity affects the cooling process—a significant factor in mold performance. Effective cooling ensures that each cavity is cooled uniformly, maintaining the dimensional stability and surface quality of the molded products. Materials with appropriate thermal properties help facilitate efficient heat dissipation, minimizing warping or other defects.

For example, certain alloy steels7 possess properties that improve both the cooling efficiency and the structural strength of the mold. These steels are specifically engineered to handle repetitive thermal cycling without compromising on performance.

Evaluating Material Properties

Selecting the right material involves evaluating various properties such as hardness, tensile strength, and corrosion resistance. Table 1 below outlines some common materials used in mold manufacturing and their key properties:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Corrosion Resistance |

|---|---|---|---|

| Alloy Steel | 50-55 | 1500-2000 | High |

| Pre-Hardened Steel | 35-45 | 1200-1500 | Moderate |

| Beryllium Copper | 30-40 | 1000-1300 | High |

Each material offers distinct advantages, making it essential to align material properties with the specific requirements of your mold design.

Considerations for Long-Term Performance

Long-term performance can also be influenced by how well the material resists wear and tear from repeated use. Choosing a material with superior wear resistance ensures that the mold can undergo numerous injection cycles without significant degradation.

Additionally, performing finite element analysis8 on the mold design can aid in anticipating stress points and optimizing material distribution within the mold. This approach allows designers to make informed decisions about reinforcing specific areas with additional support structures or selecting alternative materials where necessary.

Alloy steel enhances mold strength and rigidity.True

Alloy steel is known for its high strength, making it ideal for molds.

Pre-hardened steel offers low corrosion resistance.False

Pre-hardened steel has moderate corrosion resistance, not low.

Conclusion

In conclusion, embracing the challenges of multi-cavity mold design with strategic solutions can significantly enhance both efficiency and product quality.

-

Gain insights into the advantages of multi-cavity molds over single-cavity types.: Single-cavity molds produce a single product per cycle because it only has one cavity into which plastic resins can be injected. ↩

-

Learn about effective runner design techniques for optimal flow balance.: This lesson covers the factors to consider when implementing a multiple gating strategy, how different runner dimensions impact filling behaviors and injection … ↩

-

Explore tools for monitoring and optimizing flow in molding systems.: Mold flow analysis (MFA) software simulates the flow of plastic, which allows you to elevate part and mold design to create products of impeccable quality. ↩

-

Learn about strategic cooling channel designs for improved mold efficiency.: Cold radiating panels in series with variable pipe spacing can reduce surface temperature. •. Cost and pressure drop comparison of different … ↩

-

Discover tools for precise control of mold cooling systems.: SMARTFLOW Mold Temperature Regulators effectively control mold cooling water temperatures between 80F and 120F to maintain a steady mold temp. ↩

-

Explore detailed insights on material choice impact on mold strength.: Learn how to select the right material for your injection molding design with this technical overview of thermoplastic resins. ↩

-

Discover how alloy steel enhances cooling and strength in molds.: Alloys such as MoldMax, Moldstar, or Ampco can have a big impact on cycle time because of their excellent thermal conductivity. They also come … ↩

-

Learn about using FEA to optimize stress distribution in molds.: The Finite Element Analysis (FEA) is a specialized simulation of a physical entity using the numerical algorithm known as Finite Element … ↩