All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Best Methods to Prevent Silver Grain Defects in Injection Molded Products?

Silver grain defects in injection molded products can be minimized by focusing on raw material management, precise parameter settings, effective mold design, and process optimization to enhance product quality.

OPTIMIZATION

What Are the Key Advantages of Injection Molding Compared to Other Plastic Manufacturing Processes?

Injection molding offers significant advantages over other plastic manufacturing processes, including high production efficiency, superior product quality, design flexibility, material adaptability, and cost-effectiveness in mass production.

DEVELOPMENT

How Can You Effectively Reduce the Manufacturing Costs of Injection Molded Plastic Products?

This article explores effective strategies to reduce manufacturing costs in injection molding, focusing on optimizing raw materials, streamlining production processes, managing equipment efficiently, and implementing robust quality control measures.

OPTIMIZATION

What Are the Best Ways to Prevent Fusion Marks on Injection Molded Products?

This article explores effective strategies to prevent fusion marks in injection molded products, emphasizing the importance of mold design, process parameter adjustments, and material selection for improved quality.

OPTIMIZATION

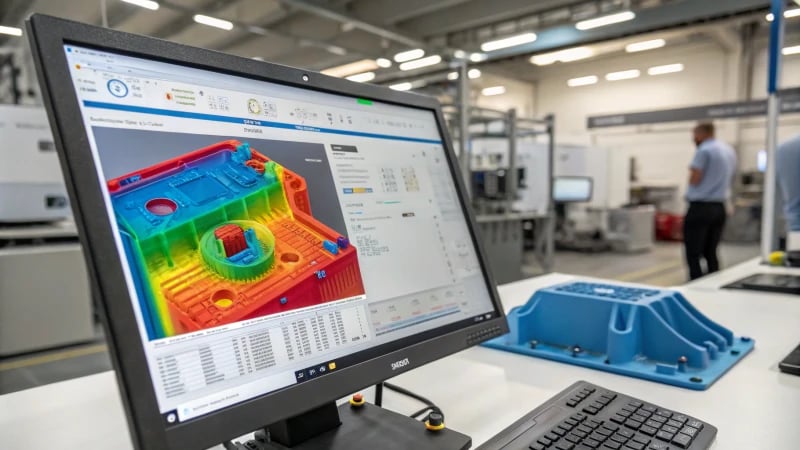

What Is Mold Flow Analysis and How Does It Predict Warpage in Injection Molded Parts?

Mold flow analysis is crucial in injection molding, predicting warpage by assessing shrinkage, residual stresses, and cooling patterns. This software enhances design accuracy and manufacturing efficiency, ensuring high-quality molded parts.

DEVELOPMENT

How Can You Ensure Uniform Wall Thickness in Your Injection Mold Design?

Ensuring uniform wall thickness in injection mold design is crucial for product quality. Key factors include gate design, runner systems, cooling layouts, and mold cavity adjustments to minimize defects.

DESIGN

What Parameters Can Be Optimized by Mold Flow Analysis in Injection Molding?

Mold Flow Analysis (MFA) optimizes injection molding parameters such as gate location, runner systems, injection pressure, and cooling times to enhance production efficiency, reduce defects, and improve product quality.

OPTIMIZATION

What Factors Influence the Duration of Plastic Injection Molding?

This article explores the key factors influencing the duration of plastic injection molding, including cycle composition, material properties, part size and shape, process parameters, and mold design. Understanding these elements can enhance efficiency and product quality.

DEVELOPMENT

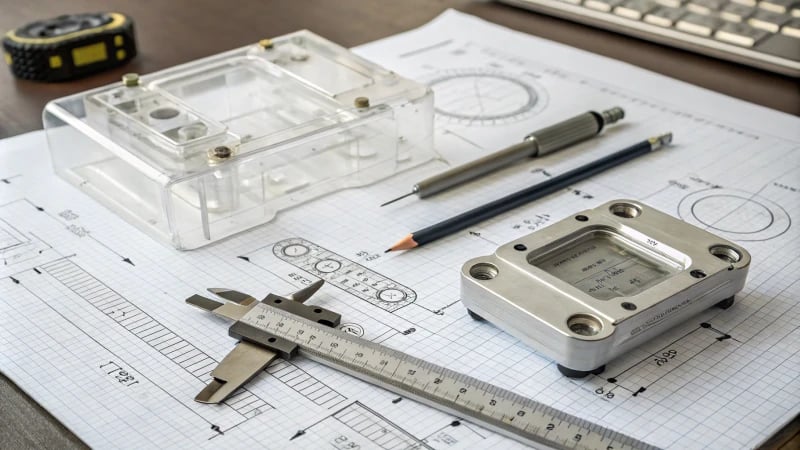

What Key Factors Should You Consider When Designing an Injection Mold?

Designing an injection mold requires careful consideration of product shape, size, wall thickness, precision needs, cooling system design, and cost management to ensure efficient production and high-quality outputs.

DESIGN

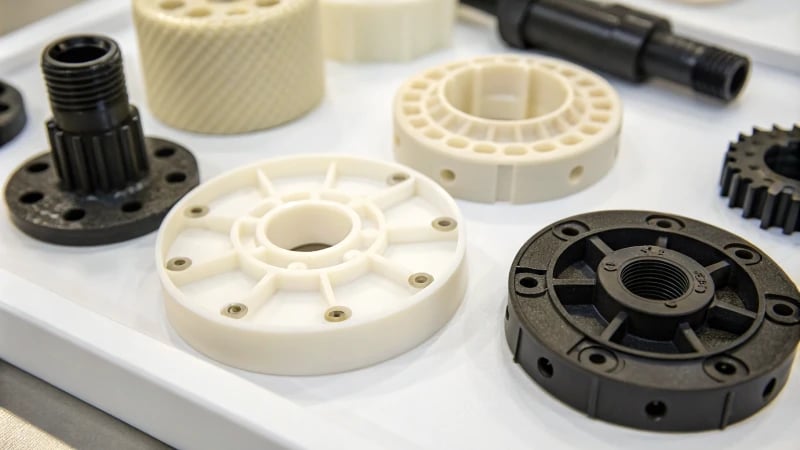

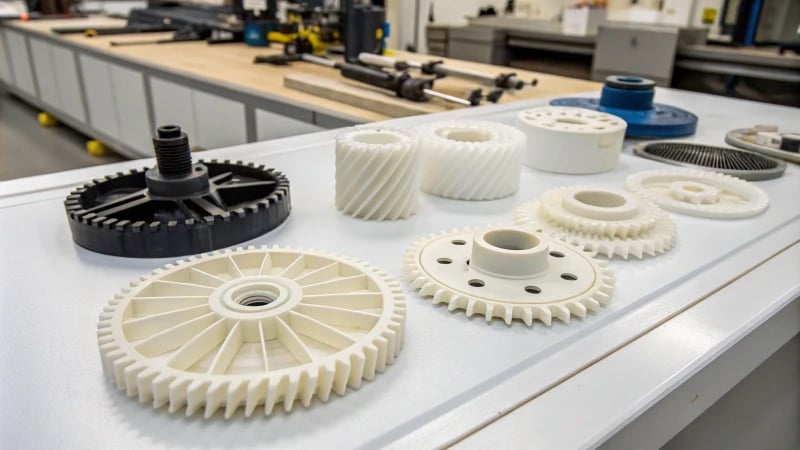

What Are Injection Molded Plastic Parts and Why Are They Important?

Injection molded plastic parts are essential in modern manufacturing, offering high precision, complex shapes, and efficiency. This versatile process is crucial for industries like automotive and consumer electronics.

DEVELOPMENT

What Role Does Injection Molding Play in Manufacturing?

Injection molding revolutionizes manufacturing by enabling the efficient production of complex, high-quality plastic parts across various industries. Its precision, speed, and innovative mold designs enhance product quality and efficiency.

DEVELOPMENT

How Do Mold Flow Analysis Results Guide Injection Mold Design?

Mold flow analysis is essential for optimizing injection mold design, influencing gate placement, runner systems, and cooling channels. It enhances production efficiency and product quality by predicting potential defects.

DESIGN

What Are the Best Ways to Adjust Melt Temperature in Injection Molding to Minimize Fusion Marks?

This article explores the importance of adjusting melt temperature in injection molding to minimize fusion marks. It discusses material properties, mold design, cooling systems, and process parameter coordination for optimal results.

OPTIMIZATION

What Are the Key Benefits of Mold Flow Analysis?

Mold Flow Analysis is a vital tool in injection molding that simulates the process to optimize mold design, predict defects, enhance product quality, and improve production efficiency.

DESIGN

How Do Injection Molding Machines Create Plastic Balls?

Injection molding machines create plastic balls through a detailed process involving mold design, material selection, and precise control of injection parameters. Each step is crucial for producing high-quality products.

MANUFACTURING

What are the Best Techniques for Removing Gates After Injection Molding?

Removing gates from injection molded parts requires careful consideration of methods such as manual, mechanical, chemical, and ultrasonic removal. Factors like gate size, material type, and production efficiency influence the best choice.

DEVELOPMENT

Why is Injection Molding Considered Fast and Cost-Effective?

Injection molding is a fast, cost-effective manufacturing process driven by automation. It features short cycle times and high material utilization, making it ideal for large-scale production across various industries.

DEVELOPMENT

What Makes a High Speed Injection Molding Machine Essential for Efficient Production?

High-speed injection molding machines significantly enhance manufacturing efficiency by reducing cycle times and improving product quality. Their advanced technology allows for rapid injection, optimizing material flow and minimizing defects.

DEVELOPMENT

What Exactly is the Runner in a Plastic Mold?

The runner in plastic injection molding is a crucial channel that directs molten plastic from the machine to the mold cavity. Understanding its design, including cold and hot runners, enhances product quality and efficiency.

MANUFACTURING

What Is the Rapid Injection Molding Process and How Does It Work?

Rapid injection molding is a fast, efficient manufacturing process that utilizes specialized machines and optimized mold designs to produce high-quality plastic parts quickly, enhancing production speed and flexibility.

DEVELOPMENT

What Exactly Do Plastic Mold Makers Do and Why Are They Important?

Plastic mold makers transform design concepts into tangible products through meticulous mold design, manufacturing, and maintenance. Their expertise is crucial across various industries, ensuring high-quality plastic components.

DEVELOPMENT

Is it Possible for an Injection Molding Machine to Produce 3kg Products?

This article explores the capabilities of injection molding machines to produce 3kg products, emphasizing key factors such as machine selection, product design, mold compatibility, material choice, and process parameters for optimal production.

MANUFACTURING

What Is the Process Behind How a Plastic Injection Molding Machine Works?

This article explores the intricate process of plastic injection molding, detailing each stage from raw material preparation to mold opening, emphasizing the importance of design and maintenance for quality production.

MANUFACTURING

Which Injection Molding Machine Is Best for Producing Plastic Chairs?

Choosing the right injection molding machine for plastic chairs is essential. Key factors include machine type, production volume, material compatibility, automation features, energy efficiency, and maintenance support to optimize efficiency and quality.

DEVELOPMENT

What Are the Steps Involved in the Plastic Molding Process?

The plastic molding process involves mixing raw materials, shaping them into molds, machining for precision, joining parts, modifying surfaces, and assembling the final product. Each step is crucial for quality.

MANUFACTURING

What Are the Best Layout Forms for Cooling Channels in Mold Cooling Systems?

This article explores the best cooling channel layouts for injection molding, including straight-through, circular, partitioned, and inlaid designs. Each layout offers unique benefits for optimizing cooling efficiency and product quality.

DESIGN

What Makes Resin Molds So Expensive?

Resin molds are expensive due to high-quality materials, complex designs, stringent performance requirements, and lengthy production cycles. Understanding these factors helps appreciate their value in various applications.

Price Evaluation

What Are the Different Plastic Molding Processes and How Do They Work?

This article explores various plastic molding processes, including injection, extrusion, blow, compression, transfer, vacuum, and rotational molding. Each method has unique features and applications in manufacturing.

DEVELOPMENT

What Are the Uses and Applications of Plastic Injection Molds?

Plastic injection molds are essential in manufacturing, providing efficient production, high precision, and design flexibility across industries like automotive, electronics, packaging, and toys. They enable rapid mass production of complex shapes.

DEVELOPMENT

What Are the Best Materials for Making Molds?

Choosing the right materials for mold-making is crucial for project success. This guide explores various options, including steel types, non-ferrous metals, hard alloys, and composites, highlighting their unique properties and applications.

Materials Recommendations