All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

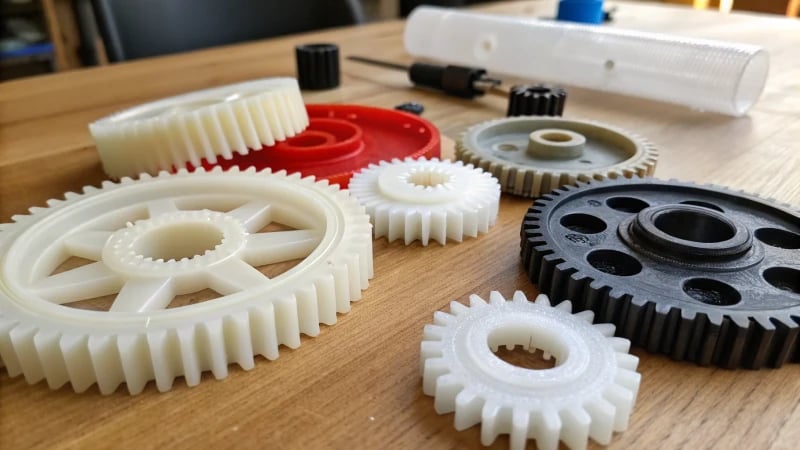

How Can an Injection Molding Machine Create a Toy Car?

This article explores how injection molding machines manufacture toy cars. It details the critical steps involved: designing molds for car bodies, wheels, and axles; selecting appropriate plastics like ABS and PMMA; executing the injection molding process by melting pellets and ...

MANUFACTURING

Can Injection Molding Machines Produce Both PPR and PVC Fittings?

This article explores how injection molding machines can produce both PPR (polypropylene random copolymer) and PVC (polyvinyl chloride) fittings. It highlights the advantages of using injection molding for each material, detailing the unique process requirements for optimal production. For PPR, ...

MANUFACTURING

Die Casting vs. Injection Moulding: What Are the Key Differences?

This article explores the key differences between die casting and injection moulding, two essential manufacturing processes. Die casting primarily uses non-ferrous metals like aluminum and zinc, requiring high temperatures and pressures to create strong, precise components. In contrast, injection moulding ...

MANUFACTURING

How Efficiently Can an Injection Molding Machine Produce PVC Fittings?

This article explores how injection molding machines produce PVC fittings with efficiency. It highlights the importance of material compatibility, custom mold design, and process control in achieving high-quality outputs. Additionally, it addresses challenges such as heat stability and the need ...

MANUFACTURING

What Are the Most Effective Ways to Reduce Part Weight in Injection Molding?

Reducing part weight in injection molding is crucial for enhancing efficiency and sustainability. Key strategies include optimizing design through wall thickness reduction, incorporating hollow structures, and refining rib designs. Material selection plays a vital role; using lightweight polymers like polyethylene ...

DEVELOPMENT

What Are the Steps to Calculate Shot Weight in Injection Molding?

Calculating shot weight in injection molding is essential for optimizing material use and product quality. This guide outlines the steps to determine shot weight using theoretical methods—calculating part volume with geometric formulas—and practical approaches like machine metering systems or weighing ...

MANUFACTURING

How Do Plastic Injection Molding Machines Create Eyeglasses?

This article explores how plastic injection molding machines are used to manufacture eyeglass frames. It details the importance of precise mold design and material selection, highlighting polycarbonate's benefits for durability and style. While frames are efficiently produced through this process, ...

MANUFACTURING

How Does an Injection Molding Machine Create a Keyboard?

This article explores the intricate process of how injection molding machines manufacture keyboards. It details the steps involved in creating keycaps and bases using materials like ABS and polycarbonate. From designing molds to selecting appropriate materials, melting plastics, and assembling ...

MANUFACTURING

How Can You Produce an Egg Tray Using an Injection Molding Machine?

Discover the fascinating process of producing egg trays with injection molding. This article delves into essential aspects such as mold design, including cavity shape and ejection systems, material selection between polystyrene and polypropylene, and the detailed steps of the injection ...

MANUFACTURING

How Do Injection Molding Machines Manufacture Rulers?

The process of manufacturing rulers through injection molding involves several intricate steps. It begins with designing a custom mold that shapes the ruler and engraves precise measurements. The right thermoplastic material, such as Acrylonitrile Butadiene Styrene (ABS) or Polypropylene (PP), ...

MANUFACTURING

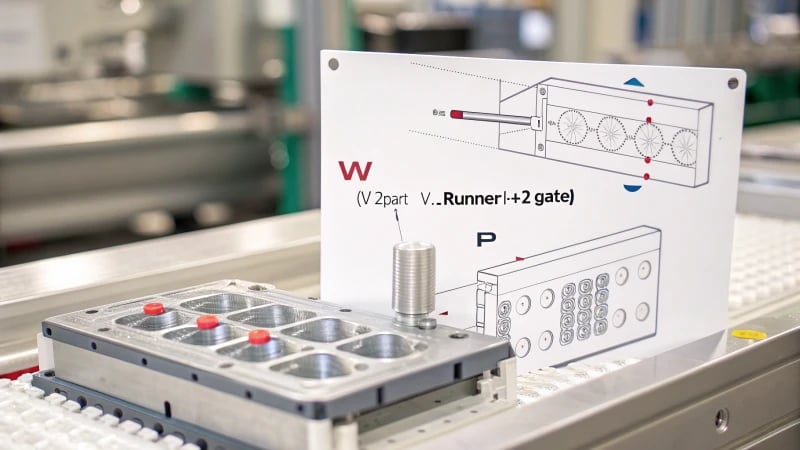

How Does the Cavity Function in Injection Molding?

This article explores the critical role of cavities in injection molding, detailing how they shape products and affect quality. It covers single-cavity versus multi-cavity molds, their applications, and the importance of temperature control and surface finishes. Understanding these elements helps ...

DEVELOPMENT

How Do Injection Molding Machines Produce Bottle Caps?

The process of producing bottle caps using injection molding involves designing precise molds, selecting suitable materials like polypropylene, and employing an injection machine to shape the caps. Quality control is crucial to ensure each cap meets industry standards. After molding, ...

MANUFACTURING

How Do Injection Molding Machines Create Plastic Flowers?

This article explores how injection molding machines bring plastic flowers to life. It delves into the importance of mold design, material selection, and the operational process involved in creating these lifelike floral components. The piece highlights the significance of choosing ...

MANUFACTURING

When Should You Use Clean Room Injection Molding?

Clean room injection molding is essential in various industries such as medical devices, pharmaceuticals, electronics, and aerospace. This process ensures that products are free from contaminants like dust and bacteria, which can compromise safety and functionality. In medical device manufacturing, ...

Quality Inspection

What Size Injection Molding Machine is Needed for an Air Conditioning Shell?

Selecting the appropriate injection molding machine for air conditioning shells involves evaluating several factors including shell dimensions, structural complexity, material type, and mold cavity count. Machines generally require clamping forces between 650 to 1350 tons. Larger or more complex shells ...

MANUFACTURING

What is the Maximum Wall Thickness Allowed for Injection Molding?

This article explores the optimal wall thickness for injection molding, emphasizing that while the general guideline is 3-4 mm for most thermoplastics, certain materials and designs may allow for thicker walls up to 6-8 mm. Factors such as flow characteristics, ...

DEVELOPMENT

How Efficiently Can Injection Molding Machines Produce Toolboxes?

Injection molding is a powerful method for producing toolboxes quickly and efficiently. This process offers remarkable design flexibility, allowing intricate shapes and features to be created. Materials such as high-density polyethylene (HDPE) and polypropylene (PP) ensure durability while maintaining lightweight ...

Uncategorized

How Much Capacity Does a Plastic Injection Molding Machine Have?

This article explores the essential factors determining the capacity of plastic injection molding machines: clamping force, shot volume, and production rate. Clamping force is vital for maintaining mold integrity during injection; small machines typically exert 5-10 tons while large industrial ...

MANUFACTURING

How Does the Injection Mold Guide System Work?

The injection mold guide system is essential for achieving precision in manufacturing. It consists of guide pillars and bushings that ensure accurate mold closure and distribute clamping forces evenly. This prevents wear and tear on molds, enhancing their longevity and ...

Uncategorized

How Can Injection Molded Parts Be Recycled Effectively?

Recycling injection molded parts is essential for sustainability. The process begins with sorting materials using techniques like visual inspection and infrared spectroscopy. Cleaning removes contaminants before reprocessing through mechanical or chemical methods. Mechanical recycling melts plastics into new products, while ...

DEVELOPMENT

How Can an Injection Molding Machine Produce Plastic Spoons?

This article explores the fascinating process of producing plastic spoons using injection molding machines. It details how these machines melt plastic pellets and inject molten plastic into spoon-shaped molds under high pressure. The method ensures high precision and efficiency while ...

MANUFACTURING

How Do You Determine the Capacity of a Plastic Injection Molding Machine?

Understanding the capacity of plastic injection molding machines involves three key factors: clamping force, shot volume, and production rate. Clamping force, measured in tons, ensures molds remain closed during injection to prevent defects. Shot volume indicates the maximum amount of ...

MANUFACTURING

Can One Injection Molding Machine Fit Any Mold?

This article explores why one injection molding machine cannot fit every mold. It discusses critical factors such as clamping force, injection capacity, mold size, and pressure requirements that influence compatibility. Understanding these elements is crucial for product designers to avoid ...

MANUFACTURING

What Are the Most Common Surface Finishing Techniques for Injection Molded Parts?

This article delves into the most common surface finishing techniques for injection molded parts, such as painting, electroplating, hot stamping, silk screening, pad printing, laser engraving, frosting, and polishing. Each method is designed to enhance both the appearance and performance ...

MANUFACTURING

What Impact Will Global Market Trends Have on the Injection Molding Industry?

The injection molding industry is undergoing significant transformation due to global market trends. Increasing demand for lightweight components in the automotive sector, personalized designs in home appliances, and sustainable practices are reshaping manufacturing processes. The rise of electric vehicles necessitates ...

DEVELOPMENT

How Does the Injection Rate Affect Injection Molding Efficiency?

Understanding the injection rate is crucial in injection molding as it directly impacts part quality, surface finish, and overall efficiency. A well-calibrated injection rate ensures complete mold filling while minimizing defects such as air entrapment or short shots. Factors influencing ...

MANUFACTURING

What Challenges Do Startups Face in Injection Molding?

Startups entering the injection molding industry encounter significant hurdles, including exorbitant equipment and mold costs, difficulties in attracting skilled talent, and intense market competition. These challenges necessitate careful strategic planning and effective resource management to ensure growth and sustainability. Funding ...

MANUFACTURING

How Can You Texture Injection Molded Surfaces Effectively?

This article delves into various methods for effectively texturing injection molded surfaces. Techniques such as Electrical Discharge Machining (EDM), chemical etching, laser texture processing, and mechanical engraving are explored. Each method offers unique benefits tailored to specific design needs and ...

MANUFACTURING

How Can You Ensure Quality Consistency from Suppliers in Injection Molding?

This article explores strategies for ensuring quality consistency from suppliers in injection molding. It emphasizes the importance of thorough supplier evaluations, clear contract agreements detailing quality standards, vigilant production oversight, and ongoing quality improvement measures. By implementing a structured approach ...

Quality Inspection

What Are the Key Standards for Injection Molded Electronic Casings?

This article explores the essential standards for designing injection molded electronic casings. It covers critical aspects such as dimension and tolerance controls, material performance requirements, appearance quality considerations, functionality standards like electromagnetic compatibility (EMC), waterproofing ratings, and rigorous quality inspection ...

Quality Inspection