Have you ever wondered how some manufacturers consistently produce high-quality products without a hitch?

Injection mold coatings enhance manufacturing by improving wear and corrosion resistance, optimizing the molding process, and increasing mold surface hardness. These benefits lead to reduced maintenance costs, improved production efficiency, and higher quality plastic products.

While the initial benefits of injection mold coatings are clear, there’s much more to explore about how these coatings can transform manufacturing processes. Delve deeper into each advantage to understand their full impact on your operations.

Injection mold coatings enhance wear resistance.True

Coatings reduce friction and extend mold life, improving efficiency.

How Do Injection Mold Coatings Improve Production Efficiency?

In the fast-paced world of manufacturing, maximizing efficiency is paramount. Injection mold coatings provide a strategic advantage in this realm.

Injection mold coatings improve production efficiency by reducing wear and corrosion, enhancing demoulding, and optimizing the molding process. These enhancements minimize downtime, lower maintenance costs, and ensure consistent product quality, ultimately boosting overall production output.

Improved Wear Resistance

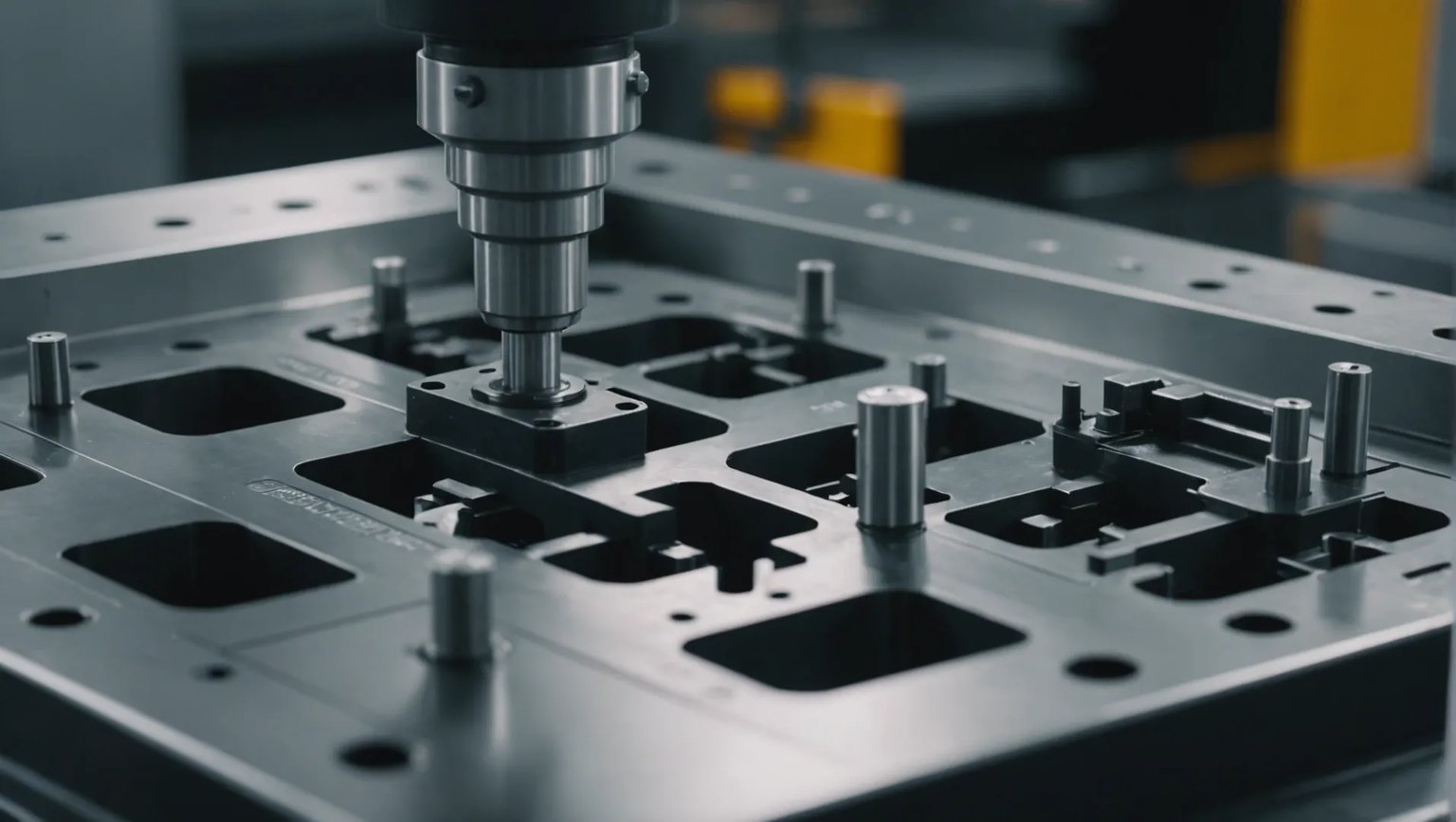

The integration of injection mold coatings1 significantly enhances the wear resistance of molds. This resistance is crucial when working with abrasive materials like glass fiber-reinforced plastics. By reducing friction within the mold cavity and core during injection, coatings extend the service life of molds. This means less frequent maintenance and replacements, leading to reduced downtime and increased productivity.

Enhanced Corrosion Resistance

When molding materials containing corrosive elements such as chlorine or fluorine, the protective layer provided by coatings prevents deterioration of the mold substrate. This protection is especially beneficial in humid environments or where molds are exposed to corrosive media for extended periods. By maintaining mold integrity, coatings ensure consistent precision and surface quality.

Improved Demoulding Performance

The smooth surface and non-stick properties of certain coatings facilitate easier demoulding of plastic products. By reducing resistance and friction during this stage, these coatings prevent defects like tearing or deformation. In some cases, they can eliminate the need for mold release agents entirely, enhancing production efficiency and reducing potential contamination.

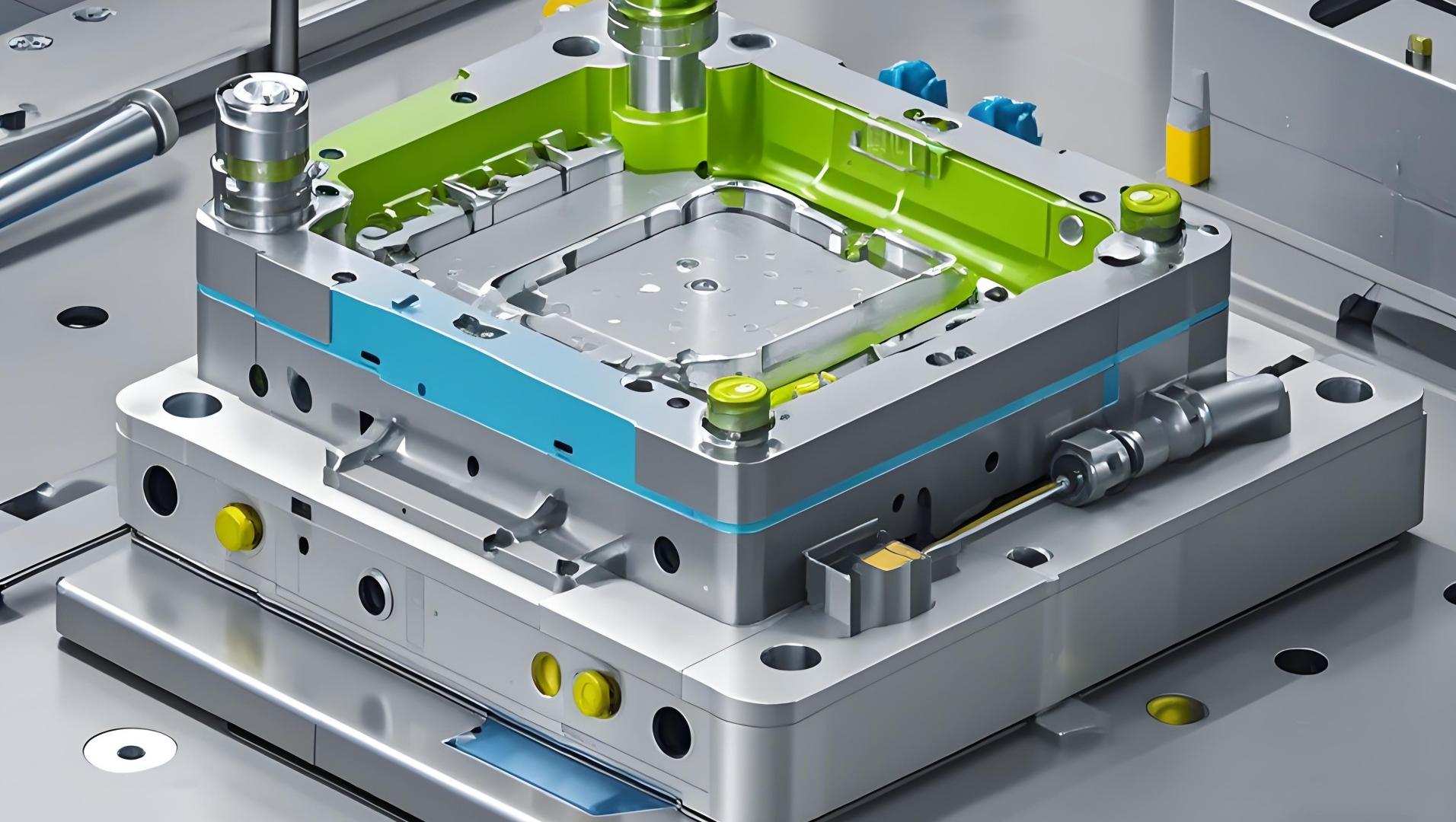

Optimized Injection Molding Process

Coatings play a pivotal role in optimizing the flow time of materials, ensuring complete filling of the mold cavity. This optimization reduces defects due to insufficient filling and improves the surface quality of finished products. Consequently, the production line sees fewer defective items, increasing overall output.

Easy Maintenance and Cleaning

Molds with coatings exhibit smooth surfaces that resist dust and oil buildup. This feature simplifies cleaning procedures and extends cleaning cycles. By reducing cleaning time and effort, manufacturers can maintain continuous production without unnecessary interruptions.

Dimensional Stability and Environmental Considerations

Coatings maintain the dimensional stability of molds, ensuring precision in both the molding process and product assembly. Moreover, many coating technologies align with modern environmental standards by minimizing energy consumption and avoiding harmful substances, fostering sustainable manufacturing practices.

Injection mold coatings reduce maintenance costs.True

Coatings enhance wear and corrosion resistance, lowering maintenance.

Coatings increase mold replacement frequency.False

Coatings extend mold life, reducing the need for replacements.

What Role Does Corrosion Resistance Play in Mold Longevity?

Corrosion resistance is crucial for the longevity of molds used in manufacturing, protecting them from chemical damage and extending their lifespan.

Corrosion resistance prevents chemical degradation in molds, ensuring prolonged durability and precision. This protection reduces maintenance needs and enhances operational efficiency.

Understanding Corrosion Resistance in Molds

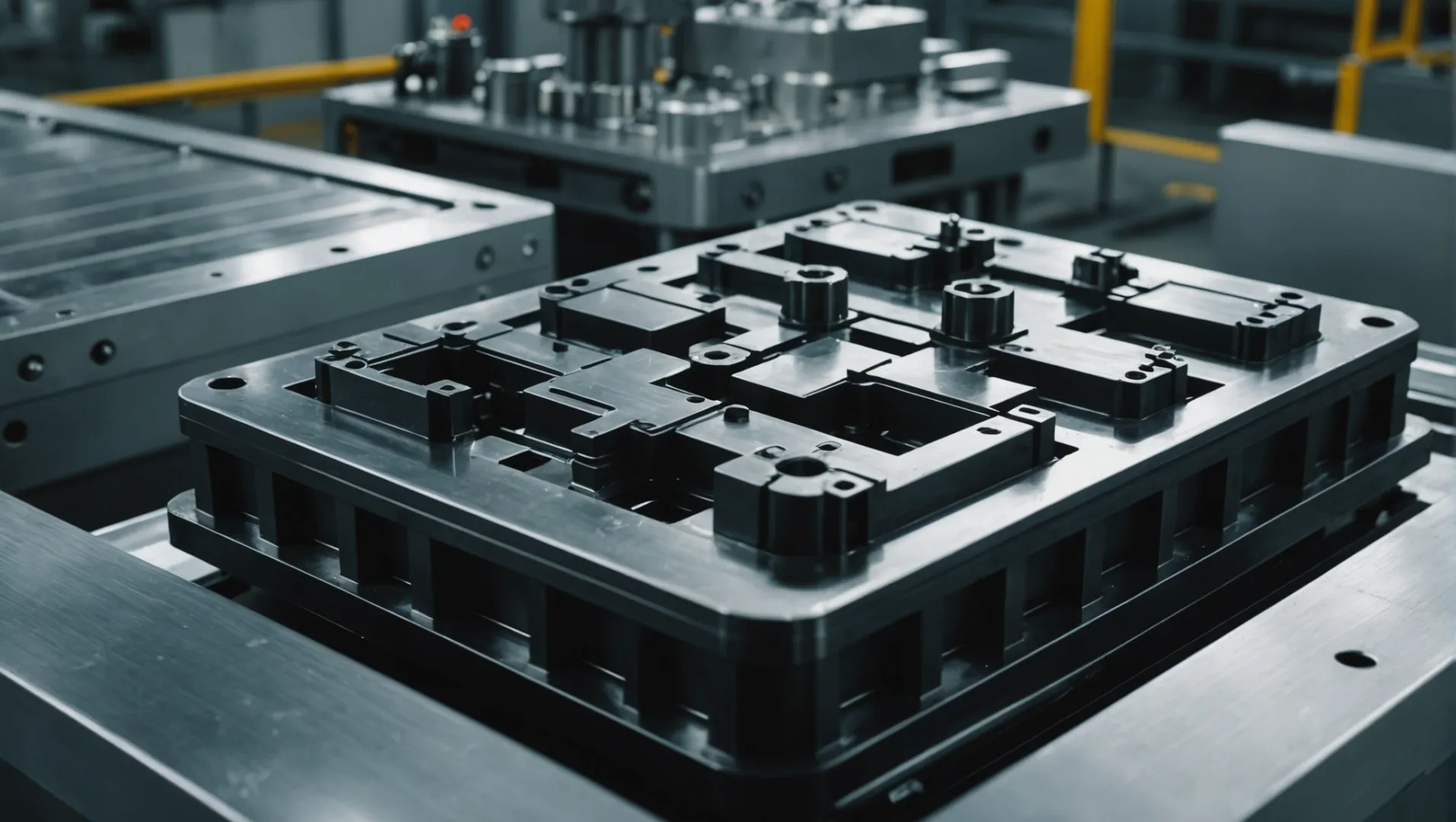

Corrosion is a major concern in manufacturing environments where molds are subjected to harsh chemicals and extreme conditions. Corrosion resistance refers to the ability of a material or coating to withstand these conditions without degrading. In the context of injection molding, corrosion-resistant coatings are applied to protect molds from corrosive substances found in certain plastics and external environments.

How Corrosion Affects Mold Longevity

Corrosive agents can lead to the deterioration of mold surfaces, compromising their structural integrity and precision. This not only shortens the lifespan of molds but also affects the quality of the molded products. Over time, corrosion can lead to pitting, rusting, and other forms of damage that require costly repairs or replacements.

Benefits of Corrosion-Resistant Coatings

-

Preservation of Mold Precision: Coatings help maintain the mold’s dimensions and surface quality by preventing chemical reactions that lead to corrosion. This is crucial for industries that require high precision and surface finish.

-

Reduction in Maintenance Costs: By protecting molds from corrosion, these coatings minimize the frequency of maintenance checks and repairs. This reduces downtime and operational costs significantly.

-

Enhanced Durability: Molds treated with corrosion-resistant coatings can withstand aggressive environments for longer periods, increasing their service life and providing a higher return on investment.

Real-World Applications

In sectors like automotive and electronics, where plastic components must meet strict standards, maintaining mold integrity is vital. Enhanced mold durability2 ensures consistent quality in mass production.

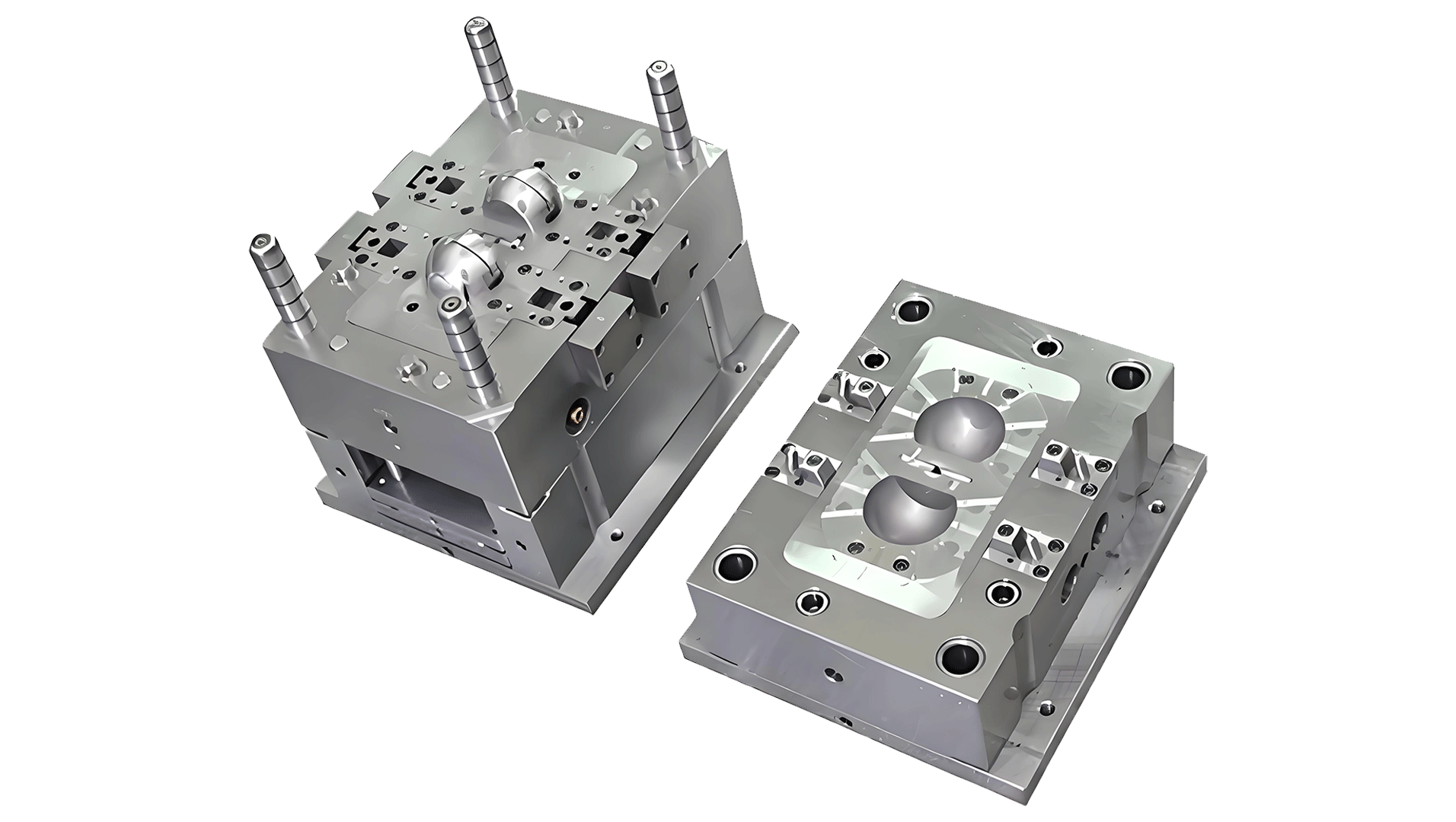

Coating Materials and Their Effectiveness

Different coatings offer varying levels of protection. Common materials used include nitrides, carbides, and certain polymers known for their robust protective qualities. Selecting the right coating depends on the specific environmental challenges a mold will face.

Choosing the Right Coating

Selecting a suitable coating requires understanding the specific chemicals involved in the molding process. For instance, molds used with PVC or other chlorine-containing plastics benefit greatly from specialized coatings that resist such aggressive agents.

By investing in corrosion-resistant coatings, manufacturers can ensure their molds remain efficient and durable, ultimately leading to more reliable production processes.

Corrosion resistance extends mold lifespan.True

Corrosion resistance prevents chemical damage, extending mold life.

Molds without coatings require less maintenance.False

Uncoated molds are more prone to corrosion, needing frequent repairs.

Can Mold Coatings Reduce Maintenance and Downtime Costs?

Mold coatings promise not only to extend the life of molds but also to significantly cut down on maintenance expenses and downtime.

Mold coatings minimize wear and corrosion, enhancing durability and reducing frequent maintenance. By improving demolding and surface hardness, they lower downtime costs, offering manufacturers a cost-effective solution to maintain efficient operations.

Understanding Wear Resistance Benefits

The primary advantage of mold coatings is improved wear resistance3. During injection molding, the constant friction between the plastic and the mold components can lead to significant wear. By applying specialized coatings, manufacturers can effectively mitigate this wear, extending the service life of molds. For instance, when dealing with materials that have high wear characteristics like glass fiber, coatings protect the mold from premature failure.

This extended lifespan directly correlates with reduced maintenance needs. Less frequent maintenance means reduced downtime, allowing for more continuous production schedules and minimizing interruptions that could affect supply chains.

Corrosion Resistance for Longevity

In environments where corrosive materials are used or when molds are exposed to humid conditions, corrosion can be a major issue. Mold coatings enhance corrosion resistance4, preventing corrosive substances from degrading the mold’s integrity. This not only maintains the mold’s precision and surface quality but also prevents costly repairs or replacements.

Demolding Efficiency

Demolding is a critical step in the injection molding process. Coatings improve demolding performance by reducing resistance and friction during the process. This efficiency minimizes defects like tearing or deformation, which can occur if a product sticks to the mold. Some advanced coatings even eliminate the need for mold release agents entirely, saving additional costs and reducing potential contamination.

Surface Hardness and Its Role in Maintenance

Increasing the surface hardness of molds through coatings allows them to withstand higher pressures and impacts without surface damage. This toughness ensures that molds remain in optimal condition longer, further reducing the frequency of maintenance. For products requiring high precision, maintaining mold surface integrity is crucial for ensuring consistent dimensional accuracy.

Cost-Benefit Analysis

A thorough cost-benefit analysis often reveals that while the initial investment in mold coatings may seem substantial, the long-term savings in maintenance and downtime are significant. By investing in these coatings, manufacturers not only enhance their production capabilities but also ensure a more reliable operation that can meet market demands efficiently.

Mold coatings reduce mold maintenance frequency.True

Coatings enhance wear and corrosion resistance, lowering maintenance needs.

Mold coatings increase downtime in production.False

They reduce downtime by improving demolding efficiency and durability.

Why Are Environmentally Friendly Coatings Important in Manufacturing?

In today’s manufacturing landscape, sustainability isn’t just a buzzword—it’s a necessity. But why are environmentally friendly coatings becoming pivotal in this sector?

Environmentally friendly coatings reduce harmful emissions, minimize waste, and enhance energy efficiency in manufacturing processes. These coatings help companies meet regulatory standards and appeal to eco-conscious consumers, ultimately improving brand reputation and sustainability.

The Role of Sustainable Coatings in Reducing Emissions

One of the primary reasons environmentally friendly coatings are critical is their ability to significantly reduce harmful emissions. Traditional coatings often contain volatile organic compounds (VOCs) that can contribute to air pollution and pose health risks. Eco-friendly coatings are designed to minimize or eliminate these compounds, leading to cleaner air and safer working environments.

For instance, water-based coatings offer a viable alternative by using water as a solvent instead of organic chemicals, drastically reducing VOC emissions.

Minimizing Waste Through Efficient Application

Eco-friendly coatings are engineered for efficiency, often requiring fewer layers to achieve desired properties like wear resistance or corrosion protection. This reduction in material usage not only cuts down on waste but also conserves resources, leading to a more sustainable production cycle.

By incorporating technologies such as nanocoatings5, manufacturers can achieve enhanced durability with minimal material usage. This efficiency translates into less frequent need for reapplication, further minimizing waste.

Enhancing Energy Efficiency

The production and application of traditional coatings can be energy-intensive. Environmentally friendly alternatives often require lower curing temperatures and shorter curing times, which helps manufacturers reduce their energy consumption. This not only decreases operational costs but also aligns with global efforts to reduce carbon footprints.

Meeting Regulatory Standards

As governments worldwide impose stricter environmental regulations, the adoption of sustainable coatings becomes essential for compliance. Non-compliance can lead to hefty fines and damage to a company’s reputation. By utilizing environmentally friendly coatings, businesses can stay ahead of regulatory changes and avoid potential legal issues.

Aligning with Consumer Expectations

Modern consumers are increasingly aware of the environmental impact of the products they purchase. They prefer brands that demonstrate a commitment to sustainability. By investing in eco-friendly coatings, companies can enhance their brand image and appeal to this growing market segment.

In conclusion, the shift towards environmentally friendly coatings is more than just a trend; it’s a strategic move that benefits the environment, enhances production efficiency, and improves a company’s market position.

Eco-friendly coatings reduce VOC emissions in manufacturing.True

Eco-friendly coatings use less harmful solvents, reducing VOC emissions.

Traditional coatings require fewer layers than eco-friendly ones.False

Eco-friendly coatings often need fewer layers due to their efficiency.

Conclusion

Injection mold coatings are transformative, offering durability, efficiency, and cost savings. Embrace these technologies to enhance production and reduce environmental impact.

-

Explore comprehensive benefits of mold coatings on manufacturing efficiency.: For more complex parts that need wear and corrosion protection, NiHard nickel-cobalt plating saves the cost of an anode (required for hard … ↩

-

Learn how enhanced mold durability impacts production quality and efficiency.: Factors that affect plastic mold durability include environment, materials, maintenance, molding conditions, and structure design. Injection … ↩

-

Learn how wear-resistant coatings prolong mold life effectively.: Excellent lubricity, high wear and corrosion resistance, higher heat resistance than PTFE-based coatings, uniform deposit, easily strippable, … ↩

-

Discover the protective benefits against corrosion from mold coatings.: Excellent lubricity, high wear and corrosion resistance, higher heat resistance than PTFE-based coatings, uniform deposit, easily strippable, … ↩

-

Nanocoatings improve durability with minimal material usage, reducing waste.: Nanocoatings have been developed with antibacterial, anti-corrosion, abrasion resistant, and weather resistant properties. ↩