Selecting the correct mold surface treatment might seem like finding the ideal shoes. The task needs the right match. The fit must suit the purpose.

When I select a mold surface treatment, I think about how resistant it is to wear and rust. Demolding must be easy. The look of the mold also matters. These factors are really important. They help the mold last longer. Functioning well in various situations is vital.

I remember when I had to choose a surface treatment for a mold for the first time. It felt like entering a maze without a guide. Balancing material properties, costs and specific needs feels overwhelming. But I learned that each factor, like steel type or mold complexity, is very important. Each piece is crucial. Understanding how treatments affect production or why precision matters is key. It’s not just about getting things to work. It’s about really optimizing each part for my needs.

Titanium plating enhances mold wear resistance.True

Titanium plating forms a hard layer that resists abrasion from fillers.

Nitriding is ideal for quick production tasks.False

Nitriding takes several hours, making it unsuitable for urgent tasks.

How Do Material Properties Influence Mold Surface Treatments?

Did you ever think about how the correct surface finish might affect a mold’s performance? Learn about different materials and see how they influence the future of injection molding.

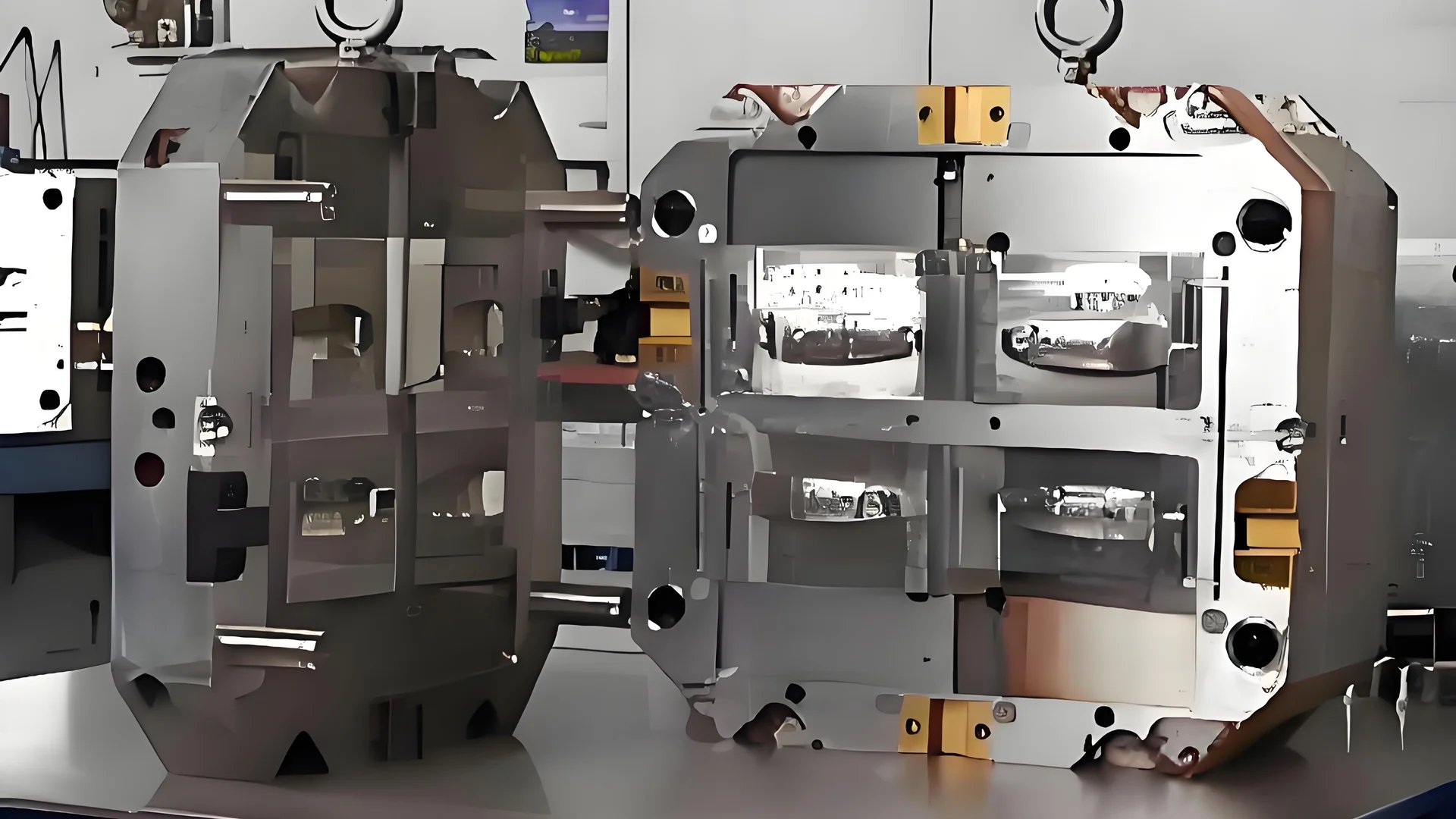

The type of steel and its hardness are very important in treatments for mold surfaces. They affect wear resistance, corrosion resistance and how easy it is to remove molded parts. Mold durability really depends on choosing the right surface treatment. Efficiency improves when treatments match steel properties properly.

Influence of Steel Type on Surface Treatments

The type of steel used in mold manufacturing has a significant impact on how effective a surface treatment will be. High alloy steels, for instance, contain more alloy elements which can form superior nitriding layers, enhancing both wear and corrosion resistance. In contrast, ordinary carbon steel may benefit more from treatments like chrome plating1 to increase surface durability affordably.

Role of Steel Hardness in Treatment Selection

Steel hardness is another critical factor in determining suitable mold treatments. Higher hardness steels often require more refined processes, such as mirror polishing with fine abrasive pastes, to avoid scratches. For steels with a hardness exceeding HRC50, specialized equipment is necessary to achieve desired finishes without damaging the surface. Conversely, softer steels require careful parameter control during processes like sandblasting2 to prevent altering the mold’s shape.

Wear Resistance and Material Properties

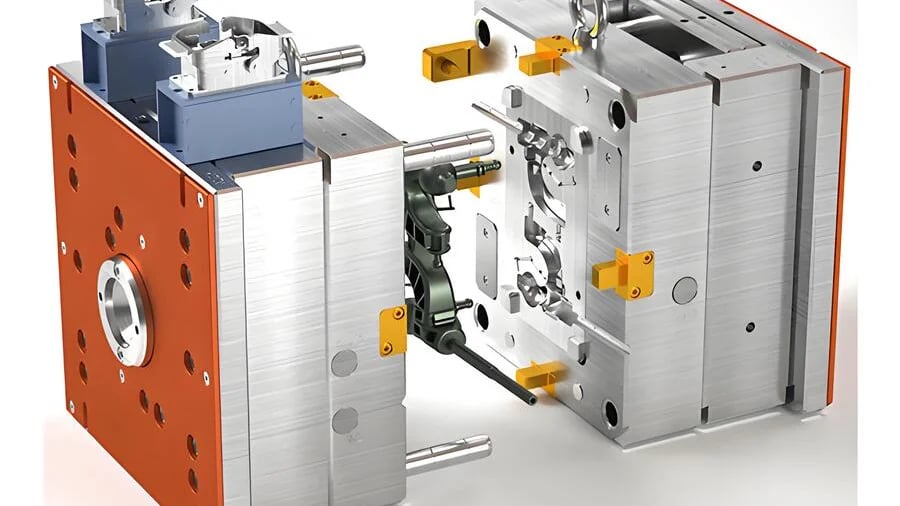

For molds used in producing high-hardness, high-filler materials like glass fiber-reinforced plastics, selecting a high wear resistance treatment is crucial. Techniques such as titanium plating (PVD) form hard, wear-resistant layers that protect the mold surface from abrasive fillers. For standard plastics, treatments like chemical nickel plating3 balance cost with performance.

Corrosion Resistance Needs

Molds used with corrosive plastics like PVC necessitate treatments that offer strong corrosion resistance. Electroless nickel plating forms a protective layer against corrosion while chrome plating provides high chemical stability. In humid environments, nitriding adds extra protection against corrosive damage.

Improving Mold Release Performance

Complex shaped products often demand molds with excellent demolding capabilities. Polishing can improve the finish, aiding in easier product release. Titanium-plated surfaces also have lower friction coefficients, enhancing demolding for intricate designs such as thin-walled electronics product shells4. This ensures precision while maintaining high productivity.

Titanium plating enhances mold wear resistance.True

Titanium plating forms a hard layer, resisting abrasion from fillers.

Chrome plating is ineffective for corrosive plastics.False

Chrome plating prevents erosion by providing high chemical stability.

How Do Different Surface Treatments Impact Costs?

Many have struggled when deciding on surface treatments for molds. Costs and performance pull in different directions. Every manufacturer deals with this tricky balance.

The price of surface treatments for molds varies. Material type influences this cost. Process complexity matters too. Large-scale production changes prices. Basic polishing is usually cheap. Titanium plating costs more. Choosing the right treatment is crucial. It must suit mold needs. Material characteristics must be considered. Budgets must not be ignored.

Understanding the Variables

Have you ever been in a store, looking at many paint cans, unsure which one to pick for your living room? Choosing treatments for molds feels similar. Each option promises better performance but comes with different prices. Titanium plating5 is like a premium finish for tough materials. It is expensive. But, polishing or nickel plating is like a simple, good-quality matte finish that works well and costs less.

Material Considerations

The right treatment depends on the mold’s material. Think about buying clothes – high-alloy steels are like fancy suits. They look better with special processes like nitriding and last longer. Regular carbon steels are like everyday blazers – chrome or nickel plating adds a nice shine.

For steel hardness, it is like choosing shoes for a long walk. Harder steels need better tools and more time. Proper tools are necessary, like choosing comfortable shoes for a long day instead of trendy ones.

Production Costs vs. Performance

It’s a common question: buy an expensive luxury car for its durability or choose something cheaper? High-value projects might need the cost of treatments like titanium plating. This choice increases performance and lifespan. But simpler items might only need polishing, which is cheaper and faster—quick methods are like using the fast checkout line to save time.

Complexity and Precision Needs

Decorating a cake with fancy designs needs special care. Complex mold shapes require specific techniques. Chemical etching or electroless nickel plating cover intricate surfaces well, just like a skilled baker decorating a cake. Simpler molds might only need polishing, similar to spreading butter on toast.

Precision is crucial for detailed molds—it’s like a jeweler making fine details; advanced polishing is necessary for high quality (costly6). However, these methods increase costs and time.

Choosing a surface treatment is about balancing material type, complexity, precision, and budget. Each decision changes initial costs and future benefits—it’s much like choosing between fast food or making a meal at home.

Titanium plating is costlier than polishing treatment.True

Titanium plating involves higher costs for equipment and materials.

Nitriding is the quickest surface treatment process.False

Nitriding can take several hours, longer than sandblasting or polishing.

How Does Mold Complexity Affect Surface Treatment Choice?

I remember when I tried to find the best surface for my mold. Mold complexity is not just a big word. It plays a key part in picking the right surface treatment. Mold complexity truly matters.

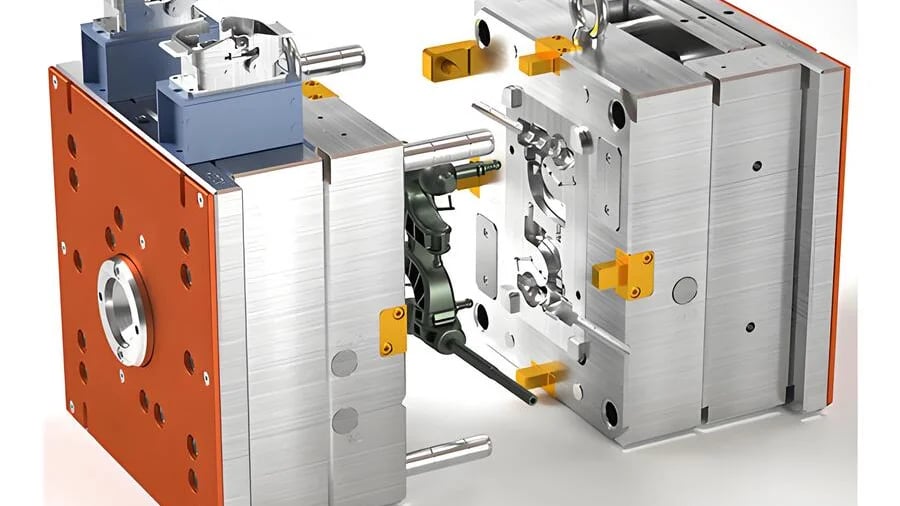

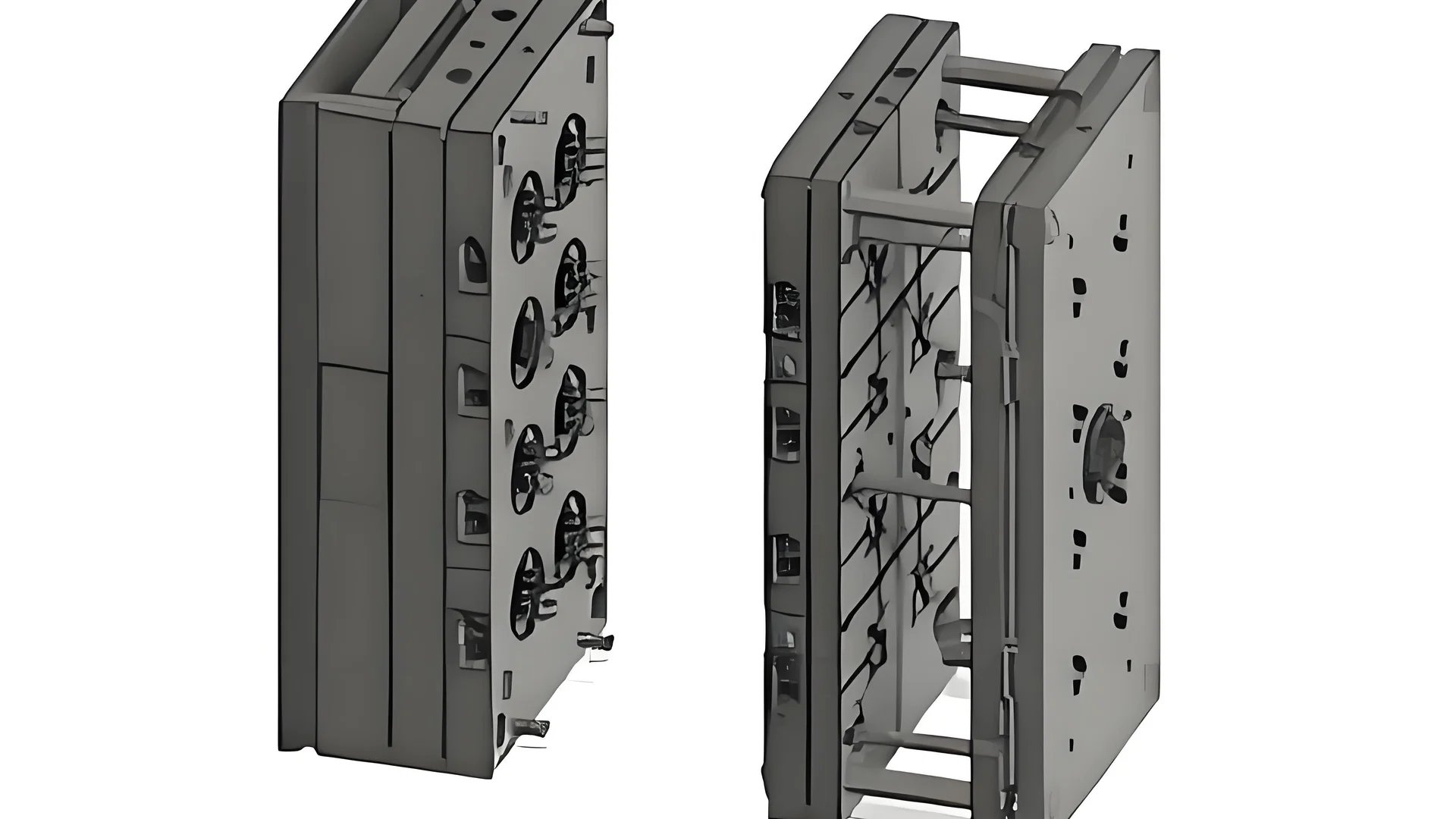

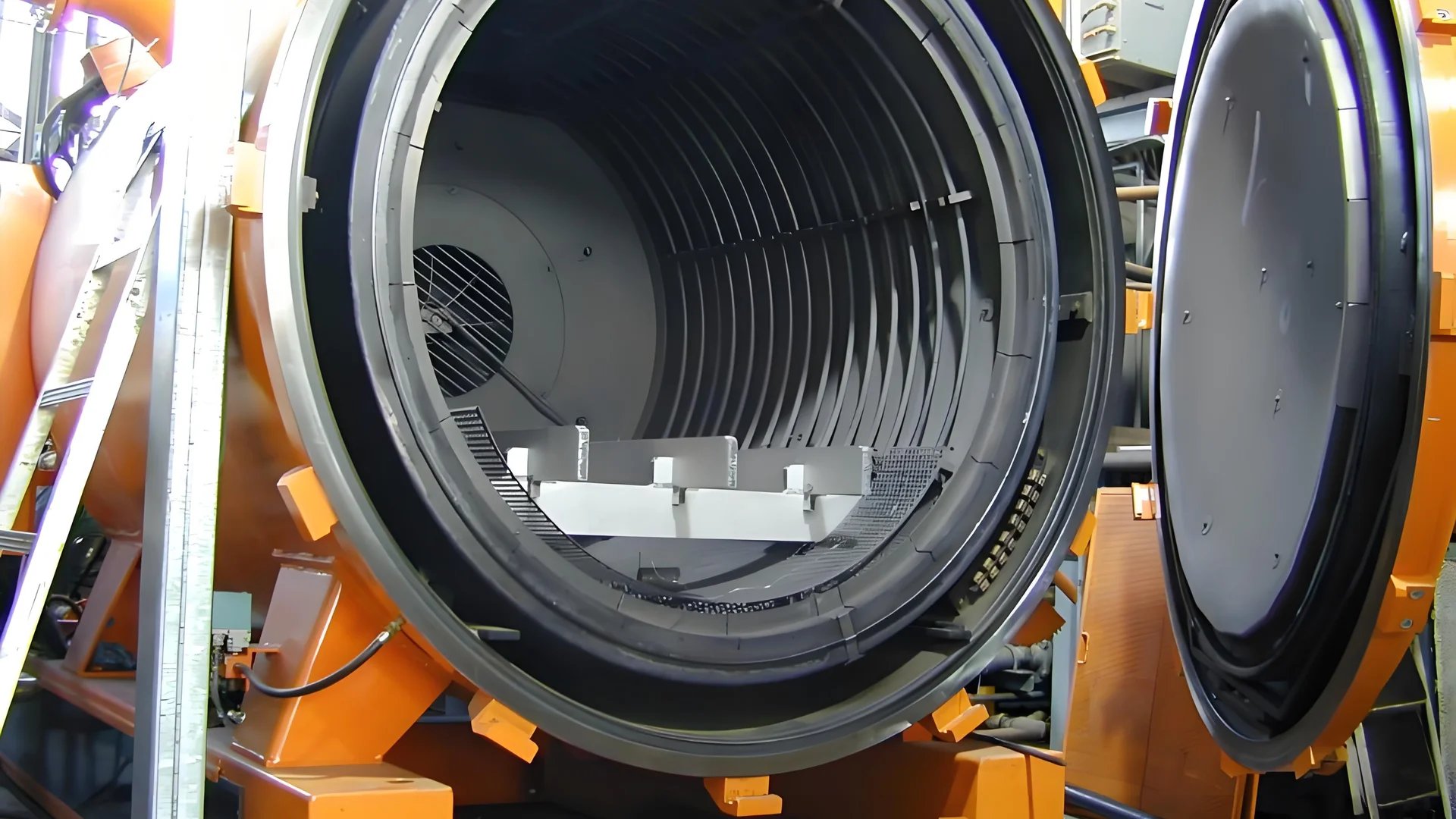

Mold complexity influences surface treatment options. It determines if properties like wear resistance, corrosion protection, easy demolding and good looks are necessary. Very complex molds might require chemical etching or nickel plating. Simpler molds often receive polishing or sandblasting. This is more affordable.

Impact of Mold Complexity on Surface Treatment

When I first explored mold creation, the mold’s details surprised me. Molds are more than metal blocks; they are like puzzles with unique challenges. Complex shapes with deep cavities need special surface treatment7. Very specific. For a mold that faced heavy wear, titanium plating (PVD) helped greatly. This treatment formed a very strong layer. It handled tasks involving high-filler materials like glass fiber reinforced plastics.

Corrosion resistance matters too. I worked on molds for humid places with PVC, a tough task. Chemical nickel plating or chrome plating provided strong corrosion resistance. They avoided mold damage over time. Another choice, nitriding, protected especially in wet, tough conditions.

Consideration of Mold Material Properties

Selecting the right mold material is like picking the perfect outfit—it’s hard! High alloy steels are top choices; they work well with nitriding, resisting wear and corrosion. Carbon steels, simpler, match with chromium or chemical nickel plating. Steel hardness is critical. Once, a mirror polish on hard steel needed very fine tools for scratch-free results.

Production Costs and Productivity

Money and time matter a lot. Cost influences surface treatment selection. Titanium or chrome plating costs more but improves performance significantly for valuable projects. Lesser-critical projects consider cheaper treatments like chemical nickel plating—it saves money. Treatment speed affects productivity too; some treatments like nitriding take too long while sandblasting finishes fast—deadlines appreciate this speed!

Precision and Treatment Uniformity

Complex mold designs need even treatment everywhere. Techniques like chemical etching or electroless nickel plating excel here—they coat complex shapes uniformly. Simpler molds succeed with basic processes like polishing and sandblasting.

High-precision molds are a different challenge altogether—I remember stressing over a mold for optical lenses where precision was a must! High-precision polishing tools achieved the exact standards required—no errors allowed! Employing advanced grinding tools8 and inspection equipment became essential for flawless results.

Titanium plating improves mold wear resistance.True

Titanium plating forms a hard layer, enhancing wear resistance for molds.

Chemical nickel plating is ideal for humid environments.True

Nickel-phosphorus alloy layer in chemical nickel plating resists corrosion.

Why is precision important in surface treatment processes?

Have you ever wondered why precise surface treatment details are very important? The distinction resembles a recipe that succeeds and one that shines like a masterpiece.

Precision in surface treatment processes helps components meet specific performance and look requirements. This process is crucial for durability. Functionality greatly improves as well. The appearance of the components may look much better.

Importance of Wear Resistance

Precision plays a pivotal role in selecting surface treatment processes that meet wear resistance requirements9. I recall the moment I realized the need for precise surface treatment during a project with hard materials. The right treatment choice was crucial. Titanium plating on molds resisted the wear from glass fiber reinforced plastics. Simpler molds required chemical nickel plating or nitriding, offering enough durability without excess.

Corrosion Resistance

When dealing with corrosive plastics, precision ensures the right treatment, such as chemical nickel plating, is applied to protect against degradation. This careful selection prevents erosion and extends the mold’s life, especially in humid environments. I saw how choosing chrome plating could really extend a mold’s life due to its high chemical stability.

Enhancing Mold Performance

Precision also impacts mold performance by facilitating demolding in complex shapes. There was another case with complex designs for electronic covers where precise surface treatments helped us. Highly polished surfaces or titanium plating can improve release performance, crucial for intricate designs like thin-walled electronic shells.

Aesthetic Requirements

For products where appearance is key, such as automotive interiors, precision in surface treatment like chrome-plating provides a high gloss finish. Looks often seem unimportant until they do; the shiny chrome finish was stunning and genuinely attractive.

Material Properties Consideration

Different steels react uniquely to surface treatments; precision ensures the correct process is matched with the material type. I experienced this with high alloy steels where nitriding improved their traits nicely. Meanwhile, simpler carbon steel molds benefited from chromium or nickel plating effectively.

Production Costs and Efficiency

Precision in choosing the appropriate surface treatment affects cost and productivity. Cost is often a big factor in decisions; while processes like PVD are expensive, they significantly enhance mold performance and longevity for high-value products. For urgent tasks, faster methods like sandblasting kept timelines without losing quality.

Handling Complex Shapes

Precision is indispensable for molds with intricate designs. Chemical etching or electroless nickel plating provided uniformity for detailed surfaces due to their uniform application capabilities. Traditional polishing was enough for simpler shapes.

Titanium plating improves mold wear resistance.True

Titanium plating creates a hard layer that resists abrasion from fillers.

Polishing is the most expensive surface treatment.False

Polishing is relatively low-cost, mainly due to labor and consumables.

Conclusion

Choosing a mold surface treatment involves considering wear and corrosion resistance, material properties, production costs, complexity, and precision requirements to optimize performance and longevity.

-

Discover how chrome plating enhances mold durability and appearance. ↩

-

Explore effective sandblasting techniques for optimal mold surface preparation. ↩

-

Learn why chemical nickel plating is favored for corrosion resistance. ↩

-

Understand advanced demolding techniques for intricate mold designs. ↩

-

Explore how titanium plating enhances mold durability despite higher costs. ↩

-

Discover the tools needed for precise mirror polishing on hard steels. ↩

-

Explore diverse treatment options for various mold complexities. ↩

-

Discover tools essential for achieving precision in mold surfaces. ↩

-

Learn why wear resistance is vital for product durability. ↩