Do you ever think about how factories create everyday plastic items with such accuracy?

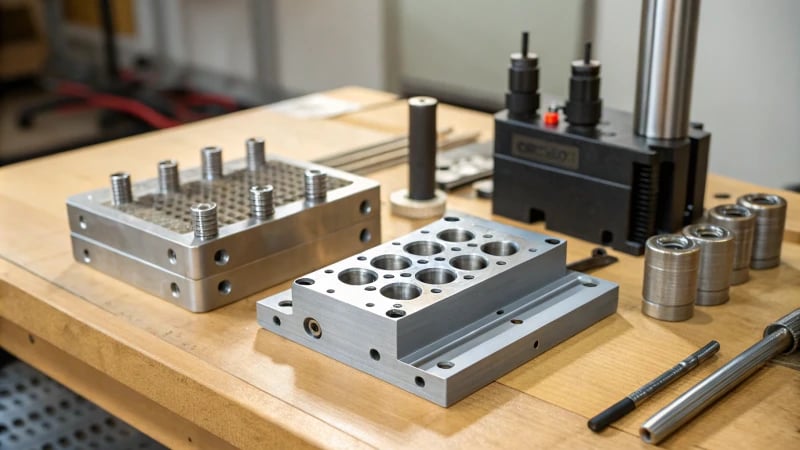

Important standard parts for injection molds include the mold frame, guide parts, ejector parts, gating system parts and cooling system parts. Each part holds a key role in achieving precise molding and smooth production.

I remember my first time exploring injection molding deeply and the complexity really confused me at first. Over time, I discovered that knowing the main parts was crucial. Important parts include the mold frame, guide parts, ejector parts, gating system and cooling system. These are not just pieces of metal. They play key roles in bringing every plastic piece to life. Let’s look closer at how each part works together to achieve perfection.

Mold frames are non-essential in injection molds.False

Mold frames are crucial for holding all components together securely.

Guide parts ensure alignment in injection molds.True

Guide parts are essential for precise alignment during the molding process.

How Do Mold Frames Influence Injection Molding Efficiency?

Mold frames act like the backbone of injection molding. These frames quietly yet vitally increase both precision and efficiency. What role do they secretly play? They guide and chill the process until it’s just right. Interested in how they truly impact efficiency?

Mold frames help injection molding work better. They give strong support and keep things lined up just right with guide parts. They also cool the process properly. The design and materials of these frames matter a lot. They influence how fast cycles run and how good the products are. Efficiency depends significantly on these choices.

Structural Support and Precision

Mold frames, composed of fixed and movable base plates and mold plates, serve as the backbone of injection molding1. They ensure stability, allowing for consistent pressure during the molding process. The choice between large or fine gate mold frames can influence cycle times and product quality.

| Type | Features | Impact on Efficiency |

|---|---|---|

| Large Gate Frame | Handles larger volumes of material | Reduces cycle time, supports heavier molds |

| Fine Gate Frame | Suitable for intricate designs | Increases precision, reduces material waste |

Role of Guide Parts

Guide pins and sleeves are crucial for aligning the mold components. These elements maintain the precision needed to avoid defects and ensure smooth operation. For instance, a positioning ring2 ensures accurate mold installation on machines, directly affecting setup time and alignment accuracy.

- Guide Pin Sizes: Available in diameters such as 16mm, 20mm, ensuring that different mold sizes are accommodated without compromising precision.

- Positioning Ring: Standard diameters (e.g., 100mm, 120mm) align molds accurately, reducing setup errors.

Ejector System Efficiency

The ejector system, including pins and plates, determines how quickly products are removed from molds without damage. A well-designed system minimizes downtime by enabling faster ejection cycles. The choice of ejector pin sizes3 affects how quickly products can be safely released.

Gating System’s Impact

The gating system, including gate sleeves and pulling rods, guides the plastic into the mold cavity efficiently. Proper sizing of these parts can prevent clogs and ensure a consistent flow of material, thereby enhancing cycle efficiency.

- Gate Sleeve Sizes: Inner diameters like 3mm or 4mm determine flow rate and pressure.

- Pulling Rods: Varieties such as Z-shaped rods facilitate easy removal of solidified material.

Cooling System Optimization

Cooling system parts like water pipes and baffles dictate how efficiently heat is removed from the mold. Efficient cooling reduces cycle times significantly by allowing quicker mold release and lessening product warping.

| Cooling Component | Standard Sizes/Models | Effectiveness |

|---|---|---|

| Water Pipe Joint | PT1/8, PT1/4 thread specs | Ensures consistent cooling performance |

| Water Baffle | Custom sizes as per channel | Directs flow for uniform cooling |

Understanding how these components interact offers insights into optimizing injection molding for better production efficiency. By selecting appropriate mold frames and components, manufacturers can significantly enhance their operational capabilities in injection molding processes4.

Large gate frames reduce cycle time in injection molding.True

Large gate frames handle more material, speeding up the process.

Guide pins are irrelevant to mold alignment precision.False

Guide pins ensure precise alignment, preventing defects.

How Do Guide Parts Ensure Mold Alignment?

Have you ever wondered how those tiny guide parts are crucial in keeping injection molding going smoothly?

Guide parts like guide pins and sleeves play an important role in aligning the movable and fixed mold plates accurately. Precise alignment is essential to avoid mistakes, lower defects and achieve excellent product quality during the injection molding procedure. Good alignment is necessary.

A Closer Look at Guide Pins and Sleeves

I remember my first mold design project. Nervous but excited, I delved into the details. I found guide pins and sleeves fascinating. They are truly the foundation of precise alignment of molds. Usually, guide pins stay on the moving mold base plate, while guide sleeves sit on the other side. Together, they keep the mold opening and closing smoothly without sideways movement. They are really important!

Why Specifications Matter

During those early days, I learned how even a small mistake in specifications caused problems later. Guide parts change with the mold frame5 size and the machine used. Common sizes for guide pins include 16mm, 20mm, and 25mm.

| Guide Part | Standard Sizes |

|---|---|

| Guide Pin | 16mm, 20mm, 25mm |

| Guide Sleeve | Corresponding sizes |

The length? It depends on things like the mold frame height. Quick observation reveals varied details.

Positioning Rings: The Unsung Heroes

While fixing an alignment problem, I found out that positioning rings work closely with guide pins and sleeves. They fit perfectly to secure the mold onto the machine. Good precision here leads to better overall alignment and that’s really essential.

Size and Precision

Positioning rings have different outer sizes, such as 100mm and 120mm. Choosing the right size is like picking the perfect shoes – it just feels right! The right choice of positioning ring enhances overall alignment precision6.

Integration with Ejector and Gating Systems

Guide parts connect effortlessly with ejector and gating systems in my experience. Ejector pins operate smoothly without causing alignment issues.

Cooling System Considerations

Cooling system parts like water pipes and baffles are very important as well. Proper cooling system7 design stops warping or misalignment because of thermal expansion. This helps keep everything structurally sound, ensuring guide parts do their job efficiently.

Guide pins prevent lateral movement in molds.True

Guide pins are crucial for preventing lateral movement during mold opening and closing.

Positioning rings are irrelevant to mold alignment.False

Positioning rings are essential for securing molds and ensuring precise alignment with the machine.

Why Are Ejector Parts Crucial for Product Release?

Ejector parts often go unnoticed in injection molding. They help release products smoothly from molds. This job keeps both quality and efficiency high.

Ejector parts like pins and plates are crucial in injection molding. Molded products need smooth release from the mold cavity, so these parts work to avoid damage. High-quality standards must be maintained. This is very important.

The Role of Ejector Parts in Injection Molding

The first time I watched an injection molding machine in action, it was like seeing a mechanical dance. All movements worked together to create something real. At the center of this dance are the ejector parts. They help every product leave its mold easily. These unnoticed but vital parts – ejector pins, push plates, and fixing plates – stop any problems like products getting stuck. Sticking causes defects and damage.

Ejector Pins (Push Rods): These are like gentle hands that push the molded product out. They come in many sizes and shapes, suited to each mold’s needs. Choosing the correct diameter is crucial, from 1mm to 10mm. Selecting the right size is very important.

Push Plates and Fixing Plates: These parts are the force behind the ejection process, pushing products out smoothly. They set everything up just right for perfect operation, like arranging a concert for a flawless performance.

| Component | Function | Standard Sizes |

|---|---|---|

| Ejector Pins | Ejects products | 1mm – 10mm |

| Push Plates | Transmit power | Customizable |

Quality and Precision

Like a clock depends on each tiny part to work well, ejector parts work smoothly with other components like guide parts8 and gating systems. These parts ensure everything lines up right during mold use, avoiding alignment problems.

Every time I observe these parts at work, I admire their strength. They are built to last through many cycles without bending. This strength leads to the reliable creation of high-quality products.

Integration with Mold Design

Choosing the proper mold frame9 is like selecting the right stage for our molding presentation. It must fit all these essential parts perfectly. During the design process, considering product sizes and machine details helps every piece fit just right.

Understanding each part’s role in this complex setup lets designers like Jacky cut down on defects and increase efficiency. This detailed approach helps solve any ejection problems effectively. It really keeps production moving smoothly as ejector parts do their best job.

Ejector pins range from 1mm to 10mm in diameter.True

Standard sizes for ejector pins range from 1mm to 10mm.

Push plates are standardized in size like ejector pins.False

Push plates are customizable based on design needs.

How Does the Gating System Affect Mold Performance?

Some molds perform better than others. The reason is often the gating system. This system plays a crucial role in shaping the quality of the final product.

The gating system plays a crucial role in mold performance. It directs how molten material flows into the mold. Well-crafted gating helps increase fill rates. It also reduces air pockets. Defects become fewer. This method leads to better product quality. Truly superior quality comes from careful design.

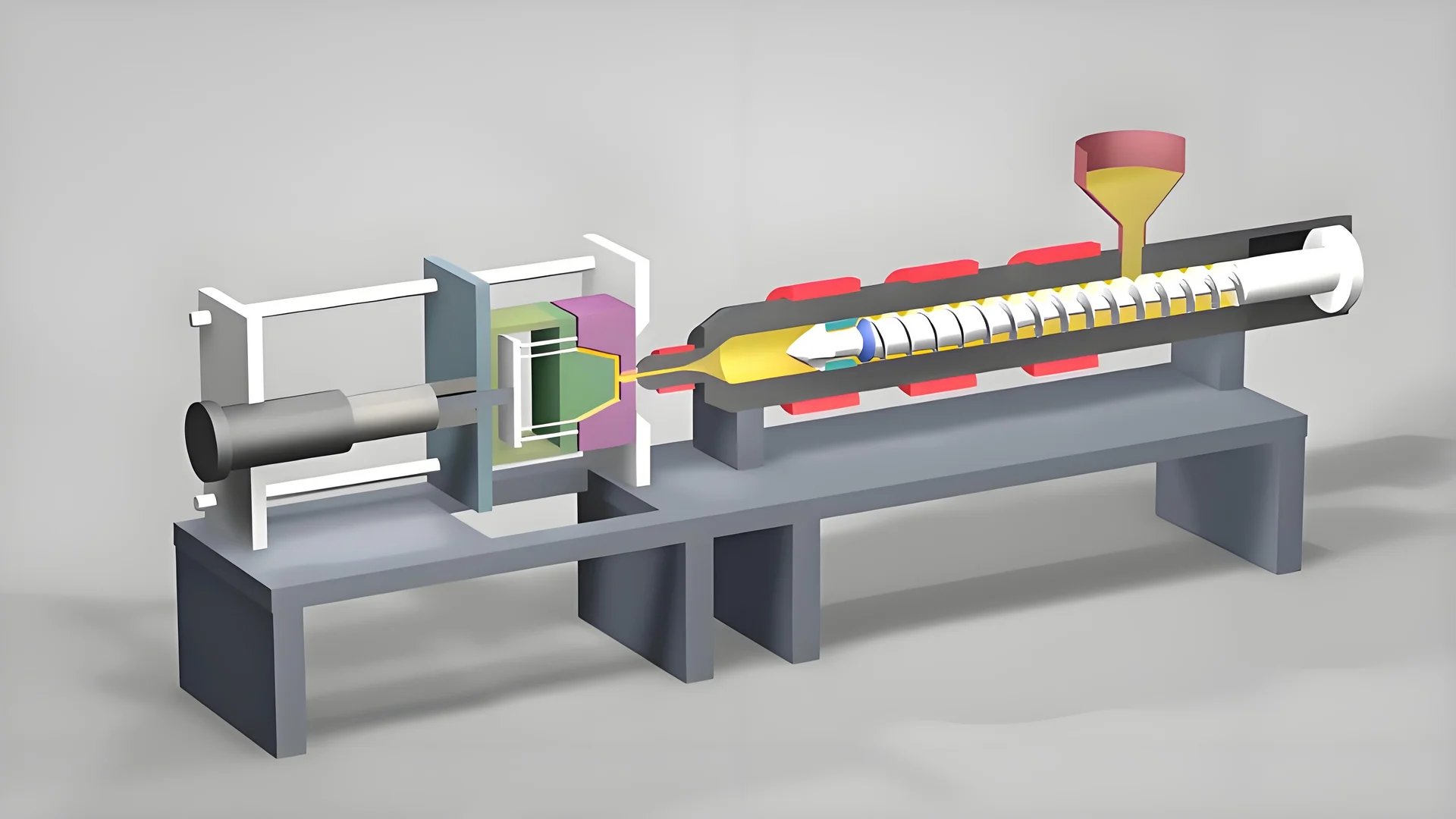

Importance of Gating Systems in Mold Performance

The gating system is crucial in mold design, acting like the heart of molding by directing molten material where it needs to go. Components such as the gate sleeve10 and pulling rods are essential for moving material smoothly from the machine into the mold.

A well-designed gating system can significantly impact a project by reducing turbulence and preventing defects like air bubbles. Depending on the task, various designs are selected based on the product’s shape and material.

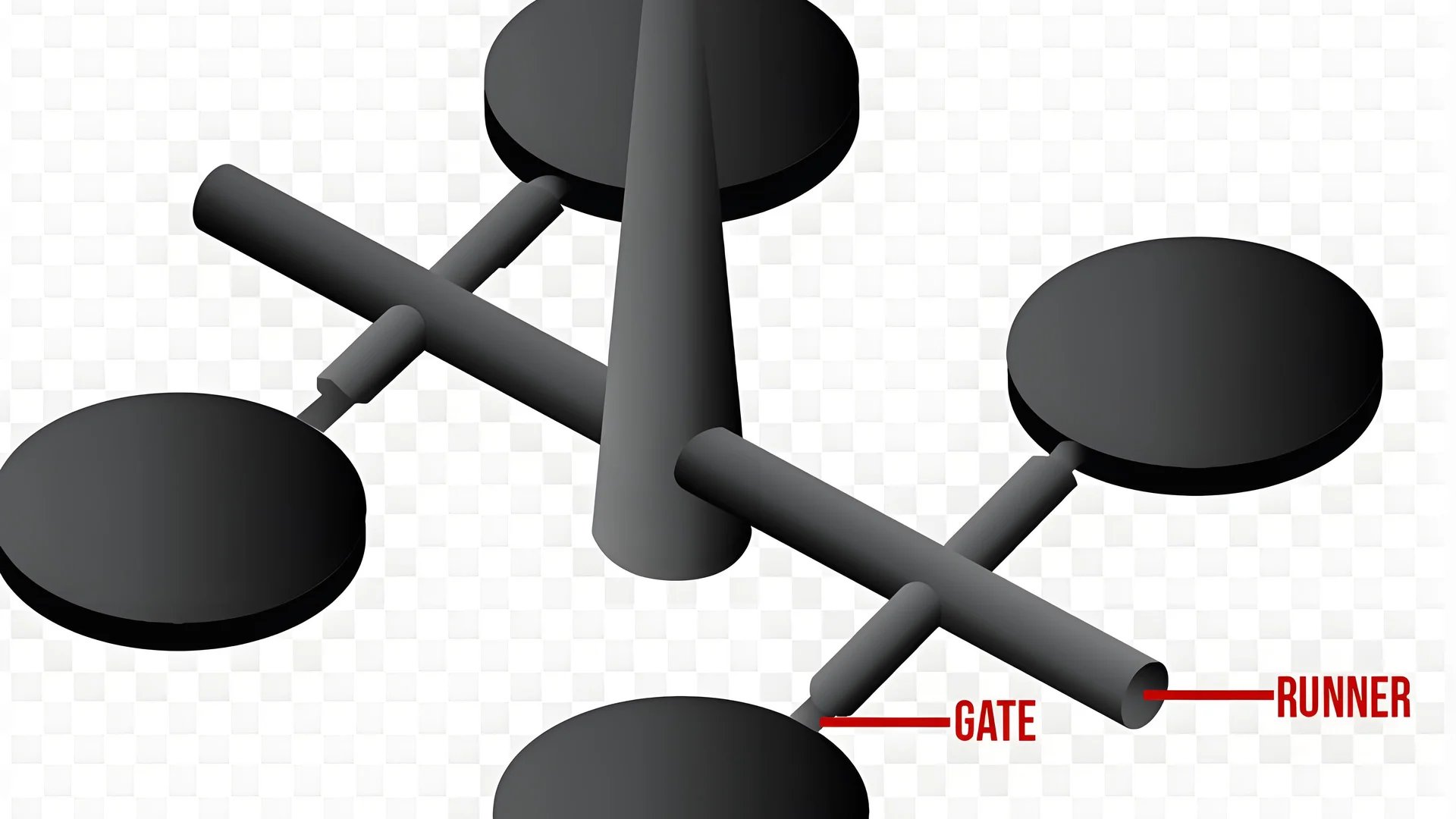

Components of a Gating System

| Component | Description |

|---|---|

| Gate Sleeve | Fits between nozzle and mold runner; size matters |

| Pulling Rod | Clears solidified material; ensures cleanliness |

Gate Sleeve: This piece fits between the nozzle and mold runner. Getting the size right to match the injection nozzle really matters.

Pulling Rod: These maintain cleanliness by clearing solidified material. They are very important for smooth operation.

Impact of Gating Systems on Material Flow

Imagine pouring a thick milkshake through a small straw—that’s what a bad gating system feels like. A proper design allows material to fill the mold quickly and evenly, preventing defects like short shots or warping.

Precision with guide parts11, such as guide pins and sleeves, is always necessary. They keep everything aligned, reducing risks that harm product consistency.

Influence on Cooling Rates

Controlling cooling rates is a hidden advantage of good gating design. With parts like cooling water pipe joints12, uniform cooling is possible, preventing stresses or cracks. A simple adjustment can make a big difference.

Examples of Gating System Configurations

Depending on my work, I select from different setups:

- Edge Gate: Suits flat surfaces; controls flow direction well.

- Tunnel Gate: Great for automated systems; no need for cutting by hand.

- Fan Gate: Spreads melt evenly; ideal for bigger parts.

Knowing these choices helps designers pick the best setup for specific uses while considering mold frame13 compatibility and efficient production results.

Gating systems reduce air bubbles in molds.True

Proper gating design ensures smooth flow, preventing air bubbles.

Fan gates are unsuitable for large parts.False

Fan gates distribute melt evenly, making them ideal for large parts.

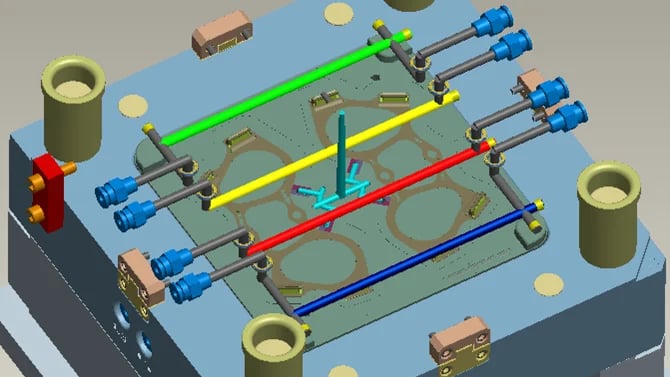

Why Are Cooling System Parts in Molds So Important?

Have you ever thought about why parts from the cooling system in molds matter so much?

Parts of cooling systems in molds, like cooling water pipe joints and water baffles, are essential for controlling temperature. They efficiently spread heat away. This helps avoid defects like warping. Cycle times become shorter. Product quality improves in injection molding.

Understanding Cooling System Parts

In injection molding, cooling systems are very important. They really change the game. Different parts work together to keep temperatures right during molding. Two important parts are the cooling water pipe joints14 and water baffles15.

-

Cooling Water Pipe Joint: These are the hidden connectors linking outside cooling sources to a mold’s core. Correct thread sizes, like PT1/8 or PT1/4, truly affect heat flow.

-

Water Baffle: Think of these as traffic controllers of your cooling water, guiding it precisely where it needs to go. This control maintains even temperatures and keeps product quality really high.

Benefits of Good Cooling Systems

When I first noticed how a good cooling system cut cycle times, it felt like witnessing magic. Faster cooling means quicker production. This is a huge win for efficiency. Consistency in product size and appearance follows too.

| Benefit | Description |

|---|---|

| Reduced Cycle Time | Faster cooling leads to quicker production cycles, boosting overall manufacturing efficiency. |

| Improved Product Quality | Uniform cooling reduces defects, ensuring consistency in product dimensions and appearance. |

No more worries about shapes changing and wrecking all the hard work.

Putting Cooling Systems into Mold Design

Designing molds with good cooling is more than choosing parts; it’s like creating a masterpiece that balances form and function. When designing, I look at everything from the mold frame16 to where each part goes to let heat scatter easily.

A well-made mold frame is like a house’s foundation—it supports everything and provides space for essential cooling channels. This careful mix leads to the best heat control and keeps the mold strong while maintaining the finished product’s quality.

Every perfect design feels like cracking an ancient code for manufacturing excellence.

Knowing these parts’ roles and functions isn’t just technical; it’s the key to building dependable molds meeting production needs without losing quality or efficiency.

Cooling water pipe joints ensure efficient heat transfer.True

They connect external cooling sources to internal channels, facilitating heat dissipation.

Water baffles are unnecessary for mold cooling systems.False

They direct cooling water flow, ensuring uniform temperature distribution.

Conclusion

Essential standard parts for injection molds include mold frames, guide parts, ejector systems, gating systems, and cooling components, each crucial for efficient and precise plastic production.

-

Discover detailed insights into how mold frames stabilize and enhance injection molding processes. ↩

-

Learn how positioning rings ensure accurate alignment and reduce setup errors in mold installations. ↩

-

Understand the importance of choosing the correct ejector pin sizes to enhance ejection cycles. ↩

-

Explore strategies to improve injection molding efficiency through optimal component selection. ↩

-

Explore standard mold frame sizes to understand their impact on guide part specifications. ↩

-

Discover how positioning rings enhance alignment precision during mold installation. ↩

-

Understand how cooling systems interact with guide parts to maintain mold alignment. ↩

-

Learn about how guide pins ensure precise mold alignment, preventing defects during product release. ↩

-

Explore factors influencing mold frame selection to accommodate ejector parts effectively. ↩

-

Learn about gate sleeves’ role in guiding melt into molds for optimal performance. ↩

-

Explore how guide pins ensure precise mold alignment and consistent product quality. ↩

-

Discover how standard joints aid in effective cooling within mold systems. ↩

-

Understand different mold frame specifications to optimize manufacturing setups. ↩

-

Learn how these joints improve heat dissipation and prevent defects in molded products. ↩

-

Explore how cooling components enhance mold performance and product quality. ↩

-

Understand how mold frame design contributes to effective thermal management. ↩