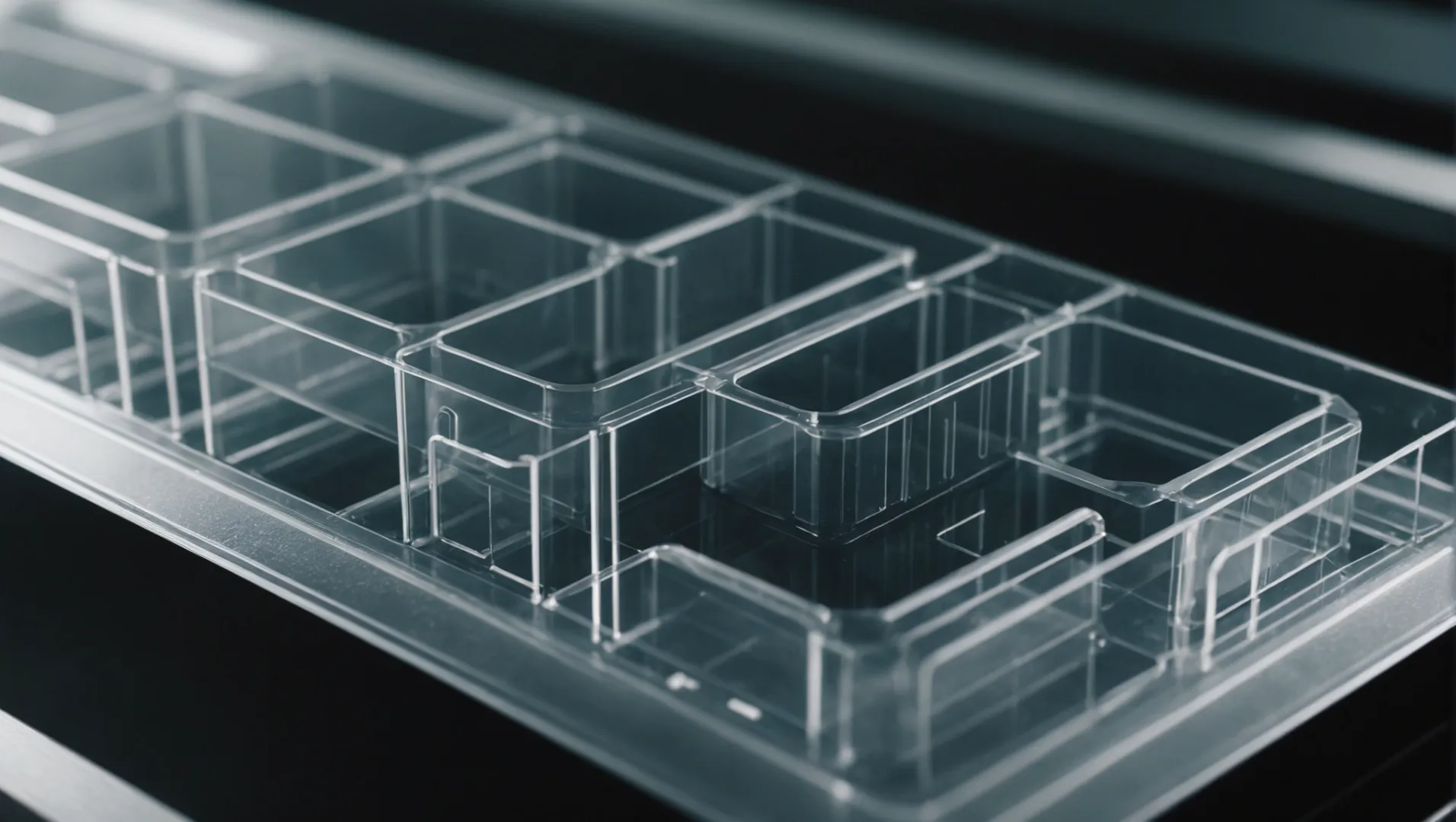

Have you ever marveled at the clarity of a perfectly molded plastic product? It’s a sign of exceptional quality and precision in manufacturing.

To ensure high transparency in injection molded products, select high-purity materials like PC or PMMA, design molds with efficient gates and exhausts, and carefully control temperature, pressure, and cooling times during the molding process.

While these initial insights provide a solid foundation, delving deeper into each aspect reveals the complexity and nuance required to perfect transparent injection molding. Let’s explore how expert techniques and meticulous planning contribute to flawless outcomes.

Material purity affects injection molding transparency.True

High-purity materials reduce light-scattering impurities, enhancing clarity.

How Does Material Purity Affect Transparency in Injection Molding?

The purity of materials is a critical factor in achieving transparency in injection molded products.

Material purity significantly impacts the transparency of injection molded products by reducing impurities that can scatter light, thus ensuring clearer, more consistent results.

The Science Behind Transparency

The transparency of an injection molded product primarily hinges on its ability to transmit light without scattering. Impurities within the material can disrupt this light transmission, leading to opacity or cloudiness. By selecting high-purity raw materials1 like polycarbonate (PC) and polymethyl methacrylate (PMMA), manufacturers can enhance the optical clarity of the final product.

Selecting the Right Materials

Materials such as PC, PS, and PMMA are renowned for their optical properties, including high light transmittance and suitable refractive indices. However, their effectiveness is contingent on purity levels. For example, PMMA is often preferred for products requiring superior light transmittance due to its inherent clarity when sourced from reliable suppliers with consistent quality.

| Material | Light Transmittance | Common Use Cases |

|---|---|---|

| PMMA | ~92% | Lenses, Displays |

| PC | ~88% | Automotive, Electronics |

| PS | ~90% | Packaging, Laboratory Ware |

Importance of Reliable Sources

Ensuring high purity also involves sourcing materials from reputable suppliers. Reliable sources not only guarantee fewer impurities but also provide stability in quality. This consistency is crucial when manufacturing products where visual clarity is paramount.

The Impact of Impurities

Impurities, even in trace amounts, can create defects such as silver streaks or flow marks on the surface of the product. These defects not only mar the aesthetic appeal but also compromise the functionality in applications where optical precision is critical, such as lenses and transparent enclosures. By minimizing impurities through rigorous material selection2, manufacturers can produce transparent products that meet stringent quality standards.

Conclusion: Embracing High Purity for Transparency

While material purity is a foundational element in achieving transparency, it is equally important to consider other factors like mold design and processing conditions. Together, they form a comprehensive approach to producing high-quality transparent injection molded products.

PMMA has higher light transmittance than PC.True

PMMA has ~92% light transmittance, while PC has ~88%.

Impurities in materials do not affect transparency.False

Impurities scatter light, leading to opacity or cloudiness.

What Role Does Mold Design Play in Achieving Clear Plastic Products?

Achieving crystal-clear plastic products requires more than just quality materials; it hinges on impeccable mold design.

Mold design is pivotal in producing clear plastic products, as it ensures precise gating, efficient air exhaust, and meticulous mold surface quality to prevent defects that can mar transparency.

The Importance of Gate Design

The gate in a mold serves as the entry point for molten plastic into the mold cavity. Its design significantly impacts product clarity. Properly positioned and sized gates help achieve an even flow of plastic, preventing issues like weld lines or flow marks, which can impair transparency. Typically, gates should be placed at thicker sections of the product to ensure uniform filling.

Effective Exhaust Systems

Air trapped inside the mold can lead to bubbles and other surface imperfections. A well-designed exhaust system is crucial to expel air efficiently. Techniques such as incorporating exhaust grooves or utilizing the ejector gap for air release can drastically improve the end product’s clarity by preventing unwanted air pockets.

Precision in Mold Processing

The surface finish of the mold directly affects the transparency of the final product. Molds for high-transparency products need to have exceptionally low roughness levels, typically Ra0.05μm or less. This precision helps in achieving a smooth surface on the final product, free from lines or blemishes that could disrupt clarity.

Comprehensive Mold Temperature Control

Maintaining an even mold temperature is critical in preventing optical distortions. A high-quality temperature control system ensures uniform heat distribution across the mold, reducing temperature variances that could lead to defects affecting transparency.

Together, these elements of mold design form a comprehensive strategy to produce clear plastic products that meet high aesthetic and functional standards. By understanding mold design techniques3, manufacturers can optimize their processes to achieve consistent quality in transparent injection molded products.

Gate design affects plastic product clarity.True

Proper gate placement ensures even plastic flow, preventing defects.

High mold roughness improves transparency.False

Low roughness levels are essential for a smooth, clear surface.

Why Is Temperature Control Crucial for Transparent Injection Molding?

Achieving transparency in injection molding hinges on precise temperature control to maintain product quality.

Temperature control is crucial in transparent injection molding because it affects the fluidity of the plastic melt, influencing product quality and transparency. The right temperature ensures even mold filling, prevents defects like bubbles, and maintains optical clarity.

The Impact of Temperature on Material Properties

In transparent injection molding, the temperature plays a pivotal role in determining the fluidity of the plastic melt4. An optimal temperature ensures that the plastic flows smoothly, filling every corner of the mold without creating air pockets. For instance, materials like polycarbonate (PC) and polymethyl methacrylate (PMMA) require specific temperature ranges to achieve their ideal viscosity.

Too high a temperature can lead to thermal degradation, causing discoloration and weakening the material structure. Conversely, too low a temperature results in poor flow and incomplete mold filling, leading to defects such as bubbles and silver streaks5, which mar the product’s transparency.

| Material | Recommended Temperature Range |

|---|---|

| PC | 280°C – 320°C |

| PMMA | 200°C – 250°C |

Temperature’s Role in Mold Filling and Cooling

Temperature control ensures that the plastic maintains its fluid state long enough to fill the mold adequately. This is crucial in preventing issues like flow marks and shrinkage. Once the mold is filled, precise cooling is essential to solidify the product without introducing stresses that can affect transparency.

A high-quality mold temperature control system6 helps maintain uniform temperature distribution across the mold surface, which is critical for preventing variations that could lead to uneven cooling and warping.

Balancing Temperature with Other Process Parameters

Temperature does not work in isolation; it must be balanced with other parameters such as pressure and speed. The injection pressure must be sufficient to push the melt into intricate mold features without causing stress marks. Meanwhile, the injection speed needs careful adjustment to avoid rapid cooling that might trap air or cause incomplete fills.

For example, when molding a lens cover, maintaining an equilibrium between these factors ensures a clear, defect-free product. Monitoring these parameters through a robust control system can significantly enhance the quality and clarity of high-transparency products7.

Too low temperature causes bubbles in molded products.True

Low temperatures lead to poor plastic flow, causing air pockets and bubbles.

High temperatures improve mold filling by reducing viscosity.True

Higher temperatures decrease plastic viscosity, aiding smooth mold filling.

How Can Post-Processing Enhance the Clarity of Molded Products?

Discover how post-processing can transform clarity in molded products, revealing their true quality.

Post-processing enhances molded product clarity by removing surface impurities and performing annealing to relieve internal stress, improving optical performance.

Removing Surface Impurities

The presence of oil and other impurities on the surface of molded products can significantly diminish their transparency. To tackle this, meticulous cleaning is essential. Techniques such as using specialized cleaning agents or mechanical wiping can effectively remove these contaminants, revealing the inherent clarity of the product. The choice of cleaning method should align with the material’s properties and the intended application. For instance, gentle solvents might be preferable for delicate materials to prevent surface damage.

Annealing Treatment for Stress Relief

Annealing is a critical post-processing technique that involves heating the product to a specific temperature and then allowing it to cool gradually. This process helps relieve internal stresses that can cause warping or distortion, thereby enhancing dimensional stability and optical clarity. The parameters for annealing, such as temperature and duration, need careful adjustment based on the type of plastic used and the product’s design requirements. For example, annealing PMMA products8 demands precise control to prevent any compromise on transparency.

Polishing and Coating Techniques

To further augment clarity, polishing techniques can be employed on the surface of molded products. Polishing not only smoothens the surface but also enhances light transmission, making the product appear clearer. In some cases, applying a thin optical coating can protect the surface from scratches and improve its reflective properties. This step is particularly beneficial for products exposed to harsh environments or where additional aesthetic quality is desired.

Quality Inspection and Testing

After post-processing, rigorous inspection is crucial to ensure that the desired clarity levels have been achieved. This involves visual inspections under varying lighting conditions and using specialized tools like gloss meters. Consistent quality checks help identify any residual defects that might impact transparency, allowing for timely corrections before the products reach consumers. Implementing a quality control checklist9 can streamline this process and uphold high standards across production batches.

By integrating these post-processing strategies, manufacturers can significantly enhance the transparency of molded products, ensuring they meet stringent quality expectations and perform optimally in their applications.

Post-processing removes surface impurities in molded products.True

Post-processing involves cleaning techniques to eliminate impurities, enhancing clarity.

Annealing does not affect the optical clarity of molded products.False

Annealing relieves internal stresses, improving dimensional stability and clarity.

Conclusion

By mastering these strategies, you can consistently produce transparent injection molded products that meet high standards of quality and performance.

-

Learn about top materials that ensure transparency in products.: These materials, which vary widely in their properties and applications, can be broadly categorized into thermoplastics, thermosets, and elastomers. ↩

-

Discover how impurities affect product clarity and quality.: Also, because clear plastics don’t hide impurities created during the molding process, material storage must ensure the material stays clean. ↩

-

Learn how specific mold design techniques enhance product transparency.: A guide to clear plastic molding material selection, design precision, and their unique challenges for manufacturers. ↩

-

Discover how temperature influences the fluidity of plastic melts.: Temperature plays an essential role in injection molding, as it affects the viscosity of the molten material and the cooling time. ↩

-

Learn about defects caused by improper temperature settings.: Excessive injection speeds or heating of the material often lead to overheating that causes burns. Consider the following preventative measures … ↩

-

Explore why mold temperature control is vital for quality.: For instance, these controllers can significantly reduce cycle times, which translates into significant savings on labor costs and energy … ↩

-

Uncover advanced techniques for clear plastic molding.: Design Tips for Clear or Translucent Parts · Use uniform wall thicknesses · Design gate runners that are wide and chunky enough · Set gate location … ↩

-

Understand annealing’s impact on PMMA clarity and stress relief.: Annealing is the process of putting the parts after molding into the oven and controlling the temperature and time. The anneal temperature depends on each grade … ↩

-

Learn how quality control ensures consistent product transparency.: Structural quality control checks that include comprehensive moisture and fatigue testing, and CMM and CT inspections to reveal hidden threats to part quality. … ↩