Do the words ‘mold’ and ‘die’ confuse you? Many people feel the same way. You are probably on a shared path of learning.

Molds shape materials like plastic or metal through processes like injection molding, while dies shape metal sheets via stamping. These tools serve distinct functions in manufacturing, essential for product design and production.

I remember the first time I heard these words in product design. Everything seemed confusing. Understanding the basics greatly helped. Molds and dies hold critical roles in manufacturing. However, they serve different purposes. A mold resembles a trusted friend. It shapes materials like plastic or metal. This happens through methods like injection or blow molding. On the other hand, a die is like a talented sculptor. It stamps metal sheets to form exact shapes. Both have their own magic. Knowing their differences can really improve your projects.

Molds are used for shaping plastic materials.True

Molds are specifically designed to shape materials like plastic through processes such as injection molding, making this claim true.

Dies are primarily used for shaping liquids.False

Dies are not used for shaping liquids; they shape metal sheets through stamping, making this claim false.

- 1. What Are the Different Types of Molds and Dies?

- 2. How Do Molds and Dies Impact Product Design?

- 3. What Are the Common Manufacturing Processes Involving Molds and Dies?

- 4. What Should You Consider When Choosing Between a Mold and a Die?

- 5. How Do Molds and Dies Influence Quality Control in Manufacturing?

- 6. Conclusion

What Are the Different Types of Molds and Dies?

Do you ever think about how everyday objects get their shape? Molds and dies are important tools used in factories. Each one has a special job. Let’s explore their interesting world. They help create the products we trust and depend on every day.

Molds shape plastics, primarily using injection molding with thermoplastics, while dies shape metals, often using punch dies. Understanding these types enhances production efficiency and product quality.

Understanding Molds

Definition and Function

Molds and dies are very important tools in factories. They shape materials into the products we enjoy. Factories use molds mostly with plastics. Dies help shape metals. Learning about different kinds and uses of molds and dies can probably improve production. It also really makes me curious about how everyday things are made.

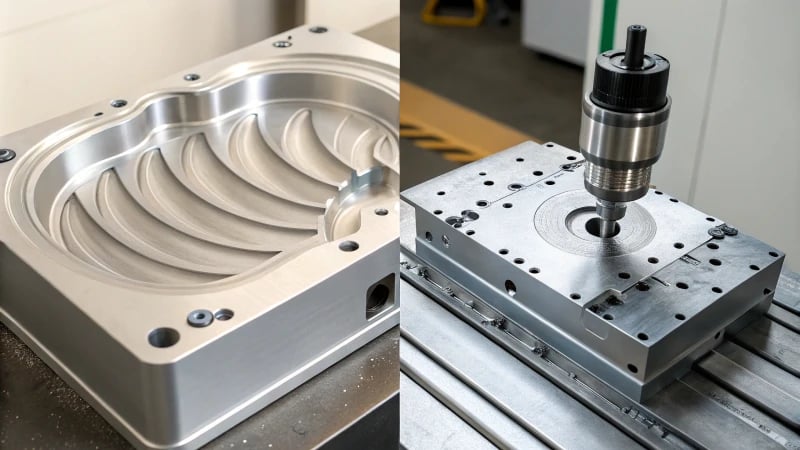

Molds play a crucial role in industrial work. They form a variety of products using methods like injection molding, blow molding, and die casting. I remember the first time I watched a mold in action. Seeing plastic pellets turn into a shiny product was truly magical. Molds press materials like plastics or metals into specific forms.

In injection molding, for example, plastic pellets heat until they melt. The machine injects them into a mold cavity. When they cool down, they become the final product. This method is very important for items with exact sizes. Precise dimensions matter to me in my work.

Types of Molds

- Injection Mold: Used mainly for thermoplastics. This mold heats and melts plastic, injecting it into a cavity. Its design involves:

- Cavity and Core: Create the internal and external shapes.

- Gate System: Manages how the plastic flows in.

- Cooling System: Probably helps the product cool evenly.

Understanding Dies

Definition and Function

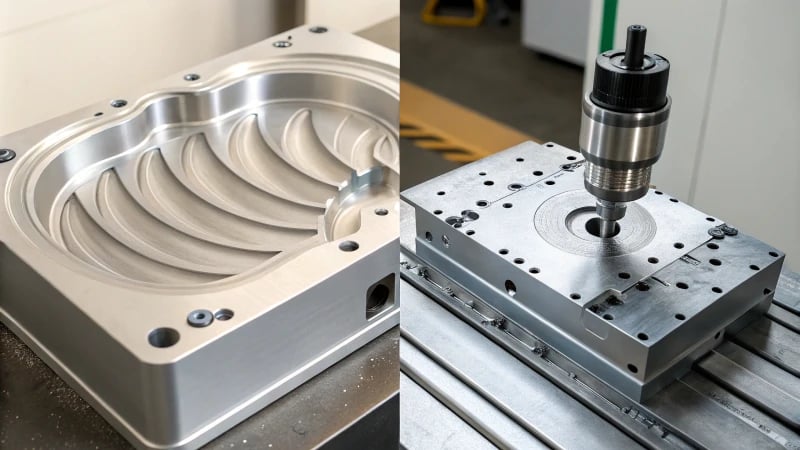

Dies have a different task. They are special molds used mostly for stamping processes. Car manufacturing uses dies a lot; they shape metal sheets into parts like car doors. It’s amazing how these tools can reshape metal so precisely.

Types of Dies

- Punch Die: This die cuts shapes or makes holes in metal sheets with force.

- Bending Die: It bends metal sheets into desired shapes or angles.

| Type | Primary Material | Process Example |

|---|---|---|

| Mold | Thermoplastics | Injection molding |

| Die | Metals | Stamping and punching |

Processing Objects and Methods

-

Molds:

- Processing Objects: Often involve plastics.

- Molding Method: Injection heats and melts materials, injecting them into molds to solidify.

-

Dies:

- Processing Objects: Usually involve metal sheets like steel or aluminum.

- Molding Method: Dies apply pressure to cut or bend metal sheets.

Quality Control in Molds and Dies

Quality control is critical for effective molds and dies. I always focus on these important aspects:

-

For Molds:

- Key Parameters: Temperature, pressure, and speed matter a lot for quality.

- Control Points: Check dimensions and appearance carefully, avoiding defects.

-

For Dies:

- Key Parameters: Punching pressure and speed are vital for smooth operation.

- Control Points: Focus on the accuracy and quality of stamped parts.

Learning about molds and dies has been really important in my work as a designer. It helps me make smart choices that probably improve production methods. If you’re interested, explore mold technology1 or die stamping methods2. This world of creativity and accuracy inspires me every day!

Molds are primarily used for shaping plastics.True

Molds function mainly in processes like injection molding to shape thermoplastics into specific forms, essential for various product manufacturing.

Dies are exclusively used for plastic molding processes.False

Dies are specialized for stamping metals, not plastics, making this claim false as they serve different functions in manufacturing.

How Do Molds and Dies Impact Product Design?

Ever wondered how those sleek gadgets we use every day come to life? Molds and dies create our favorite products. They shape them. These tools play a really important role. Discover their fascinating influence on product design!

Molds and dies shape materials in manufacturing, impacting efficiency, costs, and quality control. Understanding their role is crucial for success in product design and development.

Understanding Molds and Dies

As a product designer, I often get amazed by molds and dies. They shape not only materials but also the heart of products we use every day. Let’s explain it further.

Molds are versatile tools useful in various manufacturing methods like injection molding, blow molding and die casting. Imagine this: plastic melts, gets injected into a mold and when it cools, it becomes those everyday plastic items. This magical change really fascinates me every time!

- Dies, on the other hand, are special molds mainly used in stamping processes. They press sheets of material, usually metal, to form parts by cutting or bending. Think about when a die cuts the shape of a car door from a metal sheet. It’s a really intricate engineering and art performance that always astonishes me.

Molds and dies do more than shape; they greatly influence production efficiency and cost-effectiveness. I once redesigned a mold for a client. The new design lowered cycle times a lot, leading to quicker production and lower costs. My client’s happiness was priceless!

Impact on Design Efficiency

Design details of molds and dies greatly affect production efficiency. A well-thought-out mold significantly improves the injection process. It shortens cycle times and increases output.

For example, molds often have detailed cooling systems. These systems help materials cool even, stopping defects like warping. I had to solve this many times in my projects. On the other hand, dies need very precise alignment. This ensures perfect shapes without damaging the material. One wrong calculation can cause great wear or big product faults!

Quality Control Considerations

Quality control in mold and die making is very important. Keeping an eye on tech factors like pressure, temperature and speed is necessary. Each factor plays a key role in good quality results.

For molds, important quality checks include:

- Dimensional accuracy of molded pieces

- Surface quality (no bubbles or marks)

- Internal quality (checking for shrinkage holes)

For dies, I pay attention to:

- Dimensional accuracy of stamped parts

- Surface quality to avoid flaws like cracks

Learning about these details helps designers like me. Our creations do not only meet style standards, but they also excel in high mass production efficiency.

Innovations Shaping Product Design

The world of mold and die making keeps changing. Innovations are changing how we design products nowadays. I’ve been especially thrilled about:

3D Printing: This technology allows quick testing of molds and dies. It lets me try different shapes before deciding on full production. It is really a game changer!

Advanced Materials: New materials offer better thermal resistance and durability. They open new ways for stronger products.

Smart Molding Techniques: Placing sensors in molds lets us monitor production in real-time. This makes sure everything goes smoothly.

These breakthroughs not only raise productivity but also reduce waste. They improve product quality, truly changing how we design products today.

In my journey as a designer, I’ve seen how understanding molds and dies allows us to create better products. Products that really last.

Understanding Molds and Dies

Molds and dies are important tools. They act as the hidden heroes in product design. They play a key role in manufacturing, directly influencing the manufacturing process and the final product’s quality.

-

Molds are versatile tools used across various manufacturing techniques such as injection molding, blow molding, and die casting. They shape materials like plastics into desired forms. For instance, in injection molding, plastic is melted, injected into a mold cavity, cooled, and solidified to produce a specific shape.

-

Dies, on the other hand, are specialized molds primarily used in stamping processes. They apply pressure to sheets of material (usually metal) to create parts through cutting or deformation. An example is using a die to stamp out car door shapes from metal sheets in the automotive industry.

Molds and dies are not just about shaping; they also play a vital role in determining production efficiency and cost-effectiveness.

Impact on Design Efficiency

The design of molds and dies can significantly impact production efficiency. A well-designed mold can optimize the injection process, reducing cycle times and improving throughput.

| Aspect | Molds | Dies |

|---|---|---|

| Material Types | Plastics | Metals |

| Manufacturing Method | Injection, Blow Molding, Extrusion | Stamping |

| Design Complexity | Generally complex with multiple components | Usually simpler with fewer components |

Molds often include intricate systems for cooling and material flow, which are essential for achieving precise dimensions and surface finishes. For example, the cooling system in an injection mold ensures uniform temperature distribution to avoid defects like warping.

On the other hand, dies require precision in alignment and force application to achieve the desired shape without compromising material integrity. Any flaw in die design can lead to issues such as excessive wear or product defects.

Quality Control Considerations

Quality control is paramount in mold and die manufacturing. The technology parameters involved—such as pressure, temperature, and speed—must be carefully monitored to ensure high-quality output.

For molds, key quality control points include:

- Dimensional accuracy of molded parts

- Appearance quality (e.g., surface bubbles or flow marks)

- Internal quality (e.g., checking for shrinkage holes)

In contrast, for dies, focus is placed on:

- Dimensional accuracy of stamped parts

- Surface finish quality to prevent defects like cracks

Understanding these factors helps designers like Jacky3 ensure that their designs not only meet aesthetic requirements but are also optimized for mass production efficiency.

Innovations Shaping Product Design

The evolution of materials and technologies in mold and die manufacturing continues to shape product design significantly. Recent innovations include:

- 3D Printing: Enabling rapid prototyping of molds and dies, allowing designers to test shapes before full-scale production.

- Advanced Materials: Utilization of new materials that offer better thermal conductivity and wear resistance.

- Smart Molding Techniques: Implementing sensors in molds to monitor conditions in real-time during the production process.

These innovations can lead to increased productivity, reduced waste, and higher quality products—fundamentally impacting how products are designed and manufactured today.

Molds are primarily used for shaping plastics in manufacturing.True

Molds are versatile tools used mainly for shaping plastic materials through various techniques like injection molding.

Dies are more complex than molds in design and function.False

Dies typically have simpler designs with fewer components compared to molds, which can be quite complex.

What Are the Common Manufacturing Processes Involving Molds and Dies?

Have you ever wondered how everyday products come into being? Molds and dies silently work in the background. They shape everything, from shiny electronics to strong car parts, with great precision and speed. This world is very fascinating. Let’s explore it!

Molds and dies are essential in manufacturing, used in processes like injection molding, blow molding, die casting, forging, and stamping to shape materials and ensure high production quality.

Definition and Function of Molds and Dies

In my journey through manufacturing, I learned that molds and dies are very important. A mold acts like a canvas, where raw materials change into complex shapes. This happens through processes like injection molding, blow molding, and die casting. I recall moments when plastic pellets heated up, melted, and flowed into a mold cavity. They cooled and became toys or gadgets that we love.

A die serves a more specialized role, often used for stamping. It is like a sculptor carving stone. It applies pressure to metal sheets to create components for products we use every day. During a factory tour, I was amazed by how dies punched out car door panels or engine hoods from flat metal sheets. These became important parts of vehicles that transport us.

Common Manufacturing Processes Involving Molds

Here’s a breakdown of some common manufacturing processes utilizing molds and dies:

| Process Type | Description | Typical Materials |

|---|---|---|

| Injection Molding | Melting plastic and injecting it into a mold cavity to create detailed plastic parts. | Thermoplastic plastics |

| Blow Molding | Creating hollow plastic parts by inflating heated plastic inside a mold. | Thermoplastic plastics |

| Die Casting | Pouring molten metal into a mold to produce metal components with high precision. | Aluminum, Zinc |

| Forging | Shaping metal using localized compressive forces, often through dies. | Steel, Aluminum |

| Stamping | Using dies to cut or form sheet metal into specific shapes and components. | Steel, Aluminum plates |

Processing Object and Molding Methods

Mold (Injection Molding)

- Processing Object: Usually thermoplastics like pellets or powders.

- Molding Method: The plastic is heated, melted, injected into the mold cavity, then cooled and solidified.

This method fascinates me. It allows for complex designs and the mass production of uniform parts. We often take these parts for granted.

Die (Stamping)

- Processing Object: Mainly metallic sheets of different thicknesses.

- Molding Method: The die uses pressure through a punch to separate or shape the sheet, creating parts like brackets or panels.

Mold Structure Features

Understanding mold and die structures opened my eyes. This knowledge is key to effective manufacturing.

Injection Mold Structure

- Components: Includes cavity, core, gate system, runner system, cooling system and ejector system.

- Functionality: Each component has a role in forming the part. They guide material flow, cool it and allow easy product removal. It is like a well-played symphony where each instrument has a role.

Die Structure

- Components: Consists of punch, die, unloading device and positioning device.

- Focus: The design highlights efficient separation or shape change of the sheet while keeping accuracy. I find it amazing how these parts work together to create accurate shapes.

Technology Parameters and Quality Control Points

Injection Mold Parameters

- Key Parameters: Temperature (barrel/mold), pressure (injection/holding), speed (injection/opening).

- Quality Control Focus: Dimensional accuracy and surface finish; defects might appear from wrong temperature or pressure settings. My quality control meetings showed me how vital these settings are for high-quality products.

Punch Mold Parameters

- Key Parameters: Punching pressure, speed and stroke.

- Quality Control Focus: Ensuring accuracy of stamped parts while avoiding defects like cracks. I’ve seen how small changes can significantly improve product quality.

For those who want to know more, you might explore advanced molding techniques4 or check latest industry standards5. Understanding these processes has helped me make good decisions in my manufacturing career. I hope it helps you too!

Molds are only used for plastic manufacturing processes.False

This claim is false; molds are utilized in various processes, including metal shaping and forming, such as die casting and forging.

Die casting involves pouring molten metal into molds.True

This claim is true; die casting specifically refers to the process of pouring molten metal into a mold to create components with high precision.

What Should You Consider When Choosing Between a Mold and a Die?

Picking a mold or a die might seem overwhelming. It really does not need to be. Focus on the key points. These will probably help you decide. They may even make it feel personal.

When choosing between a mold and a die, consider material compatibility, processing methods, structural complexity, and quality control requirements to ensure high-quality production outcomes that meet your project’s specific needs.

Definition and Function

When choosing between a mold and a die, understanding their definitions and functions is crucial.

- Mold: Think of a mold as a flexible tool used in processes like injection molding and die casting. A mold shapes materials, such as plastic or metal, by applying pressure. For example, I saw plastic injected into a mold turn into a solid object like magic.

- Die: In contrast, a die is like a chisel for shaping metal sheets. Dies play a key role in car manufacturing, shaping parts like doors with precision.

Understanding these definitions helps clarify the applications of each tool in your manufacturing process.

Processing Objects and Molding Methods

The processing objects and molding methods also differ significantly between molds and dies:

| Feature | Mold | Die |

|---|---|---|

| Processing Object | Thermoplastic or thermosetting plastics | Metal sheets (steel, aluminum) |

| Molding Method | Injection molding (heating, melting, injecting) | Stamping (shear force or pressure) |

For example, injection molds heat thermoplastic materials, while dies use pressure to deform metal sheets. This distinction can influence your decision based on the materials you plan to work with.

Mold Structure Features

The complexity of the structure is another key consideration:

- Mold Structure: An injection mold has parts like the cavity, core and cooling system. Each part helps shape and release the final product. Seeing how these parts worked together in an injection mold amazed me.

- Die Structure: A die is simpler, usually just a punch and die plate. Its design focuses on separating or deforming material effectively. Watching a die transform a metal sheet into intricate shapes was impressive.

A better understanding of these structures can guide you in selecting the appropriate tool for your production needs.

Technology Parameters and Quality Control

Finally, consider the technology parameters and quality control aspects:

| Feature | Mold (Injection) | Die (Punching) |

|---|---|---|

| Key Parameters | Barrel temperature, injection pressure | Punching pressure, speed |

| Quality Control Points | Dimensional accuracy, appearance quality | Dimensional accuracy, surface quality |

For molds, controlling parameters like temperature and pressure is essential for product quality; whereas for dies, focus lies on punching speed and material characteristics. These factors significantly impact production efficiency and product integrity.

Final Considerations

Overall, when choosing between a mold and a die, consider the specific requirements of your project. If curious about molds, explore more at molds6. Want to know about dies for metal? Check out dies7.

Molds are used for plastic production only.False

This claim is false because molds can also be used for metals in die casting processes.

Dies are primarily used for stamping metal sheets.True

This claim is true as dies are specifically designed for shaping metal through stamping processes.

How Do Molds and Dies Influence Quality Control in Manufacturing?

Have you ever thought about how a small design change might improve or ruin a product’s quality? Let’s explore the interesting world of molds and dies in manufacturing. They probably have a deep impact on quality control.

Molds and dies ensure quality control in manufacturing by determining the shape, smoothness, and strength of products through precise technology settings and design elements.

Understanding Molds and Dies in Manufacturing

Molds and dies are the hidden champions in manufacturing. They play very important roles in shaping the products we use daily.

Molds refer to various tools used to shape materials through methods such as injection molding, blow molding, and die casting. The function of a mold is to form a specific shape by applying pressure to the material, which can be plastic, metal, or other substances. For example, in an injection molding process, heated plastic enters a mold cavity, cools and hardens to create a solid product. I clearly remember watching a big injection molding machine work for the first time; it felt like magic!

On the other hand, dies are specialized types of molds primarily used in stamping processes. They apply pressure to separate or deform sheet materials, usually metals, to achieve the desired shape. I visited an automotive plant and saw large metal sheets turn into complex parts like doors and hoods. The precision amazed me; these parts fit together perfectly in the end.

Quality Control in Molding Processes

Quality control in molding requires attention to a few major factors:

| Factor | Description |

|---|---|

| Dimensional Accuracy | Ensures that products meet specified measurements. |

| Surface Quality | Involves checking for defects like bubbles or flow marks. |

| Internal Quality | Looks for issues like shrinkage holes or internal stresses. |

Keeping precise technology parameters like temperature, pressure and speed is very important for good quality. For example, controlling the barrel temperature and injection pressure divides a flawless product from a defect-filled one. Learn more about quality control measures8.

Key Technology Parameters for Dies

Dies also depend on several technology parameters that affect quality:

- Punching Pressure: Depends on material thickness and type.

- Punching Speed: Influences production efficiency and die lifespan.

- Punching Stroke: Defines how far the punching action reaches.

I observed that managing these parameters avoids defects like cracks or tears during stamping. Accuracy is crucial for producing high-quality stamped parts. Explore technology parameters9.

The Role of Mold Structure in Quality Control

Mold structure greatly affects quality control. For example, an injection mold needs several complex parts:

- Cavity and Core: Shape inside and outside of the product.

- Gate System: Manages the flow of plastic into the mold.

- Cooling System: Cools the product evenly.

- Ejector System: Pushes finished products out of the mold.

Each part of a mold requires precise design for good quality. I once worked on a project with a poorly designed mold; it produced many defects which taught me about careful design and quality assurance processes. Check out mold structure features10.

Conclusion: No Conclusion Yet!

In summary, grasping the close link between molds, dies and quality control not only advances manufacturing processes but also produces reliable and high-quality products while minimizing defects and maximizing efficiency.

Molds directly shape materials in manufacturing processes.True

Molds are essential tools that form materials like plastics and metals into specific shapes during manufacturing, influencing the quality of the final product.

Die design has no effect on product quality in manufacturing.False

The design of dies is crucial as it affects stamping accuracy and prevents defects, impacting overall product quality significantly.

Conclusion

Molds shape materials through processes like injection molding, while dies primarily stamp metal sheets. Understanding their functions enhances manufacturing efficiency and product quality.

-

Explore comprehensive guides on molds and dies that can enhance your production strategies and design effectiveness. ↩

-

Learn about advanced techniques in die stamping that can improve your manufacturing processes and product quality. ↩

-

Discover how molds and dies can improve your design process by understanding their role in manufacturing. ↩

-

Discover key insights on different manufacturing processes that utilize molds and dies. This can enhance your understanding of how these tools are applied in industry. ↩

-

Explore advanced techniques in molding and die-casting processes for better production efficiency. ↩

-

Discover in-depth insights that will help you make an informed decision about using molds versus dies in your projects. ↩

-

Learn about various applications of molds to find the best fit for your specific production needs. ↩

-

This link will provide you with comprehensive insights into how molds and dies affect manufacturing quality control. ↩

-

Discover key technology parameters related to die manufacturing that ensure product quality. ↩

-

Learn more about mold structure features that are critical for maintaining quality standards. ↩