Did you ever struggle with those annoying sink marks in injection molding? Others probably face the same issue too!

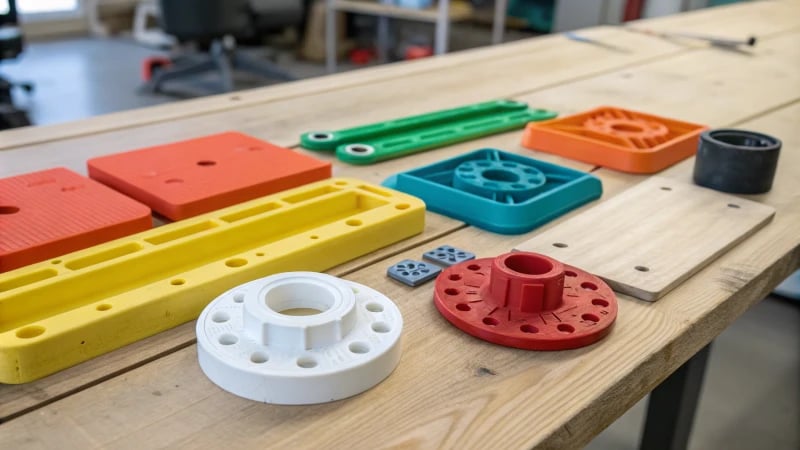

To solve sink mark defects in injection molding, increase injection speed, optimize cooling time, use higher injection pressure, adjust part thickness, and improve mold design. These methods enhance material flow and cooling, reducing shrinkage and ensuring a smoother surface finish.

When I first worked on solving sink marks, it felt like an endless game of chasing problems. Every time one problem seemed fixed, another appeared. Over time, understanding the real reasons became very important. This journey led me to focus on important areas like product design and choosing the right materials.

Uniform wall thickness and good cooling systems led to fewer defects. Changing settings like holding pressure and injection speed also helped a lot. These adjustments really improved product quality and made the process more efficient. If you face similar issues, these approaches might be the solution you need.

Uniform wall thickness reduces sink marks.True

Ensuring uniform wall thickness helps in even cooling, reducing sink marks.

High-shrinkage materials prevent sink marks.False

High-shrinkage materials can exacerbate sink marks, not prevent them.

- 1. How Does Wall Thickness Affect Sink Marks?

- 2. How Do Ribs Reduce Sink Marks in Injection Molded Parts?

- 3. How can I tweak injection molding parameters to avoid sink marks?

- 4. Why Is Mold Cooling System Design Crucial for Avoiding Sink Marks?

- 5. Which Materials Are Best for Minimizing Sink Mark Defects?

- 6. Conclusion

How Does Wall Thickness Affect Sink Marks?

Do those annoying little sink marks on your injection-molded pieces leave you confused? Others feel the same way. Wall thickness plays a key role in creating perfect designs. This knowledge could really change your work.

Wall thickness affects sink marks by changing how evenly the plastic cools and hardens. Consistent wall thickness allows even cooling, which reduces sink marks. Different thickness creates uneven cooling and visible defects.

The Science Behind Wall Thickness and Sink Marks

I remember dealing with sink marks in my designs for the first time. It felt like playing a game of whack-a-mole – fix one and another appears. Wall thickness plays a big role in this story. Uniform thickness helps plastic cool evenly, reducing stress and sink marks. But, when thickness varies, cooling happens unevenly, causing those annoying surface defects.

Design Considerations

I treat uniform wall thickness as an art form during design. Sudden thickness changes really cause issues. Gradual transitions help prevent shrinkage problems. In rib designs, ribs should not be thicker than 0.6-0.8 times the wall thickness. Sudden turns mean trouble.

| Design Element | Recommended Practice |

|---|---|

| Wall Thickness | Uniform or gradual transition |

| Rib Design | 0.6-0.8 times wall thickness |

Injection Molding Parameters

Setting the right parameters helps me fight sink marks. Adjust pressure and time – set holding pressure at 50%-80% of injection pressure to overcome volume loss as everything cools. For thicker walls, extended holding time is needed for full cooling and shaping.

Material Selection

Picking the correct materials feels like choosing the right tool for a job. I choose plastics with low shrinkage rates; polystyrene1 is better than polypropylene when possible as it makes life easier by reducing shrinkage during cooling.

Mold Design Optimization

A well-planned mold cooling system is like a good friend; it keeps things going smoothly. I have seen how altered cooling channels maintain even temperature, which reduces shrinkage differences.

| Optimization Technique | Purpose |

|---|---|

| Cooling Channels | Achieve uniform cooling |

| Gate Design | Enhance melt flow and reduce confluence issues |

Focusing on these aspects greatly reduces sink marks in molded parts, improving both looks and strength. Using these methods is very important for better product design and production success.

Dive deeper into your injection molding process improvements with more resources2.

Uniform wall thickness minimizes sink marks.True

Uniform thickness ensures even cooling, reducing stress and sink marks.

Thicker walls always reduce sink marks.False

Thicker walls require longer cooling, increasing shrinkage and potential sink marks.

How Do Ribs Reduce Sink Marks in Injection Molded Parts?

Have you ever thought about how small ribs in molded parts handle so much work to keep surfaces smooth and free from marks?

Ribs are very important in lowering sink marks. They spread shrinkage stress around. This spreads out the stress. These structures help all of the material cool evenly. Ribs stop parts from being too thin or too thick. The design adds strength without adding too much material. This leads to a really smooth and even surface.

How Ribs Work in Injection Molding

Ribs in injection molding are surprisingly important. They act as the backbone, giving strength without adding much weight. They spread stress evenly, helping the parts cool faster. This helps reduce sink marks, which are like dents on the surface. Think of it like a book’s spine holding pages together without much bulk.

Principles for Rib Design

Designing ribs is not just placing them randomly. I learned that getting the thickness right is essential. Ribs should be 0.6 to 0.8 times the wall’s thickness to be strong and to avoid sink marks.

-

Thickness Guidelines:

- Balance is crucial here. It’s like baking a cake; too much batter in one place and it cooks unevenly.

-

Smooth Wall Transition:

- Gradual changes are key. It reminds me of easing into changes slowly for better results.

| Parameter | Recommended Value |

|---|---|

| Rib Thickness | 0.6-0.8 times wall thickness |

| Holding Pressure | 50%-80% of injection pressure |

Optimizing Injection Settings

Adjusting settings like holding pressure and speed is like tuning a musical instrument. Each change affects the final product.

- Holding Pressure: Enough pressure keeps plastic shapes firm, much like a filled tire stays round.

- Injection Speed: Speeding up can reduce sink marks, giving a smoother finish.

Choosing Materials and Designing Molds

Picking the right material is like choosing the best fabric for a suit. It must fit perfectly.

- Material Choice: Use plastics with low shrinkage, like polystyrene. It really makes a big difference.

- Cooling Systems: Well-planned cooling channels maintain even temperatures, reducing defects.

Explore more on mold designs by checking out specialized resources3. Think about adding customized cooling4 to make cooling more even and cut down on sink marks significantly.

By including these elements in your design, you boost the look and strength of your products, making them stand out.

Ribs increase part weight significantly in injection molding.False

Ribs add strength without significantly increasing weight.

Proper rib design reduces sink marks in molded parts.True

Ribs distribute stress and ensure even cooling, minimizing sink marks.

How can I tweak injection molding parameters to avoid sink marks?

Sink marks in plastic parts often cause problems for both appearance and strength of the product. Fortunately, simple changes to injection molding settings help solve these issues. These annoying defects probably disappear with just a few adjustments.

Changing settings like holding pressure, speed and temperature in injection molding is very important to stop sink marks. Adjusting the mold and product design plays a big role too. Picking the right materials also helps to reduce these flaws. Proper materials matter.

Optimizing Product Design

Early projects left me frustrated with sink marks. These small dents ruined perfect designs. Ensuring wall thickness uniformity became crucial to me. Tiny thickness changes caused uneven cooling and shrinkage. I learned that gradual transitions between thicknesses helped, much like smoothing out a bumpy road.

A reasonable design of ribs followed as a revelation. Ribs seemed unimportant at first, but they helped with shrinkage stress. Keeping ribs between 0.6-0.8 times the wall thickness improved strength and reduced sink marks.

| Design Aspect | Best Practice |

|---|---|

| Wall Thickness Uniformity | Gradual transitions for thickness changes |

| Rib Design | Ribs < 0.8 times wall thickness for stress dispersion |

Adjusting Injection Molding Process Parameters

Holding Pressure Control was a game-changer. Balancing the holding pressure and time helped with shrinkage, akin to hugging the product until it cooled down.

Injection Speed and Temperature Adjustment mattered significantly. Faster injection filled cavities quickly, reducing cooling issues. Different materials needed different temperatures; for example, higher mold temperatures for crystalline plastics reduced shrinkage.

| Parameter | Adjustment Strategy |

|---|---|

| Holding Pressure | Balance pressure and time to reduce shrinkage |

| Injection Speed & Temp | Increase speed; adjust temperature per material |

Mold Optimization Design and Transformation

Cooling system design felt like building a secret network underground, aiming to spread temperature evenly across the mold with custom cooling channels—imagine wrapping the mold in a cozy blanket.

Gate Design Optimization was equally important. Placing gates well, especially at thick walls, improved plastic flow during pressure holding, leading to fewer sink marks and smoother products.

| Parameter | Adjustment Strategy |

|---|---|

| Cooling System Design | Ensure uniform cooling with tailored channels |

| Gate Design Optimization | Place gates at thicker walls for better flow |

Material Selection and Processing

Opting for low-shrinkage materials, like polystyrene, became my favorite choice as they helped reduce sink marks—like picking reliable shoes for hiking.

Proper raw material drying was very important too; for materials like nylon, drying prevented moisture problems and excessive shrinkage.

- Material Selection Tips: Choose low-shrinkage materials5 to minimize sink marks.

- Drying Protocol: Proper raw material drying techniques6 ensure consistent quality.

Implementing these strategies greatly reduced sink marks in my projects, resulting in products that met functional needs while looking polished and professional.

Uniform wall thickness prevents sink marks in injection molding.True

Uniform wall thickness ensures even cooling, reducing shrinkage and sink marks.

Higher mold temperatures increase sink marks in crystalline plastics.False

Higher mold temperatures ensure full crystallization, reducing shrinkage and sink marks.

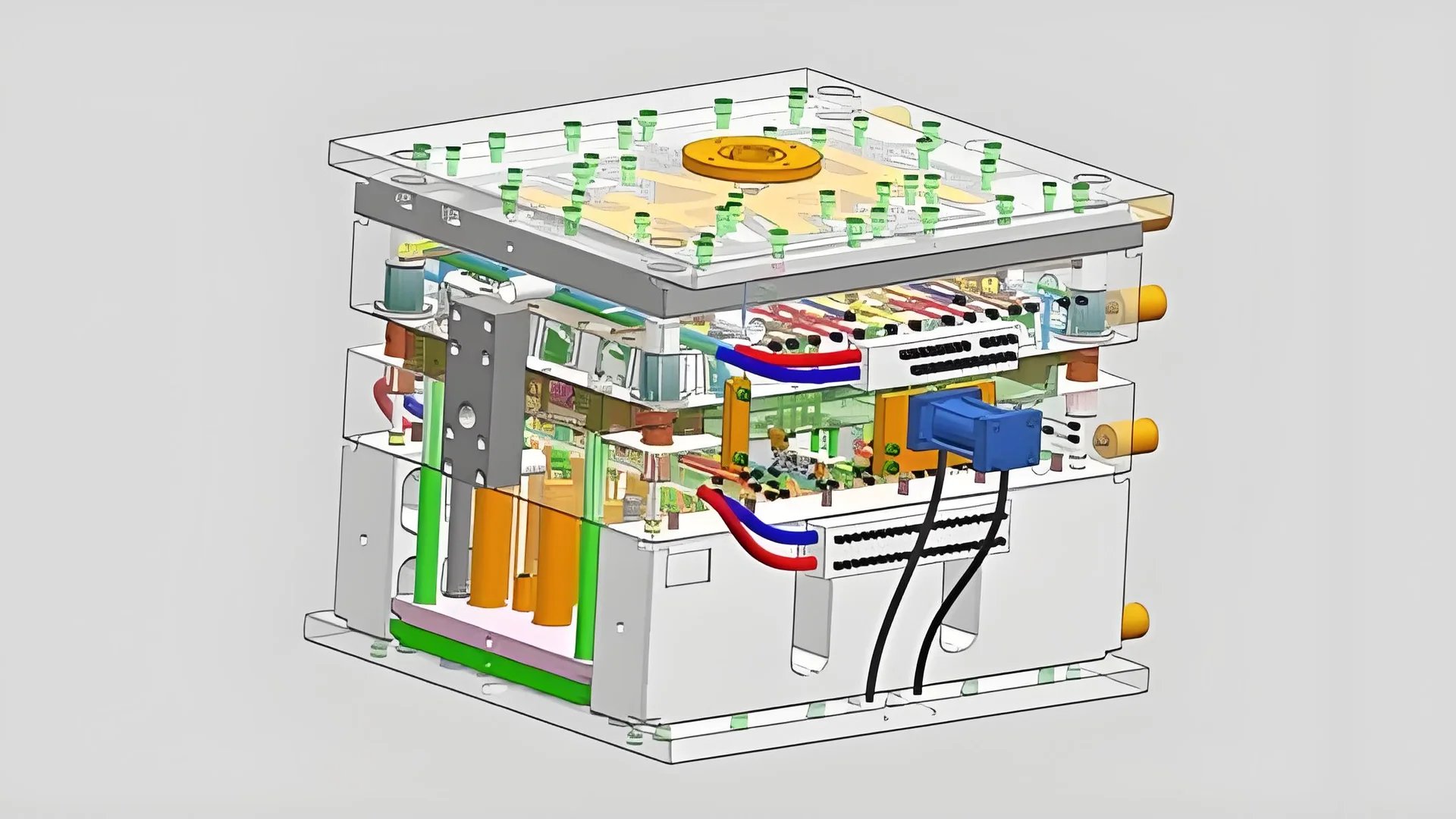

Why Is Mold Cooling System Design Crucial for Avoiding Sink Marks?

Have you ever held a plastic object and noticed small dents or dimples on it?

A well-crafted mold cooling system stops sink marks in plastic products. Strategic arrangement of cooling channels keeps the temperature the same everywhere. Material properties are very important. Manufacturers lower temperature differences by focusing on these details. These differences create surface problems.

Understanding Sink Marks

Sink marks are tiny dents on injection molded parts. They often happen because of uneven cooling and can affect both the aesthetic appeal7 and functional quality of products, making them a significant concern in manufacturing.

Role of Mold Cooling System Design

The cooling system in a mold controls the temperature during the molding process. A poorly designed system may lead to uneven cooling, causing differences in shrinkage and creating those pesky sink marks.

Key Elements of Good Cooling System Design

- Cooling Channel Layout: Designing staggered cooling channels8 or customizing them to fit the product shape helps secure even cooling. This stops overheating in certain spots, which prevents sink marks.

- Temperature Control: Keeping a steady mold temperature is very important. Different materials need specific temperatures; for example, crystalline plastics need higher temperatures to shrink less and crystallize fully.

| Material | Mold Temperature (°C) |

|---|---|

| Polystyrene (PS) | 50-70 |

| Polypropylene (PP) | 40-60 |

Optimize Product Design

Design choices greatly affect sink marks. Ensuring walls have even thickness helps plastic shrink evenly, reducing those annoying marks.

- Wall Thickness: Changing from thick to thin walls slowly avoids sudden shrinkage problems.

- Rib Design: Rib thickness should usually be 0.6-0.8 times the wall thickness. This spreads out shrinkage stress.

Adjust Injection Molding Process Parameters

- Holding Pressure and Time: More holding pressure balances the volume loss during cooling. For thick walls, more holding time helps plastic cool and hold shape.

- Injection Speed and Temperature: Fast injection speed helps fill the cavity quickly, while the right temperature adjustments stop shrinkage issues.

Focusing on these areas helps manufacturers really improve product quality and cut defects from sink marks. For more insights on optimizing injection molding processes9, check out additional resources on modern practices in the field.

Understanding these elements helps mold designers build better cooling systems. The benefit includes higher-quality products and more efficient production. Better design improves the product and makes manufacturing smoother, helping both manufacturers and consumers in the end.

Uneven cooling causes sink marks in molded parts.True

Uneven cooling leads to shrinkage differences, resulting in sink marks.

Rib thickness should be equal to wall thickness.False

Rib thickness should be 0.6-0.8 times the wall thickness.

Which Materials Are Best for Minimizing Sink Mark Defects?

Recall the annoyance of dealing with sink marks in your plastic products? I felt that too! Choosing the correct materials transforms the quality and look of your molded parts.

To reduce sink marks, choose materials such as polystyrene (PS) with low shrink rates. These materials provide even cooling. Drying treatments help to decrease shrinkage a lot. Shrinkage reduces significantly.

Understanding Sink Marks

I remember a time when a project deadline was close and those annoying sink marks seemed set to ruin everything. Sink marks occur when the surface of a molded part caves in, typically due to differential cooling rates between the core and surface. These can be minimized by carefully selecting materials that promote uniform cooling and offer low shrinkage rates.

Selecting Low-Shrinkage Materials

Experience taught me that material choice impacts success or failure. One of the most effective ways to minimize sink marks is to choose materials with inherently low shrinkage rates. For example, polystyrene (PS)10 usually shrinks less, making it ideal for achieving smooth surfaces without defects.

| Material | Shrinkage Rate |

|---|---|

| Polystyrene (PS) | Low |

| Polypropylene (PP) | High |

In contrast, polypropylene (PP)11 tends to shrink more, making it less suitable if minimizing sink marks is a primary concern.

Importance of Drying Treatments

Drying is vital. Once, I didn’t dry nylon enough and ended up with many failed parts. Moisture in raw materials can exacerbate sink mark issues. Materials like nylon require thorough drying before processing to prevent moisture-induced expansion and subsequent shrinkage. Ensuring that raw material12 is properly dried reduces the likelihood of excessive shrinkage.

Material Impact on Injection Molding Process

The right material choice affects many things like holding pressure, injection speed, and temperature. Choosing the right material also influences process parameters such as holding pressure, injection speed, and temperature. For crystalline plastics, adjusting the mold temperature is crucial for complete crystallization, thereby reducing volume shrinkage during cooling.

Integrating Material Selection with Design and Process

Choosing the right material isn’t only about selecting it; it’s about fitting it into your design and process. Material selection should not be an isolated decision. It should integrate with product design and process parameters. Keeping wall thickness even leads to even cooling across the product, further minimizing sink marks. If different thickness is necessary, using gradual changes in wall thickness helps control shrinkage evenly.

By understanding how materials and design connect13, manufacturers can come up with plans to really tackle sink marks effectively.

Polystyrene has low shrinkage rates.True

Polystyrene is known for its minimal shrinkage, reducing sink marks.

Polypropylene is ideal for minimizing sink marks.False

Polypropylene has high shrinkage, making it less suitable for minimizing sink marks.

Conclusion

This article discusses effective strategies to eliminate sink marks in injection molding, focusing on design optimization, process adjustments, material selection, and cooling system improvements for enhanced product quality.

-

Explore how cooling rate impacts defects like sink marks to improve design strategies. ↩

-

Find strategies to enhance injection molding processes and minimize defects. ↩

-

Learn advanced mold optimization techniques that complement rib design to minimize defects. ↩

-

Explore how customized cooling channels improve temperature distribution, reducing the likelihood of sink marks. ↩

-

Exploring this link helps in understanding the impact of material selection on sink mark prevention. ↩

-

This link offers insights into effective drying techniques essential for preventing defects. ↩

-

Understanding how sink marks impact product appearance can help in designing better molds to avoid these defects. ↩

-

Learn how staggered cooling channels can provide uniform temperature distribution to prevent sink marks. ↩

-

Explore cutting-edge methods to enhance injection molding processes for better product quality. ↩

-

Discover why polystyrene’s low shrinkage rate makes it a top choice for reducing sink marks. ↩

-

Understand how polypropylene’s higher shrinkage rate compares with other plastics. ↩

-

Learn why drying raw materials is crucial to prevent moisture-related defects. ↩

-

Explore how material selection affects injection molding outcomes and defect prevention. ↩