DEVELOPMENT

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Most Effective Ways to Reduce Part Weight in Injection Molding?

Reducing part weight in injection molding is crucial for enhancing efficiency and sustainability. Key strategies include optimizing design through wall thickness reduction, incorporating hollow structures, and refining rib designs. Material selection plays a vital role; using lightweight polymers like polyethylene ...

DEVELOPMENT

How Does the Cavity Function in Injection Molding?

This article explores the critical role of cavities in injection molding, detailing how they shape products and affect quality. It covers single-cavity versus multi-cavity molds, their applications, and the importance of temperature control and surface finishes. Understanding these elements helps ...

DEVELOPMENT

What is the Maximum Wall Thickness Allowed for Injection Molding?

This article explores the optimal wall thickness for injection molding, emphasizing that while the general guideline is 3-4 mm for most thermoplastics, certain materials and designs may allow for thicker walls up to 6-8 mm. Factors such as flow characteristics, ...

DEVELOPMENT

How Can Injection Molded Parts Be Recycled Effectively?

Recycling injection molded parts is essential for sustainability. The process begins with sorting materials using techniques like visual inspection and infrared spectroscopy. Cleaning removes contaminants before reprocessing through mechanical or chemical methods. Mechanical recycling melts plastics into new products, while ...

DEVELOPMENT

What Impact Will Global Market Trends Have on the Injection Molding Industry?

The injection molding industry is undergoing significant transformation due to global market trends. Increasing demand for lightweight components in the automotive sector, personalized designs in home appliances, and sustainable practices are reshaping manufacturing processes. The rise of electric vehicles necessitates ...

DEVELOPMENT

What Are Effective Solutions for Challenging Product Releases in Injection Molding?

This blog post explores effective strategies for overcoming challenges in injection molding processes. Key solutions include optimizing mold design to prevent sticking, using appropriate release agents for easier part ejection, ensuring precise temperature control to maintain agent effectiveness, and committing ...

DEVELOPMENT

How Can Mold Design Strategies Effectively Minimize Material Waste?

This article explores how effective mold design strategies can minimize material waste in manufacturing. By focusing on techniques such as precise gate placement, optimizing runner systems, and utilizing advanced CAD tools, manufacturers can enhance production efficiency while promoting sustainability. The ...

DEVELOPMENT

How Does Automation Lower Labor Costs in Injection Molding?

Automation is revolutionizing the injection molding industry by significantly lowering labor costs. By taking over manual tasks, automated systems enhance production efficiency, ensure consistent quality, and minimize errors. This shift allows human resources to focus on strategic roles rather than ...

DEVELOPMENT

What Are the Cutting-Edge Trends in Injection Molding Technology?

The latest trends in injection molding technology focus on automation, sustainability, and novel materials. These advancements are revolutionizing the manufacturing industry by improving efficiency, minimizing environmental footprints, and creating new opportunities for designers. Automation enhances precision with robotics and sensors, ...

DEVELOPMENT

What Are the Best Methods to Achieve Tight Tolerances in Injection Molding?

This blog post explores the best methods for achieving tight tolerances in injection molding. It emphasizes the importance of meticulous mold design, precise processing controls, and advanced simulation tools. Material selection plays a crucial role in influencing shrinkage rates and ...

DEVELOPMENT

What Are the Advantages of Using Recycled Materials in Injection Molding?

Integrating recycled materials into injection molding offers significant advantages such as cost savings, reduced environmental impact, and enhanced sustainability. While these materials can lower expenses and support eco-friendly practices, they also present challenges including quality inconsistency and contamination risks. Effective ...

DEVELOPMENT

How Do Biodegradable Plastics Benefit Injection Molding?

Biodegradable plastics are revolutionizing injection molding by significantly lowering landfill waste and carbon emissions. These eco-friendly materials decompose naturally, aligning with sustainability goals without compromising product quality. While they offer numerous environmental benefits, such as reduced pollution levels and decreased ...

DEVELOPMENT

How Can You Apply Lean Manufacturing Principles to Enhance Injection Molding?

This blog post explores how lean manufacturing principles can be applied to injection molding processes. By focusing on continuous improvement, employee engagement, and leveraging technology, manufacturers can streamline operations, reduce waste, and enhance product quality. Key strategies include defining value ...

DEVELOPMENT

What Are the Top Mold Testing Practices for Efficient Injection Molding?

Efficient injection molding relies on key mold testing practices such as mold flow analysis, dimensional inspection, and functional testing. These methods help identify defects early, ensure design accuracy, and improve product quality. By integrating advanced technologies like DNA sequencing and ...

DEVELOPMENT

How Can Combining Injection Molding with CNC Machining Benefit Your Production Process?

Integrating injection molding with CNC machining can significantly enhance your manufacturing process. This combination boosts production efficiency, allows for design flexibility, and reduces costs while improving product quality and minimizing waste. By leveraging advanced technologies like CAD systems and 3D ...

DEVELOPMENT

What Are Side Actions in Injection Molding and Why Are They Important?

Side actions in injection molding are essential for creating intricate designs and complex geometries that traditional molds cannot achieve. By moving perpendicular to the mold's opening direction, side actions allow designers to incorporate undercuts and detailed features into their products. ...

DEVELOPMENT

What Are the Applications and Benefits of Gas-Assisted Injection Molding Technology?

Gas-assisted injection molding technology revolutionizes manufacturing by using high-pressure gas to create hollow sections in plastic parts. This process reduces material usage by up to 40%, improves product strength and surface finish, and allows for intricate designs that traditional methods ...

DEVELOPMENT

How Does the Core Pulling Mechanism in Injection Molds Work?

Core pulling mechanisms play a vital role in injection molding by allowing the creation of intricate designs such as side holes and undercuts. These mechanisms retract cores during or after mold opening to facilitate smooth demolding without damaging the product. ...

DEVELOPMENT

What Are the Best Ways to Prevent Cracks in Injection Molded Products?

This article explores effective strategies to prevent cracks in injection molded products, emphasizing the importance of product design optimization, process control, and mold maintenance for enhanced durability and quality.

DEVELOPMENT

What Are the Key Advantages of Injection Molding Compared to Other Plastic Manufacturing Processes?

Injection molding offers significant advantages over other plastic manufacturing processes, including high production efficiency, superior product quality, design flexibility, material adaptability, and cost-effectiveness in mass production.

DEVELOPMENT

What Is Mold Flow Analysis and How Does It Predict Warpage in Injection Molded Parts?

Mold flow analysis is crucial in injection molding, predicting warpage by assessing shrinkage, residual stresses, and cooling patterns. This software enhances design accuracy and manufacturing efficiency, ensuring high-quality molded parts.

DEVELOPMENT

What Factors Influence the Duration of Plastic Injection Molding?

This article explores the key factors influencing the duration of plastic injection molding, including cycle composition, material properties, part size and shape, process parameters, and mold design. Understanding these elements can enhance efficiency and product quality.

DEVELOPMENT

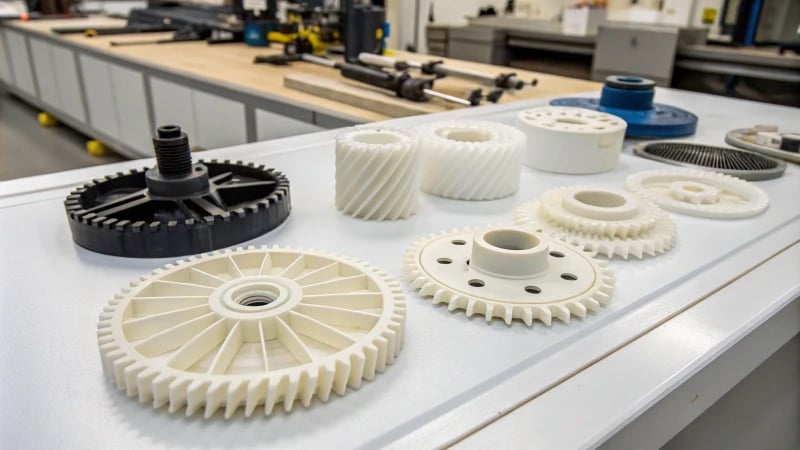

What Are Injection Molded Plastic Parts and Why Are They Important?

Injection molded plastic parts are essential in modern manufacturing, offering high precision, complex shapes, and efficiency. This versatile process is crucial for industries like automotive and consumer electronics.

DEVELOPMENT

What Role Does Injection Molding Play in Manufacturing?

Injection molding revolutionizes manufacturing by enabling the efficient production of complex, high-quality plastic parts across various industries. Its precision, speed, and innovative mold designs enhance product quality and efficiency.

DEVELOPMENT

What are the Best Techniques for Removing Gates After Injection Molding?

Removing gates from injection molded parts requires careful consideration of methods such as manual, mechanical, chemical, and ultrasonic removal. Factors like gate size, material type, and production efficiency influence the best choice.

DEVELOPMENT

Why is Injection Molding Considered Fast and Cost-Effective?

Injection molding is a fast, cost-effective manufacturing process driven by automation. It features short cycle times and high material utilization, making it ideal for large-scale production across various industries.

DEVELOPMENT

What Makes a High Speed Injection Molding Machine Essential for Efficient Production?

High-speed injection molding machines significantly enhance manufacturing efficiency by reducing cycle times and improving product quality. Their advanced technology allows for rapid injection, optimizing material flow and minimizing defects.

DEVELOPMENT

What Is the Rapid Injection Molding Process and How Does It Work?

Rapid injection molding is a fast, efficient manufacturing process that utilizes specialized machines and optimized mold designs to produce high-quality plastic parts quickly, enhancing production speed and flexibility.

DEVELOPMENT

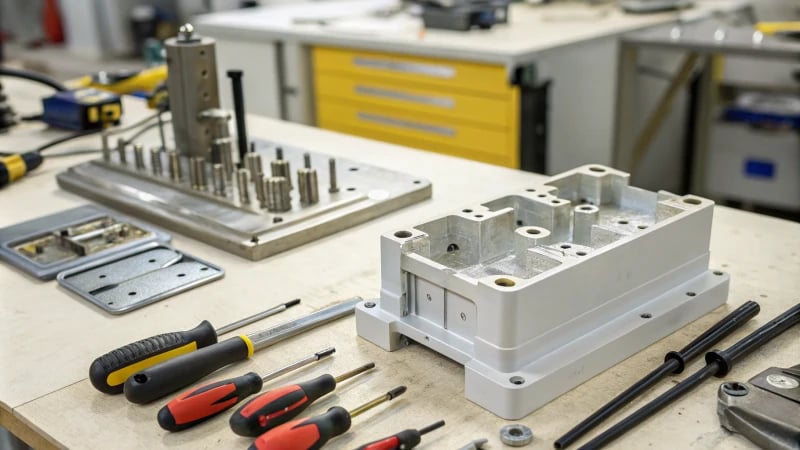

What Exactly Do Plastic Mold Makers Do and Why Are They Important?

Plastic mold makers transform design concepts into tangible products through meticulous mold design, manufacturing, and maintenance. Their expertise is crucial across various industries, ensuring high-quality plastic components.

DEVELOPMENT

Which Injection Molding Machine Is Best for Producing Plastic Chairs?

Choosing the right injection molding machine for plastic chairs is essential. Key factors include machine type, production volume, material compatibility, automation features, energy efficiency, and maintenance support to optimize efficiency and quality.

DEVELOPMENT