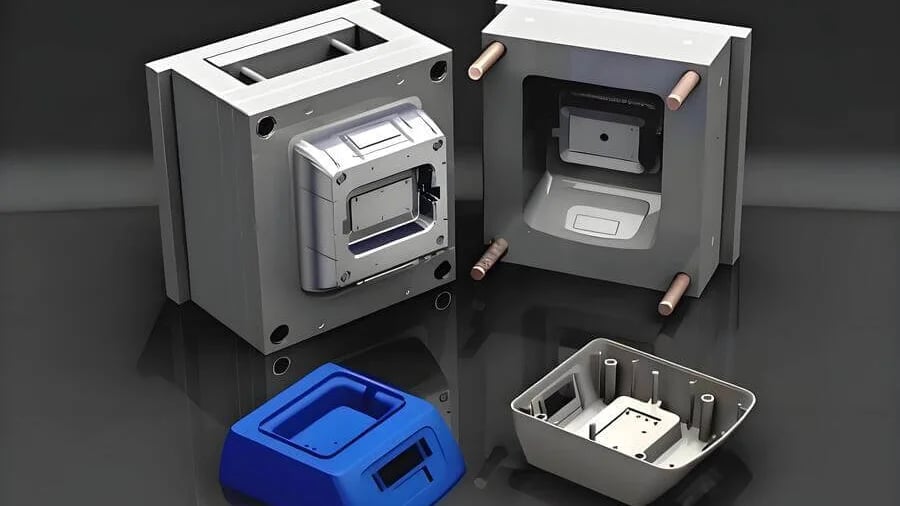

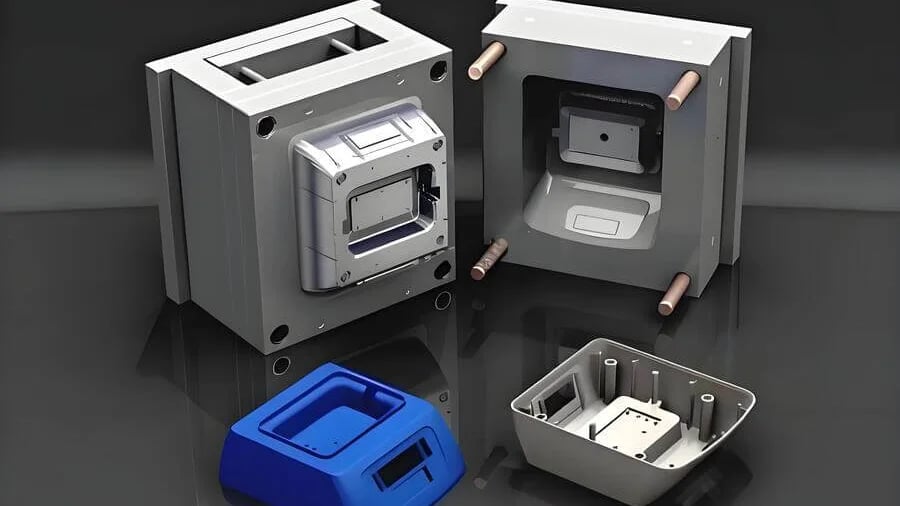

Designing an effective injection mold hinges on choosing the right parting surface angle. This decision impacts processing ease, product quality, and efficiency.

The best parting surface angle for injection molds typically aligns perpendicularly to the mold opening direction, especially for simple shapes. For complex designs, angles must be tailored to facilitate smooth demolding and ensure product quality.

While a perpendicular angle often simplifies design for basic shapes, complex products require more strategic angle considerations. Understanding these nuances can drastically improve your mold’s performance and product output.

Simple shapes use 0° parting surface angle.True

For simple shapes, the parting surface is perpendicular to mold opening.

Complex shapes always use multiple parting surfaces.False

Complex shapes may require multiple surfaces, but not always.

How Do Product Shapes Influence Parting Surface Angle?

Unravel the intricate relationship between product shapes and parting surface angles in injection molding.

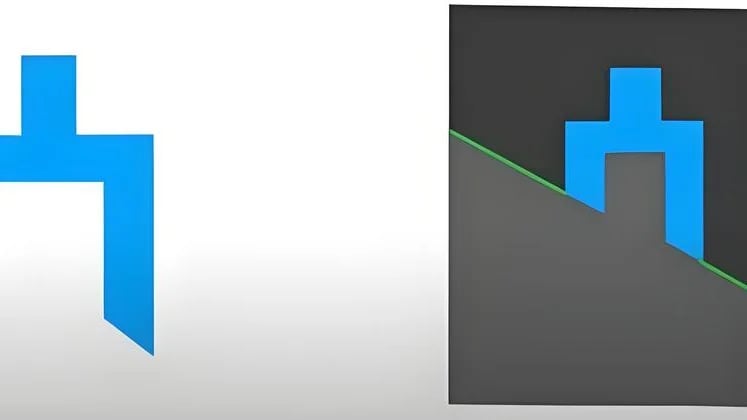

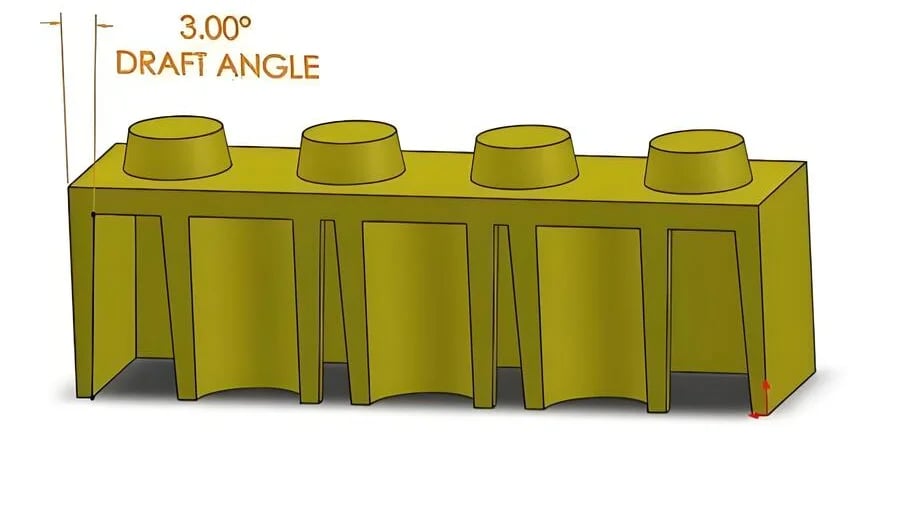

Product shapes directly influence parting surface angles due to their structural features. Simple shapes, like flat or cylindrical products, often have a parting angle of 0° for ease of mold design. Complex shapes require tailored angles to accommodate sloping surfaces or reinforcements, optimizing mold release and minimizing defects.

Simple vs. Complex Shapes

In injection molding, the shape of the product plays a crucial role in determining the parting surface angle1. For simple shaped products such as flat or cylindrical items, the angle is typically set to 0°, aligning perpendicular to the mold opening direction. This simplifies mold structure and ensures smooth demolding. For instance, when molding a simple plastic plate, the draft taper is adjusted on the upper and lower surfaces to facilitate easy release from the mold.

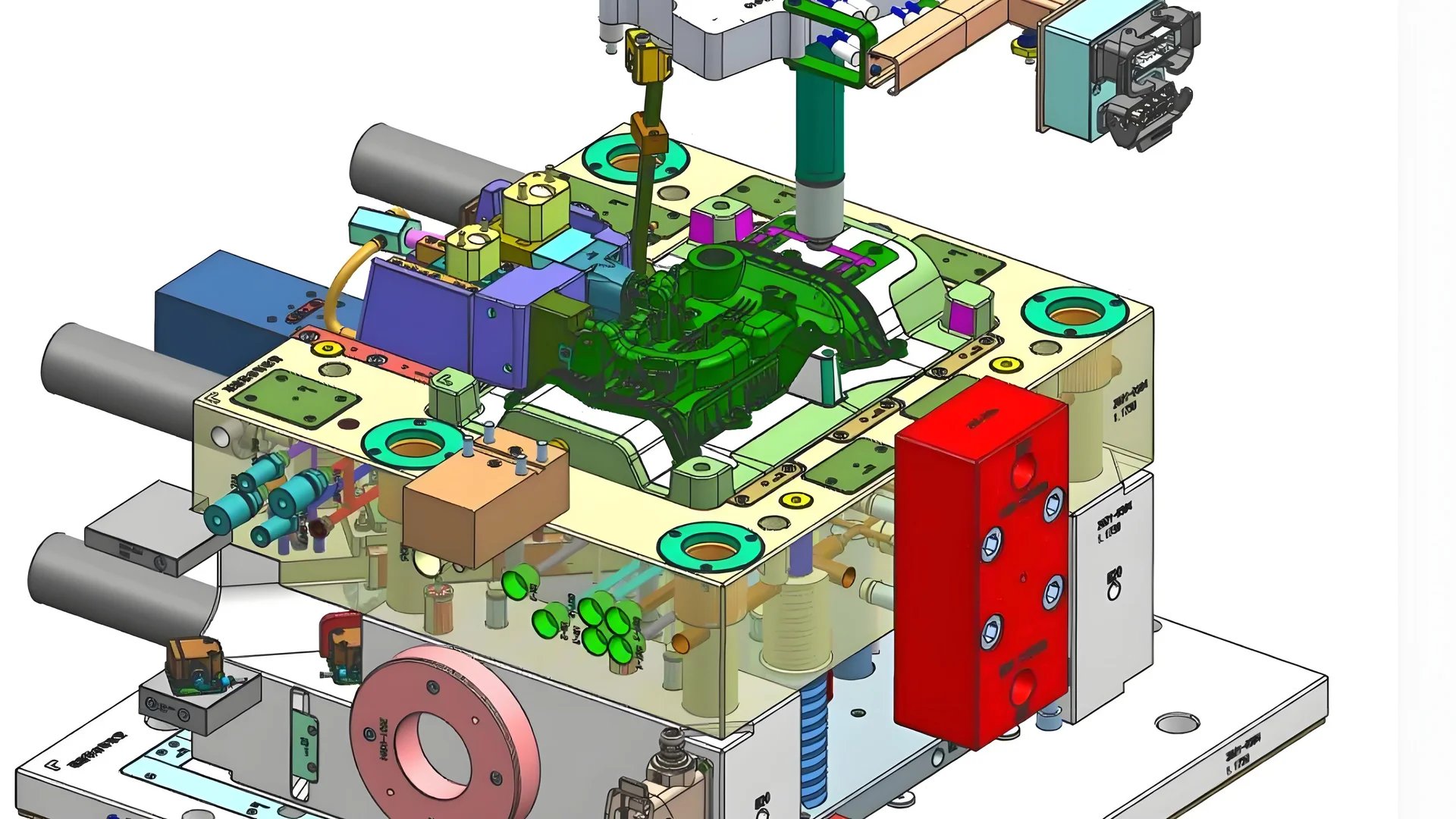

Conversely, complex product shapes demand more careful consideration. Products with sloping surfaces, inverted buckles, or reinforcements necessitate a customized approach to determine parting surface angles. When a product has a tilted outer surface, setting the parting angle perpendicular to this tilt helps in designing an effective mold pulling slope that aids in seamless product demolding. For products with intricate structures, multiple parting surfaces may be required to address varying mold release needs.

Mold Processing and Assembly Factors

Selecting an appropriate parting surface angle isn’t only about product shape but also involves processing considerations2. Mold processing complexity increases with smaller variations in parting angles, affecting CNC machining paths and parameters. Therefore, choosing common angles like 0°, 30°, or 45° can streamline machining and enhance accuracy.

Additionally, assembly accuracy is vital. An optimal parting surface angle ensures that mold parts fit closely during assembly, avoiding excessive gaps that could result in defects like flying edges. In large injection molds, precision in angle selection contributes significantly to maintaining quality standards in assembled products.

Injection Molding Process and Quality

The injection process3 itself is impacted by the parting surface angle. Correct angle selection guides plastic flow direction and pressure distribution within the cavity, crucial for reducing defects such as air traps or fusion marks. Especially for products demanding high aesthetic standards, such as automotive interiors or electronic casings, a well-chosen angle can enhance appearance and performance.

Moreover, smooth product release from the mold hinges on selecting the right angle. The risk of scratches or dimensional deviations increases if the angle doesn’t complement the product’s shape. Thus, understanding how shapes influence angles is vital for achieving quality outcomes in injection molding.

Simple shapes use 0° parting surface angle.True

For simple shapes, 0° angle simplifies mold structure, easing demolding.

Complex shapes always use multiple parting surfaces.False

Complex shapes may require multiple surfaces, but not always; it depends.

Navigating mold processing is tricky, especially with parting surface angles. These angles can significantly impact mold design and product quality, creating unique challenges for engineers. Understanding these hurdles is crucial for optimizing injection molding processes.

Mold processing challenges related to parting surface angles include difficulties in machining, assembly accuracy, and maintaining product quality during demolding. Proper angle selection is essential to ensure smooth production and reduce defects.

Impact of Product Shape and Structural Factors

The complexity of a product’s shape profoundly influences the choice of parting surface angle. For simple shaped products4, like flat or cylindrical items, the angle is typically set at 0°, simplifying mold structure and ensuring easy demolding. For instance, when injection molding a plastic plate, aligning the parting surface perpendicularly facilitates a smoother release.

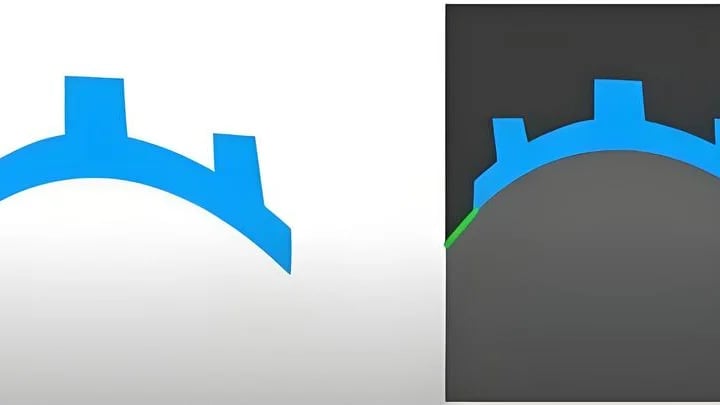

In contrast, complex shapes with sloping surfaces or inverted buckles require more thoughtful angle selection. The parting surface might need to align perpendicularly to the product’s tilted surfaces to support seamless demolding. For intricate designs, multiple parting surfaces might be necessary, each carefully angled based on different sections of the product.

Mold Processing and Assembly Challenges

Processing difficulty is a notable challenge when determining parting surface angles. Variations in these angles can complicate CNC machining, requiring special tool paths and increasing costs. Generally, choosing common angles5 like 0°, 30°, or 45° helps maintain high accuracy and efficiency.

Assembly accuracy is also crucial. The wrong angle can result in gaps or overlaps in molds, causing defects such as flying edges after assembly. Therefore, aligning angles with mold assembly methods is critical to meet accuracy requirements and enhance production outcomes.

Injection Molding Process and Quality Considerations

The angle of the parting surface directly affects the flow direction and pressure distribution of plastics during injection molding. A well-chosen angle guides plastics smoothly into the mold cavity, reducing air traps and fusion marks. For high-quality appearance products, such as automotive parts, this careful consideration can significantly enhance product quality6.

Moreover, the right angle is vital for effective product release and quality assurance. An incorrect angle can cause excessive friction during demolding, leading to surface scratches or dimensional inaccuracies. Ensuring products demold smoothly without damage underlines the importance of selecting suitable parting surface angles in mold design.

Understanding these challenges not only helps in optimizing mold processing but also in achieving higher efficiency and quality in injection molding operations.

Simple shapes use 0° parting surface angle.True

For simple shapes, the parting surface is perpendicular to mold opening.

Complex shapes require multiple parting surfaces.True

Complex shapes may need multiple angles for effective demolding.

Why Is Assembly Accuracy Crucial in Mold Design?

In mold design, precise assembly is not just a preference; it’s a necessity. Learn why.

Assembly accuracy in mold design is critical because it ensures the precise fit of mold components, affecting product quality and production efficiency. Accurate assembly minimizes defects, enhances product integrity, and optimizes manufacturing processes, leading to cost savings and improved product performance.

The Role of Product Shape and Structure

In mold design, the complexity of a product’s shape significantly influences assembly accuracy. For simple shapes like flat or cylindrical products, setting the parting surface at 0° simplifies the mold structure. This angle ensures that the product can be demolded smoothly, minimizing errors. Conversely, complex shapes require more intricate considerations. For instance, products with sloping surfaces or inverted buckles demand tailored parting angles to facilitate easy demolding. Choosing the correct angle can prevent assembly issues7 that compromise the product’s integrity.

Mold Processing and Assembly Challenges

The difficulty of processing molds also ties directly to assembly precision. Selecting an appropriate parting surface angle, such as 0°, 90°, or 45°, helps achieve high machining accuracy. This choice reduces the complexity of CNC machining paths and tools required. Proper angle selection ensures a tight fit between mold halves, preventing gaps that lead to defects like flashing. Therefore, assembly accuracy must be prioritized in mold processing8 to avoid costly adjustments.

Injection Molding Process and Quality Control

Assembly accuracy is pivotal in determining how injection molding impacts product quality. A precise parting surface angle influences plastic flow during injection, ensuring even distribution and reducing defects like air traps or weld lines. This precision is crucial for high-quality appearances in automotive or electronic parts. Moreover, during demolding, accurate assembly prevents product deformation or scratches by ensuring smooth release. Thus, maintaining assembly accuracy aligns with quality assurance9 standards in production.

Simple shapes use 0° parting surface angle.True

For simple shapes, a 0° angle simplifies mold structure and demolding.

Complex shapes always require multiple parting surfaces.False

Complex shapes may need multiple surfaces, but not always; it depends on design.

How Does Parting Surface Angle Impact Injection Molding Quality?

The angle of the parting surface in injection molding is a crucial determinant of product quality, affecting everything from flow direction to demolding efficiency.

The parting surface angle in injection molding influences product quality by affecting flow direction, pressure distribution, and demolding ease. Proper angle selection ensures smooth filling and release, minimizing defects like air traps and scratches. It also impacts mold processing complexity and assembly accuracy.

The Role of Product Shape and Structure

When dealing with simple shapes like flat or cylindrical products, the parting surface is ideally perpendicular to the mold opening, simplifying the mold structure10. This setup aids in easy demolding by ensuring smooth release. Conversely, for complex shapes with tilted surfaces or reinforcements, the angle is tailored to match the product’s specific contours. A perpendicular setup to a tilted surface can simplify demolding in these cases, but may require multiple parting surfaces for intricate designs.

Mold Processing and Assembly Considerations

The angle choice profoundly influences mold processing difficulty. Choosing common angles like 0° or 45° can streamline CNC machining, avoiding complex tool paths that increase costs. Furthermore, assembly accuracy depends on this angle—proper selection ensures tight fitting without excessive gaps, crucial for avoiding defects11 like flashing. In large molds, accurate angles ensure correct positioning during assembly, thereby maintaining quality.

Injection Molding Process and Quality Outcomes

The parting surface angle dictates how plastic flows and fills the mold cavity, impacting injection pressure and direction. A well-matched angle can facilitate even flow, reducing defects such as air traps or weld lines that mar appearance. Products demanding high aesthetic standards, like automotive interiors, benefit from optimal angle choices that enhance both process and product quality. Moreover, during demolding, an appropriate angle minimizes friction and collision with the mold, preventing scratches or dimensional inaccuracies.

Ensuring a product releases smoothly without strain is critical for maintaining its integrity and function. Therefore, selecting a suitable angle is not merely a mechanical consideration but a strategic decision impacting the entire production lifecycle.

Simple shapes require a 0° parting surface angle.True

For simple shapes, the parting surface is usually perpendicular to mold opening.

Complex shapes always use a single parting surface.False

Complex shapes may need multiple parting surfaces for effective demolding.

Conclusion

Choosing the right parting surface angle in injection molding is crucial for product quality, processing efficiency, and smooth demolding, varying between simple and complex shapes.

-

Explores detailed factors linking shapes to surface angles. ↩

-

Discusses machining challenges with varied parting angles. ↩

-

Examines how angles affect molding flow and quality. ↩

-

Explore how simple shapes influence parting surface angles. ↩

-

Discover why certain angles simplify machining processes. ↩

-

Learn how angles affect product quality in molding. ↩

-

Understand common challenges and solutions in complex mold assembly. ↩

-

Explore advanced techniques for achieving precision in mold processing. ↩

-

Learn about standards and practices for ensuring high-quality molds. ↩

-

Explore more about setting parting surfaces for simple shapes. ↩

-

Learn about defects prevented by optimal parting angles. ↩