Welcome back, everyone, to the Deep Dive. This time we're getting microscopic and diving deep into a detail that most people never even think about.

Mold thickness.

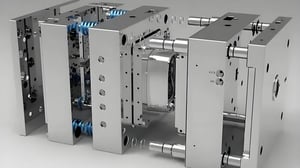

Mold thickness in injection molding. We've got some excerpts from a great.

Article titled how does mold thickness impact the quality of injection molded products?

Catchy. I know. I'm already hooked.

Me too.

So if you're interested in manufacturing, design, or even just how everyday objects are.

Made, you're in the right place.

This deep dive is going to change the way you look at everything plastic. I guarantee it.

Because what we're talking about is a chain reaction. How that initial mold thickness impacts every stage of making a plastic product.

Okay, I'm intrigued. More than just the size of the mold, right?

Way more. It all starts with how the molten plastic cools. Thicker molds act like an insulator.

Ah, so they slow down the cooling.

Exactly. Imagine something simple. A smartphone case with all its different thicknesses.

Yeah, I never thought about that.

No. Imagine it cooling in a thick mold for say, 30 seconds versus just 15 in a thinner one. Those extra seconds, they make a world of difference for precision.

Okay, now I see how those seconds add up. But what happens if it cools too fast or unevenly? Do we get like, plastic blobs?

Well, not blobs exactly, but you can get warping shrinkage parts that just don't fit right.

Oh, I see.

Imagine those tiny plastic gears inside electronics. Even a slight warp could throw the whole thing off.

Yikes. A tiny gear losing a tooth just because it cooled wrong.

Precisely. Suddenly your gadget's useless because of what seems like a tiny error in the molding process.

Crazy. Alright, so cooling speed. What's next in this chain reaction?

Injection pressure. Kind of like squeezing toothpaste into a mold.

Oh, yeah. Makes sense.

The thicker the mold, the more pressure to make sure it fills completely.

I bet getting that pressure right is tricky.

It is too much pressure and you get density variations within the object. Like, say, a big, thick walled container. The center might be super dense, but the edge is weak.

So not just filling the mold, but filling it evenly with the right amount of force.

Yeah.

Is there anything else that can go wrong with too much pressure?

Definitely. Think about those clear plastic containers, you know, with the little bumps and lines.

Oh, yeah, I've always wondered about those.

Sometimes it's because of flying edges. Too much pressure forces out bits of plastic, ruining the smooth finish. You see it a lot with clear plastics.

So that's what causes it. Okay, we've got cooling pressure. What else is there?

Patience. That Pressure needs to be held for a specific time, you know, to let the material properly solidify.

Pressure holding time.

Right. You can't rush it. Like letting a cake cool before frosting. You rush it and it all crumbles.

Good analogy.

In the plastic world, rushing it causes those little dense. You see them on those yogurt containers sometimes.

Sink marks.

Exactly. Sink marks. It makes you wonder how many products we use have these hidden flaws.

Probably tons. But wait, there's more. Right? Internal stress, you said?

Yes, internal stress.

This is getting intense.

Basically, if you rush the cooling or pressure holding, it creates tension within the object. You might not see it right away, but it weakens it over time.

Like the plastic is holding onto all that stress. You can't see it, but it's causing damage.

Exactly. And just like with people that bottled up stress, eventually it causes cracks, warping. Even if it looked fine at first.

So it's like plastic has feelings too.

In a way, it does.

Wild. So how do manufacturers deal with all this? It can't just be trial and error.

Well, there's a lot of science involved. Engineers use software to actually simulate the whole process.

Oh, wow. Real.

Yep. They can virtually test different thicknesses, cooling rates, pressures.

They can see what works best.

Exactly. It lets them optimize the process, catch potential issues before they even make the physical mold.

It's like a matrix for plastic.

Yeah.

So it's not just the mold, it's this whole ecosystem of factors.

Precisely. And, you know, it's not just about avoiding defects either. No, we can actually use mold thickness strategically to create products with specific properties.

So there's like a design philosophy to thickness. Like architects choosing thicker beams for skyscrapers.

That's a great analogy. If you need a product that's extra strong, durable, a thicker mold is often the key.

I'd say, like those heavy duty storage bins.

Exactly. They need to be tough, hold all that weight.

Makes sense. So it's not always about making things thinner and lighter.

Nope. Sometimes that extra thickness is what makes it work.

It gives it superpowers.

Exactly. It all depends on what you want the object to do. Like, some plastics are naturally more brittle.

Ah. So you need a thicker mold to make them stronger.

Right. To prevent them from cracking. It's finding the right balance between the material, what you want, and how the molding process works.

This is so cool. It's like a whole secret language behind everyday objects.

It really is. And we've only just scratched the surface.

Speaking of everyday objects, can we talk about some real world examples? You mentioned storage Bins. What about those?

Sure. Those big plastic bins in garages, workshops. They're designed to hold heavy stuff, so they need to be super strong.

Yeah. I've noticed those bins are made of much thicker plastic than, say, a water bottle.

Right. For a reason. You wouldn't want your toolbox crashing through the bottom, would you?

No, definitely not. That extra thickness really makes a difference.

It's what gives it structural integrity.

Okay, so thicker for strong stuff. What about something like a kid's toy?

Well, with toys, safety is key. So bigger toys, especially for younger kids, manufacturers often use thicker molds to make.

Them tougher, less likely to break.

Exactly. And even with smaller toys, the thickness can create specific features, textures.

I hadn't thought of it.

Like those little figurines with all the details, or toys with moving parts. You need carefully calculated thicknesses for those.

So it's not just overall thickness. It's about varying it in different spots precisely.

Like sculpting with plastic. And this level of precision is super important for things like medical devices.

Oh, yeah. Those need to be perfect.

Absolutely. Think syringes, inhalers, IV components. They have incredibly strict requirements.

Even a tiny variation could be a big deal.

Exactly. That's why mold thickness is so important in medical device design. They use advanced software, super precise techniques.

Make sure those products are safe.

Exactly.

Wow. Mold thickness really is like this hidden language influencing the strength, durability, even the safety of everything.

It really is. It's this unseen world of precision silently shaping the world around us.

I'm telling you, the more we learn about this, the more amazing it gets.

It's one of those things you never really think about it until you do.

Exactly. And now I feel like I can't not think about it. Every time I pick up something plastic, I'm going to be thinking about the mold, the cooling, the pressure, all of it.

I hope you do. That's the goal, right? To make people more aware of the amazing engineering behind everyday things.

Absolutely. So to wrap up, is there any last bit of wisdom you want to leave our listeners with? Anything they should keep in mind when they encounter their next plastic? What's it?

Well, just remember that mold thickness, it's not just some random detail.

It's had a ripple effect.

It really does. It affects everything. The strength, the durability, how safe the product is.

So the next time you're holding something plastic, take a moment to appreciate all the thought and engineering that went into.

Making it, maybe even think about how thick the plastic is, what that tells you about how it's meant to be used.

You know, you've given us a whole new way to see the world. Even just walking down the grocery aisle is going to be different now.

Haha. I hope so. Knowledge is power, right?

It definitely is. A huge thank you to our expert for guiding us through this deep dive into the mind blowing world of mold thickness.

Happy to be here.

And to our listeners, thanks for joining us. Keep those brains buzzing, keep asking questions and we'll see you next time on the Deep Dive.

See