Are you ready to explore the interesting world of plastic injection mold production with me? Let’s look into the important stages together!

The key steps in plastic injection mold manufacturing include mold design, material selection, processing methods, and quality checks, each crucial for efficient production and high-quality results. This overview offers insights and practical tips to enhance mold manufacturing processes.

As I think back on my journey through this complex process, I remember the thrill of seeing a mold design become real. Mold design and material choice are crucial for both function and beauty. Each step is very important. I guide you in understanding mold assembly details. Cooling systems hold great importance. Quality control measures play a critical role. Together, we explore how these elements blend to create top-notch products. High-quality products are our goal.

Mold design is the first step in injection mold manufacturing.True

Mold design is indeed the initial step, setting the foundation for the entire injection molding process.

Quality control measures are optional in mold manufacturing.False

Quality control is essential in mold manufacturing to ensure product reliability and performance, making it not optional.

What Should I Consider When Designing Molds?

Mold design is not just technical. It is a creative journey. The process requires a delicate balance of art and science. I invite you to discover the key considerations for crafting molds. Molds need to deliver exceptional results in manufacturing. This journey is fascinating!

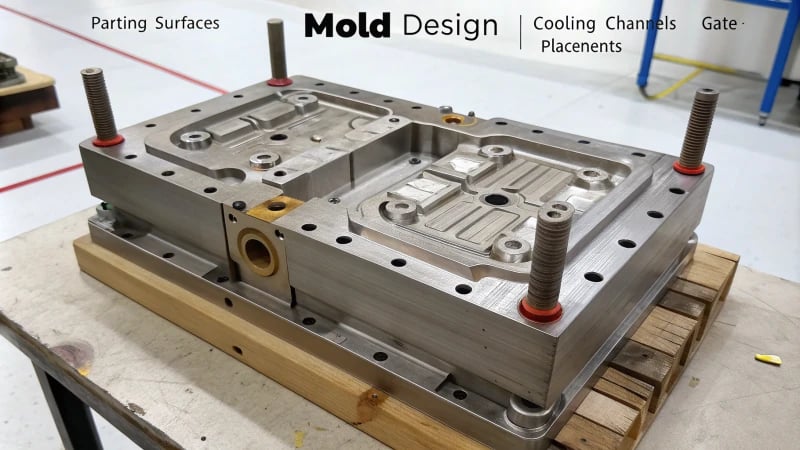

Consider parting surface configuration, cavity/core structure, gate placement, cooling systems, and material selection. Precise manufacturing is crucial for optimal mold performance and high product quality.

Understanding Mold Design Basics

Mold design feels like solving a puzzle. Each piece must fit perfectly to show the complete picture. It’s not just about creating shapes; it’s about making sure these shapes work well in real situations.

Parting Surface Design

I always start with the parting surface. This is the line that divides the mold’s cavity and core. A good parting surface allows for easy removal of the product. Factors to consider include:

- Appearance: For products with high aesthetic standards, the parting surface should be positioned to minimize visible seams.

- Shape: This can be a flat plane, slope, or curve, depending on what I’m creating.

For example, parting surface types1 can significantly influence production outcomes.

Once, I struggled with a tough design where the parting was crucial for appearance. Figuring out how to place it well changed everything! You wouldn’t believe how much easier things got after that.

Cavity and Core Design

Next is the cavity and core design. The cavity shapes the outside while the core forms the inside features. Key considerations include:

- Wall Thickness: Must adhere to product specifications to ensure durability.

- Complex Features: Ribs and undercuts require special mechanisms for effective demolding, such as sliders or inclined tops.

A practical example would be designing cores for products with internal threads that need rotational ejection methods. Refer to core design mechanisms for more insights.

Gate Design

Gates are where molten plastic enters the mold cavity. Choosing the right gate affects product fill, quality and look. Here’s an overview of gate types:

| Gate Type | Description | Suitable For |

|---|---|---|

| Side Gates | Positioned on the side, allowing for good flow control. | Thick-walled products |

| Point Gates | Ideal for thin-walled products with high appearance needs. | High-quality aesthetic requirements |

| Latent Gates | Hidden from view, reducing visible imperfections. | Complex shapes needing aesthetic care |

Choosing smartly here has probably saved me from many problems later!

Cooling System Design

A good cooling system is vital for efficient production. Experience shows that cooling channels near surfaces help even cooling to prevent warping—a lesson I learned painfully! For large flat products, parallel channels provided consistent cooling speeds which minimized defects a lot. Explore cooling channel layouts2 for further understanding.

Mold Manufacturing Process

The manufacturing process is like conducting a symphony; each step contributes to final quality and efficiency of the mold.

Mold Material Selection

Selecting materials is key. I often choose between P20 Steel for general use and H13 Steel for precise work due to its strength after heat treatment. Common materials include:

- P20 Steel: Good for general-purpose molds.

- H13 Steel: Excellent for high-precision applications due to its toughness after heat treatment.

For example, H13 steel reaches hardness levels of 48-52 HRC after processing—quite amazing! Check out mold material properties3 for more details.

Processing Technology

I use different technologies for mold creation:

- CNC Machining: Perfect for shaping complex molds precisely using programmed machines.

- Electrical Discharge Machining (EDM): Great for creating detailed shapes where traditional methods fall short.

- Wire Cutting: Essential for high precision 2D shapes.

When I used CNC machining, changes in surface finish and accuracy were outstanding! Learn more about CNC advantages4 to maximize efficiency.

Mold Assembly and Debugging

After creating components, assembly and debugging are very vital.

Mold Assembly

during assembly matching accuracy is crucial; this makes sure everything works right. Controlled clearances between parts (typically 0.03-0.08mm) are vital for accuracy and good appearance.

Mold Debugging

after assembly I test on an injection molding machine to find issues like flashing or shrinkage—each test provides great insights into needed changes such as clamping force or holding pressure!

Once I saw flashing during a trial; adjusting clamping force changed everything helping produce high-quality products! Review debugging techniques5 to enhance product quality and production efficiency.

A well-designed parting surface minimizes visible seams.True

Properly positioning the parting surface can enhance product aesthetics by reducing visible seams, which is crucial for high-quality visual standards.

Cooling systems have no impact on mold production efficiency.False

Cooling systems are essential in mold design as they ensure uniform cooling, preventing warping and defects, thus improving production efficiency.

How Do Material Choices Affect Mold Performance?

Do you ever think about how the materials we select affect the end result in injection molding? It’s interesting how a simple choice impacts everything from product quality to manufacturing efficiency. Let’s explore this complex connection together!

Choosing the right mold material, such as P20 or H13, enhances durability, heat resistance, and machinability, boosting production efficiency and product quality.

Understanding Mold Material Selection

Material choices are very important for mold performance in injection molding. They really influence the final product a lot. When I first entered this field, I was surprised by the number of choices. Each material comes with its unique properties and uses. Understanding these differences is crucial.

Mold materials must be chosen based on several factors, including the type of plastic being molded, production volume, and precision requirements. Common materials include:

| Material Type | Properties | Applications |

|---|---|---|

| P20 | Good toughness, moderate wear | General purpose molds |

| H13 | High hardness, heat resistance | High precision, high-output molds |

| Aluminum | Lightweight, good thermal conductivity | Prototype molds |

For instance, H13 steel6 is often used for high-precision injection molds due to its excellent performance characteristics after heat treatment.

Impact of Material Properties on Mold Performance

The materials we select greatly affect how molds work. In my experience, three important properties stand out:

- Wear Resistance: Important for durability, especially in high-volume production. H13 made a big difference in a project where longevity was vital.

- Thermal Conductivity: Plays a huge role in cooling efficiency. Molds with very good thermal conductivity shorten cycle times. It’s like speeding up production.

- Machinability: Materials that are easier to machine save time and money. These selections have helped me meet deadlines while keeping top quality.

Choosing a material with a balance of these properties will ensure optimal performance. For example, wear resistance in mold design is critical for maintaining mold integrity over time.

The Role of Cooling Systems in Mold Material Performance

Cooling system design is closely tied to the mold material. A good cooling system prevents defects like warping and shrinkage.

For example:

- High thermal conductivity materials use complex cooling channels. They maximize heat dissipation.

- Less conductive materials need larger channels for even cooling.

Conclusion on Material Choices

Selecting the proper mold material touches many aspects of performance. From durability to production efficiency, understanding these factors helps me make smart decisions that raise overall product quality. I often think of those who struggle with their designs. I wish I could share these insights because they really matter!

Material selection directly influences mold durability.True

Choosing the right material enhances mold durability, impacting long-term performance in production processes.

H13 steel is ideal for low-precision molds.False

H13 steel is best suited for high-precision molds due to its excellent properties, not low precision.

How Can Advanced Processing Technologies Revolutionize Mold Production?

Do you wonder how technology is changing mold creation? Let’s explore new ideas that speed up mold production. Technology helps produce molds quickly. These molds have better quality and efficiency now.

Advanced processing technologies like 3D printing and CNC machining revolutionize mold production by enhancing efficiency, accuracy, and quality, offering essential tools for competitive advantage in the industry.

On My Path as a Designer

On my path as a designer, I often stand between creativity and accuracy. This is especially true in mold production. Embracing advanced technologies has truly changed my workflow. It has also revealed a world of possibilities. These technologies transform mold production in many ways. They bring mold processes to a very new level.

1. Advanced Processing Technologies

Advanced processing technologies play a pivotal role in enhancing efficiency, precision, and the overall quality of molded products. Here, we will delve into some of these technologies that can significantly improve mold-making processes.

2. 3D Printing in Mold Design

3D printing has revolutionized the mold design landscape. This technology allows designers to create complex geometries that are often impossible to achieve with traditional methods. For instance, designers can use 3D printed molds7 to produce prototypes quickly, allowing for faster iterations and testing of designs before full-scale production.

- Benefits of 3D Printing:

- Reduces lead times for mold creation.

- Enables customization of mold features, such as cooling channels.

- Lowers material waste during the production process.

3. CNC Machining

CNC (Computer Numerical Control) machining remains a cornerstone of modern mold production. This technology allows for high precision and repeatability in creating complex parts.

- Key Features of CNC Machining:

- Precision control over machining operations.

- Ability to create intricate shapes and fine details.

- Capability to use various materials, including metals and plastics.

| Feature | CNC Machining | Traditional Machining |

|---|---|---|

| Precision | High | Moderate |

| Complexity | High | Low |

| Lead Time | Short | Longer |

4. Electrical Discharge Machining (EDM)

EDM is particularly effective for producing molds with intricate designs or hard materials. It operates by using electrical discharges to erode material.

- Applications of EDM:

- Perfect for deep holes or narrow grooves.

- Achieves high surface finishes for complex geometries.

The precision achieved through EDM can greatly enhance the functionality of molds, particularly in sectors requiring high tolerances, such as automotive or aerospace.

5. Automation and Robotics

Automation in the mold-making process can lead to increased production rates and reduced labor costs. Robotic systems can handle various tasks, from assembly to inspection, with consistent accuracy.

- Advantages of Automation:

- Increases throughput by reducing cycle times.

- Enhances consistency and reduces human error.

- Allows for continuous operation, increasing overall productivity.

6. Advanced Cooling Systems

Innovative cooling technologies are crucial for efficient mold production. Enhanced cooling systems can significantly decrease cycle times and improve product quality.

- Examples of Cooling Innovations:

- Use of conformal cooling channels designed through simulation software8 to optimize heat transfer.

- Implementation of temperature control systems that adjust cooling rates dynamically based on real-time data.

3D printing reduces lead times in mold creation.True

3D printing allows for faster mold production, enabling quicker iterations and testing of designs, thus significantly reducing lead times.

CNC machining offers lower precision than traditional methods.False

CNC machining provides high precision and repeatability, surpassing traditional machining methods in accuracy and detail.

What Are the Best Practices for Quality Control in Mold Manufacturing?

I have traveled the journey of mold manufacturing. Quality control beats as the heart of our craft. Let’s explore the best practices. These practices not only raise the level of our products but also help us feel proud. We feel proud of what we create.

Implement strict dimensional checks, enhance surface quality with post-processing, and utilize simulation software for structural assessment in mold manufacturing to ensure reliable, high-performing products.

Understanding Quality Control in Mold Manufacturing

Quality control (QC) in mold manufacturing is crucial for ensuring that the final products meet specified standards. It encompasses a range of practices and methodologies to maintain high quality throughout the manufacturing process.

Key aspects include:

-

Dimensional Accuracy Control

Accurate mold dimensions are vital as they directly influence product fit and performance. Using high-precision tools such as calipers and micrometers is essential for measuring key dimensions, ensuring they stay within the ±0.05mm tolerance range. -

Surface Quality Control

The surface finish of molds impacts the aesthetics and functionality of the molded products. Post-processing treatments like polishing can help achieve the desired roughness values, such as Ra 0.8 – 0.2μm for visually critical surfaces.

Check out this guide on mold surface treatments9 for more details. -

Strength and Rigidity Control

Molds must withstand significant pressure during injection molding. Hence, analyzing structural integrity using simulation software can ensure designs are robust, preventing failures during production. Consider reinforcing large templates to enhance performance.

Best Practices for Quality Control

Implementing effective quality control in mold manufacturing can be broken down into several best practices:

| Practice | Description |

|---|---|

| Regular Inspections | Conduct frequent checks using precision measuring tools to verify dimensional accuracy. |

| Process Monitoring | Use statistical process control (SPC) techniques to monitor critical parameters in real-time. |

| Employee Training | Ensure that all staff are well-trained in quality standards and practices relevant to mold manufacturing. |

| Documentation | Maintain detailed records of inspections and adjustments made during the manufacturing process. |

| Feedback Mechanism | Establish a system for gathering feedback from production staff to continuously improve QC practices. |

These practices not only enhance the quality of the molds produced but also improve overall production efficiency.

Quality Control Tools and Techniques

Utilizing various tools and techniques can further bolster quality control efforts:

- Computer Numerical Control (CNC): This technology enables precise machining of mold components, ensuring adherence to design specifications.

- Electrical Discharge Machining (EDM): Ideal for creating complex shapes, EDM allows for high precision in critical areas.

- Wire Cutting: This technique is useful for achieving high precision in flat mold components, thus improving dimensional accuracy.

To learn more about EDM processes, refer to this comprehensive resource10.

Continuous Improvement in QC Practices

To sustain high-quality standards, it’s essential to foster a culture of continuous improvement. Implementing feedback loops and regularly reviewing QC measures can help identify areas for enhancement, adapting to new technologies and methodologies over time.

In summary, the best practices for quality control in mold manufacturing involve a blend of careful planning, precise execution, and an ongoing commitment to improvement. By focusing on these areas, manufacturers can ensure that they consistently produce high-quality molds that meet industry standards.

Dimensional accuracy is crucial in mold manufacturing.True

Maintaining precise dimensions ensures product fit and performance, which is vital in mold manufacturing.

Employee training is unnecessary for quality control.False

Proper training for staff is essential to uphold quality standards in mold manufacturing processes.

Conclusion

Explore the key steps in plastic injection mold manufacturing, including design, material selection, processing methods, cooling systems, and quality control for optimal product quality.

-

This link provides a comprehensive guide on best practices in mold design, enhancing your understanding of the topic. ↩

-

Explore innovative cooling system designs that improve production efficiency in molding. ↩

-

Find detailed insights into material selection for molds to enhance durability and performance. ↩

-

Learn about CNC machining advantages that can significantly impact your mold design projects. ↩

-

Get expert tips on effective debugging techniques to ensure mold quality during production. ↩

-

This link provides insights on choosing the right materials for mold making, enhancing your understanding of their implications on performance. ↩

-

Explore this link to uncover essential techniques that can elevate your mold production processes and keep you ahead in the industry. ↩

-

Learn about cutting-edge CNC machining practices that ensure your molds meet the highest standards of precision and efficiency. ↩

-

This link provides valuable insights into effective quality control methods that can enhance your manufacturing processes. ↩

-

Explore this resource to gain knowledge on CNC machining techniques that improve mold accuracy. ↩