All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are Injection Speed and Injection Pressure?

Understanding injection speed and injection pressure is vital for anyone involved in injection molding. These parameters significantly influence product quality, manufacturing efficiency, and equipment longevity. In this article, I’ll share insights into how these factors interact and affect the final ...

MANUFACTURING

Are Plastic Injection Molded Parts Strong and Durable?

In the world of manufacturing, plastic injection molded parts are a staple due to their adaptability and cost-effectiveness. However, their strength and durability depend on various factors such as plastic type, molding processes, and mold design. This article explores these ...

Materials Recommendations

What Are the Key Differences Between Rigid and Plasticized PVC in Injection Molding?

Choosing the right type of PVC for injection molding can significantly impact the performance and durability of your products. In this article, I will explore the key differences between rigid and plasticized PVC, focusing on their physical properties, processing performance, ...

Materials Recommendations

Is Aluminum a Suitable Material for Injection Molds?

As I dive into the world of injection molding, I've found aluminum to be a fascinating option. It boasts unique properties that can significantly enhance production efficiency. Yet, there are crucial aspects to consider before making it your go-to material. ...

Materials Recommendations

How Do ABS, PP, and PVC Differ in Injection Molding?

Understanding the distinctions between ABS, PP, and PVC is crucial for effective injection molding. Each material brings unique properties that influence performance, cost-effectiveness, and suitability for various applications. Dive in to discover what makes each one stand out.

Materials Recommendations

What Causes Porosity in Injection Molded Plastic Products?

Porosity in injection molded plastics can lead to significant quality issues, such as weakened structures and potential failures. Understanding the causes—ranging from material choice to process adjustments and mold design—is crucial for manufacturers looking to enhance product integrity. This article ...

OPTIMIZATION

How Do Injection Molding Machines Produce EVA Products?

The intricate process of crafting EVA products using injection molding machines is both fascinating and essential for many industries. By managing temperature, mold design, and injection parameters carefully, manufacturers can harness EVA's unique properties to create high-quality products that meet ...

MANUFACTURING

How Can You Improve Injection Mold Change Efficiency?

Improving injection mold change efficiency is crucial for manufacturers aiming to boost productivity and minimize downtime. This guide delves into the essential steps, optimization techniques, and collaborative strategies that can transform your operations. Discover how thorough preparation, process optimization, and ...

DEVELOPMENT

How Can a Well-Planned Injection Mold Maintenance Schedule Boost Production Efficiency?

In the fast-paced world of manufacturing, staying ahead means maximizing efficiency, especially in injection molding. A solid maintenance schedule is not just about keeping machines running; it’s about enhancing production quality and longevity while saving costs. Let’s explore how a ...

DEVELOPMENT

What Are the Key Design and Quality Considerations for Injection Molded Sports Equipment?

When it comes to designing and manufacturing injection molded sports equipment, several key considerations must be addressed. From material selection to structural design, surface quality, and dimensional accuracy, these factors play a vital role in ensuring that the final product ...

DESIGN

What Are the Safety Standards and Technical Challenges in Food Packaging Injection Molded Products?

Navigating the world of food packaging can be daunting. Understanding the safety standards that govern materials and production processes is crucial for ensuring consumer safety. This article explores raw material standards, sanitary controls, production processes, and innovative technologies that are ...

Materials Recommendations

What Makes the Design and Manufacturing Process of Cosmetic Packaging Injection Molded Products Exquisite?

Cosmetic packaging is not just a container; it's an art form that encapsulates beauty. Through the lens of injection molding, we explore the exquisite designs that captivate consumers while ensuring functionality. From material selection to quality control, discover how each ...

MANUFACTURING

Is Plastic Injection Molding a Profitable Business Opportunity?

Venturing into the plastic injection molding business offers exciting potential for profit. With global demand for plastic products on the rise, this industry presents numerous growth opportunities. However, challenges such as competition and high equipment costs persist. Success depends on ...

MANUFACTURING

What Are the High Performance Requirements for Injection Molded Products in Aerospace?

In the aerospace industry, the stakes are incredibly high, and every component must perform flawlessly under extreme conditions. Injection molded products are no exception. They must meet stringent performance requirements to ensure safety and reliability in flight. This blog explores ...

MANUFACTURING

How Does the Injection Mold-Making Process Work?

Understanding the injection mold-making process is vital for anyone in manufacturing. It encompasses various stages, from product design analysis to mechanical processing, ensuring high-quality molds. This article dives deep into each step, highlighting the intricacies of this fascinating manufacturing technique.

MANUFACTURING

What Are the Unique Applications of Injection Molding Technology in the Toy Industry?

Injection molding technology is a game-changer in the toy industry, revolutionizing how toys are designed, manufactured, and brought to market. This blog explores the unique applications of this technology, highlighting its impact on innovative design, material selection, and sustainable production ...

MANUFACTURING

How Can You Adjust Injection Molding Parameters to Reduce Defective Rates?

Injection molding is more than just a manufacturing process; it’s an art form that requires meticulous attention to detail. By fine-tuning parameters such as temperature, pressure, speed, and timing, I have seen firsthand how we can dramatically reduce defective rates ...

OPTIMIZATION

How Can You Prevent Material Degradation in Injection Molding?

In the world of injection molding, ensuring material integrity is vital for producing high-quality products. Material degradation can severely impact the appearance, performance, and longevity of the final product. This article explores essential strategies to prevent degradation and enhance manufacturing ...

OPTIMIZATION

What Are the Causes and Solutions for Insufficient Mold Clamping Force?

Facing challenges with mold clamping force in your injection molding operations can be frustrating. However, understanding the root causes is the first step to finding effective solutions. From mold design issues to incorrect machine settings, this guide will explore common ...

OPTIMIZATION

How Can You Accurately Estimate Injection Molding Costs?

Understanding the cost structure of injection molding is crucial for manufacturers and designers aiming to budget efficiently for production projects. This guide explores the essential factors that influence costs and provides effective estimation methods to help manage budgets wisely.

Price Evaluation

What Are the Key Points of Process Control for Transparent Injection Molding Products?

Creating flawless transparent injection molded products is a blend of art and science. By focusing on raw material purity, mold design, injection parameters, and post-processing techniques, manufacturers can achieve exceptional clarity and quality in their products. This guide explores the ...

MANUFACTURING

What Are the Challenges and Opportunities of Environmental Protection in Injection Molding?

Injection molding is crucial in manufacturing, but its environmental impact raises significant concerns. This article delves into the challenges and opportunities faced by companies navigating sustainable practices in injection molding, including material selection, technological advancements, energy efficiency, and supportive policies.

DEVELOPMENT

What Are the Best Methods to Optimize Injection Molding Cycles?

Optimizing injection molding cycles is crucial for manufacturers aiming to enhance efficiency and reduce costs. This article explores various strategies, including mold design, material selection, cooling system enhancements, and the importance of operator training, to ensure a seamless production process ...

DEVELOPMENT

What Are the Common Problems and Solutions in Small Batch Injection Molding Production?

Navigating the intricate world of small batch injection molding can feel like walking a tightrope. From high costs to quality control issues, understanding the common challenges—and their solutions—is crucial for efficient production. Let’s dive into the most pressing issues and ...

OPTIMIZATION

What Are the Solutions to Demolding Problems in Complex Structure Injection Molding?

Demolding challenges in injection molding of complex structures can significantly impact production efficiency and product quality. Understanding these challenges and implementing effective solutions is crucial for manufacturers. From optimizing mold design to improving surface quality, this article explores comprehensive strategies ...

DEVELOPMENT

What Types of Injection Molded Plastic Are Recyclable?

Injection molding is a staple in plastic manufacturing, but its environmental footprint is significant. Understanding which types of injection molded plastics can be recycled is crucial for reducing waste and promoting sustainability. This article explores the recycling processes, benefits, and ...

Materials Recommendations

What Are Effective Ways to Reduce Stress Concentration in Injection Molding?

Injection molding is a critical manufacturing process that often faces challenges with stress concentration, leading to defects like cracking and deformation. Understanding how to effectively manage this issue through material selection, mold design, and process parameters is essential. This article ...

OPTIMIZATION

How Does Plastic Fluidity Affect Injection Molding and How Can It Be Controlled?

Understanding plastic fluidity is essential for optimizing injection molding processes. It directly influences filling performance, product quality, and production efficiency. This guide explores how to control fluidity through material selection, process parameters, and mold design for improved manufacturing outcomes.

DEVELOPMENT

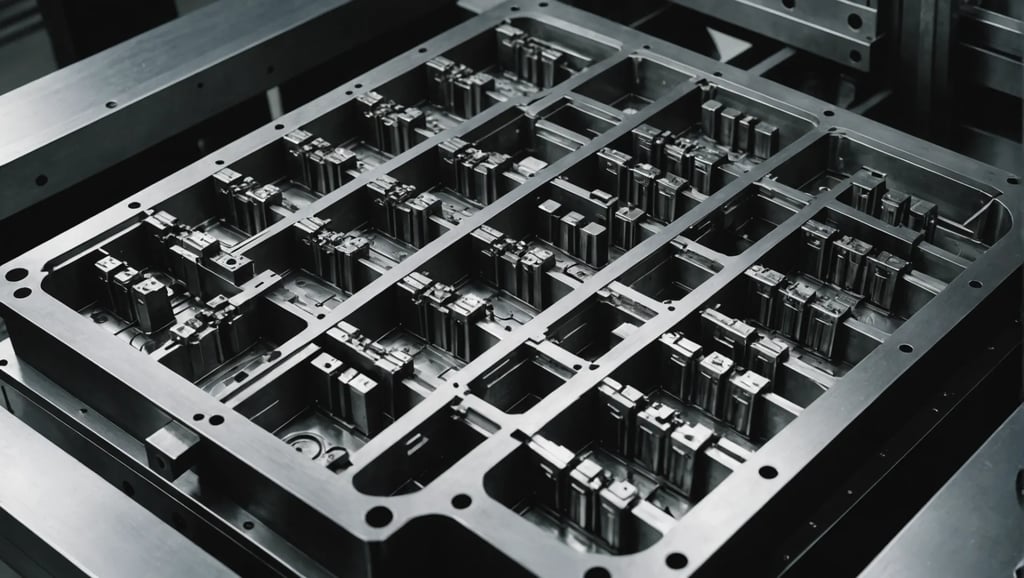

What Are the Best Strategies to Optimize Filling Balance in Multi-Cavity Molds?

Achieving optimal filling balance in multi-cavity molds is essential for high-quality injection molding processes. By focusing on runner and gate design, process parameter adjustments, and rigorous equipment maintenance, manufacturers can significantly improve both product quality and operational efficiency.

DEVELOPMENT

What Are the Causes and Preventive Measures for Mold Sticking in Injection Molded Products?

Mold sticking in injection molded products poses a significant challenge for manufacturers, impacting efficiency and product quality. Understanding the underlying causes—such as mold design flaws, improper process parameters, and unsuitable material choices—is crucial. This article explores effective preventive measures to ...

DEVELOPMENT