Ever feel like you’re drowning in the details of mold design?

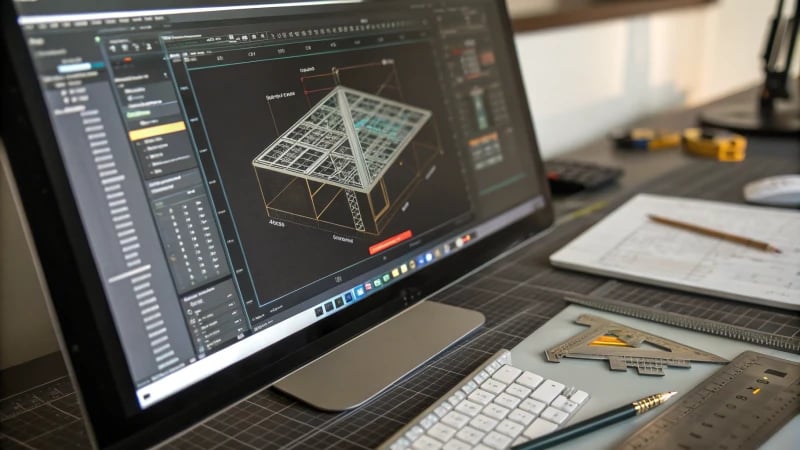

Integrating CAD/CAM technology into mold design enhances accuracy, reduces errors, and streamlines production, enabling designers to create precise and intricate molds that meet high-quality aesthetic and functional requirements.

When I first dabbled with CAD/CAM, it felt like unlocking a whole new dimension of possibilities. This isn’t just about convenience; it’s about transforming your entire approach to design. Imagine spending less time double-checking details and more time innovating. Dive into how CAD/CAM can elevate your workflow with real-world applications and tips that have made all the difference for seasoned designers like us.

CAD/CAM reduces mold design errors significantly.True

CAD/CAM automates and refines processes, minimizing human errors in designs.

Using CAD/CAM increases mold production time.False

CAD/CAM streamlines processes, thus reducing the time needed for production.

- 1. How Does CAD/CAM Transform Mold Design?

- 2. How does CAD/CAM technology improve design precision?

- 3. What Are Common Challenges When Integrating CAD/CAM?

- 4. How Can CAD/CAM Reduce Production Errors in Mold Design?

- 5. How Can You Get the Most Out of CAD/CAM Tools?

- 6. How Do CAD/CAM Innovations Impact Future Mold Design Trends?

- 7. Conclusion

How Does CAD/CAM Transform Mold Design?

Ever wondered how seasoned mold designers achieve such precision and speed? Let me take you through the incredible world of CAD/CAM, where designing molds becomes a seamless blend of creativity and technology.

CAD/CAM revolutionizes mold design through precision, reduced lead times, enhanced accuracy, and improved collaboration, boosting workflow efficiency and innovation.

Precision and Accuracy in Mold Design

When I first started using CAD/CAM, I was blown away by how it transformed my design accuracy. Imagine being able to craft every detail of a mold design1 with pinpoint precision, knowing that even the most intricate designs would come out exactly as planned. It’s like having a superpower in your toolbox that minimizes human error and ensures quality standards are consistently met. I remember the first time I used CAD to refine a complex design; it felt like magic seeing the precise lines come together on my screen.

Streamlined Design Process

Before CAD/CAM, modifying designs was often a frustrating, time-consuming affair. Now, it’s like having a fast-forward button for creativity. I can easily tweak and iterate on designs without having to start from scratch—saving both time and my sanity. Plus, the seamless integration from CAD to CAM makes transitioning to manufacturing almost too easy. It’s incredible how much faster products reach development with these tools.

| Traditional Design | CAD/CAM Design |

|---|---|

| Manual adjustments | Automatic updates |

| Longer lead times | Shorter cycles |

| Higher error rates | Enhanced accuracy |

Cost-Effectiveness

Let’s talk money—because CAD/CAM is a game-changer here too. By cutting down on material waste and streamlining production, costs have dropped significantly. Imagine catching potential design flaws before they hit the production line—that’s fewer expensive fixes later. For me, the cost savings have been one of the most tangible benefits of adopting this technology.

Improved Collaboration and Innovation

One of the things I love most about CAD/CAM is how it brings teams together. With collaborative features, it’s like working in a virtual studio where ideas flow freely. My team and I can work on projects simultaneously, refining ideas in real-time. This has not only improved communication but also sparked innovation, allowing us to align more closely with project goals through collaborative design platforms2.

Enhanced Visualization and Simulation

Visualization and simulation capabilities were something I didn’t know I needed until I had them. They offer a full view of projects, letting me test different scenarios before manufacturing starts. It’s like having a crystal ball that shows potential issues early on, which boosts design efficiency3 and encourages bold experimentation.

By weaving these technologies into our processes, we’re not just keeping up—we’re setting the pace for innovation and staying competitive in the market.

CAD/CAM reduces lead times in mold design.True

The integration of CAD/CAM allows for a seamless transition from design to manufacturing, reducing lead times.

Traditional mold design is more cost-effective than CAD/CAM.False

CAD/CAM reduces material waste and detects design flaws early, leading to cost savings.

How does CAD/CAM technology improve design precision?

Ever felt like you’re on a creative rollercoaster, trying to balance imagination with precision? CAD/CAM technology is like that steady hand guiding you through each loop, bringing both accuracy and efficiency into your designs.

CAD/CAM technology improves design precision by automating complex calculations and creating accurate digital models, allowing designers to visualize and test ideas with reduced errors, ensuring designs meet exact specifications.

Automated Precision in Calculations

I remember the early days when I had to manually calculate dimensions for molds—hours spent double-checking figures. Now, with CAD (Computer-Aided Design) software, those complex calculations are automated with incredible accuracy, making human errors almost a thing of the past. It’s like having a calculator with a mind of its own. By automating geometry creation and dimensioning, I can focus more on the creative aspects4 of design rather than getting bogged down in tedious manual adjustments.

Realistic Simulations and Testing

I once worked on a project where the material seemed perfect on paper but failed during physical testing. With CAD‘s detailed simulations, I can now test stress points and material properties beforehand, saving both time and resources. It’s like having a crystal ball that shows you exactly how your design will perform under various conditions.

| Feature | Benefit |

|---|---|

| Stress Analysis | Identifies weak points early |

| Material Property Testing | Ensures suitability of materials |

Integration with CAM for Seamless Production

After perfecting a design in CAD, the seamless transition to CAM (Computer-Aided Manufacturing) feels like magic. The precise digital models are translated into instructions for manufacturing equipment, ensuring the final output is a true reflection of my design—down to the tiniest detail.

Enhanced Visualization and Collaboration

Thanks to 3D modeling capabilities in CAD, visualizing the final product has never been easier. It’s like watching a blueprint come to life, helping everyone involved—from stakeholders to team members—grasp the design intent clearly. Plus, collaboration5 becomes a breeze when multiple users can work on the same model simultaneously, ensuring consistency throughout.

Examples from Various Industries

- Dentistry: I’ve seen how digital impressions and CAD/CAM crown fabrication drastically reduce chair time while increasing precision.

- Automotive: Ensuring parts fit together perfectly enhances both safety and performance.

- Consumer Electronics: This tech facilitates miniaturization without sacrificing functionality.

Embracing CAD/CAM technology in design not only boosts precision but also accelerates production timelines and reduces error-related costs. As more industries adopt these technologies, the horizon for innovation and improvement seems limitless. Every project feels like an opportunity to redefine what’s possible in design.

CAD software automates geometry creation.True

CAD software automates geometry creation, reducing manual errors.

CAM technology increases production errors.False

CAM technology reduces production errors by following precise instructions.

What Are Common Challenges When Integrating CAD/CAM?

Ever felt like you’re wading through a digital swamp when integrating new tech into your workflow? You’re not alone!

Common challenges in CAD/CAM integration include software compatibility, data transfer issues, the need for skilled personnel, high costs, and system maintenance, all of which impact manufacturing efficiency.

Software Compatibility Issues

When I first started diving into CAD/CAM systems, I remember the headache of software compatibility. It was like trying to piece together a jigsaw puzzle with pieces from different sets. Each application seemed to speak its own language, leading to frustrating data conversion errors or, worse, losing critical information altogether. That’s why I’ve learned the importance of choosing software solutions6 that support industry-standard formats. It’s kind of like making sure all your friends are on the same group chat platform—no more missed messages!

Data Transfer and Management

Another hurdle that I’ve tripped over more times than I’d like to admit is data transfer. Inconsistent data is the nemesis of any designer—just one glitch can lead to costly manufacturing errors or drag out production times. I’ve found that implementing robust data management strategies and leveraging cloud-based platforms can facilitate smoother7 transitions from design to production. Imagine the relief of having everything synced and ready to go, just like having your playlist ready before a long drive.

| Challenge | Solution |

|---|---|

| Data loss | Use standard file formats |

| Inconsistent data | Cloud-based data management |

Need for Skilled Personnel

Finding skilled personnel is another battle. Early in my career, I quickly realized that knowing just the basics of CAD or CAM wasn’t enough. The systems are complex and require hands-on experience. Investing in training programs has been a game-changer for me and my team. Offering ongoing training8 helps bridge the skill gap and keeps us all sharp—kind of like going back to school but way more fun!

High Costs and Maintenance

Then there’s the cost issue—oh boy! Integrating CAD/CAM systems can hit hard on the wallet with software fees and high-performance hardware needs. Plus, regular maintenance to prevent downtime is crucial. I’ve learned that investing in cost-effective solutions9 and scheduling maintenance is vital. Think of it like regular oil changes for your car; it might seem like an added expense, but it saves you from bigger problems down the road.

By tackling these challenges head-on, I’ve been able to optimize my workflows and boost productivity significantly. Each step in the integration process requires thoughtful consideration of specific needs and potential obstacles unique to every organization. But once you get the hang of it, it’s incredibly rewarding to see everything click into place.

CAD/CAM integration requires skilled personnel.True

Skilled personnel are essential for managing complex CAD/CAM systems efficiently.

Using any file format prevents data loss in CAD/CAM.False

Standard file formats are necessary to prevent data conversion errors and loss.

How Can CAD/CAM Reduce Production Errors in Mold Design?

Ever wondered how adopting CAD/CAM in mold design could save you from costly production blunders?

CAD/CAM systems enhance mold design by automating complex tasks, improving precision, and reducing manual errors. They ensure consistency, enable seamless collaboration, and streamline manufacturing workflows, effectively minimizing production errors.

Improving Precision and Consistency

I remember my early days in mold design, where every tiny detail had to be painstakingly checked and re-checked. It felt like a never-ending cycle of adjustments. But with CAD/CAM systems, we can create highly detailed digital models that capture every nuance. This precision ensures our molds meet exact specifications. Automated machining through CAM software further minimizes human error. For instance, automated CNC programming10 helps us precisely replicate digital designs, giving us consistent results every time.

Reducing Manual Errors

Gone are the days when I’d spend hours manually calculating measurements or fitting parts together, only to find errors that cost time and materials. CAD/CAM automates these tasks with remarkable accuracy. It speeds up our design process while significantly reducing errors. It’s like having a reliable assistant who gets everything right the first time.

Enhancing Collaboration

Working as part of a team, I’ve realized how crucial collaboration is in mold design. CAD/CAM provides a unified platform for design review and feedback, making it easier for us to share 3D models and annotations via cloud-based CAD platforms11. This openness helps us resolve problems quickly and make decisions faster.

| Benefits of CAD/CAM in Mold Design |

|---|

| Increased precision |

| Reduced production time |

| Minimized material waste |

| Enhanced team collaboration |

| Improved scalability for production |

From my experience, integrating CAD/CAM technologies into our workflow doesn’t just cut down on errors; it transforms the entire mold design and production process into a seamless, efficient operation.

CAD/CAM systems reduce manual measurement errors.True

Automated tasks in CAD/CAM replace manual measurements, reducing errors.

Cloud-based CAD platforms hinder team collaboration.False

Cloud-based CAD platforms enhance collaboration by enabling easy model sharing.

How Can You Get the Most Out of CAD/CAM Tools?

Ever felt like your CAD/CAM tools aren’t living up to their full potential? I’ve been there too, grappling with the intricacies of design software in a fast-paced world.

Maximize CAD/CAM tools by updating software, investing in training, customizing settings for projects, and using collaborative features to enhance teamwork.

Keep Software Updated

Imagine this: I’m knee-deep in a critical project, and suddenly the software crashes because it wasn’t updated. Trust me, keeping CAD/CAM software current is essential. Updates often come with performance boosts and fixes for pesky bugs, not to mention ensuring compatibility with the latest file formats. It’s like getting a tune-up for your car—it keeps things running smoothly.

Advanced Training for Users

I once thought I knew all there was to know about my CAD/CAM tools—until I attended an advanced training session. It was eye-opening! Investing in training can greatly enhance productivity by unlocking advanced features that streamline tasks and minimize time spent on repetitive actions. These sessions often reveal tips on leveraging the newest functionalities12, helping me stay ahead of the curve.

Customize Settings for Specific Needs

Early on in my career, I learned the hard way how crucial it is to customize settings for each project. Tailoring things like resolution or default templates can significantly optimize performance. Here’s a table of common settings adjustments I find helpful:

| Setting | Description |

|---|---|

| Resolution | Adjust to balance detail and processing speed |

| Templates | Use pre-defined layouts for recurring projects |

| Hotkeys | Customize shortcuts for frequently used commands |

These tweaks save time and help ensure that I’m meeting project requirements efficiently.

Integrate Collaborative Tools

In my team, communication is key. Using collaborative platforms enhances our efficiency by allowing real-time feedback and easy file sharing, which cuts down on errors and improves overall communication. Integrating with cloud-based solutions13 has given us that extra edge in accessibility.

Leverage Automation Features

Automation was a game-changer for me. Many CAD/CAM tools have automation features that handle repetitive tasks without the need for constant input. This not only saves time but also reduces human error—something I’ve learned the importance of after a few too many late nights fixing mistakes. Automation scripts can be customized for specific design processes14, making my workflow more consistent and efficient.

By embracing these strategies, I’ve noticed a significant improvement in my workflow, allowing me to stay competitive in the bustling field of product design. The key is understanding both the software’s potential and the unique needs of each project.

Regular software updates enhance CAD/CAM tool performance.True

Updates provide bug fixes, enhancements, and new format compatibility.

Automation features in CAD/CAM tools increase human error.False

Automation reduces human error by executing repetitive tasks consistently.

How Do CAD/CAM Innovations Impact Future Mold Design Trends?

Ever wonder how new tech like CAD/CAM is shaking up mold design? It’s not just about saving time; it’s a game-changer for precision and creativity in the manufacturing world.

CAD/CAM innovations enhance mold design by improving precision, reducing lead times, and enabling complex geometries, leading to more efficient moldmaking that adapts to future industry needs.

Revolutionizing Precision and Efficiency

Every time I sit down to work on a new mold design, I can’t help but marvel at how CAD/CAM has reshaped my entire approach. Back in the day, creating intricate molds felt like trying to paint a masterpiece with a broomstick. Now, thanks to CAD/CAM, I can automate those detailed processes with a precision that seemed out of reach before.

The transition from design to production feels almost seamless now. Mistakes that used to haunt me in my early career have dwindled. I remember spending countless hours redoing parts just because of a tiny error. With CAD/CAM, I’ve cut down on those mistakes and shortened lead times. It’s like having an extra pair of hands that never get tired or distracted.

| Feature | Impact on Mold Design |

|---|---|

| Enhanced Precision | Allows for detailed, intricate molds |

| Automation | Reduces manual errors and speeds up production |

| Complex Geometries | Enables innovative product designs |

Embracing Complexity in Mold Design

I used to shy away from complex designs because of the risks involved. Now, it’s a different ball game. With advanced CAD/CAM tools, I can simulate mold performance with digital twins before even lifting a finger in the manufacturing15 process. This ability not only saves me time but also spares me the headache and costs of having to redo molds.

By predicting material behavior and stress points, I can optimize molds for both durability and performance right from the start. This foresight is like having a crystal ball for design issues.

Future-Proofing Moldmaking Processes

As someone who’s been around the block a few times in this industry, I’ve learned that staying ahead means embracing change. With CAD/CAM, AI and machine learning are the new kids on the block, helping me predict outcomes and suggest improvements that I might have missed.

Using data analytics, I can dig into material efficiencies and process optimizations, which has made my production workflow smoother than ever. It’s clear that the future of mold design is digital, driven by these ever-evolving technologies. And I’m all for it—because who doesn’t want to be part of the future16?

CAD/CAM reduces lead times in mold design.True

CAD/CAM automates processes, streamlining design-to-production transitions.

AI in CAD/CAM hinders mold design innovation.False

AI enhances predictive capabilities, aiding in innovative mold design.

Conclusion

Integrating CAD/CAM technology in mold design enhances precision, reduces errors, and streamlines production, enabling designers to innovate while ensuring high-quality results efficiently.

-

This link elaborates on how precision in CAD/CAM mold design can improve product quality and reduce errors. ↩

-

Exploring this link will help you find tools that enhance teamwork and streamline project workflows. ↩

-

This link explains how improving design efficiency can lead to better manufacturing outcomes and cost savings. ↩

-

Explore how CAD automation shifts focus from tedious calculations to creative design enhancements, enriching overall project outcomes. ↩

-

Learn how CAD tools enable seamless collaboration, allowing multiple designers to contribute simultaneously while maintaining consistency in projects. ↩

-

Exploring software solutions ensures compatibility, preventing data loss and enhancing workflow efficiency. ↩

-

Cloud-based solutions offer seamless data transfer and management, reducing errors and improving efficiency. ↩

-

Training programs equip employees with necessary skills, improving system management and reducing errors. ↩

-

Discovering cost-effective solutions helps reduce expenses related to software and hardware for CAD CAM systems. ↩

-

Learn how automated CNC programming replicates digital models accurately, ensuring consistent production quality. ↩

-

Explore top cloud-based CAD platforms that facilitate seamless team collaboration and quick decision-making. ↩

-

Learn about new features that can streamline your design process and improve tool utilization. ↩

-

Discover cloud solutions that offer real-time collaboration features, enhancing team synergy. ↩

-

Find out how automation can save time and reduce errors by executing repetitive tasks automatically. ↩

-

Explore how digital twins simulate mold performance, providing valuable insights that prevent costly manufacturing errors. ↩

-

Discover how AI-driven CAD/CAM software enhances predictive capabilities, optimizing mold design processes for future needs. ↩